Ianadmin

emtec at CIDPEX 2015 in China

Process Optimization in the Tissue and Nonwoven Industry

emtec Electronic at the CIDPEX 2015 in Shenzhen, China

emtec Electronic GmbH will participate at the “CIDPEX 2015” China International Disposable Paper Expo in Shenzhen, Guangdong in China from May 25th until 27th. The company will present different testing instruments at the exhibition booth no. 1R39M – together with Shanghai Forest & Paper Scientific Instrument – its representative for China.

By the application of the different testing instruments the complete production process from the pulp to the finished product can be controlled and guided in the right direction to get an efficient process and the best possible quality with the lowest possible cost.

In the wet end it is extremely important to have detailed information about the charges of particles in the pulp suspension, which can be determined by CAS Charge Analyzing System. Also important is the knowledge about the surface charge of the pulp fibers, which can be measured with the FPA – Fiber Potential Analyzer. Furthermore, emtec Electronic developed a new Online measuring device FPO – Fiber Zeta Potential Analyzer Online, which measures the Zeta Potential of fibers directly during the production process and delivers immediately reliable and necessary information concerning the dosing of chemicals to the pulp.

In the case of tissue and nonwoven production it is necessary to get an idea of the quality of base product after production and of finished products after converting. This can be realized by the TSA – Tissue Softness Analyzer, which gives reliable and objective information about the real softness, smoothness/ roughness, stiffness as well as the final hand feeling. The availability of these three parameters opens a huge amount of chances for the optimization of the tissue and nonwoven production and converting processes.

On Monday, 25th May at 3.40 pm, Mr. Alexander Gruener will explain all the possibilities to obtain an efficient production and converting process with the application of these devices in his presentation “Process Optimization from the Wet to the Dry End of the Tissue Production Process”.

Kemira Oyj's Interim Report January-March 2015: Performance continued to improve

This is a summary of the January - March 2015 Interim report. The complete January - March 2015 Interim report with tables is attached to this release and available at www.kemira.com/investors.

This is a summary of the January - March 2015 Interim report. The complete January - March 2015 Interim report with tables is attached to this release and available at www.kemira.com/investors.

- Revenue increased 4% to EUR 553.0 million (529.9) supported by favorable currency exchange rates. Revenues in local currencies, excluding acquisitions and divestments remained flat.

- Operative EBITDA increased 15% to EUR 66.4 million (57.5) with a margin of 12.0% (10.9%).

- Earnings per share decreased to EUR 0.16 (0.28). Comparable period included a capital gain of EUR 37 million related to the divestment of formic acid business.

- Kemira maintains its outlook for 2015.

Kemira's President and CEO Jari Rosendal:

"Kemira's year started according to plan. The revenue in the first quarter increased by 8%, excluding the impact of the divested formic acid business in Q1 2014. Operative EBITDA margin improved from 10.9% to 12.0% in Q1 2015. The strengthened U.S. dollar was the main reason for revenue growth. Nearly 40% of Kemira's revenue is either directly U.S. dollar-based or linked to the U.S dollar, like the Chinese renminbi.

Growth in the Paper segment was solid in the first quarter, supported by favorable currency exchange rates and stable organic growth. Organic growth was driven by increased sales of new innovative solutions to our packaging board and paper customers, thus improving their operational efficiency as well as their end-product quality. In addition, pulp chemical deliveries to Montes del Plata pulp mill in Uruguay continued in line with the ramp up of the new mill.

In the Oil & Mining segment, demand for our products for US shale operations has slowed down in Q1 due to significant reduction in the drilling and fracking activity in the region. Uncertainty around the US shale operations is expected to continue at least for the next couple of quarters. Strong U.S. dollar alleviates the situation to some extent but reaching topline growth in the Oil & Mining segment will be challenging in 2015. In the longer term, we remain optimistic about the growth in the business.

I am pleased with the continued good progress in the Municipal & Industrial segment. The segment's revenue has stabilized after the restructuring period, and profitability has improved substantially, over 30% in the first quarter of 2015.

