Ianadmin

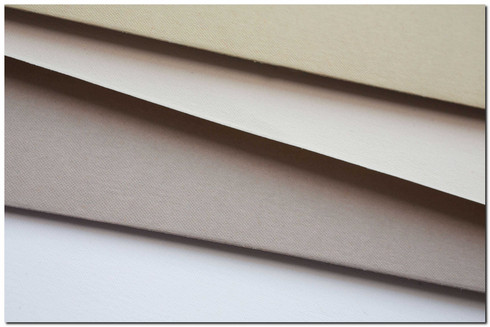

Looks like suede and feels just like suede: James Cropper’s leather-effect papers

Responding to the demands of the luxury market, British paper innovators create a packaging solution that may more accurately mimic the texture of premium, napped leathers than any other produced.

Putting their technological capabilities to the test, product developers at James Cropper Paper have succeeded in closely reproducing the soft, yet durable qualities of suede leathers in a paper-based form. Following the merge of the company’s production and converting functions earlier this year, the launch of Carvetian Suede heralds a new era of innovation, with luxury brands set to benefit from the close links between the mill and co-located facility.

Taking its name from Iron Age settlers in the North of England, the Carvetii, Carvetian Suede has been produced to better mimic one of both ancient and modern civilisation’s most widely used and versatile materials. Initially available to buyers in four colours drawn from a natural palette - Crystal, Calico, Sandstone and Pebble – the product will formally launch at Luxepack Monaco 2014 between Mon 27 – Wed 29 October 2014 at the Grimaldi Forum, Monaco.

The delicate feel of Carvetian Suede was trialled in May 2013, when a dog sculpture was created using the product for the Gerald and James exhibition in New York, an event that showcased the product alongside James Cropper’s commitment to supporting the best in contemporary design. The dog, resplendent in its stylish suede coat, was a keen demonstration of the creative potential offered by the paper. Carvetian Suede is now available to international buyers and presents itself as an opportunity for packaging designers around the world.

Chris Brown, Commercial Director of James Cropper, said: “Papers that recreate the textures and behaviours of other materials sometimes fall short due to the quality of the base paper and the expertise involved in their creation. With Carvetian Suede, James Cropper uses a high quality foundation in our papers and hundreds of hours of expert-led product development to ensure the product is flawless and fit for purpose. The inclusion of a high percentage of recycled fibres, a characteristic of the vast majority of James Cropper papers, means commercial buyers also buy into our commitment to sustainable production.”

Each run of Carvetian Suede, in any of the available colours, is manufactured with a minimum of 40% recycled, post-consumer fibres. The product is intended to provide not only luxury brands with a lavish packaging solution, but also encourage those compiling business documents, brochures and creative advertising materials with a show stopping finish.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

For further information

Julie Tomlinson

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

T: +44 1539 818413

Stora Enso invests in quality and cost-competitiveness of Imatra Mills in Finland

Stora Enso invests EUR 27 million to improve the quality and cost-competitiveness and to increase the capacity of the consumer board machine 5 by 20 000 tonnes at its Imatra Mills in Finland. The investment will focus on the coating part of the machine and on modernising the winder and reel packaging section.

Stora Enso invests EUR 27 million to improve the quality and cost-competitiveness and to increase the capacity of the consumer board machine 5 by 20 000 tonnes at its Imatra Mills in Finland. The investment will focus on the coating part of the machine and on modernising the winder and reel packaging section.

”The investment is in line with Stora Enso’s transformation into a customer focused renewable materials company. In addition to the capacity increase, the investment will enhance the quality and cost-competitiveness of our Tainionkoski unit in the global markets,” says Vesa Simola, Head of Consumer Board Business Unit.

According to the plan, the modernisation of the reel packaging section will take place in the spring 2015 while the machine is running. The rest of the work is planned to be carried out during the scheduled maintenance stoppage in September 2015.

Imatra Mills consists of two units, Kaukopää and Tainionkoski. The annual capacity of the mills is over one million tonnes of board and paper. The mills employ approximately 870 people, about 90 of them work at Tainionkoski.

