Ianadmin

Outotec completes the acquisition of TME Group in Australia

Outotec has successfully completed the acquisition of Australian-owned TME Group. TME is a mining services company with offices throughout Australia and in South Africa. The parties do not disclose the acquisition price. The transaction was announced on July 10, 2012.

TME provides grinding mill relining and mineral processing plant maintenance services to customers mainly in Australia, Africa and South East Asia. With annual sales of approximately EUR 35 million, TME has 130 permanent employees and a large casual labor workforce. With the acquisition Outotec aims to accelerate its service business growth.

"Our target is to grow our global annual services sales to EUR 500 million by 2015. This acquisition will expand our offerings and strengthen our capabilities to provide Operation and Maintenance services to our customers in the mining and metals industries in the South East Asia Pacific region, Africa and beyond", says Pertti Korhonen, CEO of Outotec.

Metso-supplied spray sizing unit successfully started up at Papierfabrik Schoellershammer in Germany

Metso and Papierfabrik Schoellershammer have together succesfully started up Europe’s first spray sizing unit for the mill’s swing testliner and recycled fluting machine, PM 5, located in Düren, Germany. The new two-sided spraying unit was installed in an existing pond size press, originally delivered by Metso in 2005. After the start-up on May 12, 2012, the production line has produced sellable paper from day one and has since been able to successfully produce its full product range with the new equipment.

“This is a big step forward in terms of runnability. Thanks to higher solids we can now also use increased starch amounts without compromising production capacity. We foresee considerable savings in steam consumption as well,” says Konrad Franken, Production Manager at Papierfabrik Schoellershammer.

The 5-m-wide PM 5 produces testliner and fluting grades in the basis weight range of 90-170 g/m2 at the maximum production speed of 1,100 m/min.

Metso has been developing the spray sizing technology for several years, and the work has its foundations in Metso’s long tradition with film sizing, water sprays and earlier spray coating developments. The technology is protected by several international patents and applications. In 2008 Metso started up the first one-sided prototype unit of spray sizing for fluting in Korea. Since then the company has delivered five spray sizing projects in total in Asia, three of them with two-sided spray. “We see that spray sizing is clearly the future method for surface sizing of containerboards and it has potential benefits in other applications as well,” says Topi Tynkkynen, RTD Project Manager at Metso. Spray sizing has a major role in Metso’s new OptiSizer family, to be launched to the market in 2012.

Papierfabrik Schoellershammer, located in Düren, Germany, produces testliner and fluting board grades from 100 % recycled paper 220,000 tonnes a year and high-quality specialty papers 6,000 tonnes a year. The company has a good market position in their main market area in Europe. The family-owned company employs a total of 230 persons.Vaahto Paper Technology to supply fine paper machine headbox to China

Vaahto Paper Technology will supply a new dilution controlled headbox to Henan Tianbang Group Paper Co., Ltd.

Vaahto HQZ+ headbox is of latest design and features new technology for on-line fiber orientation control. Complete pre-assembly and workshop testing makes it ideal solution especially for rebuilds.

Headbox is the most critical component of the paper machine and majority of end product properties are determined by its performance.

Henan Tienbang Paper Co., Ltd. is one of the leading private Fine Paper producers in China. This order will further strengthen Vaahto Paper Technology position in fast growing Chinese market as one of the leading supplier of high quality equipment and services.

Vaahto Paper Technology is part of Vaahto Group, which is a globally operating high technology company serving process industry in the fields of pulp and paper machinery and process machinery.

UPM Timber sold its share in RETS Timber to Stora Enso

Rets Timber has exported the owner companies’ softwood timber to Middle East and North Africa. UPM Timber will remain an active player in the market co-operating with its re-organized sales network.

For further information, please contact:

Marko Koskela, Vice President, Finance, Energy and Pulp Business Group, tel. +358 40 764 0477

Mikko Hyvärinen, Director, Sales and Supply Chain, UPM Timber, tel. +358 40 566 5701

Stora Enso to become sole owner of RETS Timber

Stora Enso Building and Living has today acquired UPM Kymmene’s 50% shareholding in the sawn timber trading company RETS Timber Oy Ltd. The acquisition makes Stora Enso Building and Living the sole owner of RETS Timber. The transaction is effective immediately.

RETS Timber is a leading European softwood sawn products supplier to the Middle East and North Africa.

“The Middle East and North Africa are very important markets for us due to increasing construction activity, and the acquisition of RETS shows our commitment to these markets. RETS customers will continue to have the most attractive product offering, a reliable supply and a specialised sales force, and for Nordic sawn timber producers RETS will continue to be the most cost-efficient marketing channel. What will change is that being the sole owner will enable us to further develop the RETS business together with our Central European trading business, focusing on the same markets,” says Hannu Kasurinen, EVP, Stora Enso Building and Living.

The transaction will increase the annual sales of Stora Enso Building and Living by approximately EUR 70 million but will not have a material impact on the operating profit of Stora Enso Building and Living. RETS Timber has about 20 employees.

Putney Paper and Pike Industries Sign Contracts for Service in 2013

Södra decides to divest Södra Cell Folla

The Södra Cell Folla management has been given the task of creating a divestment plan for Södra's ownership of the mill.

The Follafoss mill produces CTMP (chemithermomechanical pulp) which has a variety of uses including the manufacture of paperboard and tissue. Södra Cell is planning to leave the CTMP market from 1 November 2012.

"We've been struggling to create profitability in CTMP for several years. In spite of all the measures we've taken, we've found it increasingly difficult to find a profitable market for what we produce," explained Gunilla Saltin, President of Södra Cell.

