Ianadmin

James Cropper gears up for Paperworld

British master papermaker James Cropper is making the final preparations for its appearance at Paperworld 2017, with plans to promote a number of its products and services.

Some of the highlights showcased at the exhibition – which takes place from 28 to 31 January in Frankfurt – will be the company’s new Tailor Made service, its new range of food contact-approved papers and its Kendal Manilla collection.

Tailor Made was launched to allow brands to work with James Cropper to develop unique, custom-made paper solutions for brand presentation and packaging. The extensive variables available through the service range from the individual fibres used to make paper to the ways they’re engineered, coloured, embossed and converted.

Andy Smith, director of export sales at James Cropper, said: “We’ve always worked with brands to create personalised solutions for them but now, with Tailor Made, we’re taking this service to the next level.

“It’s absolutely vital for brands to stand out, and a lot of that comes down to expressing their individuality through the materials they use – whether that be the use of post-consumer waste in production to champion sustainability, or using unique shades of soft-touch papers to evoke sophistication.”

Meanwhile, Dolcelicious – a range of premium food contact-approved papers – has been developed to help food and drink brands elevate the packaging experience and is suitable for contact with dry, moist and fatty foodstuffs. The range is available in 11 eye-catching colours, including Lemon Drizzle, Liquorice, Silver Spoon and Kiwi Fizz.

Norbert Spiegel, sales manager for the DACH region, adds: “With the launch of the Dolcelicious collection, we have another string to our bow. We’re now able to widen our service to German brands in the food and drink industry, allowing them to benefit from the range’s diverse colours and textures – from subtle and natural to glamorous and bold.”

In addition, James Cropper will feature Kendal Manilla, the papermaker’s range of high-quality boards established as a benchmark for outstanding performance within the filing and stationery markets.

Norbert added: “Kendal Manilla is one of our core ranges of papers and has been a go-to product for business folders and files for many years. With its versatility and wide range of weights and colours, we’re looking forward to bringing this stationery stalwart to Paperworld.”

For more information about Dolcelicious or to request a sample, visit www.dolcelicious.com. For more information about Tailor Made, Kendal Manilla or the James Cropper brand, visit www.jamescropper.com.

A Christmas card with 44,000 variations

Iggesund Paperboard’s tradition of producing sophisticated Christmas cards continues. One says every single snowflake is unique and so will the Christmas card 2016 also be. This year Iggesund has created a snowflake that can be folded in many thousands of possible variations, from crystal white to winter blue colours.

The card consists of seven die-cut snowflakes with each side printed with a different pattern. These 14 variations can then be folded to create more than 44,000 different patterns. The design is the brainchild of German designer Peter Dahmen, who in recent years has specialised in digital finishing, often together with the Israeli print house Highcon. The snowflake created by the card’s recipient then encloses a card made of Invercote Metalprint 359 g/m2 with shades of cyan printed on metal foil and the traditional Christmas greeting on the reverse side.

“Digital finishing is an exciting field and Iggesund’s Christmas card is one of the most sophisticated commissions I’ve done in this area,” says Peter Dahmen. “In theory the project could be done using traditional die-cutting tools but with an edition of this size that would be much more expensive because then you have to remove the excess strips of paperboard manually.”

This year’s Christmas card made of Invercote from Iggesund Paperboard can be enjoyed in more than 44,000 different ways, offering the ultimate in versatility. © Iggesund

Highcon’s design engineer Yaron Eshel supported Dahmen in the creative process.

“I got the idea for the card the night before I was to fly to Israel,” Dahmen explains. “I was having trouble getting to sleep but when the idea came to me I had to jump out of bed and write it down before it went out of my head.”

During the flight the next day he refined the drawings on his iPad and showed them to Eshel on arrival.

“When he said it could be done using Highcon’s process, the basics fell into place.”

Dahmen has worked both with digital and traditional die cutting and creasing and is very familiar with all the techniques. But he says digital technology makes it possible to do more fine adjustments at the last minute.

“After you get the cutting tool and see how it functions, you may realise your idea won’t work quite the way you’d thought, or that a few more adjustments would raise the quality of the end result. Then digital technology gives me as a designer greater freedom because usually there’s no time to wait for a mechanical adjustment to the cutting tool.”

Iggesund Paperboard’s motive for producing sophisticated Christmas cards is not only to send an elegant greeting to its customers.