For more information, please contact:

Marko Pekkola, VP Mill Director, Imatra Mills, tel. +358 40 672 2578

Ulla Paajanen-Sainio, SVP, Investor Relations, tel. +358 2046 21242

Tommy Borglund, SVP Communications, Stora Enso Renewable Packaging, tel. +46 1046 71709

www.storaenso.com

www.storaenso.com/investors

Stora Enso is the global rethinker of the paper, biomaterials, wood products and packaging industry. We always rethink the old and expand to the new to offer our customers innovative solutions based on renewable materials. Stora Enso employs some 29 000 people worldwide, and our sales in 2013 amounted to EUR 10.6 billion. Stora Enso shares are listed on NASDAQ OMX Helsinki (STEAV, STERV) and Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) in the International OTCQX over-the-counter market.

DUBLNATURE® BY WAUSAU PAPER PPI’S 2014 MOST INNOVATIVE NEW PRODUCTS

Wausau Paper (NYSE:WPP) announced that its DublNature family of premium towel and tissue products produced from 100 percent recycled fiber received the 2014 Most Innovative Product Award from PPI at the RISI 29th North American Forest Products Outlook Conference in Boston, Massachusetts on Wednesday, October 8. Pulp and Paper International, (“PPI”), is an on-line and print publication of RISI, a recognized leading information provider in the global paper and forest products industry.

Wausau Paper (NYSE:WPP) announced that its DublNature family of premium towel and tissue products produced from 100 percent recycled fiber received the 2014 Most Innovative Product Award from PPI at the RISI 29th North American Forest Products Outlook Conference in Boston, Massachusetts on Wednesday, October 8. Pulp and Paper International, (“PPI”), is an on-line and print publication of RISI, a recognized leading information provider in the global paper and forest products industry.

First introduced in May 2013, Wausau Paper’s Green Seal™-certified, DublNature® line of premium, plush, cloth-like towel and tissue products utilizes 100 percent recycled fiber and is produced on the Company’s unique ATMOS technology-enabled paper machine at its facilities in Harrodsburg, Kentucky. DublNature products are designed for both comfort and functionality and provide exceptional softness, strength, absorbency and brightness. DublNature is made from high-quality 100 percent recycled fibers and is certified by Green Seal, Inc., as environmentally preferable. DublNature products, and their upscale packaging, are well suited to a wide range of applications and are targeted at businesses and institutions seeking the finest quality while supporting green purchasing initiatives.

“We are pleased with this recognition from an important voice in the industry. During a challenging period for our Company we remained committed to producing the finest 100 percent recycled fiber premium towel and tissue products for the away-from-home segment of the Tissue industry,” commented Michael C. Burandt, chairman and CEO. “I’d like to thank our engineering, product design, papermaking, converting and marketing teams, all of whom are responsible for bringing these products to fruition and meeting the high growth demands we continue to experience.”

Matthew L. Urmanski, president and COO, added, “A year into the significant revamping of our product portfolio we again recognize the key role in our success played by the highly engaged network of Wausau Paper distributors. Their call for a broader expression of premium towel and tissue products in the away-from-home market and commitment to the process underwrote our development of the DublNature premium product. This, along with the launch earlier this year of our premium brand Artisan™ and the revolutionary Alliance™ high-capacity electronic roll towel dispensing system has been the driver of our growth and expectations for improved performance beyond

2014.”

Artisan™ is a line of premium towels which are brilliant white, remarkably strong, yet designed to provide a soft and thorough hand drying experience. The toweling has a clean and hygienic appearance as well as cloth-like durability and strength for exceptional performance. Artisan is the only line of premium quality roll and folded towels that feature Green Seal™ certification and are made from superior quality 100 percent recycled fibers and cater to high-end facilities seeking exceptional quality products that reinforce an upscale image.

Alliance™ is a high-capacity electronic roll towel dispensing system featuring twice the capacity of typical roll towel dispensers. The revolutionary patent-pending design of Alliance accommodates two full rolls – up to 1,000 feet each – that seamlessly transfer by automatically switching to the second roll when the first is completely depleted. This unique transfer feature results in fewer service interruptions and reduced maintenance time. Combined with Wausau’s EcoSoft®, DublNature® or Artisan™ Green Seal™-certified toweling, Alliance offers a new, unique hand-

drying experience superior to other systems in the market.

Green Seal™ is a trademark of Green Seal, Inc. in Washington, DC. Used by permission. ATMOS is a trademark of Voith GmBH in Heidenheim, Germany. Used by permission.