The closure of AkzoNobel's paper chemical business acquisition is now expected to take place in Q2 2015, due to the pending approval from the competition authority in Ukraine. Our readiness to start the integration is very good.

I consider Kemira to be well positioned to focus on growth with clear strategic objectives, customer-driven innovation, responsible business practices, and engaged and skilled professionals."

KEY FIGURES AND RATIOS

| EUR million | Jan-Mar 2015 | Jan-Mar 2014 | 2014 |

| Revenue | 553.0 | 529.9 | 2,136.7 |

| Operative EBITDA | 66.4 | 57.5 | 252.9 |

| Operative EBITDA, % | 12.0 | 10.9 | 11.8 |

| EBITDA | 65.2 | 77.7 | 252.9 |

| EBITDA, % | 11.8 | 14.7 | 11.8 |

| Operative EBIT | 39.1 | 36.3 | 158.3 |

| Operative EBIT, % | 7.1 | 6.9 | 7.4 |

| EBIT | 37.8 | 54.3 | 152.6 |

| EBIT, % | 6.8 | 10.2 | 7.1 |

| Share of profit or loss of associates | 0.2 | 0.0 | 0.2 |

| Financing income and expense | -7.5 | -5.3 | -30.7 |

| Profit before tax | 30.5 | 49.0 | 122.1 |

| Net profit | 26.4 | 43.1 | 95.8 |

| Earnings per share, EUR | 0.16 | 0.28 | 0.59 |

| Operative earnings per share | 0.13 | 0.15 | 0.63 |

| Capital employed* | 1,466.2 | 1,460.0 | 1.427.7 |

| Operative ROCE* | 11.0 | 10.8 | 11.1 |

| ROCE* | 9.3 | 4.0 | 10.7 |

| Capital expenditure | 27.0 | 25.6 | 145.1 |

| Cash flow after investing activities | 16.0 | 130.3 | 75.2 |

| Equity ratio, % at period-end | 48 | 50 | 51 |

| Gearing, % at period-end | 49 | 30 | 42 |

| Personnel at period-end | 4,285 | 4,267 | 4,248 |

*12-month rolling average (ROCE, % based on the reported EBIT)

Definitions of key figures are available at www.kemira.com > Investors > Financial information. Comparative 2014 figures are provided in parentheses for some financial results, where appropriate. Operative EBITDA, operative EBIT, operative earnings per share and operative ROCE do not include non-recurring items.

KEMIRA'S FINANCIAL TARGETS FOR 2017 AND OUTLOOK 2015 (UNCHANGED)

Kemira will continue to focus on improving its profitability and operative cash flow. The company will also continue to invest in order to secure future growth to serve selected water intensive industries.

The company's financial targets for 2017 are:

- revenue EUR 2.7 billion

- Operative EBITDA-% of revenue 15%

- gearing level <60%.

Kemira expects its capital expenditure-to-sales ratio, excluding acquisitions to increase in the next few years from the 2014 level of 6.3%. In addition, Kemira expects its medium-term operative tax rate to be in the range of 22%-25%. This rate excludes non-recurring items.

The basis for growth is the expanding market for chemicals and Kemira's expertise that helps customers in water intensive industries to increase their water, energy and raw material efficiency. The need to increase operational efficiency in our customer industries creates opportunities for Kemira to develop new products and services for both current and new customers. Research and Development is a critical enabler of organic growth for Kemira, providing differentiation capabilities in its relevant markets. Kemira will invest in innovation, technical expertise, and competencies in its selected focus areas.

Outlook for 2015

In 2015, Kemira will focus on profitable growth both organically and inorganically. Kemira's revenue in 2015 is expected to increase compared to 2014 and operative EBITDA in 2015 to remain approximately at the same level or to increase compared to 2014. The outlook excludes the impact of AkzoNobel paper chemical business (acquisition expected to close in the second quarter of 2015). At closing, AkzoNobel paper chemical business is expected to add revenue of more than EUR 200 million on an annualized basis.

