Ianadmin

Paper sector’s growth slows down

The growth of the paper sector has slowed down recently in terms of consumption, production, export and import, according to the Vietnam Pulp and Paper Association (VPPA).

The slowdown went against the rises in consumption (5 percent), production (5.4 percent), imports (4.3 percent), and exports (1.7 percent), recorded in the first half of this year, reported the association.

The slowdown went against the rises in consumption (5 percent), production (5.4 percent), imports (4.3 percent), and exports (1.7 percent), recorded in the first half of this year, reported the association.

It added that sales of paper for printing newspapers dropped 46 percent year on year, while that of printing paper went down for the first time.

Meanwhile, sales of tissue paper still enjoyed high and stable growth at 16.5 percent, while its production rose 11 percent and imports increased 71 percent.

The VPPA attributed the rise to the improvement of people’s living standards and their higher requirements of high-quality tissues.

Many enterprises held that the domestic paper businesses are less competitive compared to foreign and FDI firms, forcing many domestic factories to operate under their capacity.

The association proposed that authorised agencies should design support policies for paper firms to assist them in capital and technology transfer and trade promotion in line with the Government’s Resolution 35/CP on supporting the paper sector’s growth to 2020.

The aid is expected to help the firms expand their market, improve products’ quality and access low-cost materials, thus re-gaining their market share amidst challenges from the current strong international integration, added the VPPA.

UAE packaging paper industry set for 5pc growth

UAE paper and packaging industry is the fastest in terms of growth in the Mena region, reaching a market valued at $ 2.3 billion and will maintain an annual growth rate of 5 per cent till 2019, said a report.

In the light of the rapid growth of paper and paper related products’ market in the Mena region, Paper Arabia 2016, the 9th edition of the international exhibition for paper, tissue and converting industry will take place from December 13 to 15 at the Dubai International Convention and Exhibition centre, DWTC.

In the light of the rapid growth of paper and paper related products’ market in the Mena region, Paper Arabia 2016, the 9th edition of the international exhibition for paper, tissue and converting industry will take place from December 13 to 15 at the Dubai International Convention and Exhibition centre, DWTC.

“The exhibition is a unique platform and this edition brings together manufacturers, buyers and traders from 30 countries .Strong presence of participants representing Europe, a Canadian engineering and manufacturing company and Morocco as well. Also exhibiting are the renowned Saudi Paper Group from KSA and Fine Hygienic Paper FZE, UAE,” said Satish Khanna, general manager of Al Fajer Information and Services, the show’s organisers.

“Paper Arabia 2015 witnessed the attendance of more than 8,500 trade visitors from 60 countries, concluding deals that reached more than AED 800 million and our expectations are higher for the 2016 edition. In addition to the tissue industry, the focus will be on the corrugated and carton industry, with new technologies and trends and the latest machinery which will be on display,” added Lamyae Zafati, exhibition manager.

The focus in the UAE is a sustainable future and one will witness that the paper industry is already adopting greener and smarter solutions to allow the use of sustainable paper and environmental friendly packaging.

China which remains the world’s largest retail consumer tissue and disposable hygiene market is very significant at the event.

According to Euromonitor, the population growth in UAE remains a major factor influencing sales of tissue and hygiene products. Other factors include the increasing number of retail outlets and malls and shopping centres across the country.

The market is set to continue witnessing the introduction of new products and innovations, especially from the leading multinational brands. This event is an opportunity for local and global providers and buyers to find out about the latest industry trends, sources, to negotiate and strike deals.

The Board of Directors of Valmet resolved on continuing the long-term incentive plan for key employees

The Board of Directors of Valmet has decided to continue the share based incentive program for Valmet's key employees approved in December 2014. The aim of the program is to combine the objectives of the shareholders and the key employees in order to increase the value of the company, to commit the key employees to Valmet, and to offer them a competitive reward plan based on holding the company's shares.

The program approved in 2014 includes three discretionary periods, which are the calendar years 2015, 2016 and 2017. The Board of Directors of Valmet shall decide on the performance criteria and targets in the beginning of each discretionary period. The potential reward of the program from the discretionary period 2017 is based on Comparable EBITA % and orders received growth % of the stable business, that is, the Services and Automation business lines. The potential reward of the plan from the discretionary period 2017 will be paid partly as Valmet shares and partly in cash in 2018. The proportion to be paid in cash is intended to cover taxes and tax-related costs arising from the reward to the key employee. As a rule, no reward is paid, if the key employee's employment or service ends before the reward payment.

