Ianadmin

Valmet to supply three board machine rebuilds in North America

Valmet will supply three board machine rebuilds in North America. The customers remain confidential. The goals of the rebuilds are e.g. to increase production and the use of recycled and non-bleached fibers. The start-ups of the rebuilt board machines are scheduled for 2017 and 2018.

The orders are included in Valmet's fourth quarter of 2016 orders received. The value of the orders will not be disclosed. The combined value of these types of orders is typically valued at EUR 20-30 million.

"Due to large installed base of paper and board machines in North America and their ageing technology, the need for machine modernizations is quite constant. In number of cases, important reason for the modernizations is to increase energy and resource efficiency. This is also linked to the growing trend of lightweighting in board production. Additionally our customers want to increase the use of recycled and non-bleached fibers," comments Sales Director Jari Siitonen from Valmet.

"Due to large installed base of paper and board machines in North America and their ageing technology, the need for machine modernizations is quite constant. In number of cases, important reason for the modernizations is to increase energy and resource efficiency. This is also linked to the growing trend of lightweighting in board production. Additionally our customers want to increase the use of recycled and non-bleached fibers," comments Sales Director Jari Siitonen from Valmet.

All together these three deliveries will include modifications to two stock preparation systems and a modification to approach flow system, a number of modifications to the wet ends of the board machines, including a new headbox, and a rebuilt forming section, a new press section, a press section rebuild and modifications to two dryer sections.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Pensacola Mill Incident

On the evening of Jan. 22, International Paper Company (NYSE: IP) experienced significant structural damage to the largest pulp digester as well as the power house at its Pensacola pulp and paper mill in Cantonment, Fla. No one at the mill was injured.

![]() Response teams are working with local, state and federal agencies to provide information for those impacted. The incident released a mixture of wood fiber, water and pulping liquor into the surrounding community. We have engaged contractors to develop and implement plans to clean up and dispose of the discharged material as quickly as possible. We are providing all necessary support and resources to our local community and residents as we work through the clean-up.

Response teams are working with local, state and federal agencies to provide information for those impacted. The incident released a mixture of wood fiber, water and pulping liquor into the surrounding community. We have engaged contractors to develop and implement plans to clean up and dispose of the discharged material as quickly as possible. We are providing all necessary support and resources to our local community and residents as we work through the clean-up.

Our primary focus is on ensuring the health and safety of our employees, contractors and neighbors and on the clean-up of the affected areas and property.

Currently, the mill is not operating. We are assessing the extent of the damage to the mill, evaluating supply options and will be working closely with our customers to meet their needs.

About International Paper

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 55,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2015 were $22 billion. For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com.

Valmet to supply a defibrator system to Luso Finsa in Portugal

Valmet will deliver a defibrator system to Luso Finsa in Portugal for their fiberboard production plant. The very first developed EVO-56 defibrator system was also ordered by the Finsa Group back in 2006 to its Padron mill in Spain and now they have rewarded Valmet with a repeat order. The system is scheduled to be delivered in the second quarter of 2017.

Valmet EVO-56 defibrator

The order is included in Valmet's fourth quarter 2016 orders received.

"As we have had an EVO-56 defibrator for ten years we know that the system works well and it was natural to choose the same system also in this new project. The operational cost of the system is low and Valmet was able to handle the short delivery time we needed," says Manuel Mera Franqueiro, Technical Manager at Finsa.

"Finsa Group was the first customer to purchase our new EVO concept when we released it ten years ago. The now received repeat order is a proof of the customer satisfaction," says Jan Laredius, Senior Product Manager at Valmet.

Technical details about the order

The defibrator system is a Valmet EVO-56 type for 25 t/h of medium density fiberboard (MDF). The EVO system has many benefits as it has lowest electrical, steam, resin and water consumption for any given fiber quality on the market.

About the customer Finsa Group

Luso Finsa in Portugal is part of the Finsa Group, one of the leading companies in the wood processing sector in Europe. The number of employees in the Finsa Group is 3,000 and the Net sales 2015 was 816 million euros.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

One of the world’s sustainability leaders

Iggesund Paperboard’s parent company, the Holmen Group, has gained a place on the Global 100, an index of the hundred most sustainable corporations in the world. Holmen ranks 21 and is the only company from the forest industry on the prestigious list.