Helsinki, April 24, 2015

Kemira Oyj

Board of Directors

FINANCIAL CALENDAR 2015 AND 2016

Interim Report January-June 2015 July 22, 2015

Interim Report January-September 2015 October 23, 2015

Financial Statements Bulletin 2015 February 11, 2016

Interim Report January-March 2016 April 26, 2016

Interim Report January-June 2016 July 21, 2016

Interim Report January-September 2016 October 25, 2016

Kemira Capital Markets Day will be held in Espoo R&D Center, Finland on September 17, 2015.

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2014, Kemira had annual revenue of EUR 2.1 billion and around 4,250 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

www.kemira.com

Announcement from SCA's Chairman

Anders Nyrén has today announced that he is leaving his assignment as member of the SCA Board of Directors as of April 30, 2015.

Anders Nyrén has today announced that he is leaving his assignment as member of the SCA Board of Directors as of April 30, 2015.

NB

This information is such that SCA must disclose in accordance with the Securities Markets Act. The information was submitted for publication on April 27, 2015, at 07:50 CET.

For further information, please contact:

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Xerium To Present Four Technical Papers at Technical Seminar for Board & Packaging Customers in Russia

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, announced it will present four technical papers at the Technical Seminar for Russian Board & Packaging Customers in Saint Petersburg, Russia on April 28th and 29th 2015. This event is hosted by Xerium and BKT Service, Xerium’s local PMC and Rolls sales partner in Russia, and will highlight several technological advancements in machine clothing, rolls and analytical tools. It will also demonstrate how customers are applying the new applications to reduce cost and improve both product quality and productivity.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, announced it will present four technical papers at the Technical Seminar for Russian Board & Packaging Customers in Saint Petersburg, Russia on April 28th and 29th 2015. This event is hosted by Xerium and BKT Service, Xerium’s local PMC and Rolls sales partner in Russia, and will highlight several technological advancements in machine clothing, rolls and analytical tools. It will also demonstrate how customers are applying the new applications to reduce cost and improve both product quality and productivity.

Presentations:

“Xerium Forming Fabric Technology: Innovative Technology”, presented by Stephan Ernst - Director of Application Technology Forming EMEA

“Xerium Roll and SMART Technology: Optimizing the press nip performance” presented by Petteri Voutilainen, Director of Roll Sales Europe North-East

“Xerium Press Felt Technology: Innovative Press Felt Solutions for Board & Packaging”, presented by Jürgen Dominik -Director of Application Technology for Rolls, Pressing and Drying EMEA

“Xerium Technology: Rezolve – Press Optimization”, presented by Philipp Salmannshofer - Press Optimization & Area Application Mgr.

Location: Saint Petersburg Park Inn Hotel, Russia

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 26 manufacturing facilities in 12 countries, two new plants under construction in 2 countries and employs approximately 3,100 employees.

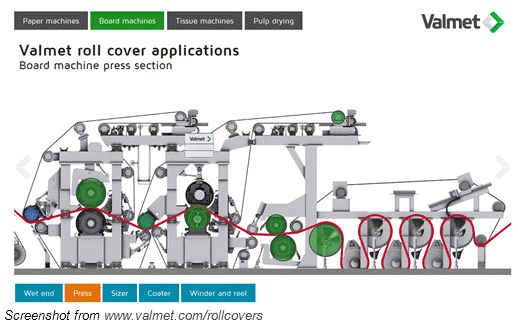

Valmet introduces new online tool for choosing optimal roll covers

Valmet has launched a new and intuitive roll cover online tool in April 2015. This interactive application enables users to locate and select the correct roll cover for any paper, board or tissue production line roll positions, as well as for pulp drying machines.

The new online tool will serve Valmet's customers even more efficiently by collating Valmet's entire roll cover and coating product range and presenting the products in one user-friendly view along with all related product information. You can find the application at www.valmet.com/rollcovers.

Easily browse through the entire Valmet roll cover range

"As an industry-leading roll cover supplier, we wanted to make it easy to search for and select a roll cover for each position. In addition to looking at roll cover options and qualities, this is also a quick way to open and download product datasheets", explains Samppa Ahmaniemi, director of Roll Covers at Valmet. The user-friendly online tool can be conveniently accessed even from tablet devices.

