Ianadmin

ANDRITZ acquires Franssons Recycling Machines

International technology Group ANDRITZ has acquired technology and intellectual property assets from Franssons Recycling Machines AB, located in Sundsvall, Sweden.

Franssons Recycling Machines is a global pioneer in manufacturing and development of machinery for treating waste, wood, and biomass as well as for recycling plastic, paper, and cardboard. Franssons has been an established und experienced supplier of industrial shredding and recycling technologies for 70 years, with many references around the globe.

Franssons Universal Shredder FRP Photo - Andritz

The well-known and proven products and solutions of Franssons will be assigned to ANDRITZ’s Recycling product group (part of the Pulping and Fiber Systems Division, PULP & PAPER business area), further complementing its product offerings in recycling, which extend from refrigerator and electronic waste recycling to reject systems for the pulp and paper industry. ANDRITZ is thus able to provide its customers with even more comprehensive solutions and services in the recycling sector.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,500 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Brigl & Bergmeister – Changes in Mangement

By February 28th Michael Sablatnig will retire from his position as Managing Director of Brigl & Bergmeister. He will however remain in the Roxcel Group in an advisory role and for specific projects. We thank Mr. Sablatnig for his excellent work in the last years with the B&B Group.

Until further notice Mr. Bernhard Mayer will act as the sole Managing Director of Brigl & Bergmeister and will also take over the agenda of Mr. Sablatnig. Mr. Mayer joined the company in 1985 and was appointed as Managing Director in the technical field, for both Brigl & Bergmeister and Papirnica Vevče in July 2015.

Until further notice Mr. Bernhard Mayer will act as the sole Managing Director of Brigl & Bergmeister and will also take over the agenda of Mr. Sablatnig. Mr. Mayer joined the company in 1985 and was appointed as Managing Director in the technical field, for both Brigl & Bergmeister and Papirnica Vevče in July 2015.

Mr. Norbert Peintinger will be appointed as general manager and head of sales and marketing for Brigl & Bergmeister and Papirnica Vevče. Mr. Peintinger has joined the company in 1993 and gained great experience in several roles.

BRIGL & BERGMEISTER

B&B is the leading manufacturer of label papers and flexible packaging papers. Annually, some 100 billion labels are printed on B&B papers, and our papers bear the face of innumerable famous brands.

The Brigl & Bergmeister plant is located at the heart of Europe, in Niklasdorf in Styria | Austria.

ENAGES, the thermal recycling plant of B&B, supplies the factory with 100% CO2-neutral energy in the form of steam and electricity.

The Papirnica Vevče factory is situated in Slovenia, in the greater area of Ljubljana.

Brigl & Bergmeister, ENAGES as well as Papirnica Vevče are part of the Vienna-based Roxcel group of companies.

Xerium Technologies Granted Patent for EnerVent Roll Cover Venting Technology

Customers Saving Hundreds of Thousands of Dollars Annually in Reduced Energy Consumption and Improved Machine Output

Xerium Technologies, Inc. (NYSE: XRM), a leading producer of fabrics and roll covers used in the production of paper and packaging, nonwovens, and other industrial manufacturing processes, announced today that the US Patent and Trademark Office (USPTO) has granted patent number 9,488,217 for its EnerVent roll cover venting technology.

Xerium Technologies, Inc. (NYSE: XRM), a leading producer of fabrics and roll covers used in the production of paper and packaging, nonwovens, and other industrial manufacturing processes, announced today that the US Patent and Trademark Office (USPTO) has granted patent number 9,488,217 for its EnerVent roll cover venting technology.

First introduced in 2014, EnerVent’s unique technology is proven to reduce energy consumption, improve drying rates and increase production output for machines producing tissue, paperboard and packaging, and graphical papers.

