Ianadmin

Endress+Hauser increases commitment to ODVA

ODVA in Ann Arbor, Michigan, USA, has announced that Endress+Hauser, one of the world’s leading suppliers of measurement, automation equipment and solutions for the process industries, will become a principal member, joining leading suppliers Bosch Rexroth, Cisco Systems, Rockwell Automation, Omron and Schneider Electric.

Endress+Hauser’s increased participation in ODVA builds on its long-term support of open industrial networking technologies, including the company’s portfolio of mass flowmeters designed for the EtherNet/IP network.

“ODVA is one of the world’s largest consortiums advancing open, industrial networking

standards through commercially-off-the-shelf (COTS) technology and a media-independent network protocol,” said Katherine Voss, executive director, ODVA. “We welcome Endress+

Hauser in this consortium as we have a shared vision for leveraging EtherNet/IP to

simplify an end user’s network architecture.”

With leading industrial automation suppliers, such as Endress+Hauser, as principal members, ODVA is one of the first associations which strive to support Industrial Ethernet down to the field level in process automation. This will help provide manufacturers a complete, plant-wide network infrastructure for process, motion, safety and discrete applications and from plant-floor to IT systems.

Traditionally, devices measuring and controlling process variables rely on a field network to transfer information, while other devices within the plant use completely different networks for data communication. By improving this complex multi-tier networking strategy with one

standard network architecture, namely EtherNet/IP, users have a simplified network structure as well as better access to plant-floor information. This enhances the ability to monitor overall performance, troubleshoot out-of-margin conditions and minimize downtime.

“Our customers demand open, interoperable solutions such as EtherNet/IP, as it enables

higher-level software such as ERP systems, process historians, control loop tuning programs, and asset management systems to access data from process instrumentation,” said Raimund Sommer, managing director of Endress+Hauser Process Solutions AG. “We look forward to continue working through ODVA to help users achieve seamless integration of our instruments into system architectures.”

Endress+Hauser made its first major commitment to ODVA technologies in 2009 when the company launched the Promass 83 – the world’s first Coriolis mass flowmeter with EtherNet/IP connectivity – capable of measuring mass flow, density and temperature, featuring an integrated Web Server that allows authorized users to remotely conduct diagnostics, configure the instrument or perform process optimization. The company also recently launched its

Promag 53 electromagnetic flowmeter with EtherNet/IP connectivity. By using EtherNet/IP, up to 10 measured variables can be configured and transmitted including volume flow, calculated mass flow and totalized flow.

ODVA will introduce Endress+Hauser as a principal member at its 2012 Industry Conference and 15th Annual meeting, to be held 16-18 October 2012 in Stone Mountain, Georgia, USA. For more information about the ODVA event, visit www.odva.org.

The European Paper Industry supports the Italian Waste Shipment Law

“The Confederation of European Paper Industries (CEPI) supports global trade and a free market, but a pre-condition to this is a level playing field. This is why we support requiring broadly equal environmental standards from our competitors in Asia," said Jori Ringman-Beck, CEPI Director for Recycling, Products and Environment, at bvse (Bundesverbard Sekundaerrohstoffe und Entsorgung e.V.) International Recovered Paper Conference in Dusseldorf, Germany, on Thursday 19 April.

"This is also the reason why CEPI supports the recent Italian waste law amendment enforcing good global environmental standards in recycling," said Mr. Ringman-Beck. According to the decree dated 4 April 2012, each international waste shipment must now be accompanied by a certificate issued by the authorities in the destination country confirming that the environmental standards applicable in that country are comparable to those prescribed in the EU. Recently, the Internal Committee of the Italian Parliament advised the Parliament to repeal the amendment.

CEPI reminds that the principle of requiring comparable environmental standards is already included in the European Waste Directive and the Waste Shipment Regulation, and is also recognised in the international Basel Convention on waste transports. “As such the Italian decree does not seem to be conflicting with either EU law or international law” says Mr. Ringman-Beck. “It is also giving strong support to the European green growth, resource efficiency and recycling society,” complements CEPI Director General, Teresa Presas.