The program approved in 2014 includes three discretionary periods, which are the calendar years 2015, 2016 and 2017. The Board of Directors of Valmet shall decide on the performance criteria and targets in the beginning of each discretionary period. The potential reward of the program from the discretionary period 2017 is based on Comparable EBITA % and orders received growth % of the stable business, that is, the Services and Automation business lines. The potential reward of the plan from the discretionary period 2017 will be paid partly as Valmet shares and partly in cash in 2018. The proportion to be paid in cash is intended to cover taxes and tax-related costs arising from the reward to the key employee. As a rule, no reward is paid, if the key employee's employment or service ends before the reward payment.

As part of the share based incentive program members of the Valmet Executive Team shall have a possibility to receive a matching share reward for the discretionary period 2017 provided that he or she owns or acquires Valmet shares up to a number determined by the Board of Directors by December 31, 2017. Reward receipt is tied to the continued employment or service of the Valmet Executive Team member upon reward payment.

The reward of the plan may not exceed 120 percent of the key employee's annual total base salary. The shares paid as reward may not be transferred during the restriction period, which will end two years from the end of the discretionary period. Should a key employee's employment or service end during the restriction period, as a rule, he or she must gratuitously return the shares given as reward to Valmet.

The plan is directed to approximately 80 key employees. The rewards to be paid on the basis of the plan are in total an approximate maximum of 550,000 shares in Valmet.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

ZELLCHEMING-Expo 2017: Proven location, new hall

The exhibition ground in Frankfurt am Main remains venue of ZELLCHEMING-Expo until 2020. In close cooperation with the association ZELLCHEMING e.V. as patron of the event, the organizer Mesago Messe Frankfurt GmbH has decided to keep the previous location. Over a certain number of months, four different cities were under discussion. They had been analyzed and evaluated based on well defined criteria. In comparison, Frankfurt am Main achieved the best results. Petra Hanke, Managing Director of the association ZELLCHEMING e.V., explains the decision as follows:

“In fact, the process was not easily done. The new location should be open for growth and is expected to offer development potential for new concepts and new collaborations. After having taken all criteria into consideration, Frankfurt provided the all-inclusive package in the end. For us it was very important that our members and visitors of the annual general meeting have a pleasant setting with an attractive environment and a good accessibility in future as well.”

Simone Pfisterer, Vice President at Mesago Messe Frankfurt GmbH, adds the location advantage: “The Main metropolis additionally offers the best infrastructural requirements. With its favorable geographical situation in the heart of Europe, Frankfurt is perfectly accessible by public transport for both exhibitors and visitors.”

New: Event located in hall 4.1.

In future ZELLCHEMING-Expo will be domiciled in hall 4.1 of the Frankfurt fairground. The change in halls will be implemented for the event in 2017. The exhibition will take place from 4 – 6 July 2017.

Hall 4.1 provides some infrastructural advantages: Directly placed in the middle of the exhibition ground, with a light-flooded foyer, the hall is best connected to the public transport system. Furthermore, hall 4.1 has own parking levels which are related directly with the area. There are various food and beverage offerings in close proximity and one café on the exhibition hall, as well. This improvement should allow very short and so efficient distances.

Cooperative partnership remains

The Mesago Messe Frankfurt GmbH and the association ZELLCHEMING e.V. are looking forward to many future years of cooperative partnership.

“Together with Mesago it has been possible to professionalize and to develop ZELLCHEMING-Expo. We have set commonly established goals and are looking forward to meeting these together,” summarizes Petra Hanke.

Further information to the event are available at zellcheming-expo.com.

About Mesago

Mesago, founded in 1982 and located in Stuttgart, specializes in exhibitions and conferences on various topics of technology. The company belongs to the Messe Frankfurt Group. Mesago operates internationally and is not tied to a specific venue. With 130 members of staff Mesago organizes events for the benefit of more than 3,300 exhibitors and over 110,000 trade visitors, conference delegates and speakers from all over the world. Numerous trade associations, publishing houses, scientific institutes and universities work with Mesago closely as advisers, co-organizers and partners. Mesago comprises three companies: Mesago Messe Frankfurt GmbH, Mesago Messemanagement GmbH and Mesago PCIM GmbH. (mesago.com)

About ZELLCHEMING e. V.