Fit-for-purpose roll covers for all applications

Valmet's roll cover portfolio contains a wide range of high technology solutions for all applications. For decades, Valmet has utilized the latest technology and research results in the development of roll covers. This work has resulted in modern roll cover materials and innovative coating solutions.

Regardless of the paper grade or machine brand, Valmet offers its customers a comprehensive selection of roll covers to suit their particular needs. Valmet has developed long-lasting, compliant covers ranging from rubber and polyurethane all the way to ultra-hard carbides and ceramics. These materials provide excellent wear resistance and long, disturbance-free run times. As a result, mills can increase their machine efficiency, extend roll running times and reduce their maintenance costs.

Further information, please contact:

Samppa Ahmaniemi, Director, Roll Covers, Valmet

tel. +358 10 672 6837

Juha Ruotsi, Global Technology Manager, Roll Covers, Valmet

tel. +358 10 672 0950

Forest2Market and Indufor Partnership

Forest2Market, Indufor Partner to Offer Europe’s First Transaction-based Log and Fibre Pricing and Supply Chain Optimisation System

Recent announcements of new mill investments in Scandinavia, the Baltic Rim and Northwest Russia have led to concern over increased competition, tighter fibre supply and higher raw material prices. Market concerns like these are often exacerbated by inadequate and inaccurate market data. Poor data leads to the inability to measure performance and assess the results of strategic initiatives. It also makes it impossible to identify performance gaps and eradicate supply chain inefficiencies.

Recent announcements of new mill investments in Scandinavia, the Baltic Rim and Northwest Russia have led to concern over increased competition, tighter fibre supply and higher raw material prices. Market concerns like these are often exacerbated by inadequate and inaccurate market data. Poor data leads to the inability to measure performance and assess the results of strategic initiatives. It also makes it impossible to identify performance gaps and eradicate supply chain inefficiencies.

To counteract inadequate and inaccurate data, Forest2Market, a leading provider of market data and analytics in the US, Canada and Brazil, and Indufor, a global forest consulting service provider, have formed a partnership to bring the first transaction-based log and fibre pricing and supply chain optimisation system to the region.

For this new supply chain optimisation system, Forest2Market will collect transaction data from subscribers and produce its flagship measurement tool, the wood raw material price benchmark. The benchmark serves as the foundation from which value-added analytical tools are produced to help subscribers reduce their costs and optimize their supply chains. Startup for this service is expected in 2015.

This service will bring a new level of confidence and transparency to the European forest products, timberland and bioenergy industries. For the first time, buyers and sellers will be able to clearly and confidently compare performance to market, accurately assess market prices and build strong partner relationships, as well as define, measure and adjust strategic decisions based on actual, real-time and actionable data.

“We are happy to be working with Indufor to introduce our supply chain optimisation system to Europe. We have used this system to help many of our clients in North America, and believe it will be of great value to European forest products industries as well,” said Pete Stewart, President and CEO of Forest2Market.

“Forest2Market is the only market service that creates and maintains its own proprietary database of actual transaction data. We have long-term, loyal industry relationships in North America since 2000, and in 2013, we expanded to Brazil with great success. We look forward to working with Indufor here in Scandinavia, the Baltic Rim and Russia to provide the industry with data and other powerful tools for improving business decisions.”

“We are pleased to be Forest2Market’s partner in Europe for this one of a kind benchmarking service that utilises actual transaction data,” said Jarno Seppälä, Head of Forest Industry & Bio Solutions Consulting at Indufor. “We strongly believe it will be a valuable addition to the general price information that is currently available and to existing supply chain analysis currently being conducted by industry players themselves. Now companies will be able to analyse the real efficiency of their operations.”

About Forest2Market

Headquartered in Charlotte, N.C., Forest2Market provides market pricing data, benchmarks, supply chain expertise and other decision support services to customers in the forestry, wood and paper products, and bioenergy and biochemicals industries. For more information, visit www.forest2market.com or read our blog at http://blog.forest2market.com.