About Wausau Paper:

Wausau Paper produces and markets a complete line of away-from-home towel and tissue products, as well as soap and dispensing systems. The Company is listed on the NYSE under the symbol WPP. To learn more about Wausau Paper visit www.wausaupaper.com

Industry and Customer Contact:

Younette Sleet

Director of Marketing Communications

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: 859.733.7927

1150 Industry Road

Harrodsburg, KY 40330-0189

New from Mitsubishi: Satin coated Inkjet Paper with Offset Characteristics

With JETSCRIPT DLS 9020, Mitsubishi HiTec Paper is offering a new, double-sided satin coated inkjet paper for the growing market of high-speed inkjet printing. The special feature is that the 90g paper provides a unique offset- feel and is ideally suited for use with both pigment and dye inks.

More and more high-speed inkjet users want to use a paper that displays offset characteristics. With DLS 9020, Mitsubishi now meets this requirement. This creates a new business opportunity for printing specialists, because DLS 9020 is designed specifically for applications such as print-on-demand, brochures & magazines, transpromo and direct mail.

The new paper offers a number of features:

- Satin coated both sides

- Satin on printed surface also

- Unique offset feel

- Good opacity and very good colour reflection

- High White

- Wide colour gamut allows for accurate reproduction of even critical colours

- Very good full-area reproduction

- Designed for pigment & dye inks

- Immediate and fast processing in post printing process

- De-inkable and thus ecologically sustainable

JETSCRIPT DLS 9020 is available in jumbo rolls in various widths from now. Inkjet Papers for all applications from one source - only at Mitsubishi HiTec Paper.

For more information and samples please contact us at: This email address is being protected from spambots. You need JavaScript enabled to view it..

![]() Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's most important manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality thermal papers (thermoscript), digital imaging papers (jetscript), carbonless papers (giroform) and label papers (supercote) at two tradition-rich locations in Bielefeld and Flensburg.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's most important manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality thermal papers (thermoscript), digital imaging papers (jetscript), carbonless papers (giroform) and label papers (supercote) at two tradition-rich locations in Bielefeld and Flensburg.

Each factory stands out for integrated paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of speciality papers featuring a modular system for every application – and is a highly capable partner whenever customised coated communication paper solutions are required.

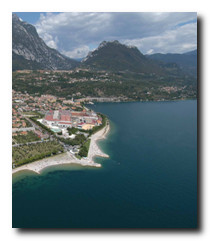

UNI EN 15593:2008 CERTIFICATION FOR THE TOSCOLANO MADERNO PLANT

The Burgo Group plant in Toscolano Maderno (BS) has achieved UNI EN 15593:2008 certification for “Management of hygiene in the production of packaging for foodstuffs”.

The Burgo Group plant in Toscolano Maderno (BS) has achieved UNI EN 15593:2008 certification for “Management of hygiene in the production of packaging for foodstuffs”.

The Toscolano paper mill is now able to guarantee, with the seal of approval of an external certification agency SGS: that its products conform to the legal requirements applicable for food safety; the possibility of accessing markets where this standard is adopted as a selection criterion for packaging suppliers; the protection of the image of those who market food products.

The quality on the management systems applied by the Toscolano paper mill complies with the implementation of good manufacturing practices (GMP) in the production of materials that come into contact with foods. European UNI EN 15593 standard is based on the analysis and evaluation of the risks connected to potential contamination of a product at all stages of its production, including the personnel, the premises and equipment, the manufacture and supporting documentation.

The quality on the management systems applied by the Toscolano paper mill complies with the implementation of good manufacturing practices (GMP) in the production of materials that come into contact with foods. European UNI EN 15593 standard is based on the analysis and evaluation of the risks connected to potential contamination of a product at all stages of its production, including the personnel, the premises and equipment, the manufacture and supporting documentation.

This major achievement guarantee the safety of a food for the consumer’s benefit, all along the chain, from the producer to the person marketing it; it comes after the certification obtained by the Treviso mill (in Mignagola di Carbonera) in 2010, the first Italian paper mill to have achieved UNI EN 15593:2008, and by Chiampo mill (in Vicenza) in 2011.

The range of specialty papers produced by the Toscolano mill has been recently developed and it offers a wide choice of one-side coated papers for labels and packaging designed for the food and beverage industry, alongside the traditional production of two- sides coated woodfree papers for the publishing market.