The Association of Chemical Pulp and Paper Chemists and Engineers is an association which has dedicated itself fully to the various issues and topics surrounding chemical pulp production and paper making. We see ourselves as a technical-scientific professional association for the chemical pulp paper industry as well as its suppliers. Anybody who is involved with chemical pulp production and paper making in Europe will find that we offer a comprehensive range of information as well as strong representation of interests for the concerns and issues affecting our high-tech sector. We provide our members with an international network for the exchange of information and technical contacts in which topics discussed range from research and development concerning paper making through to ecology and the future of the chemical pulp industry and paper industry. (zellcheming.com)

Kapstone Paper And Packaging Corporation Announces Approval Of New Contract Offer By AWPPW Local 153 Members At Its Longview Mill And Box Plant

KapStone Paper and Packaging Corporation (NYSE:KS) (the "Company" or "KapStone") is pleased to announce that, yesterday, union members at its Longview, Washington paper mill and box plant, AWPPW Local 153 ("the Union"), voted to ratify and approved a new contract offer. The Union's bargaining board unanimously supported ratification of the new contract, which expires on May 31, 2024, for the 700-plus members of AWPPW Local 153.

Commenting on the contract ratification, Randy Nebel, President of KapStone Kraft Paper Corporation, said: "We are pleased with the outcome of the vote. The contract is a competitive agreement, both for the Company and our union employees at Longview. It provides us with greater stability at Longview to focus on building an even stronger business for our customers, employees and shareholders."

Commenting on the contract ratification, Randy Nebel, President of KapStone Kraft Paper Corporation, said: "We are pleased with the outcome of the vote. The contract is a competitive agreement, both for the Company and our union employees at Longview. It provides us with greater stability at Longview to focus on building an even stronger business for our customers, employees and shareholders."

About KapStone

Headquartered in Northbrook, Illinois, KapStone is the fifth largest producer of containerboard and corrugated packaging products and is the largest kraft paper producer in the United States. The Company has 4 paper mills, 22 corrugated converting facilities, 65 distribution centers, and approximately 6,300 employees.

SOURCE KapStone Paper and Packaging Corporation

Lenzing invests in new TENCEL® fiber plant in the USA

The Lenzing Group aims to increase the share of specialty fibers as a percentage of revenue to 50 percent by 2020. Following the previously announced expansion plans for Lenzing, Heiligenkreuz (Austria) and Grimsby (Great Britain), the Supervisory Board of Lenzing AG has just approved the investment for a TENCEL® fiber plant in the USA. Lenzing now plans to construct a state-of-the-art plant with a production capacity of 90,000 tons per year at its site in Mobile, Alabama. The new facility will be the largest TENCEL® fiber plant in the world, it will set a new milestone in the history of lyocell fibers. The investment volume will total USD 293 mn (EUR 275 mn). The new plant will utilize the latest technological standards and is scheduled to start in the first quarter of 2019.

The Lenzing Group currently has a worldwide production capacity of 222,000 tons per year of TENCEL® fibers. The new plant in Mobile plus the already announced debottlenecking projects at the other TENCEL® fiber sites will increase the total TENCEL® fiber capacity by more than 50 percent by 2019. The decision to build this plant in the US was supported by the good infrastructure at our Mobile site and attractive energy costs.

“This investment represents another major milestone in the implementation of our corporate strategy sCore TEN. It will bring us a big step further to reach our target of 50 percent revenue from specialty fibers by 2020“, explained Lenzing CEO Stefan Doboczky. “This expansion also underscores our commitment to all our TENCEL® fiber customers, who continue to make their products even more sustainable using TENCEL® fiber, the world’s most sustainable botanic fiber,“ added Doboczky.

