Ianadmin

Valmet to supply an automation system for Kemira's new sodium chlorate production line in Joutseno, Finland

Valmet will supply an automation system for Kemira's new sodium chlorate production line under construction in Joutseno, Finland. The automation system will control the production process and ensure its reliable operation.

The order was included in Valmet's third quarter 2016 orders received. The system will be delivered in April 2017.

"The choice of a supplier was influenced by various factors, such as the skills of our staff, life-cycle stages of our present systems and integration synergies with them, as well as the expected lifetime costs. Additionally, the reliability of our present systems supported the choice," says Tony Granqvist, Electrical Automation Manager, Kemira.

Valmet will supply an automation system for Kemira's new sodium chlorate production line under construction in Joutseno, Finland

"We have cooperated closely with Kemira's Joutseno plant since the early 1990s. The plant has Valmet automation systems that we have expanded and upgraded over the years to meet its automation needs," notes Kari Karppinen, Sales Director, Automation business line, Valmet.

The new chlorate production unit is expected to be in operation during the fourth quarter of 2017. Sodium chlorate is the raw material for chlorine dioxide (ClO2), which is produced on-site at the pulp mills and is the primary bleaching agent for kraft pulp.

Valmet will deliver a Valmet DNA automation and information management system for the new production line. The delivery will include installation, commissioning and also training.

Information about the customer Kemira

Kemira is a global chemicals company serving customers in water-intensive industries. It provides expertise, application know-how and chemicals that improve its customers' water, energy and raw material efficiency. The company's focus is on pulp & paper, oil & gas, mining and water treatment. In 2015, Kemira had annual revenue of EUR 2.4 billion and around 4,700 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Klabin earns Leadership Status from Carbon Disclosure Project

The company participated in three of the platform’s programs:Climate Change, Water and Forests

Klabin, Brazil's largest paper producer and exporter and the leading manufacturer of corrugated board packaging and industrial bags, was classified as a Climate Disclosure Leader by the Carbon Disclosure Project (CDP) in the categories Climate Change and Forest with scores of “A-”. These scores mean that the company adopts some of the best practices on the platform and has implemented a series of actions to manage climate change in its own operations and those of third parties.A non-profit international organization, CDP analyzes and recognizes the efforts of companies around the world to manage the environmental impacts of their activities.

In the Water category, the company attained "Management" status with a score of "B".The progress of each company is categorized as follows:information disclosure (D- and D), awareness (C- and C), management (B- and B) and leadership (A and A-).Klabin's results are above the industry average and CDP noted that the company is measuring its impacts with the aim of reducing them, setting new targets and implementing strategic policies and structures to support adequate measures.Klabin’s initiatives include monitoring all of its water withdrawals, reducing the impact and improving the performance of its wastewater treatment and establishing a commitment to the UN Sustainable Development Goals related directly to water.

In the Water category, the company attained "Management" status with a score of "B".The progress of each company is categorized as follows:information disclosure (D- and D), awareness (C- and C), management (B- and B) and leadership (A and A-).Klabin's results are above the industry average and CDP noted that the company is measuring its impacts with the aim of reducing them, setting new targets and implementing strategic policies and structures to support adequate measures.Klabin’s initiatives include monitoring all of its water withdrawals, reducing the impact and improving the performance of its wastewater treatment and establishing a commitment to the UN Sustainable Development Goals related directly to water.

In Climate Change, CDP made specific notes about Klabin's results, which it classified as excellent.The score achieved by the company positions it two levels above the industry average and the Brazilian average.The Leadership level attest to the existence of significant activities related to emission reduction targets and verified emissions data.Klabin has a Climate Committee that discusses, plans and carries out actions related to anticipating weather events and maintains a strategic agenda for low-impact air emissions; received the Gold seal from the GHG Protocol, a program of the Center for Sustainability Studies (GVces) of the Getúlio Vargas Foundation (FGV); and has air emission standards focused on the production of clean energy.

In the Forest category, Klabin achieved advances in actions to ensure a value chain free of deforestation, with its practices were considered the best in deforestation risk management.Klabin, whose forest stewardship practices are a global reference in yields, was the first company in the southern hemisphere to receive an international certification attesting to its responsible and economically feasible forest management practices that promote healthy relationships with local communities and to it being a pioneer in promoting forest certification for small rural partner producers.