The Global 100 list of the world's most sustainable corporations is announced each year at the World Economic Forum in Davos, Switzerland. The index has been published by the Canadian analysis firm Corporate Knights since 2005 and is based on an overall assessment of how a company handles issues concerning resource management, employees and financial management. Almost 5 000 companies have taken part in the assessment, with the hundred best featuring on the Global 100 index.

Iggesund Paperboard’s parent company, the Holmen Group is listed as number 21 on Global 100, a list of the world’s most sustainable companies.© Iggesund

"We are both proud and pleased to be on the Global 100 list as one of the most sustainable companies in the world. Holmen has taken a focused approach to sustainability issues for many years now. Being recognised and ranked highly by leading analysts is an acknowledgement of this work," says Lars Strömberg, Director of Sustainable and Environmental Affairs at Holmen.

"This ranking is the result of dedicated work and the strategic choices and investments we've made for the future, which have reinforced our sustainability profile. There is no doubt that the forest has good prospects as a raw material, especially amid a transition to a bio-economy in which products made from fossil raw materials are being replaced with renewable alternatives," comments Henrik Sjölund, President and CEO of both Holmen and Iggesund Paperboard.

Reaching the position on Global 100 is especially important for Iggesund Paperboard. The company’s products, Invercote and Incada, are targeting the high end packaging segment where a good track record in sustainability is a valuable asset.

“We have been ranked high on indices like the UN Global Compact Index, Carbon Disclosure Project, and now the Global 100. To repeatedly be acknowledged by these well renowned indices clearly shows that we are among the most sustainable companies in the world and is a recognition of the holistic and long term approach that characterizes our sustainability work”, says Johan Granås, Sustainability Communications Manager at Iggesund Paperboard.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Zelfo Technology Opens an Engineered Fibre Production and R&D unit.

Zelfo Technology (ZT) has reached an important milestone in its technical development program and will open an Engineered Fibre production and R&D unit in Schwedt, Northern Germany.

The company engineers cellulosic and ligno-cellulosic fibres from a wide range of sources including industrial, agricultural and horticultural waste streams to impart user specific fibre properties including a high degree of defibrillation thus multiplying the binding capability of the material by a factor of several thousand.

The engineered fibre products offered by Zelfo Technology include Micro Fibrillated Cellulose (MFC) which has been a widely talked about subject in recent years, resulting an incredible amount of scientific research and patents being registered. Such intensive activity in MFC has resulted as pulp producers look to find new uses for their prime product, cellulose, and because its foreseen applications are extremely wide in many industries. Zelfo Technology takes the subject one step further in producing controlled mixtures of macro, micro and nano scale fibres using a patented production process thereby dramatically extending the range of uses.

Zelfo Technology has been a pioneer in this kind of fibre engineering since 2010, focusing primarily on upgrading waste sources. The company is now committing to developing and producing packaging based fibre additives with, for example, immediate applications in the liner and fluting sectors.

Indications are that the use of a percentage of engineered corrugated container waste (OCC) can allow liner and fluting producers to make significant reductions in grammage, without negatively impacting on the end-product performance. “This means raw material savings, but this also and more importantly means a reduction of the weight of the final product, which has far more sustainable implications throughout the product’s lifecycle” says ZT CEO Richard Hurding. Furthermore, engineered fibre can carry more filler and performance enhancing chemistry etc.

ZT is concentrating on the containerboard market as it is primarily driven by increasing industrial and manufacturing activity. Better transportation and shipment facilities, improved durability and strength of container boxes, as well as safety and aesthetics of the packaging are anticipated to be major drivers of the market. The growing demand for lightweight and innovative packaging is also driving the global containerboard market, as eco-friendly and recyclable product specification obtained due to containerboard are forcing manufacturers and industries to use corrugated boxes.