The disciplined implementation of the Lenzing’s expansion program is essential for driving the Lenzing Group’s organic growth agenda. Therefore it was decided to create a new Management Board role, pooling together the key technical, operational and engineering responsibilities. The Supervisory Board of the company appointed today Heiko Arnold as the new Chief Technology Officer. In addition to a strong scientific and technical education, Arnold has gained many years of experience with BASF in the realization of major investment projects and continuous operational improvements as well as extensive know-how in Research & Development. He will be responsible for all technical departments in the Lenzing Group.

“We are pleased to welcome Heiko Arnold, a further expert with broad international experience, to Lenzing’s Management Board team“, commented Hanno Bästlein, Chairman of the Lenzing Supervisory Board. “Lenzing is on a successful, dynamic growth course with the development and implementation of the new sCore TEN corporate strategy, and that makes an increase in the Management Board to four persons a reasonable step. His 15 years of experience in Asia, in the realization of major investment projects and in operational excellence make Arnold a perfect match for the challenges faced by Lenzing“, explained Bästlein.

The Lenzing Group

The Lenzing Group is a world market leader headquartered in Austria, with production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality, botanic cellulose fibers. Its portfolio ranges from dissolving pulp to standard and specialty cellulose fibers.

Lenzing quality and innovative strength set global standards for cellulose fibers. With 78 years of experience in fiber production, the Lenzing Group is the only company worldwide combining the manufacturing of all three cellulose fiber generations on a large scale under one roof – from the classic viscose to modal and the lyocell fiber TENCEL®.

The success of the Lenzing Group is based on its consistent customer orientation together with its leadership in innovation, technology and quality. Lenzing is committed to the principles of sustainable management and very high environmental standards. In addition to its core business of fibers, the Lenzing Group also operates in the field of engineering and plant construction.

This is it! Don’t let poor tank cleaning performance waste your time, water and energy

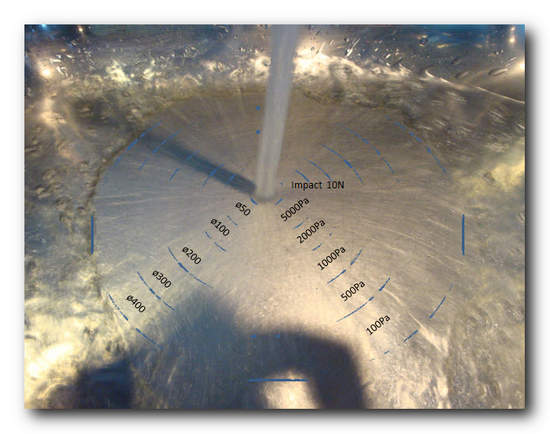

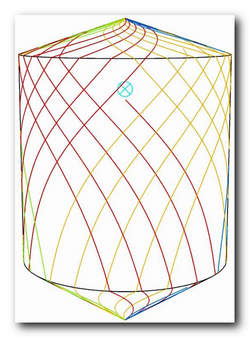

When the water jet, coming from a rotary jet head cleaning device, hits the tank wall, it generates a force of impact (N). After impact, the jet spreads out and creates a cleaning footprint with high wall sheer stress force (Pa). As the cleaning machine is rotating in a 3D motion, the footprint is "moving" around inside the tank in a predefined pattern and cleans the entire tank surface with high wall shear stress. The further away from the impact point the less wall shear stress (mechanical action) is achieved.

Traditional spray balls are static. This means the majority of the tank cleaning energy comes from water cascading down over the tank wall at low wall shear stress. This way of cleaning requires large amounts of time, water and energy in order to compensate for the poor cleaning performance.

One cleaning cycle might be sufficient

Because of the unique design of Alfa Laval Rotary Jet Head, the first - out of eight - cleaning cycles is hitting the tank wall at an evenly dense cleaning pattern throughout the entire tank surface. The distance between the footprint tracks is relatively wide, but if the product is easy to clean off (e.g. milk or syrup) it only requires little wall shear stress to be removed. This means the pre-rinse cleaning of the tank is done using only one cleaning cycle and you are saving time, water and energy.

Because of the unique design of Alfa Laval Rotary Jet Head, the first - out of eight - cleaning cycles is hitting the tank wall at an evenly dense cleaning pattern throughout the entire tank surface. The distance between the footprint tracks is relatively wide, but if the product is easy to clean off (e.g. milk or syrup) it only requires little wall shear stress to be removed. This means the pre-rinse cleaning of the tank is done using only one cleaning cycle and you are saving time, water and energy.

