Ianadmin

Stora Enso successfully issues a 5.5-year EUR 500 million Eurobond

The bond will be listed on the Luxembourg Stock Exchange. The proceeds of the offering will be used for general corporate purposes.

Barclays, Citigroup, J.P. Morgan and Nordea acted as joint bookrunners for the transaction.

“We decided to take advantage of the strong credit market conditions and issued a bond to strengthen our liquidity further. We continue to manage our maturity profile proactively,” says Jyrki Tammivuori, SVP, Group Treasurer.

Ahlstrom to increase filtration material capacity in Turin, Italy

Ahlstrom, a high performance materials company, will invest into additional capacity in filtration materials at its site in Turin, Italy. The investment will be operational by the third quarter of 2013 and will consist of an upgrade to a paper machine producing filter media for transportation and gas turbine applications.

Total investment is approximately EUR 10 million and it will significantly increase the Turin plant capacity to supply filter media to customers globally.

"This investment is another important step in our growth roadmap, where we are strengthening our platform in Europe. By expanding our filtration operations, we are reinforcing our position as a global supplier in the filtration market with a full offering of filter media," said Tommi Björnman, Executive Vice President Filtration.

"Our global filtration platform has grown significantly in the past two years, with the recent investments in the new saturator line in Turin, the expansion at our plant in Louveira in Brazil and the acquisition and the expansion of the Binzhou plant in China. We will continue to work with our customers to grow in regions where they are focused," added Gary Blevins, Vice President, Transportation Filtration.

Ahlstrom is a leading manufacturer of filtration materials with 11 production sites producing filter media across four continents.No paper without skilled, healthy and safe people

CEPI and industriAllEurope launched a good practice report on health and safety in the European paper industry at a conference in Germany. CEPI – the Confederation of European Paper Industries – and industriAllEurope – the European Trade Union Federation – worked jointly on this new report compiling a set of 22 exemplary practices that were collected from members under the auspices of the paper sector social dialogue, funded with the support of the European Commission, DG Employment, Social Affairs and Inclusion.

CEPI and industriAllEurope launched a good practice report on health and safety in the European paper industry at a conference in Germany. CEPI – the Confederation of European Paper Industries – and industriAllEurope – the European Trade Union Federation – worked jointly on this new report compiling a set of 22 exemplary practices that were collected from members under the auspices of the paper sector social dialogue, funded with the support of the European Commission, DG Employment, Social Affairs and Inclusion.

“In both our organisations - CEPI and industriAllEurope - we believe in the merits of awareness raising and sharing experiences. We hope that this report will be one of the reference tools for health and safety managers in the European paper industry. It should contribute to the indispensable effort to reduce health and safety risks at work in the sector on the route to “zero accidents”, said Teresa Presas, CEPI Director General.

The good practice report addresses different types of pulp and/or paper mills and the health and safety issues they may carry, as well as various kinds of activities (daily operation, transport and handling, maintenance) and can in most cases be adapted and transposed. The good practices included in the report are not exhaustive, but the report paves the way to identify more practices to be shared. It also illustrates the benefits of constructive co-operation towards a common goal.

“Producing pulp and paper in Europe requires the use of a wide range of resources, of which ‘people’ are the most important”, mentioned Jorma Rusanen from industriAllEurope in his presentation. ”We both - industriAllEurope and CEPI - invite our members to use and discuss the proposed practices. We also invite other industries to read the report and adapt the good practices to their own circumstances.”

This report is part of the EU-OSHA campaigns towards healthier and safer workplaces. It will be distributed to all pulp and paper mills in Europe.

Paper mills compete on the Kemira sponsored Water Efficiency Award

The annual PPI Awards recognize the achievements of companies, mills and individuals in the pulp and paper sector. The awards provide an opportunity for pulp and papermakers worldwide to show off their strategic accomplishment as well as achievements in leadership, vision, and innovation on a global platform.

Kemira participates in PPI Awards 2012 by sponsoring the Water Efficiency Award. “Water is a vital resource for the pulp and paper sector and the topic is becoming even more important as the global spotlight falls on the possible shortage in the future”, says Kenneth Nysten, Senior Vice President, Printing & Writing, Paper. “The worsening imbalance between water demand and supply will require new water treatment solutions, especially such that can increase water reuse and enable utilization of poor-quality raw water sources. The winner of this award will be the mill that has clearly reduced the need for raw water while at the same time demonstrating that it is maximizing water reuse by filtering and circulation.”

The finalists in the Water Efficiency Award category are:

- Bignardi Papeis, Brazil

- BILT Graphic Paper Products Limited, Bhigwan Unit, India

- Cascades Candiac Mill, Canada

- Klabin Monte Alegre, Brazil

- Shandong Sun Paper Industry Joint Stock Co, Ltd, China

- Tamil Nadu Newsprint and Papers Ltd, India

The PPI Awards 2012 will be held in Brussels, Belgium on November 12, 2012 alongside the CEPI European Paper Week event. The finalists of each category have been chosen by an international panel of independent judges made up of industry experts. The finalists are invited to attend a gala dinner where the winners are revealed. Winners are presented with their trophies by the sponsor of each category and a celebrity host. More information at www.ppiawards.com.