“The rationale and justification of the Italian amendment is very valid and is a valuable attempt to implement the requirement of ‘broadly equivalent standards’ which has existed in EU waste legislation for years but has rarely been enforced. Not enforcing it erodes both the environmental and the economic foundations of sustainability,” says Ms. Presas.

PepsiCo plant to reduce up to 70% of fresh water consumption using Siemens’ integrated reuse solution

PepsiCo is installing an integrated reuse solution from Siemens Industry Automation Division at its snack food production plant in Santiago, Chile. As part of a wastewater treatment plant upgrade, the manufacturing facility is increasing its wastewater treatment capacity by 20% and incorporating environmentally beneficial technologies. The Siemens system will lower fresh water consumption by up to 70%. It is expected to become operational in April 2012.

The integrated solution from Siemens will help eventually reduce the amount of fresh water used in making potato chips and other snack food lines at the Santiago plant by an estimated two-thirds. Water savings will be accomplished by taking the initial water used in production, extracting the impurities and cycling it back into the production systems. Wastewater treated by the Siemens system will be reused in various internal manufacturing processes.

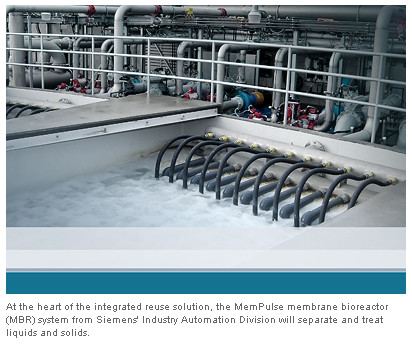

The installation is part of a corporate initiative to help standardize water reuse at PepsiCo facilities throughout South America. At the Santiago facility, most of the wastewater first passes through an extensive starch recovery system and is then screened before it moves on to primary treatment, which includes oil and grease removal. After this stage, it will flow to a MemPulse membrane bioreactor (MBR) system from Siemens that will separate and treat liquids and solids. Additionally, a remote supervision system will allow MBR performance parameters to be monitored online from Siemens' technology center in Waukesha, Wisconsin, USA. From the MBR, the water will be pretreated before it passes through tertiary treatment, including a reverse-osmosis (RO) system and a Barrier M ultraviolet (UV) disinfection system, both also from Siemens. The integrated reuse solution is more advanced than conventional wastewater treatment processes, producing consistently high-quality effluent in a smaller footprint.

While PepsiCo has used a combination of MBR and RO technologies at a few of its manufacturing facilities throughout Latin America, this marks the first known time the technology combination has been entirely offered by a single manufacturer in South America. Increasingly stringent local regulations, coupled with the company's growing green initiatives, might make using the technology combination in its processes more prevalent in the future.

MemPulse and Barrier are trademarks of Siemens and/or its affiliates in some countries

Further information about solutions for water treatment is available at:

http://www.siemens.com/water

Ashland Inc. to transfer a portion of its North American middle market commercial assets

Ashland Inc. to transfer a portion of its North American middle market commercial assets within its Water Technologies business to Rochester Midland Corporation

Ashland Inc. has announced that its subsidiary, Hercules Incorporated, conducting business as Ashland Water Technologies, has entered into a definitive agreement to transfer a portion of its middle market commercial business assets to Rochester Midland Corporation (RMC). The business to be transferred includes roughly 5,000 customer locations, with total annualized revenues of approximately $15 million. Financial terms of the transaction were not disclosed.

Under the agreement, RMC will have the right to make and sell Ashland water treatment products into the North American commercial market. Going forward, Ashland and RMC will be working together to provide high-quality, innovative products and services to this segment.

"The transfer of this portion of our North America commercial business to Rochester Midland is consistent with our decision to focus more on heavy industrial markets, while maintaining our long-standing commitments to our commercial customers," said Paul Raymond, president, Water Technologies. "We believe Rochester Midland is well positioned to serve these customers and grow this business to realize a greater return for both companies, and we look forward to working with them."