Strong, lightweight and cost effective containerboards are anticipated to be the major opportunity criteria for the developing global containerboard market. “Forming strategic tie-ups with container box producers to produce industry specific products to penetrate in new application sectors is considered to be a major opportunity for the global containerboard market, and Zelfo Technology’s Engineered Fibres allow such opportunities to become a reality, not in the future, but today” says ZT’s Technical Director Trevor Dean. “Imagine the impact of grammage reduction on this over 200 billion m2 market!”. This figure comes from 2013 and is expected to keep growing in the years to come.

The Schwedt location “will allow ZT to be part of the pulp and paper ecosystem” continues Richard Hurding, “because we will be operating alongside the EMFOS GmbH (European Moulded Fibre Operation Services) independent packaging R&D Centre and are situated in between the two Leipa Paper facilities, which combined form the biggest paper and packaging production site in Germany”. ZT will continue to offer tailor-made developments to its clients both with cellulose and ligno-cellulosic materials.

The throughput with OCC has now reached 1,5 tonnes per day thanks to the latest process developments patented in summer 2016 and this therefore allows ZT to transform waste carton board into high quality fibres for reinforcement and binder applications. Sample quantities are available for testing and pre-industrial quantities can be supplied.

The same type of throughput can be reached with many agro-materials and agro-wastes, giving growers the possibility to turn a waste disposal cost into a potential revenue while contributing to circular economy principles. This is particularly well illustrated by the partnership ZT has with bio-packaging company Bio-Lutions GmbH ( www.bio-lutions.com ).

About Zelfo Technology

Zelfo Technology GmbH is focused on the development and optimisation of ligno-cellulosic materials for the advancement of sustainable manufacturing. The company’s Engineered Fibre solutions are the result of several years of know-how development resulting in a portfolio of patented systems. As well as in-house expertise, a series of international partnerships substantiate the company’s bio-based materials, design and manufacturing knowledge. The company is headquartered in Germany with bases in France and the United Kingdom. Further information on Zelfo Technology: www.zelfo-technology.com

All images copyright Zelfo Technology GmbH. Sonoco Implementing Price Increase for Paperboard Tubes and Cores

Sonoco (NYSE:SON) has just announced it is implementing price increases for all paperboard tubes and cores in the United States and Canada by a minimum of 8 percent.

Sonoco previously announced a 6 percent to 8 percent price increase on all paperboard tubes and cores in October 2016 and the Company is revising the increase to a minimum of 8 percent, effective with shipments beginning February 13, 2017.

Sonoco previously announced a 6 percent to 8 percent price increase on all paperboard tubes and cores in October 2016 and the Company is revising the increase to a minimum of 8 percent, effective with shipments beginning February 13, 2017.

“This price adjustment is necessary to recover continuing cost increases in uncoated recycled paperboard, our primary raw material, combined with higher costs for energy, labor and other input costs,” said James Harrell, corporate vice president for Sonoco’s U.S. and Canada Tubes and Cores Division.

Sonoco is the largest producer of paper-based tubes and cores in North America, which are used to serve the paper, textile, plastic film, and tape and specialty industries. For more information about Sonoco’s complete line of paperboard tubes and cores or to learn more about current pricing, please visit the Company’s website or contact the Company at +800-377-2692.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging and display and packaging supply chain services. With annualized net sales of approximately $5.0 billion, the Company has 20,000 employees working in more than 300 facilities in 35 countries, serving many of the world’s best known brands in some 85 nations. For more information on the Company, visit our website at www.sonoco.com.

Smithers Pira: Paper Industry Professionals to Gather at Specialty Papers Europe Conference in Cologne, Germany 3-5 April 2017

Over 150 key industry experts from the paper industry will assemble in Cologne, Germany from 3 – 5 April 2017 to attend Smithers Pira’s Specialty Papers Europe (http://www.specialtypaperconference.com/europe).

With the global market for specialty papers expected to increase at an annual rate of 1.8% over the period of 2015-2020, more than 150 key industry professionals from across the supply chain are expected to gather at this year’s Specialty Papers Europe to hear the latest updates on advancements and trends affecting the industry and to exchange their knowledge and ideas.