Södra has used considerable resources to reverse the negative trend, including energy efficiency improvements, product development and cutting the workforce.

"We've been trying for a long time to find a solution to make operating the mill profitable but we now have to accept that previous conditions for profitable CTMP production at Follafoss no longer exist. We deeply regret that this is the case," said Saltin.

"The flexibility and creativity of Folla's employees have kept quality and productivity at a high level and they've fought valiantly to keep production costs low," she added.

The Folla mill produced 83,500 tonnes of pulp in 2011. Average annual production has been 107,000 tonnes. There are currently 51 employees at the mill. If it closes, a career transition process will be initiated that will include all employees.

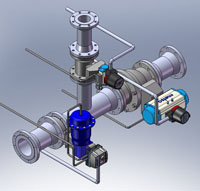

New RapidDraw3D™ Valve Model Generator from Metso

Metso's new RapidDraw3D Valve Model Generator is a free automated valve assembly model generator that allows users to quickly create realistic, to-scale, 3D valve assemblies and export them to any CAD program for use in plant piping diagrams.

Metso's new RapidDraw3D Valve Model Generator is a free automated valve assembly model generator that allows users to quickly create realistic, to-scale, 3D valve assemblies and export them to any CAD program for use in plant piping diagrams.

According to Bruce Weetherbee, Metso's Sr. Engineering Manager, "Drawing simple boxes to represent sophisticated valve assemblies in the CAD program leaves a lot of unanswered questions, such as: Which components? What's the scale? Where are the electric, air, or pneumatic connections? RapidDraw3D is a better solution that assures that these important questions are clearly answered."

RapidDraw3D is easy to use- simply choose the desired Metso valve and actuator. RapidDraw3D automatically displays the linkage available for that combination, allowing the user to then specify the orientation of the actuator and pick accessories such as positioners, solenoids, etc.

The final step is selecting the appropriate file output based on the user's CAD program (PDF, AutoCAD, SolidWorks 2D, SolidWorks 3D, DXF, STEP, IGES, Parasolids, etc..) A realistic 3D rendering can then be downloaded from the Internet for import into the chosen CAD program. These 3D files stay on the RapidDraw3D server for 90 days so they can be modified and retrieved easily.

For free access to RapidDraw3D: http://www.RapidDraw3D.com to register, and start using the program right away.

NewPage Unveils OmniPoint™ A New Heavyweight Wet Strength Label Paper

NewPageCorporation (NewPage) has announced the introduction of OmniPoint™, a new 60 lb. (89 gsm) heavyweight wet strength label paper designed for large glass and plastic containers used in food, beverage and condiment applications.

NewPageCorporation (NewPage) has announced the introduction of OmniPoint™, a new 60 lb. (89 gsm) heavyweight wet strength label paper designed for large glass and plastic containers used in food, beverage and condiment applications.

With specific expertise and technological capabilities in manufacturing wet strength label papers for the food and beverage market, the product development team at NewPage set its sights on developing a new heavyweight label paper that maintains a premium appearance, and consistently performs well in all aspects of production; from label printing, to die cutting and high speed label application.

"We worked closely with our customers to develop a heavyweight label paper solution that meets their needs for consistent quality, durability and label converting performance, while allowing them to deliver the best possible label graphics for their food and beverage brand owner customers," said David Diekelman, executive director of Sales and Marketing for specialty papers. "OmniPoint achieves these critical objectives."

OmniPoint is available with third-party chain-of-custody certifications to the Forest Stewardship Council (FSC®) (BV-COC-953662), the Sustainable Forestry Initiative® (SFI) and the Programme for the Endorsement of Forest Certification (PEFC™).

OmniPoint joins the broader range of label papers from NewPage which includes DuraPoint™, ProPoint™, LithoPoint™ and EcoPoint™ product brands. In addition, NewPage manufactures specialty papers used in flexible packaging, technical and pressure-sensitive labeling applications.

For more information or product samples, visit the NewPage booth #1539 at Labelexpo Americas in Chicago, Illinois, September 11 – 13, 2012, email This email address is being protected from spambots. You need JavaScript enabled to view it., or call 888-557-3565.

SOURCE NewPage Corporation

Walki invests in cutting-edge printing technology in Poland

Walki Group, a leading producer of technical laminates and protective packaging materials, will invest in a new multi-colour flexographic printing machine in Poland to further enhance the printing quality of its ream wrap products offered to Central and Eastern European markets.

The investment includes a new 10-colour flexo printing machine that will be utilised in the production of ream wrap used mainly for the wrapping of A4 and A3 copy paper reams.

The new machine, estimated to be in full production during the fourth quarter of 2013, will be located at Walki’s Jatne plant, situated 40 kilometres South-East from Warsaw. The supplier of the printing machine will be Comexi Group of Spain.

-The printing machine’s possibility to use 10 colours gives our customers more possibilities in terms of design and special effects. Accuracy of the machine’s printing result is excellent and the machine will also be using environmentally friendly water-based inks, notes Marko Siltala, VP of Walki’s Operations & Business Line Ream Wrapping, Paper Packaging division.

Preparing for growth in Eastern Europe and Russia

- Paper is still the best media to read longer documents and texts and the consumption of copy paper is expected to grow in Eastern Europe and Russia in the near future. Walki wants to strengthen its position as the leading supplier of ream wrapping material in Europe and the new investment is aimed to serve our customers in Central and East Europe even better than today supporting their needs for attractive packaging, Siltala says.

Due to the anticipated growth for paper products in Eastern Europe and Russia, Walki also opened a new plant in May in Russia, Siltala adds.