Since 2006, Klabin has been involved in the Carbon Disclosure Project's global initiative, which facilitates dialogue between investors and companies seeking to minimize the environmental impacts of their business in light of climate change.As part of this effort, in 2015, Klabin was recognized as the company with the Best Practice of Natural Capital Management by the CDP.In 2014, it was selected as one of the companies that most encourages good stewardship practices, which encompass controlling impacts and actions through supplier engagement and the certification and traceability of its wood as a means to guarantee a deforestation-free value chain.

CDP has the largest and most complete global environmental disclosure system for companies, cities, states and regions, enabling them to better measure and manage their environmental impacts.With a network of investors and buyers, companies and political decision-makers use the CDP's data and considerations to make better decisions, manage risks and capitalize on opportunities.

About Klabin

Klabin is Brazil's largest paper producer and exporter and the leading manufacturer of paper and board for packaging, corrugated board packaging and industrial bags. Founded in 1899, it has 16 industrial units in Brazil and one in Argentina. Klabin is organized into four business units: Forestry, Pulp (hardwood, softwood and fluff pulp), Paper (paperboard, kraft paper and recycled) and Packaging (corrugated board and industrial bags).

The company’s management is entirely oriented towards Sustainable Development in the pursuit of integrated and responsible growth that combines profitability, social development and commitment to the environment. Klabin has been included in the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (BM&FBovespa) since 2014. It is also a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, and seeks suppliers and business partners that adopt the same values of ethics, transparency and respect for the principles of sustainability. Learn more at: www.klabin.com.br

ABB releases new full-sheet dirt count system for pulp mills

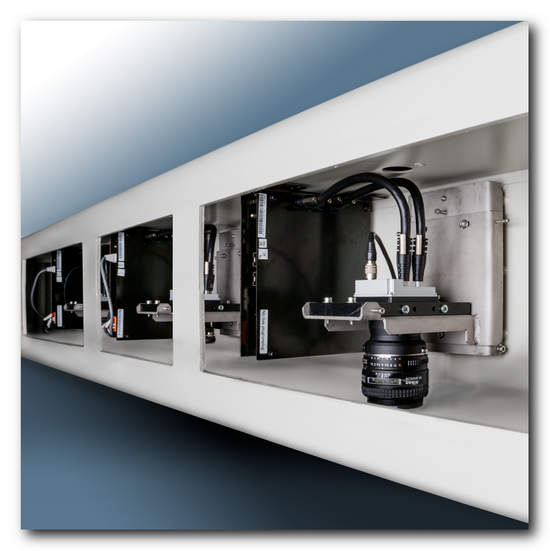

ABB’s HPINet WIS dirt count system provides full web width inspection, imaging and identification in real-time to improve pulp quality and production yield, as well as customer satisfaction.

Accurate dirt detection, imaging and classification all play a crucial role in quality control and process improvement for pulp production. ABB’s dirt count web imaging system meets today’s demands for increased quality and runnability, with 100% inspection of pulp and reduced customer claims.

Using high resolution, complementary metal-oxide semiconductor (CMOS) digital cameras together with advanced machine vision tools to improve performance, the dirt count system provides an exceptional level of real-time defect detection on the fastest and widest width modern paper machines. Real-time detection of dirt and shives in pulp allows operators to take corrective actions earlier, resulting in improved production yield and quality and reduced customer claims.

ABB’s HPINet dirt count web imaging system meets today’s demands for increased quality and runnability with

100 percent inspection of pulp and reduced customer claims

Dirt detection and analysis are performed by specialized, high-speed field-programmable gate array (FPGA) devices. Automated detection and counting yields consistent and repeatable results leading to improved grading of production. Defects as small as 0.02 mm2 (less than half of the width of a human hair) may be detected which enables ABB’s dirt count system to fully comply with all defect size classifications in the ISO/TAPPI/ANSI standards. Connectivity to mill-wide systems and integration with ABB pulp and paper automation systems ensures that defect data can be acted upon at the quality management and process control levels.

Unlike older technology that attempted to count dirt based on single sheets or narrow webs, ABB’s full web dirt count system can detect and classify information across the entire web in real-time. The system can be configured with either transmission or reflection illumination methods.