"We look forward to a long-term relationship with Ashland Water Technologies in multiple areas of mutual interest in our markets and geographies," added Harlan Calkins, Rochester Midland chief executive officer.

The transaction is expected to close by early May, subject to fulfillment of certain conditions. The parties have agreed to work together to ensure a seamless transition with no disruption in customer service.

Approximately 70 employees who currently work in the business are being transferred. RMC has committed to offering jobs to all of these employees.

Donald Duck's Finnish design on UPM paper

UPM has partnered with the Sanoma Magazines Finland to produce a special Design Donald Duck edition as part of the World Design Capital Helsinki 2012 programme.

What is design today? Donald Duck ponders this fundamental question, which, of course, results in several funny incidents, in a special Donald Duck spring issue. Daily life in Duckburg is seamlessly combined with the history, present day and future of Finnish design in a storyline written by Finnish author and cartoonist Kari Korhonen. New characters that appear in the story alongside the citizens of Duckburg bear a close resemblance to well-known Finnish designers such as Alvar Aalto, Vuokko Nurmesniemi, Stefan Lindfors and Paola Suhonen.

“With printed Donald Duck the reader can escape to Duckburg” says Aki Hyyppä, the editor in chief for Donald Duck Finland at Sanoma Magazines. “The purpose of reading whether it’s high literature or cartoons, is to create a physical experience, offering a break in our hectic everyday life. The added touch of high quality paper creates a feeling that can’t be compared with anything else. A cartoon collection on the book shelf is a pleasure itself”, he continues.

The special Donald Duck edition has upgraded the standard paper grade to highlight this special version. “High quality UPM Finesse was chosen to create a prestigious first impression for the cover and UPM Star matt to enhance the versatile details of the cartoons inside of the magazine“, explains Eeva-Liisa Heinaro, Sales Director, Magazine Publishers and Printers, Finland.

The Design Donald Duck is published in four languages: Finnish, Swedish, English and German. The limited edition special publication is not available through normal sales channels, but Finnish Donald Duck readers can enjoy the design story as part of the 16/2012 issue in April.

To find out more visit the World Design Capital Helsinki website at: http://wdchelsinki2012.fi/en

Verso Paper Corp. Announces Retirement of CEO

Verso Paper Corp. have announced that Michael A. Jackson will retire as the President and Chief Executive Officer and a director of Verso and that David J. Paterson has been elected by Verso's board of directors to serve in such roles, with both events to occur effective as of May 14, 2012.

Scott Kleinman, Verso's Chairman of the Board, said, "Verso truly has been fortunate to have Mike Jackson as our CEO during the past five years. Mike has established a solid culture and strategic foundation at Verso since we became an independent entity in 2006. Under Mike's direction, Verso has improved and refined our core product portfolio, developed and marketed a series of specialty products, and formulated and begun executing a forward-looking renewable energy strategy. Verso is on sound footing thanks to Mike's steady leadership. On behalf of the entire Verso team — our employees, board of directors, and stockholders — I want to thank Mike for his distinguished service and tremendous contributions to Verso."

Kleinman continued, "Going forward, we are pleased and honored that Dave Paterson will become Verso's new CEO. Dave brings to Verso a wealth of experience garnered during his many years of service as an executive with AbitibiBowater Inc., Bowater Incorporated, and Georgia-Pacific Corporation. Dave is an outstanding leader, a respected and knowledgeable businessman, and absolutely the right person to lead Verso in the next phase of its business life."

Dave Paterson added, "I am pleased to be appointed as CEO and am excited about the opportunities ahead for Verso. Verso has a strategic focus, exceptional people, and a nimble management approach that should bode well for the future. I am truly excited to be joining the Verso team."

Mike Jackson concluded, "It has been an honor and privilege for me to serve as Verso's CEO during the past several years. I have so much appreciation for the incredible work and indomitable spirit of our employees. I am confident that this will be a seamless CEO transition and that Dave Paterson is well prepared to continue the evolution and execution of Verso's strategies."