“We’re actively looking for new solutions and techniques, or innovative uses of traditional methods, that can inspire our customers around the world. The Christmas card is a printed sample which shows what people can achieve with our paperboards, Invercote and Incada,” explains Iggesund Paperboard’s project manager Anna Adler, who has about a dozen such cards to her credit so far.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

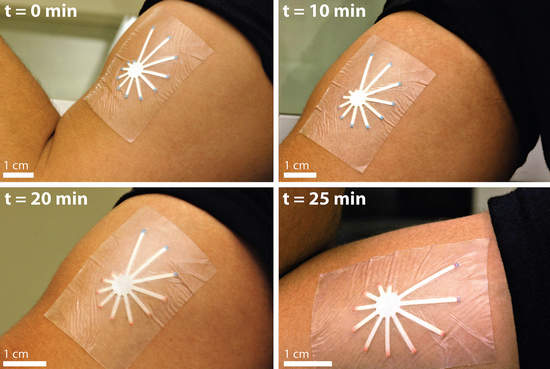

Low-cost paper-based skin patch monitors dehydration by changing color from sweat

Researchers have developed a low-cost skin patch that changes color to indicate different levels of hydration, representing a potential new medical technology.

Such an innovation might be used by marathon runners, military personnel and others to help prevent dehydration.

“Hydration in humans is a delicate parameter,” said Babak Ziaie, a professor of biomedical engineering and electrical and computer engineering at Purdue University. “Even small deviations such as 2 percent from normal levels can affect a person’s cognitive and physical performance by more than 30 percent.”

The palm-size patch consists of filter paper that is laser-machined to create a radial array of strips, which are laminated with a water-impermeable film to form microchannels. The channels are loaded with a water-activated dye at one end. As sweat secretion increases, the strips are activated sequentially, changing from blue to red and providing easily identifiable levels of moisture loss.

Findings were detailed in a research paper presented during the MicroTAS 2016 Conference in October.

“We have talked to many experts including marathon directors, the Ironman World Championship, Olympic triathlon athletes and many collegiate and professional coaches, athletes, race directors and EMTs to validate the need for this kind of product,” said graduate student Vaibhav Jain. “Also, two industrial companies have shown interest in our technology, and we are in talks with them.”

Conventional methods for monitoring hydration are either invasive, require non-portable equipment or do not yield results immediately.

“In comparison, our approach is a fast, user-friendly dermal patch for collecting and measuring sweat secretion," Ziaie said. “And our fabrication process could be scaled up to large-volume manufacturing.”

The patch was tested at a sweating rate of 90 microliters per hour over a square centimeter of skin, which corresponds to normal human sweat rates.

The researchers have filed a patent application for the concept through the Office of Technology Commercialization of the Purdue Research Foundation.

Funding for this work was provided in part by the National Science Foundation. The research is based at the Birck Nanotechnology Center in Purdue’s Discovery Park.

During the MicroTAS conference, Jain was awarded a Ninth Annual Art in Science Award, sponsored by National Institute of Standards and Technology and Lab on a Chip magazine. The paper was co-authored by Jain; postdoctoral research associate Manuel Ochoa; and Ziaie.

BillerudKorsnäs makes strategic investment in Gruvön

The board of BillerudKorsnäs has today made the decision to carry out the largest investment in the history of the company and one of the largest in Sweden in recent years - the investment in a new board machine at the Gruvön site. The decision has been made in view of growing demand for sustainable packaging solutions for food and beverages globally.

The investment of SEK 5.7 billion includes the construction of a new board machine at the Gruvön production site and rebuilds in the existing pulp mill. The board machine will have an annual capacity of 550,000 tonnes of board, making it one of the largest of its kind in the world. The machine will produce liquid packaging board, cartonboard, food service board and liner. The investment project will start immediately and production is expected to start in the first quarter of 2019.

“This is a historical decision for BillerudKorsnäs. The stable market growth in liquid packaging board and other cartonboards, together with our unique expertise in this area, mean that we are perfectly positioned to satisfy global demand. Access to renewable raw materials from sustainably managed forests in the Nordic region was a key factor when evaluating different alternatives,” says Per Lindberg, President and CEO of BillerudKorsnäs.

Smart packaging solutions can reduce dependence on fossil fuels, reduce climate impact and littering, and also increase food safety. Demand for sustainable solutions is growing around the world as increasing numbers of brand owners, food retailers and consumers make conscious choices. As current capacity at BillerudKorsnäs’ production units is not sufficient to meet future demand, the opportunity of new board production at Gruvön has been investigated in detail since 2015.