ABB’s dirt count system sets the new standards in web imaging systems to optimize product quality for the paper industry. Since the 1970’s, ABB has delivered over 1,300 web imaging systems around the world. The system is backed by ABB’s longstanding commitment to support its products over an extended lifecycle and by ABB’s dedicated global network of highly trained service personnel.

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids, serving customers in utilities, industry and transport & infrastructure globally. Continuing a more than 125-year history of innovation, ABB today is writing the future of industrial digitalization and driving the Energy and Fourth Industrial Revolutions. ABB operates in more than 100 countries with about 135,000 employees. http://www.abb.com

Voith receives order for BillerudKorsnäs 550.000 t/y board machine in Gruvön, Sweden

BillerudKorsnäs has awarded Voith with a fully equipped XcelLine board machine. The machine with a design speed of 1.200 m/min producing liquid packaging board, carton board, food service board and white kraft liner will be one of the largest board machines of its kind.

![]() Start-up of this new production line with a wire width of 8.800 mm will be first quarter 2019 and it will be installed at the existing site of BillerudKorsnäs in Gruvön, Sweden. The XcelLine machine offers fast and easy start-up, excellent value for money, pioneering technologies, ease of use and integrated solutions. The new board machine in Gruvön will become one of the most efficient and largest production lines for board grades.

Start-up of this new production line with a wire width of 8.800 mm will be first quarter 2019 and it will be installed at the existing site of BillerudKorsnäs in Gruvön, Sweden. The XcelLine machine offers fast and easy start-up, excellent value for money, pioneering technologies, ease of use and integrated solutions. The new board machine in Gruvön will become one of the most efficient and largest production lines for board grades.

The scope of delivery includes a three-ply wire section including a Duo DII hybrid former, equipped with two state of the art DuoShake units, a Tandem NipcoFlex shoe press with SolarPress roll cover and drying section equipped with EvoDry steel cylinders as well as multiple coating and calendering stations and a VariFlex L winding unit.

A core part of the delivery will be the Papermaking 4.0 features OnEfficiency Forming and OnCare which will give full online control of all process data. With the OnEfficiency Forming, dewatering, retention and flocculation are stabilized and coordinated at the same time. The OnCare package ensures efficient maintenance of the entire paper machine. Beside the delivery Voith will provide a new level of training for the operators and the maintenance teams.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

ABB releases new Network Platform 800 (NP800) scanner for quality control systems

The Network Platform 800 (NP800) is a completely new scanner design which provides pulp and paper customers with a perpetual foundation on which to evolve their ABB quality control (QCS) systems

NP800 is a high-performance scanner right-sized for today’s small-to-mid size paper machines of up to 6.2 meters (244 inches) sheet width. When combined with ABB’s leading-edge paper sensors and controls, NP800 is a critical component of the QCS system for improving paper quality, optimizing paper machine stability and improving process efficiency.

NP800’s combination of powerful processing and real-time data acquisition provides precise sensor and frame coordination, fast signal processing and world-class measurement accuracy.

ABB has used its extensive Pulp and Paper product and service experience to design a scanner for easy expansion, robustness, reliability and serviceability. All system electronics and moving parts are fully integrated into the end columns and completely accessible from off the paper machine for easy and safe maintenance. No water cooling is required for either the scanner or any of its sensors. These features minimize installation down-time, start-up requirements and utility costs - reducing overall system lifecycle costs.

NP800 is a right-sized for today’s small-to-mid size paper machines of up to 6.2 meters (244 inches) sheet width.

NP800 is a robust, reliable and stable platform, consisting of reinforced carbon steel “A”-beam construction with rigid end-columns that provide superior vertical, horizontal and torsional rigidity. This stable structure is critical for the precise alignment of sensor source and detector heads in harsh environments without the need for measurement profile compensation. The NP800’s smooth exterior design with no external openings, covers, exposed hardware or cables minimizes the possibilities for external contamination.

Integration with ABB’s 800xA and AC450-based QCS systems is supported along with a full range of engineering tools for configuration, monitoring and local and remote diagnostics. On-board diagnostics include spectral analysis capabilities that can provide further process insight. By studying the frequency of disturbances in the paper machine, changes in the performance can be linked to process upsets, helping customers to identify and eliminate sources of variation.