Mr. Jackson will continue to serve as the President and Chief Executive Officer and a director of Verso through Verso's first quarter earnings call on May 14, 2012, after which Mr. Paterson's appointment to these positions will become effective. Mr. Paterson will serve as a Class II director of Verso with an initial term expiring at our 2013 annual meeting of stockholders.

Mr. Paterson, age 57, served as President and Chief Executive Officer and a director of AbitibiBowater Inc. (now doing business as Resolute Forest Products), a leading global producer of newsprint, coated and specialty papers, market pulp and wood products, from 2007 to 2011. He was Chairman, President and Chief Executive Officer of Bowater Incorporated during 2007 and President and Chief Executive Officer of Bowater Incorporated from 2006 to 2007. From 1987 to 2006, Mr. Paterson worked in various executive and sales and marketing positions for Georgia-Pacific Corporation, a leading global manufacturer of tissue, packaging, paper, building products and related chemicals, including most recently as Executive Vice President of the Building Products division from 2003 to 2006, Executive Vice President of the Pulp and Paperboard division from 2001 to 2003, President of the Paper and Bleached Board division in 2001, and Senior Vice President of the Communication Papers division from 2000 to 2001.

Source: Verso Paper Corp.

Resolute Forest Products and National Envelope Announce Partnership

Resolute Forest Products and National Envelope have announced a unique partnership that will provide customers with an expanded portfolio of solutions, including folio-size sheets using Resolute's innovative, high-yield, sustainable paper. This alliance is an integral part of both companies' continued emphasis on providing customers with industry-leading eco-friendly solutions.

Resolute recently launched Align™, its family of high-opacity, high-bulk, environmentally responsible papers that can be used as alternatives to chemical pulp coated and uncoated freesheet in most commercial printing applications. When compared to traditional offset papers, Align grades deliver a smaller environmental footprint and greater cost savings to customers.

When comparing the overall product life cycle, Align grades have less impact on the environment than traditional freesheet papers, including a carbon footprint that is from 35% to 85% smaller than that of the average freesheet grade. Furthermore, thanks to its higher bulk and opacity at a lower basis weight, customers receive all the printability they expect, but at a lower cost. Based on their needs, Align customers can either pay less for paper, pay less for postage, or print and mail more at the same cost.

"Through this partnership with National Envelope, even more end-users - including those supplied by sheet-fed printers - can benefit from the environmental and economic savings that the Align paper line brings," stated Richard Garneau, President and Chief Executive Officer of Resolute Forest Products. "This effort fits with Resolute's goal of helping more customers reduce their own environmental footprint."

"As National Envelope continues to evolve, this is a strategic milestone toward transforming into a more diversified sustainability-oriented supplier," said Ken Winterhalter, Chief Executive Officer of National Envelope. "This partnership will enable more customers to have access to environmental solutions without having to pay a premium."

To learn more about Resolute's Align papers or to order samples, please visit www.alignpaper.com.

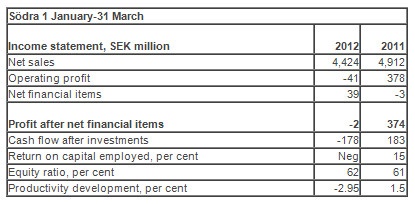

Södra's income statement for the first quarter of 2012

Södra's operating profit for the first quarter of 2012 amounted to SEK -41 million. Profit after net financial items amounted to SEK -2 million. Reduced production and a number of market stoppages characterised the first quarter of the year.

"We started the year with most of our sawmills implementing market stoppages, while production at two of our Norwegian pulp mills was down for much of the quarter. Production at our pulp mills was just 73 per cent of our normal capacity. For the sawmills, the corresponding figure was a low 70 per cent," said Group Chief Executive Leif Brodén. Together with the first quarter of 2009, this is historically the lowest level of capacity utilisation the company has seen. January and February experienced the lowest production figures, but they also mark the turning point. All production units have been back to normal production capacity since 20 March.