For further details: www.burgogroup.com www.mosaicopapers.com

European Paper and Paperboard Market Report 2014-2020

![]() Research and Markets (http://www.researchandmarkets.com/research/tbzb8k/eu_paper_and) has announced the addition of the "EU: Paper And Paperboard - Market Report. Analysis and Forecast to 2020" report to their offering.

Research and Markets (http://www.researchandmarkets.com/research/tbzb8k/eu_paper_and) has announced the addition of the "EU: Paper And Paperboard - Market Report. Analysis and Forecast to 2020" report to their offering.

“EU: Paper And Paperboard - Market Report. Analysis and Forecast to 2020”

The report provides an in-depth analysis of the EU Market of Paper And Paperboard. It presents the latest data of the market size and volume, domestic production, exports and imports, price dynamics and turnover in the industry. The report shows the sales data, allowing you to identify the key drivers and restraints. You can find here a strategic analysis of key factors influencing the market. Forecasts illustrate how the market will be transformed in the medium term. Profiles of the leading companies and brands are also included.

Product coverage:

- Composite paper and paperboard (made by sticking flat layers of paper or paperboard together with an adhesive), not surface-coated or impregnated, whether or not internally reinforced, in rolls or sheets.

- Paper and paperboard, coated on one or both sides with kaolin (China clay) or other inorganic substances, with or without a binder, and with no other coating, whether or not surface-coloured, surface-decorated or printed, in rolls or rectangular (including square) sheets, of any size.

- Carbon paper, self-copy paper and other copying or transfer papers (including coated or impregnated paper for duplicator stencils or offset plates), whether or not printed, in rolls or sheets; paper, paperboard, cellulose wadding and webs of cellulose fibres, coated, impregnated, covered, surface-coloured, surface-decorated or printed, in rolls or rectangular (including square) sheets, of any size.

Why buy this report?

- Get the full picture of the market

- Assess future market prospects

- Identify key success factors on the market

- Adjust your marketing strategy

Key Topics Covered:

- Introduction

- Executive Summary

- Market Overview

- Domestic Production

- Imports

- Exports

- Prices

- Turnover And Sales In Industry

- Business Environment Overview

- Company Profiles

For more information visit http://www.researchandmarkets.com/research/tbzb8k/eu_paper_and

Contacts

Research and Markets

Laura Wood, Senior Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

For E.S.T Office Hours Call 1-917-300-0470

For U.S./CAN Toll Free Call 1-800-526-8630

For GMT Office Hours Call +353-1-416-8900

U.S. Fax: 646-607-1907

Fax (outside U.S.): +353-1-481-1716

European Uncoated Kraftliner Market Report 2014-2020

![]() Research and Markets (http://www.researchandmarkets.com/research/qhjwhs/eu_uncoated) has announced the addition of the "EU: Uncoated Kraftliner - Market Report. Analysis and Forecast to 2020" report to their offering.

Research and Markets (http://www.researchandmarkets.com/research/qhjwhs/eu_uncoated) has announced the addition of the "EU: Uncoated Kraftliner - Market Report. Analysis and Forecast to 2020" report to their offering.

“EU: Uncoated Kraftliner - Market Report. Analysis and Forecast to 2020”

The report provides an in-depth analysis of the EU Market of Uncoated Kraftliner. It presents the latest data of the market size and volume, domestic production, exports and imports, price dynamics and turnover in the industry. The report shows the sales data, allowing you to identify the key drivers and restraints. You can find here a strategic analysis of key factors influencing the market. Forecasts illustrate how the market will be transformed in the medium term. Profiles of the leading companies and brands are also included.

Why buy this report?

- Get the full picture of the market

- Assess future market prospects

- Identify Key success factors on the market

- Adjust your marketing strategy

Key Topics Covered:

1. Introduction

2. Executive Summary

3. Market Overview

4. Domestic Production

5. Imports

6. Exports

7. Prices

8. Turnover And Sales In Industry

9. Business Environment Overview

10. Company Profiles

For more information visit http://www.researchandmarkets.com/research/qhjwhs/eu_uncoated

Contacts

Research and Markets

Laura Wood, Senior Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

For E.S.T Office Hours Call 1-917-300-0470

For U.S./CAN Toll Free Call 1-800-526-8630

For GMT Office Hours Call +353-1-416-8900

U.S. Fax: 646-607-1907

Fax (outside U.S.): +353-1-481-1716

Valmet's new OptiBin innovation in use at Nordic Paper's Bäckhammar pulp mill

Valmet has developed a new chip bin, OptiBin, for pulp mills' digester chip feeding. Its task is to serve as a buffer before the digester and to remove air from the chips in an odorless manner. The new design is the result of years of development aimed at a cost-effective solution with as few moving parts as possible.