In addition to growth in liquid packaging board and other cartonboards, today’s decision will result in a streamlining of the production structure within the company. Current paper production at Gruvön will gradually be transferred to other plants within the company during ramp up of the new board machine, with the aim of offering customers fully satisfactory alternatives. Gruvön’s production of high quality fluting will not be affected by the investment.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 7 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Finnish government lifts biofuel targets

Finland's center-right government has said it planned to lift the share of biofuels blended in transport fuel to 30 percent by 2030 to help meet the country's emissions reduction targets.

The biofuels will mostly fall into the EU's "double-counting" counting, as they are produced from forest industry waste and residues. On that basis, the new target translates into a "double counting" share of more than 53%.

The biofuels will mostly fall into the EU's "double-counting" counting, as they are produced from forest industry waste and residues. On that basis, the new target translates into a "double counting" share of more than 53%.

That compares with the government's previous "double counting" goals of 20% by 2020 and 40% by 2030, and an EU target of 10 percent by 2020.

The government also confirmed its plans to halve the use of imported oil for domestic needs, ban the use of coal in power generation and increase the use of electric cars to 10 percent of the country's vehicles by 2030.

Paper maker UPM-Kymmene has recently started the world's first plant in commercial use to make biofuel from crude tall oil, a residue of pulp production.

China's Sunshine Kaidi New Energy Group and Nordic energy company St1 are also planning investments to make biofuel from sawdust and other wood residues.

Sonoco to Invest $20 Million in New Atlanta-area Packaging Center Supporting Duracell’s North America Operations

Sonoco (NYSE:SON), one of the largest global diversified packaging companies, today announced it will invest $20 million in the development of a new packaging center to support Duracell’s new North America battery packaging operation.

Sonoco’s Display and Packaging unit will be located in Duracell’s new leased facility in the Atlanta area. Sonoco will install and operate state-of-the-art primary packaging equipment at the new center and provide all packaging materials. In addition, the Company will produce retail merchandising displays which will also be packed out at the same facility.

Sonoco’s Display and Packaging unit will be located in Duracell’s new leased facility in the Atlanta area. Sonoco will install and operate state-of-the-art primary packaging equipment at the new center and provide all packaging materials. In addition, the Company will produce retail merchandising displays which will also be packed out at the same facility.

“This unprecedented go-to-market packaging solution for Duracell is unlike any effort provided in our industry,” said Jack Sanders, Sonoco president and chief executive officer. “Because Sonoco is a solutions company which offers multiple packaging products and services, we are able to meet all of Duracell’s unique packaging and retail merchandising needs.”

Full production is expected in the fourth quarter of 2018. Sales of packaging and services annualized over the five-year contract period are expected to be more than $50 million.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5 billion, the Company has 20,000 employees working in more than 300 operations in 35 countries, serving some of the world’s best known brands in some 85 nations. For more information on the Company, visit our website at www.sonoco.com.

About Duracell

Started in the 1920’s, the Duracell brand and company was recently acquired by Berkshire Hathaway, Inc. and has grown to be the leader in the single-use battery market in North America. Its iconic brand is known the world over. Duracell products are trusted in the devices that keep people connected, protect their families, entertain them, and simplify their increasingly mobile lifestyles. Berkshire Hathaway is a $210 billion holding company owning subsidiaries that engage in diverse business activities. Visit www.duracell.com for more

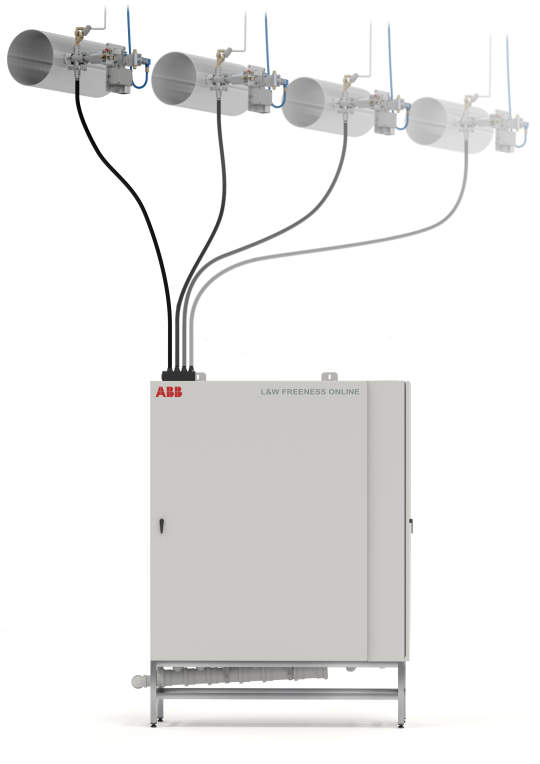

ABB launches online system for measuring, monitoring and controlling freeness in pulp mixtures

L&W Freeness Online expands offering for pulp measurements to help improve quality and reduce costs for paper producers.