About Indufor

Indufor Oy is an independent international consulting company with the head office in Helsinki, Finland and regional offices in Auckland, New Zealand and Melbourne, Australia. The company provides world class advisory services to a wide range of public and private sector clients around the world in forestry, sustainable natural resource management and forest/bio industries. For more information, visit www.indufor.fi

NG Advantage to Provide Compressed Natural Gas via “Virtual Pipeline” to International Paper in Ticonderoga, NY

NG Advantage LLC – a Clean Energy company (NASDAQ: CLNE) - announced that it has signed a contract to work with International Paper (NYSE: IP) to deliver compressed natural gas (CNG) to International Paper’s Ticonderoga, N.Y. mill.

![]() NG Advantage will deliver CNG to the mill using its Virtual Pipeline which consists of compressor stations located on natural gas pipelines, a fleet of specially designed carbon fiber CNG trailers, and off-loading and monitoring equipment which NG Advantage is installing at the mill. Deliveries will begin in May of 2015.

NG Advantage will deliver CNG to the mill using its Virtual Pipeline which consists of compressor stations located on natural gas pipelines, a fleet of specially designed carbon fiber CNG trailers, and off-loading and monitoring equipment which NG Advantage is installing at the mill. Deliveries will begin in May of 2015.

International Paper initially awarded this contract to NG Advantage in order to begin using natural gas prior to the completion of a planned natural gas pipeline. However, as previously announced, International Paper decided to cancel the pipeline project for cost reasons.

Despite the cancellation of the project to deliver natural gas to the mill by constructing a pipeline under Lake Champlain, contributing to a cleaner environment and reducing fuel costs remain very important to International Paper. The company has issued a new RFP for a long term trucked-CNG contract, starting when the current contract with NG Advantage ends. NG Advantage is a bidder for the long term contract as well.

The mill is currently International Paper’s largest US plant without access to natural gas. In order to meet this huge demand safely and reliably, NG Advantage has invented the “Private Virtual Pipeline”, a high volume variant of the Virtual Pipeline service, which the company introduced to the US market in March of 2013. Tractors and drivers will be based in Ticonderoga, NY – where the mill is - and gas can be provided from any of several compressor stations used by NG Advantage.

Clean-burning North American natural gas is expected to displace at least 32,000 gallons of fuel oil a day during this contract. The gas will be used to run the mill’s kiln and power boiler.

NG Advantage’s CEO Tom Evslin said “Because International Paper is staunchly committed to their environmental goals, they have done years of design work to extend a pipeline under Lake Champlain to replace fuel oil with natural gas. They will now be able to convert to burning natural gas even though the pipeline extension proved uneconomical. We are proud to use our equipment, technology, and experience to deliver the economic and environmental benefits of natural gas using our “Private Virtual Pipeline” to the Ticonderoga mill and to contribute to the economy of that region.”

NG Advantage was the first company to deliver compressed natural gas to industrial customers in the United States and is the US industry leader in volumes delivered. It is a US based mid/downstream company which currently trucks CNG to 22 large industrial and institutional customer sites in New England and New York State. With its majority investor, Clean Energy Fuels, NG Advantage is expanding its coverage area nationwide in 2015.

About NG Advantage LLC: NG Advantage is a US based mid/downstream provider and the leader in the new “Virtual Pipeline” industry of trucking compressed natural gas (CNG) in the U.S. – bringing the economic and environmental benefits of North American natural gas to large institutions and industrial customers without access to a pipeline or on a pipeline without sufficient capacity. The Company’s current customers include large regional hospitals, paper mills, asphalt facilities, food processors, industrial dry cleaners, LDCs, and manufacturing facilities. As a result of the purchase of a controlling interest in the company by Clean Energy Fuels (NASDAQ: CLNE), NG Advantage is expanding its service area nationwide beginning in 2015.

About International Paper: International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 58,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2014 were $24 billion. For more information about International Paper, its products and stewardship efforts, visit www.internationalpaper.com

A.Celli: destination China for an eventful May.