The NP800 is supported by ABB’s commitment to service our products over an extended lifecycle and by an unmatched global network of highly trained personnel.

ABB (www.abb.com) is a leading global technology company in power and automation that enables utility, industry, and transport & infrastructure customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in roughly 100 countries and employs about 135,000 people.

Toscotec to supply two MODULO-PLUS ES tissue machines to Hengan Group.

These MODULO-PLUS ES are the first two tissue machines supplied by Toscotec to Hengan Group. They have a production speed of 1,600 m/min and a net sheet width of 2.8 m. They are equipped with TT Headbox SLT full hydraulic single layer headbox, TT SuctionPressRoll-SPR1200 big diameter suction press roll, TT SYD-12FT 2°GENERATION steel yankee with optimized rib design, TT Milltech high efficiency natural gas heated hybrid hood, Steam and Condensate System. The scope of supply also includes complete control system and electrical plant (MSC,DCS and Drive system), as well as erection supervision, commissioning, start up assistance and training programs. Hengan Group has favored the advantages of Toscotec’s well known TT DOES (Drying Optimization for Energy Saving) solution at the dry end, as well as the latest design at wet end including headbox, which ensures the highest drying capacity at the lowest energy cost for the mill, and the high quality finished product. These two MODULO-PLUS ES machines are scheduled for start-up within 2017. With this Hengan order, Toscotec becomes the unique supplier in the market who is able to serve all the top four tissue players in China.

These MODULO-PLUS ES are the first two tissue machines supplied by Toscotec to Hengan Group. They have a production speed of 1,600 m/min and a net sheet width of 2.8 m. They are equipped with TT Headbox SLT full hydraulic single layer headbox, TT SuctionPressRoll-SPR1200 big diameter suction press roll, TT SYD-12FT 2°GENERATION steel yankee with optimized rib design, TT Milltech high efficiency natural gas heated hybrid hood, Steam and Condensate System. The scope of supply also includes complete control system and electrical plant (MSC,DCS and Drive system), as well as erection supervision, commissioning, start up assistance and training programs. Hengan Group has favored the advantages of Toscotec’s well known TT DOES (Drying Optimization for Energy Saving) solution at the dry end, as well as the latest design at wet end including headbox, which ensures the highest drying capacity at the lowest energy cost for the mill, and the high quality finished product. These two MODULO-PLUS ES machines are scheduled for start-up within 2017. With this Hengan order, Toscotec becomes the unique supplier in the market who is able to serve all the top four tissue players in China.

About Toscotec

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects and individual machineries. The Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

International Paper Foodservice Facilities Earn Elite Certification in Global Food Safety

International Paper (NYSE: IP) is committed to improving food safety throughout the supply chain. The Company announced their Kenton, Ohio and Visalia, California facilities achieved food safety certification by exceeding the standards of the benchmarking procedures as dictated by the Global Food Safety Initiative (GFSI). The two sites join IP's Shelbyville, Ill. Facility that was certified in March, 2016. All three sites achieved scores above 99%.

Earlier this year, International Paper set the goal of exceeding the GFSI standards at 100% of the company's U.S. Foodservice Facilities before year-end and that has been done.

![]() GFSI is a non-profit, international benchmarking organization created to standardize food safety rules and has been rapidly recognized as the 'gold standard' for international food safety. These global specifications promoted by GFSI address food, packaging, packaging materials, storage and distribution. Certification is a very stringent and demanding process that requires a facility to organize its Quality Management System (QMS) to address components in the manufacturing process such as management responsibility, hazard analysis, resource management and document control of procedures, policies and records.

GFSI is a non-profit, international benchmarking organization created to standardize food safety rules and has been rapidly recognized as the 'gold standard' for international food safety. These global specifications promoted by GFSI address food, packaging, packaging materials, storage and distribution. Certification is a very stringent and demanding process that requires a facility to organize its Quality Management System (QMS) to address components in the manufacturing process such as management responsibility, hazard analysis, resource management and document control of procedures, policies and records.

"Safety as a whole is deep-seated part of our everyday operations and our number one priority," stated Jon Ernst, Vice-President and General Manager of International Paper's Foodservice Business. "We are proactively doing our part to ensure we have the systems in place to eliminate food safety risks in the packaging arena and continue to provide a top quality product."