ABB has launched L&W Freeness Online, a reliable, repeatable and cost-effective online system for measuring, monitoring and controlling key quality variables - Canadian Standard Freeness (CSF) and Schopper-Riegler (SR) - in paper stock preparation. This helps pulp and paper customers to save production costs by reducing energy consumption through elimination of over-refining, and to improve quality by generating uniform pulp furnish for the paper, board or tissue machines.

L&W Freeness Online measures Canadian Standard Freeness (CSF) and Schopper-Riegler (SR) for full control of the refining process. Well-proven pulp samplers connected to the process automatically take samples before and after refiners to ensure that the set point value is being met.

L&W Freeness Online solves the problem of inconsistent and inaccurate manually-measured results with an automatic and complete measurement cycle, reporting results that are compensated for consistency and temperature, with measurement results that approach laboratory standards.

The system also allows for multiple sampling points with a single instrument, reducing initial investment cost and ongoing maintenance costs.

”Now we can offer a robust and responsive CSF/SR measurement online, which gives our customers an easy way to pinpoint and follow trends on pulp quality while its being made, and at the same time helps them to reduce refining energy,” says Anna Schärman, Global Product Manager, ABB Pulp & Paper products.

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids, serving customers in utilities, industry and transport & infrastructure globally. Continuing a more than 125-year history of innovation, ABB today is writing the future of industrial digitalization and driving the Energy and Fourth Industrial Revolutions. ABB operates in more than 100 countries with about 135,000 employees. http://www.abb.com

Xerium's New TransForm Forming Fabric Delivers Cost Reduction and Operational Improvements for Paperboard and Packaging Manufacturers

Xerium Technologies, Inc. (NYSE:XRM), introduces TransForm, a revolutionary new generation of forming fabrics designed specifically for paperboard and packaging machines that lowers energy consumption and extends fabric life, among other considerable benefits.

“Utilizing new proprietary polymers and structural designs, our new TransForm line is already helping customers reduce energy consumption by more than 15 percent while extending fabric life between 15 and 25 percent.”

“Our board and packaging customers continuously demand improvements in uptime efficiency and reduced operating costs while delivering higher product quality at maximum output,” said Bill Butterfield, EVP and CTO of Xerium. “Utilizing new proprietary polymers and structural designs, our new TransForm line is already helping customers reduce energy consumption by more than 15 percent while extending fabric life between 15 and 25 percent.”

![]()

Representing half of the global tonnage produced, paperboard and packaging grades continue to grow globally compared to other paper grades. TransForm forming fabrics have been tailor-made for every type of board and packaging former: fourdriniers, twin wire formers, top formers, gap formers, and multiply formers.

“We trialed these new TransForm products in select board and packaging mills with excellent results of improved drainage rates and sheet quality. The performance continues to exceed our customers’ expectations,” adds Butterfield.

TransForm technology is applicable for machines producing: paperboard, containerboard, fluting/corrugating, linerboard, kraft bag, liquid packaging board, food and beverage containers, bleach board, white top paperboard, boxboard, and other related subgrades.

About Xerium Technologies, Inc.:

Xerium is a leading producer of fabrics and roll covers used in the production of paper and packaging, nonwovens, and other industrial manufacturing processes. Xerium’s technology portfolio also includes integrated machine monitoring and automation applications that analyze and deliver real-time machine performance data. With a breadth of patented and proprietary products and services, Xerium provides customers with tailored solutions all designed to reduce their operational costs and optimize their machine’s performance. Xerium is headquartered in Youngsville, NC and has 28 manufacturing facilities in 13 countries with approximately 2,900 employees.

BillerudKorsnäs explores new technologies – launches full scale tests adding MFC to its paperboard

After promising initial tests, BillerudKorsnäs is now moving ahead with full scale trials adding microfibrillated cellulose, MFC, to its paperboard products. The initiative is made possible through a new cooperation with Norwegian biorefinery pioneer Borregaard.

Recent development has allowed for industrial scale extraction of the components of cellulosic fibres in wood, the fibrils. For a paper and board maker, adding microfibrillated cellulose, MFC, in the production process opens up opportunities for new functionality and for further improved resource efficiency.