The first installation in the world

The first OptiBin was recently started up at the Nordic Paper Bäckhammar pulp and paper mill nearby Kristinehamn, Sweden. In spite of a very tight schedule, the installation and assembly of the new chip bin exceeded expectations at Nordic Paper - everything had to be completed during the regular eight-day mill shutdown.

"The startup was very successful. We started production according to our schedule. What's more, even the startup curve, with a gradual increase in output, followed our plans. A week after the shutdown, we reached full production," says Jonas Lindqvist, Deputy Director of Production and Project Manager at Nordic Paper. "There is still some residual points and, of course, some trimming to ensure that we achieve the goals we have set for the project," he adds.

"For us at Valmet, Bäckhammar was the perfect partner for taking our new development into practice. Partly because the mill is close to our development center in Karlstad, Sweden, and also because we've always had a very good relationship with Bäckhammar," says David Elfman, Sales Manager at Valmet.

Valmet and Nordic Paper project representatives at the Bäckhammar pulp and paper mill

OptiBin reduces fiber loss and environmental impact

Valmet's new OptiBin can be used in various cooking processes. The innovations in the OptiBin design bring several benefits. The design allows chips to flow smoothly and results in even pre-steaming and less runnability problems. Without good pre-steaming before cooking the cooking liquor will not penetrate the whole chip and results in uncooked chips.

The flow design allows a cold top to be used. This means that the bin itself will form a lid of chips that disables gases to flow to the atmosphere which results in less odors to the surroundings.

Thanks to the new chip bin, Nordic Paper estimates an increase in production of about 1,000 Adt/yr. In addition, the OptiBin has led to substantial fiber savings, and as a bonus for those living nearby the mill, it is expected to minimize malodorous emissions into the environment.

For further information, please contact:

Kjell Ljungkvist, General Manager CPU/WLP Services, Valmet, Tel. +46 54 142301, +46 70 6317355

Jonas Lindqvist, Deputy Director of Production, Nordic Paper, Tel. +46 72 2225532

Marie Stenquist, Corporate Communications/PR, Nordic Paper, Tel. +46 72 5189773, +46 550 599773

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Metso strengthens its position as a leading flow control supplier by establishing new valve service centers in Europe

Metso opens new service centers in Germany and France to support the company's strategy to grow its valve and field device service business and to strengthen its service capabilities for the petrochemical, energy, oil & gas, and pulp & paper industries. Since 2012, Metso has established ten new valve service centers around the world. By the end of 2014, the total number of Metso valve and field device service centers will exceed 40.

Metso opens new service centers in Germany and France to support the company's strategy to grow its valve and field device service business and to strengthen its service capabilities for the petrochemical, energy, oil & gas, and pulp & paper industries. Since 2012, Metso has established ten new valve service centers around the world. By the end of 2014, the total number of Metso valve and field device service centers will exceed 40.

"Our target is to continuously improve our service capability and scope of offering to help our customers ensure outstanding long-term process performance with high reliability and safety. The new service centers, where overhauls are carried out according to Metso's accurately defined service procedures, offer our customers the full advantage of the Metso product experience and industry expertise," says Timo Hänninen, Vice President, Services, Flow Control, Metso.

"The products are reconditioned to their original product specifications by our skilled experts and returned to the customers with the same warranty as new products. All our quality and environmental procedures naturally meet the ISO 9001 standard, and our service personnel have ATEX qualification to ensure the safe use of electrical and mechanical equipment in hazardous areas," he adds.

Services are provided for Metso and third-party field devices, including valves, actuators, smart devices and pumps. In addition, the service centers provide spare parts, field support and diagnostic services as well as training programs. Building on these technical services, Metso offers business solutions, such as Intelligent Shutdown, Intelligent Maintenance, Device Management and Control Performance, to optimize maintenance and production efficiency.