Requests for GFSI-benchmarked audits have been quickly growing. Ernst says that many large retailers and foodservice industry brands are calling for this type of certification as a pre-requisite to doing business. "International Paper continuously strives to exceed our commitment of excellence to our customers. As the needs of our customers continue to grow, we are well positioned to meet those needs."

About International Paper

International Paper (NYSE: IP) is a leading global producer of renewable fiber-based packaging, pulp and paper products with manufacturing operations in North America, Latin America, Europe, North Africa, Asia and Russia. We produce packaging products that enable world-wide commerce; pulp for diapers, tissue and other personal hygiene products; papers that drive communication; paper bags that carry groceries; and paper cups and food containers. We are headquartered in Memphis, Tenn., and employ roughly 55,000 colleagues located in more than 24 countries. Net sales for 2015 were $22 billion. For more information about International Paper, our products and global citizenship efforts, please visit www.internationalpaper.com

About IP Foodservice

Based in Memphis, Tenn., International Paper's Foodservice business is a leading global marketer and manufacturer of single-use packaging for the foodservice industry. The company's paper cups, food containers, plates and accessories are found in leading chain restaurants around the world. The company has a solid record of bringing innovative products and brands to market including Hold&Go®, a patented insulated paper hot cup using ThermaShield™ technology which provides a versatile solution for on-the-go beverages and ecotainer®, a commercially compostable product line made from fully renewable resources along with products made from FDA-compliant, post-consumer fiber. The foodservice business has operations in Kenton, Ohio, Shelbyville, Ill., and Visalia, Calif., Shanghai and Tianjin China, Winsford, UK and Bogota, Colombia. For more information on our product, visit www.ipfoodservice.com

Clearwater Paper Acquires Manchester Industries

Clearwater Paper Corporation (NYSE:CLW) have just announced it has acquired Manchester Industries of Richmond, Virginia, a leading, independently-owned paperboard sales, sheeting and distribution supplier to the packaging and commercial print industries.

Clearwater Paper has acquired Manchester Industries in a cash transaction from PaperWorks Industries, an integrated full-service packaging provider for a purchase price of $68.25 million. With approximately 170 full-time employees, Manchester Industries operates five facilities located in Richmond, Virginia; Wilkes-Barre, Pennsylvania; Hagerstown, Indiana; Dallas, Texas and Mendon, Michigan. Clearwater Paper believes the acquisition will be immediately accretive.

Clearwater Paper has acquired Manchester Industries in a cash transaction from PaperWorks Industries, an integrated full-service packaging provider for a purchase price of $68.25 million. With approximately 170 full-time employees, Manchester Industries operates five facilities located in Richmond, Virginia; Wilkes-Barre, Pennsylvania; Hagerstown, Indiana; Dallas, Texas and Mendon, Michigan. Clearwater Paper believes the acquisition will be immediately accretive.

"Manchester Industries offers an excellent range of converting services that include custom sheeting, slitting, and cutting," said Linda Massman, president and CEO of Clearwater Paper. "These five plants are expected to be a valuable asset for Clearwater Paper as we look to extend our reach and service platform to the small and mid-sized folding carton plants. On behalf of Clearwater Paper, we welcome Manchester Industries employees to our team."

FBR Capital Markets & Co., led by Matthew Spain, advised Clearwater Paper on the acquisition. Pillsbury Winthrop Shaw Pittman LLP acted as legal advisor to Clearwater Paper.

ABOUT CLEARWATER PAPER

Clearwater Paper manufactures quality consumer tissue, away-from-home tissue, parent roll tissue, bleached paperboard and pulp at manufacturing facilities across the nation. The company is a premier supplier of private label tissue to major retailers and wholesale distributors, including grocery, drug, mass merchants and discount stores. In addition, the company produces bleached paperboard used by quality-conscious printers and packaging converters. Clearwater Paper's employees build shareholder value by developing strong customer partnerships through quality and service.

ABOUT PAPERWORKS INDUSTRIES, INC.