“Specialty Papers conference always provides excellent insight into the near and future paper market. We find it especially helpful when considering medium to long term direction for our development program.”

Alicia B Richards, AquaSol Corporation

By attending Specialty Papers Europe, delegates will learn what is happening within the paper industry, gain updates on the latest policy issues, hear from high-level speakers and learn about new technologies and innovations, whilst having the opportunity to build network relationships, expand their business opportunities and meet leading personalities in the industry. Attendees to the conference will include brand owners, raw material suppliers, converters, machinery/equipment suppliers, graphic designers and packaging designers from within the specialty papers industry.

With 20 expert speakers set to provide high-level insight and advice, this year’s conference will focus on specific topics related to the specialty paper manufacturing and paper supply industry including Innovation in Packaging, Barrier Developments, Coatings, Digital Printing, Innovations and New Technologies and more.

Sessions include:

- Alexey Vishtal, Nestlé, Packaging sustainability and a role of fibre-based packaging in it

- Dr. Fikri E. Alemdaroglu, Daikin Chemical Europe, Fluorine or no fluorine – a comparative analysis of barrier chemicals for grease proof paper

- Anna Jonhed, BillerudKorsnäs, New fiber based products for a sustainable future

- Mark Crable, Crable Engineering, Colour is a key attribute of specialty papers and must be properly managed

- Jan Duffhues, Mars Europe, How paper can deliver added value to consumer packaging

- Plus many more

This year’s conference promises to provide an unparalled learning and networking opportunity for anyone from within the paper industry and SNP Inc who attended a past edition of the conference labelled it as “A highly-targeted interesting conference with exceptional networking opportunities”.

Exclusive to 2017 - Delegates to Specialty Papers 2017 will also have the opportunity to sign up to an exclusive tour at Zanders paper mill taking place the day before the conference on Monday 3rd April. During the tour, delegates will see the Zanders paper mill including the high quality specialty papers and boards facilities. The accompanying presentation will focus on the continuous change in the international paper industry and how the “old lady” Zanders managed to return to success with new structures, products and services.

For more information on Specialty Papers Europe 2017, visit http://www.specialtypaperconference.com/europe

About Smithers Pira

Smithers Pira is the worldwide authority on the packaging, paper and print industry supply chains. They provide world-leading expertise and market intelligence, and offer a range of testing services supported by comprehensive facilities in the UK and US. With over 80 years’ technical and scientific experience Smithers Pira help clients around the world with their business and testing requirements.

Stora Enso reconsiders its plans to build a chemical pulp mill in Beihai, China

Stora Enso has initiated a process with the Government of Guangxi with the target to remove the authorisation for the hardwood chemical pulp mill from its investment permit. Stora Enso has previously announced that it considers building a chemical pulp mill at its Beihai Mill site, once the consumer board machine is up and running. The final decision is still subject to the decision of Stora Enso’s Board of Directors.

“The market demand for high-quality food packaging board will continue to grow in China and neighbouring Asian markets. Our investment in a consumer board mill in Beihai is ideally placed to serve this market. Meanwhile, the supply-demand of the global pulp market has been negatively impacted by new investments in hardwood pulp production. At the same time, we consider the wood costs to supply the potential chemical pulp mill to be too high, which reduces the competitiveness of such a mill. Therefore, sourcing the chemical pulp to Beihai Mill from the market or utilising our current captive global hardwood supply is a viable option for us,” says Stora Enso’s CEO Karl-Henrik Sundström.

“The market demand for high-quality food packaging board will continue to grow in China and neighbouring Asian markets. Our investment in a consumer board mill in Beihai is ideally placed to serve this market. Meanwhile, the supply-demand of the global pulp market has been negatively impacted by new investments in hardwood pulp production. At the same time, we consider the wood costs to supply the potential chemical pulp mill to be too high, which reduces the competitiveness of such a mill. Therefore, sourcing the chemical pulp to Beihai Mill from the market or utilising our current captive global hardwood supply is a viable option for us,” says Stora Enso’s CEO Karl-Henrik Sundström.