"We are seeing a recovering pulp market and anticipating economic recovery," said Brodén. Price announcements have been accepted, and as of 1 April the price of NSBK is USD 870 per tonne. We are now seeing strong increases in volumes to China, which up to now has been more or less solely responsible for the increase. We are expecting to see higher prices for sawn timber products over the course of the year, but only small volume increases. Viewed from a new development perspective, it seems that 2012 will be another lost year. The sawmill structure will probably need further streamlining.

"For the rest of 2012, we will see normal capacity utilisation, and we think we will see a profit for the year which is just below last year's result, along with a 7 to 8 per cent return on capital employed," said Brodén.

The pulp market started to show signs of recovery during the first quarter of 2012. The world market price of bleached softwood sulphate pulp went up as inventories decreased.

Pulp production at Södra's five mills over the period amounted to 380,000 tonnes, compared with 522,000 tonnes over the same period last year. This reduction is due to the market stoppages which took place at Södra Cell Tofte and Södra Cell Folla.

Textile pulp is now being produced at Södra Cell Mörrum. Annual production is expected to reach 170,000 tonnes, which will give Södra a competitive textile pulp product based on hardwood.

Production of DuraPulp is ongoing at Södra Cell Värö. This is a material which has attracted significant attention due to its unique properties, combined with the fact that it is renewable and biodegradable. DuraPulp is made up of a specially selected pulp from Södra Cell and a renewable biopolymer. On further processing, these two components provide special properties such as moisture resistance, strength and hardness. For the most part, a lamp and a children's chair have been in the spotlight to date, and work is now ongoing with a number of partners which are testing the material at their production facilities.

The market for sawn timber products remains weak, although supply and demand remain balanced. High raw material prices combined with the weak market are having an adverse impact on profitability.

Södra produced 371,000 m3 of sawn timber products over the period, compared with 391,000 m3 over the same period last year. Production at the new sawmill in Värö is continuing to develop positively towards stable, high production levels as planned.

The market for interior products is hesitant in Sweden and remains weak in Denmark, but both sales and earning capacity are strong in Norway.

Over the quarter, Södra Interiör acquired parquet flooring manufacturer Berg & Berg in Kallinge, employing around 90 staff. The company produces more than 500,000 m2 of high quality parquet flooring per year, with net sales of around SEK 130 million. This acquisition will further increase the range of products available to Södra Interiör's customers, while at the same time providing good opportunities for synergies between the businesses in fields such as marketing, logistics and product development.

As a consequence of the sawmill and pulp mill stoppages, the volumes handled by Södra Skog over the first quarter were 800,000 m3 lower than at normal capacity. The price of softwood pulp timber was reduced by SEK 25 on 16 January to SEK 300 per cubic metre sub (solid volume under bark). Since the end of the quarter on 13 April, the price of softwood pulp timber and the assortment mixed hardwood has been reduced by SEK 20 to SEK 280 per m3sub. At the same time, the price of aspen pulp timber went up by SEK 25 to SEK 325 per m3sub.

Over the period, Södra has installed and commissioned a new machine for applying wax protection to its bare root saplings and "plug plus one" saplings as an effective, non-toxic means of protecting against pine weevil damage. This machine is the first of its type. The wax makes it difficult for pine weevils to gnaw their way through to the bark and has been specially developed for high elasticity. This project is a cooperation between Södra Skogsplantor, Ramlösa Plantskola and Sundins Skogsplantor.

The forestry plans, with a newly prepared plan, have been available online to Södra members since March thanks to a newly developed function on Skogsägarnätet, the forest owners' network. The Skogsägare - forest owners - app was launched at the same time, making it possible to access the forestry plans on the iPhone and iPad.

Productivity improvement within the group continues apace, mainly due to ideas contributed by staff.