Founded in 2008, PaperWorks Industries, Inc. (PWI) is a leading, integrated North American full-service packaging provider of recycled paperboard and specialized folding cartons. The company is committed to the highest sustainable forestry and procurement standards. Product certifications include the Forest Stewardship Council, Sustainable Forestry Initiative and the Programme for the Endorsement of Forestry Certification. For more information: www.paperwrks.com.

New Managing Directors at Mitsubishi HiTec Paper

Effective January 1, 2017, Dr. Martin Schreer and Andreas Jastrzembowski will become the new Managing Directors of Mitsubishi HiTec Paper Europe GmbH. They succeed Gerhard Schoon, who is retiring at the end of 2016.

After 38 years of working for the company, including 4 years as mill manager and 8 years as managing director, Gerhard Schoon, a versatile industry expert who has led the company with great commitment and great recognition, is leaving the Bielefeld-based speciality paper manufacturer.

Andreas Jastrzembowski, Gerhard Schoon, Dr. Martin Schreer (from left to right)

Dr. Martin Schreer (57) will become the Technical Managing Director. He has been with Mitsubishi HiTec Paper since 2012, and is currently Director of Research & Development, following a career spanning over 24 years in research & development of the production and processing of speciality papers.

Andreas Jastrzembowski (59) will become the Commercial Managing Director. He has been with Mitsubishi HiTec Paper since 1985, and is currently Director of Human Resources IT & Administration. During his career, he has successfully fulfilled a number of different functions in production, personnel, administration, Real Estate GmbH, and IT.

"I am very pleased that we were able to fill the positions of Managing Directors from within our own ranks," says Gerhard Schoon. "This ensures the continuity of our successful business policy and consistent market orientation."

Valmet to supply key technology for Sun Paper's new dissolving pulp mill in Laos

Valmet will deliver key technology for a new green field dissolving pulp mill to Sun Paper's new investment in Laos. The mill site, Muang Phin, is located in the southern province of Savanakhet. The target is to start pulp production during the 2nd quarter of 2018.

The order is included in Valmet's fourth quarter 2016 orders received. The value of the order is around EUR 20 million.

"This is our first international investment where we are expanding beyond China. Laos has shown to be a good location for this mill from where we will supply high profit dissolving to China. China is an important market for dissolving pulp and we expect to gain higher profits from dissolving pulp compared to kraft pulp in China," says Liu Yanbo, Mill Manager at Sun Paper".

"This is our first international investment where we are expanding beyond China. Laos has shown to be a good location for this mill from where we will supply high profit dissolving to China. China is an important market for dissolving pulp and we expect to gain higher profits from dissolving pulp compared to kraft pulp in China," says Liu Yanbo, Mill Manager at Sun Paper".

"We are very pleased to start this dissolving pulp mill project together with Sun Paper. Valmet has long experience and a wide scope of technologies in supplying equipment and processes for the production of dissolving pulp for various end products. Together with our customer we will create a mill producing pure high-quality pulp," says Pasi Mäkelä, Vice President, Pulp Mill Sales at Valmet.

Valmet has strong market position and is systematically increasing its presence at the Asia Pacific region. All of Valmet's businesses are present in the area and in 2015 it represented about 13% of Valmet's net sales, excluding China that represented another 10 % of Valmet's net sales. Valmet has 10 service points in the area and is opening a new services center in Indonesia in 2017.

Technical details about the delivery

Valmet delivery to Sun Paper's new 250 kt/year dissolving pulp mill in Laos includes key technology for various process areas. Valmet's scope of supply includes batch cooking with engineering package, brown stock and bleaching presses for the fiber line, wood powder firing, belt dryer and lime kiln. Valmet also establishes site services for all goods delivered.

The batch cooking is an ideal fit for this kind of dissolving pulp production. In batch cooking the process can utilize raw materials with varying quality. The wood powder firing solution provides fuel for the lime kiln solution and reduces the need for fossil fuels. This wood power firing implementation is first of its kind in the Asia Pacific region.

About the customer Sun Paper

Sun Paper is one of the biggest private enterprises in China, the biggest high class coated wrapping board production base and the leading enterprise of food wrapping paper board. The business of Sun Paper covers many fields such as papermaking, chemical industry, foreign trade, power, scientific research, forestry and paper industry, hotel, investment, textiles, and food. The company has more than 10,000 employees, and the annual pulp and paper production capacity of Sun Paper is around 5.7 million tons.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.