Metsä's New urban eating with Snack & Pack

Metsä Tissue and Metsä Board contributed to creating a tastier, more sustainable street food culture by taking part in Snack & Pack, an experimental project organised as part of Helsinki’s World Design Capital 2012 programme.

Snack & Pack brought together top chefs, designers and food industry experts to brainstorm fresh ideas for healthier, visually appealing street kitchen dishes. With an emphasis on locally-grown organic food and eco-friendliness, the teams set about redesigning the whole street food experience, renewing not only the flavours and ingredients, but also the packaging design.

The results can be enjoyed in test kitchens at various cultural events through autumn. Talented young chefs including Arto Rastas, Sami Tallberg and Mikko Pölkki have put together a mouth-watering menu of nutritious ecological snacks served in visually innovative packaging, such as toasted rye-spelt wraps in grill paper pockets and crispy vegetable chips in paper boats with attractive board sleeves.

Metsä Tissue’s SAGA Cooking Paper brand jumped at the chance to take part in the project. “It was perfect for our image, because the SAGA brand’s mission is all about creating a new cooking culture. SAGA will have its official Finnish launch next year, so now is a good time to start increasing our visibility at mass consumer events,” says SAGA’s Marketing Director Jenni Kujala.

Metsä Board took an immediate interest in exploring new ways of using cartonboard for street kitchen applications and combining it with SAGA Cooking Paper. “The sleeve is quite simple as a packaging, but it is also a postcard that you can detach and send,” says Metsä Board VP of Marketing Communications, Katri Kauppila.

The project was a good occasion for Metsä Board to demonstrate the design potential and excellent printability of Carta Solida, she adds. “We were also happy to work with young designers and creative chefs.”

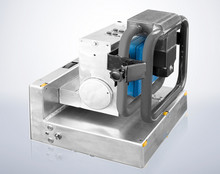

ProTect: safe and easy press fabric measurements

In order to bring safety to the conduct of press fabric measurements Voith has developed ProTect. This tool allows essential measurements to be carried out but eliminates risks to the operator from working close to rotat-ing parts or walking on slippery surfaces.

ProTect was designed to safeguard operating personnel while giving relia-ble press fabric measurements at various positions in the press section of the paper machine. This new tool is very easy to operate and adapts flexi-bly to different measuring equipment items. ProTect is a safe solution, giv-ing exact and repeatable measurements of the press fabric.

ProTect was designed to safeguard operating personnel while giving relia-ble press fabric measurements at various positions in the press section of the paper machine. This new tool is very easy to operate and adapts flexi-bly to different measuring equipment items. ProTect is a safe solution, giv-ing exact and repeatable measurements of the press fabric.

Press fabric measurements are very important to ensure efficient paper production. Measurements need to be taken while the paper machine is running, exposing operators to a number of safety risks. ProTect eliminates these risks. It consists of a self-propelled carriage, fixture and any number of traverse beams. It can be used with all common manual measurement devices. The moving parts of ProTect are predominantly located outside the machine, so wear and additional maintenance outlay are minimized.

Booshoot and Kimberly-Clark Sign Development Agreement

World's Largest Tissue Manufacturer Teams with Global Leader in Bamboo Forestry to Develop Fiber Alternatives and Protect Threatened Natural Forests

Booshoot, a biotechnology company focused on bamboo forestry, agriculture and nursery wholesale, and Kimberly-Clark (NYSE: KMB), today announced an important development agreement that will enable Kimberly-Clark to explore the manufacturing of tissue products containing fiber derived from Booshoot's proprietary bamboo propagation technology.

Booshoot, a biotechnology company focused on bamboo forestry, agriculture and nursery wholesale, and Kimberly-Clark (NYSE: KMB), today announced an important development agreement that will enable Kimberly-Clark to explore the manufacturing of tissue products containing fiber derived from Booshoot's proprietary bamboo propagation technology.

The partnership marks a significant breakthrough for the tissue industry and the planet, as the companies will work together to develop high-yield fiber alternatives that can be grown domestically on a mass agricultural scale in environmentally and socially responsible ways.

Under the agreement, Booshoot will deliver tens of thousands of bamboo starts to be grown in Kimberly-Clark pilot projects. The trials are designed to prove the viability of several species of giant bamboos, including 'Moso' (Phyllostachys edulis), as a scalable and sustainable tree fiber alternatives. Where conventional Northern Softwood trees take 60 or more years to reach harvestable maturity, Moso grows close to 100 feet tall and is harvestable in less than a decade, producing several times the fiber of traditional timber, and capturing four times the carbon dioxide (a greenhouse gas) of most trees.

"We are pleased to be working with such an established global leader in the tissue industry, and to play a role helping Kimberly-Clark meet their ambitious environmental targets," said Booshoot CEO Jackie Heinricher. "Booshoot has the proven science and production capacity required to eventually produce millions of bamboo plants annually, which will play a critical part in reducing the world's dependence on native forests."