This decision would not affect Stora Enso’s operations at Beihai Mill, which cover the consumer board machine with an annual capacity of 450 000 tonnes, a polyethylene extrusion (PE) coating line and a bleached chemi-thermomechanical pulp (BCTMP) plant. Stora Enso’s current investment permit covers also a second board machine at the site in Beihai, but the group has not made any decisions regarding it.

As a consequence of the change in scope, Stora Enso would decrease the area of its leased forest lands in the Guangxi region. The scope and schedule for the reduction of fibre base will be decided later. The group will keep parts of the plantations to supply raw material for the BCTMP plant. Stora Enso leases currently some 84 000 hectares of forest land in the region.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

ANDRITZ to deliver complete folding box board production line to KAMA Karton LLC in Krasnokamsk, Perm Region, Russia

International technology Group ANDRITZ has received an order from KAMA Karton LLC, Krasnokamsk, Russia to supply a complete production line for folding box board with a basis weight range from 200 to 350 g/m2.

The board machine has an annual capacity of 220,000 tons and is complemented by a new wood handling line, a BCTMP plant with HC bleaching, as well as stock preparation, approach flow, broke, and fiber recovery systems. ANDRITZ will also deliver the Motor Control Center, the Multi Motor Drive and a complete PrimeControl system for the entire line. The line is scheduled to be started up during the first quarter of 2019.

The board machine has an annual capacity of 220,000 tons and is complemented by a new wood handling line, a BCTMP plant with HC bleaching, as well as stock preparation, approach flow, broke, and fiber recovery systems. ANDRITZ will also deliver the Motor Control Center, the Multi Motor Drive and a complete PrimeControl system for the entire line. The line is scheduled to be started up during the first quarter of 2019.

The new wood handling line for aspen will be added to an existing line for birch and is designed for a debarking capacity of 80m3 sob/h. It encompasses a Rotabarker debarking line, an HHQ Chipper with a capacity of 70m3 sub/h, chip screening and a chip silo reclaimer, chip conveyors to BCTMP, a bark line and bark feeding to existing bark conveyors, as well as further transportation to the existing bark and waste handling system.

The new BCTMP line with a design capacity of 360 admt/d contains chip washing, pre-steaming and impregnation units, two high-consistency refining stages, bleaching, washing, screening and reject treatment equipment, a disc filter for thickening purposes, and a storage tower. The stock preparation system handles NBKP and LBKP fibers in two lines and includes two ANDRITZ FiberSolve FSV pulpers, cleaning with two AhlCleaners, and eight ANDRITZ TwinFlo low-consistency disc refiners. The approach flow system is designed for three layers. Broke and fiber recovery systems round off the stock preparation and approach flow systems.

The board machine has three PrimeForm Fourdrinier layers – one containing a PrimeForm HB hybrid former with a wire width of 4,200 mm – and will operate at a design speed of 800 m/min. The press section consists of two PrimePress X shoe presses and one smoothing press. The pre-drying section contains steel drying cylinders and is followed by a PrimeCoat film press with a post-drying section, also equipped with steel drying cylinders. The machine is complemented by two PrimeCal calenders (one hard nip, one soft nip) and a coating section with the latest PrimeCoat roll coating heads technology, as well as a PrimeReel pope reeler and a slitter rewinder at the end.

The entire production line will be equipped with an ANDRITZ PrimeControl system that is aligned to the specific needs of paper machines. It includes extended features for process automation throughout the paper mill and minimizes the number of subsystems and associated interfaces. The advanced Multi Motor Drive system will complement the automation system and ensure reduced energy and power consumption.

Delivery will be handled on an EPS basis, where ANDRITZ provides advisory services relating to installation, commissioning, and training. KAMA will perform the civil and installation work.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers, recovery and reuse of chemicals, preparation of paper machine furnish; the production of paper, tissue, and board; calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF) as well as recycling plants are also allocated to the business area.