One cleaning cycle typically takes 1-3 min. and now that the product is effectively removed from the tank wall, the jet will offset the second cleaning cycle and thereby minimizing the distances between the jets. More cleaning cycles are needed for products that are harder to clean.

Payback time

Compared to a static spray ball, the Alfa Laval Rotary Jet Head is a higher initial investment, but its low operating cost gives a short payback time - often less than one year.

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2015, posted annual sales of about SEK 39.7 billion (approx. 4.25 billion Euros). The company has about 17,500 employees.

The only thing that is constant is change

As you may have heard Powerflute has a new owner. The past 12 years have been extremely interesting; I have been able to follow very closely how our Chairman Dermot Smurfit first led the buy-out of the company and then, together with our team, took it to where we are today. We all at Savon Sellu are very grateful to Dermot – we sincerely believe that without him we would not have been able to achieve the remarkable turnaround that has occurred. Under Dermot’s leadership the Savon Sellu mill has been transformed from “most likely to close” to “most successful” paper and board mill in Finland; indeed quite a leap given that the forest products industry is the most important industry in our country!

As one era ends, maybe with a feeling of some sadness, another one immediately starts offering new and exciting prospects! Our new owner Madison Dearborn Partners is a very experienced investor in our industry with an excellent investment track record. I am convinced that Madison Dearborn has bought a very good company in Powerflute; a company with excellent personnel, mills and products, and that we in Savon Sellu have gotten a very good new owner. We are already looking forward to see how much more we can improve!

As one era ends, maybe with a feeling of some sadness, another one immediately starts offering new and exciting prospects! Our new owner Madison Dearborn Partners is a very experienced investor in our industry with an excellent investment track record. I am convinced that Madison Dearborn has bought a very good company in Powerflute; a company with excellent personnel, mills and products, and that we in Savon Sellu have gotten a very good new owner. We are already looking forward to see how much more we can improve!

During the due diligence process the operative focus has been “business as usual”. For us that, among other, has meant that we have made a new quarterly production record in Q3, continued our long term development plan by installing a breast roll shaker on the paper machine and new refiners in the pulping section and that we have opened a new sales office in Italy. The optimisation process of the new equipment and quality fine-tuning is currently in process and I hope to be able to tell you some interesting quality-related news latest by the end of Q1 2017.

I would like to thank you all, dear customers and friends, for your support and co-operation during 2016. Wishing you all relaxing festive season and a prosperous New Year 2017!

Juha Koukka

CEO of Savon Sellu Ltd.

Södra provides SEK 10 million in funding for research and development

In November, the Södra Foundation for Research, Development and Education decided to contribute an additional SEK 10 million to research projects connected with forestry. Six different projects have been awarded grants, one of which focuses on addressing the future market for wood fibre-based products by developing new fibres from existing processing environments.

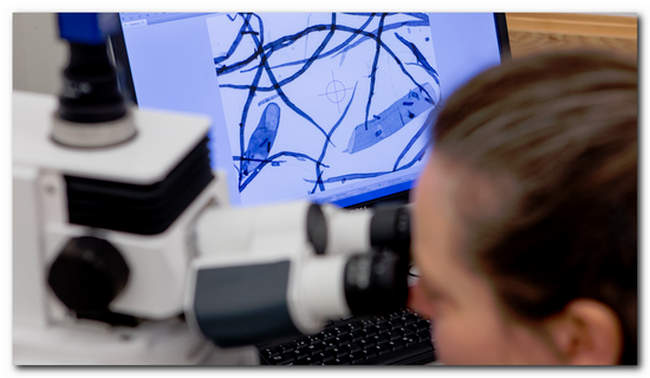

To meet the requirements imposed on new cellulose-based products, such as paper and packaging, it must be possible to regulate and vary the core properties of the pulp used. Chalmers University of Technology has launched the project AvanCell: New Fibres from Existing Processing Environments, and has been awarded SEK 8 million to do research on this topic.

“The project aims to establish new knowledge about how we can regulate the properties of pulp. If we learn more about how to utilise the processing environment and the chemistry in the final bleaching stage, we can change the flexibility and interaction properties of the fibre, something that is highly sought after by both pulp customers and consumers” said Laila Rogestedt, Senior Vice President of Innovation and New Business at Södra.