About the Horgau and Vitrolles service centers

The Horgau global service center, located in Southern Germany near Munich, operates in the same premises as Metso's Horgau valve manufacturing factory. Operating under one roof provides synergies, for example, in laboratory testing. The service center supplies spare parts for the Mapag® valves manufactured in Horgau as well as provides services for Metso's end customers and sales offices around the world. Thanks to its central location, the Horgau center is able to efficiently provide Metso valve solutions support and training for European customers.

The Vitrolles valve service center is located near Marseille and serves the Southwestern part of France.

Leading flow control technology for improved safety and sustainability

Metso has a long track record of delivering engineered performance and reliability to the oil & gas industry through its leading product brands Neles®, Jamesbury® and Mapag®.

The company has delivered millions of valves, control valves, and on-off valves globally for more than 90 years, and is one of the leading suppliers of intelligent valve controllers. Metso's valve technology centers and production facilities are in Finland, the United States, Germany, China, South Korea, India and Brazil.

Metso's flow control services focus on three main areas: solving technical and process issues, improving business performance, and managing a business area. The maintenance services range from servicing single Metso valves all the way to maintenance and device management solutions for complete plants.

Metso is a leading process performance provider with customers in the mining, oil and gas, and aggregates industries. Metso's cutting-edge services and solutions improve the availability and reliability in minerals processing and flow control, providing sustainable process and profit improvements. Metso is listed on the NASDAQ OMX Helsinki, Finland. In 2013, Metso's net sales totaled EUR 3.8 billion. Metso employs approximately 16,000 industry experts in 50 countries. Expect results. www.metso.com, www.twitter.com/metsogroup

For further information, please contact:

Timo Hänninen, Vice President, Services, Flow Control, Metso

tel. +358 20 483 5546,

email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Jussi Ollila, Vice President, Global Communications, Metso Corporation

tel. +358 20 484 3212,

email: This email address is being protected from spambots. You need JavaScript enabled to view it.

FIBERMARK SHOWCASES NEWLY EXPANDED CONVERD BRAND AT SGIA

For the first time since the acquisition, FiberMark (www.fibermark.com), a world-class fully integrated manufacturer and global distributor crafting its fiber based specialty materials in the U.S., announces that it will showcase the new and improved conVerd™ line of products at SGIA in Las Vegas, October 22-24.

For the first time since the acquisition, FiberMark (www.fibermark.com), a world-class fully integrated manufacturer and global distributor crafting its fiber based specialty materials in the U.S., announces that it will showcase the new and improved conVerd™ line of products at SGIA in Las Vegas, October 22-24.

conVerd is recognized around the world for being the leader in providing sustainable paper based print media solutions to the wide and grand format print markets. Now coupled with FiberMark’s existing line of wide format inkjet business, the conVerd family of brands offer the wide format print market the most durable line of fiber-based, PVC-alternative print substrates for UV, latex, eco-solvent, solvent, screen and offset printing.

From paper based rigid boards that are high quality 100% recyclable PVC alternatives, to durable fiber based flexible media substrates that are widely used around the world for point of purchase, backlit & frontlit displays, murals, wallcovering, banners and hanging signage applications, FiberMark’s conVerd brand offers specifiers and brand holders environmentally-friendly and sustainable solutions for any type of campaign requiring wide or grand format applications.

“FiberMark is excited to share the new product developments and fresh look of the conVerd brand at SGIA this month” said Milene Ribas, FiberMark’s Wide Format Product Manager and Director of International Sales. Adding, “The FiberMark booth will have samples that showcase the full capability of the conVerd brand as well as demonstrate the superior image quality when printed.”

Visit FiberMark at SGIA, Las Vegas Convention Center – Booth 1301. For more information on FiberMark Wide Format Media visit www.fibermark.com/business#!wide-format-media.

ABOUT FIBERMARK

FiberMark, a manufacturer of specialty cellulose and synthetic fiber-based printing media, announces a portfolio of FiberMark branded products for wide format inkjet printers. FiberMark capabilities include paper manufacturing, saturating, performance coating, calendering, laminating, embossing, and roll converting. FiberMark is Forest Stewardship Council™ (FSC®) – certified (FSC-C020981). FiberMark has been manufacturing saturated papers and nonwovens for specialty applications for more than 100 years. Core businesses include: Luxury Packaging, Decorative Covering Materials, Performance Boards, Technical Specialties, and Digital Print Media.