Two are the important appointments for the coming month of May that the A.Celli Group is about to take part in:

ANEX 2015

The first of these is the ANEX show (Asia Nonwovens Exhibition and Conference) taking place at the Shanghai World Expo Exhibition & Convention Center in Shanghai (China), from 13 to 15 May 2015. For this edition, ANEX will be combined with SINCE (Shanghai International Nonwovens Conference & Exhibition). A.Celli Nonwovens together with the staff of A.Celli Shanghai Machinery Co. Ltd., will be present at stand No. W51, and will be pleased to welcome you and invite you to discover the most innovative system solutions in winding, rewinding and packaging, palletizing and reel handling for nonwovens. In addition to this, all the auxiliary technology systems such as automatic positioning systems for cutting units and automatic cutting systems for cardboard cores, unwinders and multifunctional lines with printing systems and the technology for the production of airlaid-type nonwovens.

For further details or to reserve a dedicated meeting at our stand, please contact us at: This email address is being protected from spambots. You need JavaScript enabled to view it.

CIDPEX 2015

The second appointment will be at the CIDPEX show (China International Disposable Paper Expo) to be held at the Shenzhen Convention & Exhibition Center, in Shenzhen, in the province of Guangdong, (China), from 25 to 27 May 2015. A.Celli Paper and A.Celli Nonwovens, together with the staff of A.Celli Shanghai Machinery Co. Ltd., will be present at stand No. 1H20M, and will be pleased to welcome you and invite you to discover the latest novelties in the field of system solutions for turn-key plants, in the design and rebuild of tissue machines and rewinders for tissue, flat papers and cardboard. The wide range of the A.Celli offer is completed by solutions dedicated to lines for winding, rewinding and packaging, palletizing and reel handling for nonwovens. And everything underscored by a focus on printing technologies dedicated to different substrates (including TNT, PP/PE film and tissue in a wide range of grammages).

For further details or to reserve a dedicated meeting at our stand, please contact us at: This email address is being protected from spambots. You need JavaScript enabled to view it.

We look forward to your visit ...Come and see us!

Sonoco's Tulsa, Okla. Facility Achieves Landfill Free Status

Sonoco one of the largest diversified packaging companies, has named its Tulsa, Okla. Tubes and Cores plant a gold-level Sonoco Sustainability Star Award recipient for the plant's successful efforts to achieve landfill free status.

Sonoco one of the largest diversified packaging companies, has named its Tulsa, Okla. Tubes and Cores plant a gold-level Sonoco Sustainability Star Award recipient for the plant's successful efforts to achieve landfill free status.

While recycling had been a plant priority for some time, its staff wanted to take it completely landfill free. In 2014, they identified an opportunity to divert non-recyclable coated tube scrap to a sourcing company and initiated a recovery program.

"In addition to recovering this coated tube scrap, which is difficult to manage, this program also reduced overall facility costs," said Lynn Ratliff, plant manager. "It was truly a win-win."

Administered by Sonoco Recycling, the Company's recycling business, the Sonoco Sustainability Star Awards program is comprised of three tiers:

- Gold recognizes facilities that have achieved 99% landfill diversion;

- Silver is awarded to facilities achieving 95% landfill diversion; and

- Bronze recognizes facilities that have made significant waste reduction achievements, such as drastically reducing their waste streams or implementing a new composting system.

A recycling leader with locations and expertise worldwide, Sonoco Recycling annually collects more than 3 million tons of old corrugated containers, various grades of paper, metals and plastics. In addition, the Company has experts who provide secure, reliable and innovative recycling solutions to residential and commercial customers. Currently, Sonoco Recycling operates five material recovery facilities (MRFs) serving more than 125 communities in which curbside-collected residential and commercial materials are processed. The Company also operates recycling programs, which identify waste reduction opportunities that reduce operating expenses for many of the largest consumer product companies in the United States.

About Sonoco:

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5 billion, the Company has 20,800 employees working in more than 330 operations in 34 countries, serving some of the world's best known brands in some 85 nations. Sonoco is a proud member of the 2014/2015 Dow Jones Sustainability World Index.