Research grants have also been awarded to several projects in the field of sustainable forest management. The grants were presented to researchers at the Swedish University of Agricultural Sciences and Skogforsk for studies related to the damage of saplings, birch production, more effective use of harvesting data and work environment issues pertaining to forestry machinery.

Project contributions decided in November 2016

|

Project |

Contribution |

Company |

Researcher |

|

Transparency and the Swedish Forest Agency: What should we do now going forward? A proposal |

SEK 550,000 |

King’s College, London |

Roland Lofstedt |

|

The effect of plant type, land preparation and pine weevil protection on damage by black bark beetles to spruce saplings in Southern Sweden |

SEK 605,000 |

Asa Försökspark |

Kristina Wallertz |

|

Development and testing of model for calculating harvesting costs based on tree size |

SEK 300,000 |

Skogsforsk |

Johan Möller |

|

Measurement of load level during partial automation |

SEK 375,000 |

Skogsforsk |

Martin Englund |

|

Application for funding for continuation of the forest research project Birch for High-Value Timber Production |

SEK 350,000 |

Swedish University of Agricultural Sciences |

Jens Peter Skovsgaard |

|

AvanCell: New Fibres from Existing Processing Environments |

SEK 8,280,000 |

Chalmers |

Hans Theliander |

The Södra Foundation for Research, Development and Educationapproved the provision a total of SEK 10,460,000 in funding for new projects. Altogether, the Foundation has provided SEK 15,591,000 in project funding during the year

Facts

The mission of the Södra Foundation for Research, Development and Education is to promote research and education of significance to forestry and forest industry operations in Southern Sweden.

The projects that are granted funding include fields of research and development that are relevant and important for both forestry and the forest industry. Since the inception of the Foundation in 1995, some 150 research projects have been awarded grants. The findings of the research projects have been significant both from a social perspective and for the forest industry.

The Foundation holds four Board meetings per year, at which grant applications are considered. Information about the rules regarding applications for grants from the Foundation is available on Södra’s website.

Södra was founded in 1938 and is the largest forest-owner association in Sweden, with a membership of more than 50,000 forest owners. We engage in modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. Through value-generating relationships and a long-term approach, Södra is leading the way for the next generation of forestry. Valmet to supply a capacity increase project for Matías Gomá Tomás' board mill

Valmet has received an order for a board machine capacity increase upgrade and a three year paper machine clothing agreement from Matías Gomá Tomás S.A.'s board mill in La Riba, Catalonia, Spain. The delivery of the capacity increase project is scheduled to take place by the end of 2016 and the start-up to be in the end of February 2017.

The order was included in Valmet's third quarter 2016 orders received. The value of an upgrade of this scope is usually valued around EUR 4 million excluding the paper machine clothing agreement.

The target of the rebuild is to increase production capacity and production speed by improving runnability, reducing breaks and increasing drying capacity.

Matías Gomá Tomás mill broduces corrucated board and linerboard in La Riba, Catalonia, Spain

"Valmet's wide offering and good work during the study phase, providing our mill a suitable technical solution according to our requirements, made us to choose Valmet as the key supplier to our project. I want to highlight the great collaboration with Valmet team. Our needs were fully taken into account in the solution. Having Valmet as a main partner we are confident this rebuild will to be a success," says Josep Mª Grau, Mill Manager from Matías Gomá Tomás.

"In this kind of an improvement project which has a wide scope we can really show our expertise in helping customer to improve their performance and reaching their targets," says Eduardo Ruiz, Senior Product Sales Manager, Spain.

Technical information of the delivery

Matías Gomá Tomás, S.A. produces corrugated board and linerboard with 5.0 m wide board machine with the top speed of 350 m/min.

Valmet's delivery for the capacity increase includes a new pick-up felt loop, perforated uhle box covers, hood ventilation upgrade, steam and condensate system upgrade and additional drying cylinders.

About the customer Matías Gomá Tomás, S.A.

Matías Gomá Tomás belongs to Grupondunova Group. Grupondunova is one of the main corrugated cardboard manufacturing groups in Catalonia, Spain.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.