“Conventional roll cover venting products feature narrow grooves that are inherently ineffective and become even more ineffective with age, with softer cover materials, or under higher loads,” said Bill Butterfield, EVP and CTO of Xerium. “This inherent narrowing causes the bottom portion of the void volume to be unavailable thereby preventing the grooves to remove water effectively. This tendency increases in softer roll covers, and cover swelling can accelerate the effect leading to significant efficiency loss in water removal.”

Patented EnerVent Roll Grooving Technology Saving Customers $ Millions! from Xerium on Vimeo.

Now patented, EnerVent is engineered with wider grooves and shallower depths creating greater groove wall stability and void volume longevity. EnerVent covers remain effective under load, with softer covers, and throughout the cover life, creating optimal running conditions. Additionally, this technology is available in rubber and polyurethane covers, supplied only by Xerium.

“Obtaining this latest patent represents our ongoing strategic focus of being the technology leader in our markets and creating documented value for our customers. EnerVent technology is creating benefits approaching, or in excess of, $1 million dollars in energy savings and production gains for several customers,” adds Butterfield.

About Xerium Technologies, Inc.:

Xerium is a leading producer of fabrics and roll covers used in the production of paper and packaging, nonwovens, and other industrial manufacturing processes. Xerium’s technology portfolio also includes integrated machine monitoring and automation applications that analyze and deliver real-time machine performance data. With a breadth of patented and proprietary products and services, Xerium provides customers with tailored solutions all designed to reduce their operational costs and optimize their machine’s performance. Xerium is headquartered in Youngsville, NC and has 28 manufacturing facilities in 13 countries with approximately 2,900 employees.

Sappi Limited launches new website highlighting global presence, increased functionality and robust educational resources

SappiLimited (JSE), a leading global provider of sustainable woodfibre products and solutions, have just announced the launch of its new website with significant updates benefitting customers, investors, employees and other stakeholders. This newly redesigned website is one of the many steps Sappi is taking to unite its global divisions as part of its groundbreaking 2020Vision strategy, which seeks to pursue growth opportunities in the woodfibre industry.

The new www.sappi.com features full descriptions of products and services offered; comprehensive award-winning educational materials for customers; in-depth sustainability reporting; easy access to corporate social responsibility efforts; dynamic portals for customers and investors and a prominent social media presence.

“A dedicated team of Sappi employees across the world has been working tirelessly over the last year to create a website that not only encapsulates our global 2020Vision, but that serves each of our key stakeholders in a way that is both informative, actionable and personalised,” said André Oberholzer, Group Head Corporate Affairs of Sappi Limited. “Sappi.com is now an essential source of information for all our stakeholders. We’re proud and excited by this launch, but our work is far from done. We’ve laid a solid foundation and will remain dedicated to quality. The team at Sappi will be making continuous improvements for each of our unique stakeholders.”

While the entire website was redesigned, there are two features with increased functionality that offer additional benefits to users.

First, the Sappi&You Online portal for European customers offers a personalised online experience for printers, publishers and brand owners. Supported by eCommerce, It provides increased functionality to support our customers. Information is tailored to the customers’ specific needs allowing fast access to transactional information, local specialists, detailed product information, sample ordering or benefit from Sappi’s in depth technical knowledge and support areas. It is not only customers who benefit from Sappi&You Online, companies who would like to learn more about how Sappi&You can support their businesses will find useful information about our co-development approach as well as putting them in touch with our local specialists.

Second, a new hub dedicated to investors will provide background information on Sappi and the industry, as well as regularly updated share pricing, financial results, upcoming financial events, financial presentations and information on the 2020Vision.

“We see this investment as a key resource that helps drive our company toward our goal of ‘One Sappi’ - a single global brand,” continued Oberholzer. “With more resources immediately available to our audiences than ever before, and our resulting increased transparency, we will continue our position as a thought leader in the industry. We are excited to enter the next phase of our business strategy, where we will continue to innovate and offer products and services that are of the highest quality to our customers.”