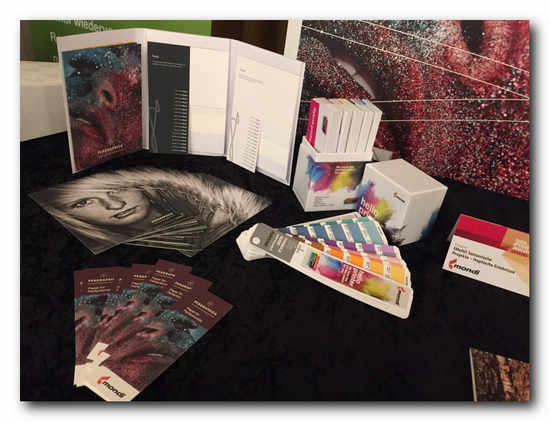

Mondi sponsors design awards to celebrate new PERGRAPHICA® portfolio

Launched last year, PERGRAPHICA® is Mondi’s portfolio of premium uncoated fine papers designed for the exacting needs of the creative and commercial print industries. Since then, it has won the admiration of many in the graphic design and printing industries across Europe. To celebrate the success of this new portfolio, Mondi sponsored awards in two print & design competitions: the Joseph Binder Award and the Golden Pixel Award.

The Joseph Binder Award is an international competition focused on graphic design and illustration. More than 300 graphic designers and illustrators from 27 countries entered their projects for the 2016 awards, which were presented on 10 November at an awards ceremony in Vienna. (More information and pictures from the event can be found on the Joseph Binder Award Facebook page.)

As sponsor of the award category for ‘Editorial Design Books’, Mondi presented the trophy to gold award winner Konstantin Eremenko of Eremenko Visual Communication agency. He won for a fascinating book project called ‘Rediscovering’, a visual interpretation of the periodic table of the elements in the chronological order of their discovery. Mr Eremenko commented, “My challenge as a graphic designer was to find a new way of visually explaining epistemological knowledge. The haptic effect was quite important for the combination of paper texture and multi-layered silkscreen printing.”

The Golden Pixel Award recognises progressive and innovative printing projects in Austria. In 2016 Mondi sponsored the category for ‘(Multi)sensory Projects’ and presented the award at the ceremony in November. The winning project was the HoHo brochure, produced by printing house Ferdinand Berger and Sons for their client Kerbler Holding. Commenting on the paper choice, Mario Vucic of Ferdinand Berger and Sons said, “It is not only the haptics of the paper – the visual and olfactory effects should also have an immediate impact. Only then are all elements joined through the symbiosis of the material and the print craftsmanship to produce a virtual work of art.”

Caroline Palfy, project leader for the HoHo brochure at Kerbler Holding, was pleased with the award-winning result: “The haptic experience – from the cover to the last page – is simply magnificent!”

Customer focused. Every day.

PERGRAPHICA® is known as ‘Paper for Perfectionists’ because it fulfils the most demanding requirements for sophisticated and elegant printed documents while meeting top sustainability standards. The portfolio provides excellent printability on a choice of textures, shades and weights. It is available in two textures (Rough and Smooth), three shades (High White, Classic and Natural) and six grammages between 90 and 300 g/m2.

Customers in many European countries can obtain samples and purchase PERGRAPHICA® through local distribution companies. In central and eastern Europe, it is sold exclusively through Mondi’s long-term partner Europapier. It is available in Germany from Paper Union, in Italy from Burgo Distribuzione, and in Russia from Double V.

Sustainable. Every day.

PERGRAPHICA® is a Mondi Green Range product – one of many that support customers in going green. It is FSC® certified for responsible forestry, bears the EU’s Ecolabel and is produced exclusively in an ISO 14001-certified mill. It is also the only design paper brand included in the WWF’s ‘Check Your Paper’ resource for third-party audited, environmentally friendly pulp and paper products (checkyourpaper.panda.org).

More information about PERGRAPHICA® design papers is available at www.mondigroup.com/PERGRAPHICA

We are Mondi: IN TOUCH EVERY DAY

At Mondi, our products protect and preserve the things that matter.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are located in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers, end consumers and industrial end uses - touching the lives of millions of people every day. In 2015, Mondi had revenues of €6.8 billion and a return on capital employed of 20.5%.

The Mondi Group is fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and compound plastics, to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI.

For us, acting sustainably makes good business sense and is part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.