"We have implemented 1,281 suggested improvements over the quarter. These ideas will improve our profits by a total of SEK 32 million per year. However, overall productivity fell by 2.95 per cent over the quarter, mainly due to the fact that this figure is calculated on the basis of volumes supplied. March saw the marking of the 20,000th idea implemented since we started our systematic productivity programmes in 2000," added Brodén.

Renewed UPM DIGI Color jet – an ideal choice for direct mailing with duplex colour printing

UPM has renewed its UPM DIGI Color jet paper. During the past two years the printing properties of the paper have been improved and now it is possible to achieve even better printing results with low ink amount. UPM DIGI Color jet was initially launched in May 2010.

UPM DIGI Color jet is a special surface treated paper. It is an ideal surface to display invoice information added with some appealing promotional material - an excellent choice for direct mailing, transpromotional and transactional documents in addition to many other colourful mailing documents and books.

UPM DIGI Color jet is developed for dye based inks and it provides high print density and wide colour gamut. High ink drying speed enables fast print-outs without colour-to-colour bleed.

Excellent product for growing markets

“We see growth potential in this product since nowadays there is more promotional material included in the invoices than before. UPM DIGI Color jet is a very competitive product and fulfills the demanding market requirements. Excellent end result is achieved with low ink usage and this means cost-savings for customers. It has optimized optical properties which guarantee low print-through and enable printing of four colour advertisements,” says Arto Kipinä, Sales Operations Director, UPM Label and Postal papers.

UPM DIGI Color jet has EU Ecolabel and it is FSC® or PEFC™ granted.

Univar announces board changes

Univar Inc., a leading global chemical distributor, announced today that J. Erik (Erik) Fyrwald will join Univar as president and chief executive officer effective May 7. Fyrwald, age 52, is currently president of

Ecolab (NYSE: ECL) a global provider of water, hygiene and energy technologies that merged with Nalco in December 2011. Fyrwald will also become a member of Univar's board of directors.

As a result of the addition of Fyrwald to the executive team, Univar's current President and Chief Executive Officer (CEO) John J. Zillmer will assume the position of executive chairman of Univar and its board of directors, succeeding William S. Stavropoulos, who will move to the role of lead director. As executive chairman, Zillmer will continue to focus on leadership development, corporate strategy, and the company's global growth initiatives.

"This is a great opportunity for Univar to continue strengthening its leadership team and business momentum," said Univar President and CEO, John Zillmer. "At Nalco, Erik brought focused attention to creating the capabilities needed to support the company's dynamic growth. With his record of strong business leadership and results, the board of directors and I are very confident in his ability to help lead Univar as we continue to expand our global footprint."

Fyrwald brings extensive global experience to his new role with Univar. Prior to the merger with Ecolab in 2011, he was chairman and chief executive officer at Nalco. Before joining Nalco in 2008, Fyrwald held several executive positions during his 27-year career at DuPont, including group vice president of DuPont's Agriculture and Nutrition division and vice president of DuPont's Nutrition and Health business. Fyrwald earned a Bachelor's Degree in Chemical Engineering from the University of Delaware and completed the Advanced Management Program at Harvard Business School. Fyrwald serves as a Director of Eli Lilly and Company, the Society of Chemical Industry, the American Chemistry Council, the Chicago Public Education Fund and is a Trustee of the Field Museum of Chicago.

"I am pleased to be joining a strong Univar team," said Univar President and Chief Executive Officer-Elect, Erik Fyrwald. "As we build on Univar's successes, we will be looking for more opportunities to execute key strategies and strengthen Univar's leadership position in the global marketplace."

Univar's current chairman of the board William S. Stavropoulos will remain on the board as lead director.

"Univar has experienced tremendous growth in the past several years," said William S. Stavropoulos, current chairman of Univar's board of directors. "John's continued focus on leadership development, corporate strategy, and the company's growth initiatives, coupled with Erik's strong industry and international experience, provide Univar with a strong team to accelerate global growth and expansion."

Univar continues to be primarily owned by private equity firms CVC Capital Partners and Clayton Dubilier & Rice with its remaining equity held by Univar management and other existing investors.