"As a leader in bamboo technology, Booshoot is well positioned to support Kimberly-Clark's objective to develop sustainable fiber alternatives and take them to commercial scale," said Gordon Knapp, President of North American Consumer Tissue for Kimberly-Clark. "Introducing alternatives to natural forest fiber to our supply chain is important to our goals associated with responsible fiber sourcing as well as our goals to improve management of input cost risk and variability."

In 2011 Kimberly-Clark used nearly 750 thousand metric tons of primary wood fiber sourced from natural forests. The agreement with Booshoot is designed to help Kimberly-Clark meet its pledge to cut the amount of natural forest fiber in half by the year 2025, an amount equivalent to the fiber used to manufacture over three billion rolls of toilet paper.

Booshoot's patent-pending bamboo are "true to type" species that are not genetically modified, producing more biomass on less land, in less time than other traditional forest products. In addition to providing fiber for the paper industry, bamboo from Booshoot is an ideal raw material for everything from textiles to biofuels to building materials.

Resolute Announces Further Debt Reduction and Share Repurchase Milestone

Resolute Forest Products Inc.has announced that it would take advantage of its strong liquidity position to redeem an additional $85 million of its 10.25% senior secured notes due 2018. The Company also announced that it had now repurchased 3.7 million shares of its common stock under the existing $100 million share repurchase program.

"I'm pleased to say that we have now repurchased more shares than we issued to acquire Fibrek," stated Richard Garneau, president and chief executive officer. "Today's announcements demonstrate our commitment to disciplined capital management - we are using our strong financial position to reduce debt, while also returning cash to shareholders. We will continue to manage capital with the utmost discipline, carefully balancing initiatives to return cash to shareholders with other considerations, such as pursuing sound capital investments and opportunities to further increase Resolute's earnings power."

The Company will use available cash for the redemption of $85 million in principal amount of the notes, plus accrued and unpaid interest. The redemption is scheduled to occur on October 10, at a redemption price of 103%. Following the redemption, the aggregate face amount of the notes will be approximately $500 million.

SOURCE: RESOLUTE FOREST PRODUCTS INC.

KapStone Announces $29MM Investment in North Charleston Paper Mill

The Board of Directors of KapStone Paper and Packaging Corporation (NYSE: KS) has approved a $29MM investment in the company's North Charleston, SC Paper Mill. The investment is expected to improve the capability and efficiency of No. 3 Paper Machine in producing Ultra High Performance (UPL) lightweight linerboard grades by replacing the press section. The new press section will be supplied by PMT Italia. The investment also includes projects in the fiber and utilities areas to support production of these strategically important grades.

KapStone has become a market leader among independent box makers by developing and selling lighter weight, high performance, virgin-fiber-based kraft linerboard.

Engineering and construction are expected to occur over the next 18 months, targeting installation of the press section during the 1st Quarter 2014.

SOURCE KapStone Paper and Packaging Corporation

Mondi hosts 2nd annual “Green Event”

Hosted by Mondi Uncoated Fine Paper UK, sustainability managers from PEFC™, WWF, WWT, HP and Mondi will present at the Green Event. Topic highlights include: sustainability in the paper and printing industries, current climate change issues, and Mondi’s active environmental projects.

Mondi Uncoated Fine Paper (UFP), a business unit of the international packaging and paper manufacturer Mondi Group, will host the 2nd annual “Green Event” at the WWT Wetland Centre in Barnes, London, UK, on October 24th 2012. Guest speakers include representatives from WWF, PEFC®, the Wildfowl & Wetlands Trust (WWT), HP and Mondi’s Sustainable Development team. The event is free to attend but places are limited and offered on a first come first served basis.

Mondi Uncoated Fine Paper (UFP), a business unit of the international packaging and paper manufacturer Mondi Group, will host the 2nd annual “Green Event” at the WWT Wetland Centre in Barnes, London, UK, on October 24th 2012. Guest speakers include representatives from WWF, PEFC®, the Wildfowl & Wetlands Trust (WWT), HP and Mondi’s Sustainable Development team. The event is free to attend but places are limited and offered on a first come first served basis.

“Sustainable paper making is a core part of Mondi’s business strategy,” said Johannes Klumpp, Marketing and Sales Director for Mondi Uncoated Fine Paper. He added, “All Mondi UFP mills are certified FSC®, PEFC™, EU Ecolabel, IS0 14001 and ISO 9001. These third party certifications underscore Mondi’s commitment to responsible forestry and resource management such as reduced water and energy usage, fewer emissions to air and water, and less waste to landfill.”

Among the list of experts present, Peter Gardiner, Mondi’s Natural Resources Manager will give an update on Mondi’s wetland conservation and rehabilitation projects and new and or upcoming environmental initiatives.

Green Event guests will also have an opportunity to explore Mondi’s Green Range of eco-conscious papers. All Mondi-branded papers now meet Green Range criteria and are FSC® or PEFC™ certified, or 100% recycled, or TCF [Totally Chlorine Free].

To reserve a place at Mondi’s Green Event, please register at www.mondigroup.com/GreenEventUK. All attendees will be entered into a prize draw that will take place at the Green Event. The 1st prize is a mountain bike.