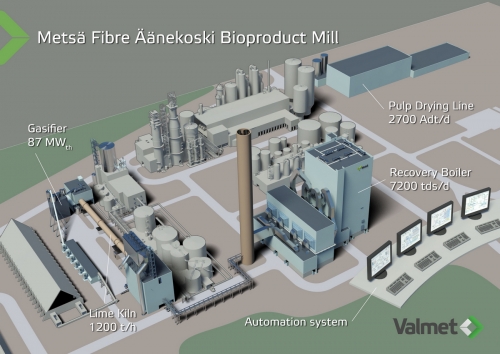

Valmet and Metsä Fibre finalized the order agreement for key technology to Äänekoski bioproduct mill

Valmet and Metsä Fibre have signed the agreement for the supply of key technology to Metsä Fibre's new Äänekoski bioproduct mill in Finland. Valmet announced the letter of intent of the delivery on February 13, 2015.

Valmet delivery includes recovery boiler, pulp drying line, gasification plant, lime kiln and a mill wide Valmet DNA automation system. The estimated value of Valmet's delivery, which includes only the core equipment supplied by Valmet, is about EUR 125-150 million. The order is included in Valmet's second quarter 2015 orders received.

The construction of the bioproduct mill will start immediately and the production at the new mill is scheduled to begin during the third quarter of 2017.

"The bioproduct mill will strengthen Metsä Group's leading position in northern softwood pulp market and will improve our profitability. We have had long term and successful cooperation with Valmet which is a strong supplier of equipment of this scale," says Ilkka Hämälä, CEO of Metsä Fibre.

Technological innovations and important employment impact

Valmet delivers leading technology for the Äänekoski bioproduct mill. The recovery boiler, pulp drying line and lime kiln will be the largest in Europe. All the equipment will have high energy efficiency.

"Our gasification technology and recovery boiler maximize the use of bioenergy and makes the pulp mill totally fossil fuel free. Valmet delivers a modern gasification plant, where bark is dried and gasified to product gas which is then used as fuel in the lime kiln. The Valmet delivered recovery boiler has multiple high power features including patented heat recovery from flue gas to combustion air enabling the mill to sell outside 1.4 times more electricity than it needs for its own operation," says Bertel Karlstedt, Pulp and Energy Business Line President from Valmet.

Valmet's delivery for the bioproduct mill will have an important employment impact on Valmet and its subcontractors. The employment impact of Valmet's project delivery is expected to be around 250 man years, out of which half in Finland mainly in Tampere, Jyväskylä, Ulvila and Raisio.

Details about Valmet's technology delivery to Metsä Fibre Äänekoski bioproduct mill

The new bioproduct mill in Äänekoski is the largest investment of the forest industry in Finland. Metsä Fibre's total investment will amount to approximately EUR 1.2 billion and the mill's annual pulp production will be approximately 1.3 million tonnes.

Valmet's delivery includes engineering, procurement, supply and construction management of a recovery boiler, a pulp drying line, a lime kiln and a gasification plant. The recovery boiler will have a capacity of 7,200 tds/d (tonnes dry solids a day). It provides steam to a turbine with 260 MW electrical capacity, which makes Metsä Fibre's recovery boiler plant the largest renewable energy production unit in Europe. The pulp drying line will have a trimmed width of 8.25 meters and a capacity of 2,700 Adt/d (air dry tonnes a day). The lime kiln will have a capacity of 1,200 t/d and will be operated by renewable fuel provided by 87 MW product gas capacity biomass gasification plant.

Valmet's automation delivery includes an extensive Valmet DNA automation and process information system covering the entire pulp mill and Valmet IQ quality control system for the pulp drying machine.

Information about the customer Metsä Fibre

Metsä Fibre is a world-leading producer of softwood pulp, whose main brand is Botnia. The company's main products are sustainably and cost-efficiently produced bleached softwood and birch pulps. Metsä Fibre has four pulp mills in Finland. Metsä Fibre's sales in 2014 totalled approximately EUR 1.3 billion, and it employs some 850 people. Metsä Fibre is part of Metsä Group.

For further information, please contact:

Bertel Karlstedt, President Pulp and Energy business line, Valmet, tel. +358 40 553 3859

Kari Remes, Vice President, Recovery, Pulp and Energy business line, Valmet, tel. +358 40 709 2015

Pasi Mäkelä, Vice President, Pulp Mill Sales, Pulp and Energy business line, Valmet, tel. +358 40 505 4199

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.