Recent development has allowed for industrial scale extraction of the components of cellulosic fibres in wood, the fibrils. For a paper and board maker, adding microfibrillated cellulose, MFC, in the production process opens up opportunities for new functionality and for further improved resource efficiency.

To explore these opportunities, BillerudKorsnäs has during 2016 carried out small scale testing in full production. Based on the results of these initial tests, the company has now decided on full scale trials to start in early 2017. BillerudKorsnäs’ short term aim is achieving the same strength properties of its paperboard products, but with lesser material, so called light weighting. For the future, using MFC could possibly also be a key to replace the thin barrier layers of plastics or aluminium today often added to the otherwise renewable fibre based packaging.

The full scale trials are made possible through a new cooperation with Borregaard, a global leader in biorefinery innovation. Under this cooperation, BillerudKorsnäs will be supplied with MFC from the recently started MFC plant of Borregaard in Sarpsborg, Norway.

“By adding MFC we want to explore how to further improve our world class materials to make them even more competitive against their main competitor, fossil based plastic packaging. That is how we increase our positive contribution from a sustainability standpoint. We are enthusiastic over our cooperation with Borregaard and with them as our supplier of MFC in this development program”, says Magnus Wikström, CTO at BillerudKorsnäs.

“Borregaard welcomes this cooperation with BillerudKorsnäs. Our Exilva MFC products have excellent strength and barrier properties and should hence be good materials for BillerudKorsnäs to further develop their position as a world leader in sustainable packaging solutions, says Pål Romberg, Excecutive Vice President Exilva.

Borregaard has used more than 10 years to develop the Exilva MFC technology and is the first company in the world to commercialize MFC through its new 1.000 ton plant which started in Q3 this year.

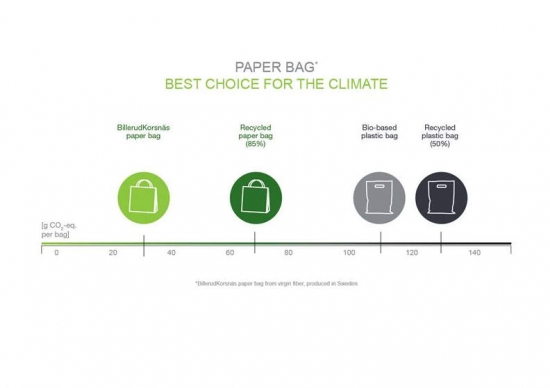

Paper bags are the low-carbon choice, new study finds

Plastic bags are commonplace in retail. But there’s an alternative that is much better for the climate. “Of the different carrier bags that we studied, the paper bag made by material from BillerudKorsnäs has the smallest carbon footprint,” said Lena Dahlgren from IVL Swedish Environmental Research Institute.

Plastic bags are commonplace in retail. But there’s an alternative that is much better for the climate. “Of the different carrier bags that we studied, the paper bag made by material from BillerudKorsnäs has the smallest carbon footprint,” said Lena Dahlgren from IVL Swedish Environmental Research Institute.

EU citizens use an average of 200 plastic bags a year, many of which are used in the current Christmas shopping period. Lots of plastic bags are only used once and end up in landfill.

A Swedish life cycle analysis carried out by IVL Swedish Environmental Institute has now shown that the carbon footprint of a carrier bag made from recycled plastic is twice that of a paper bag made by material from BillerudKorsnäs.

“The company uses a significant proportion of renewable energy in its production. That contributes considerably to paper bags made by their materials having the smallest carbon footprint,” said Lena Dahlgren, project manager at IVL.

BillerudKorsnäs is a Swedish company that aims to be a leader in the transition to a sustainable society. The company produces low-carbon packaging material based on responsibly managed forests in the Nordic region and is now encouraging retailers across Europe to reduce their carbon footprint.

“The study clearly shows the advantages of our bio-based material and our energy-efficient production. We now know with certainty that our product has significant climate benefits over other materials,” said Henrik Essén, SVP Communication & Sustainability at BillerudKorsnäs.

An EU directive from last year requires a reduction in the number of plastic bags. The EU’s main aim is to reduce the number of plastic bags being thrown away. But the new study shows that switching to paper bags also offers lower carbon emissions.

“The results of this study now offer retail chains the opportunity to review their carrier bag offering and choose low-carbon bags, and we can be part of that solution,” said Henrik Essén.

Read the full report here:

http://www.billerudkorsnas.com/lifecycleassessment

BillerudKorsnäs provides packaging materials and -solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com