To learn more about Sappi, please visit: www.sappi.com

About Sappi Limited

A global leader in paper, paper pulp and dissolving wood pulp solutions, Sappi Limited (listed and in the Top 40 on the JSE), is headquartered in Johannesburg, South Africa; has over 12,000 employees; manufacturing operations on three continents, in seven countries (seven mills in Europe, three mills in America and four mills in South Africa) and customers in over 150 countries worldwide

Sappi works closely with customers to provide relevant and sustainable paper, paper pulp, dissolving wood pulp and biomaterial products and related services and innovations. Our market-leading range of paper products includes: coated fine papers used by printers, publishers and corporate end-users; casting release papers used by suppliers to the fashion, textiles, automobile and household industries; and in our Southern African region newsprint, uncoated graphic and business papers, premium quality packaging papers and paper grade pulp. Our dissolving wood pulp products are used worldwide by converters to produce viscose fibre, pharmaceutical products as well as a wide range of household and consumer products.

In FY2016 we produced approximately:

- 5.4 million tons per year of graphic and printing paper and packaging and speciality paper

- 2.3 million tons per year of market paper pulp, and

- 1.3 million tons per year of dissolving wood pulp.

We continue to grow into a profitable and cash-generative diversified business with an exciting future in woodfibre, a renewable resource.

For further information visit www.sappi.com

GL&V to supply new equipment to BillerudKorsnäs Gruvön Mill

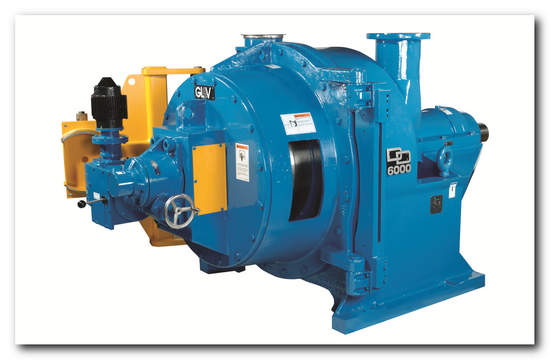

GL&V Sweden AB is pleased to announce that BillerudKorsnäs Gruvön Mill has placed an order for a complete Refiner and Deflaker system and a combined Save-All/Broke Thickener together with Duflo® Pump technology to their new Board Machine, Next Generation project.

GL&V Sweden AB will deliver thirteen DD®6000 Refiner and three DF-20-2 Deflakers for print-, middle- and back ply. The energy efficient DD6000 refiners will be equipped with the patented Anti-Plate Clash System, APCS, which detects and prevents Refiner Plate clashing. GL&V´s Refiner Plate Wear Indicator, an accurate laser-based system that measures the refiner plate wear, is also included in the scope.

GL&V Sweden AB will also supply a combined Save-All/Broke Thickener including a Duflo Pump to BillerudKorsnäs Gruvön Mill, this will be the 5th Celleco® Centerdisc® CDI disc filter for the BillerudKorsnäs group. The unique and strong design of the CDI filter makes it a perfect filter for this type of application. The ability to combine the Save-All and Broke Thickening applications saves the investment of a separate Broke Thickener filter. The CDI filter will be equipped with stainless steel filter covers to improves the runnability and reduce maintenance cost.

The Duflo technology is well known in the pulp and paper industry and in the Gruvön Mill specifically. The Duflo pump will take care of the big difference in flow as well as in consistencywhich is common with the operation of a disc filter installed as a Save-All/Broke Thickener. A key success for this is the efficient Duflo Impeller and the possibility to easily turn the internal vacuum system on and off.

Planned start-up is scheduled to spring 2019.

Four Valmet supplied tissue lines started up within three months at Lee & Man Paper Manufacturing in China

Four Valmet supplied tissue lines has been successfully started up at Lee & Man Paper Manufacturing's Chongqing mill in China within three months. The new lines, which are designed for production of high quality tissue products with low energy consumption, were all producing sellable paper from the very start.

Previously Valmet has installed an Advantage DCT 200 tissue line at the same mill in 2015. All five machines are equipped with advanced tissue technology to reach high quality with lowest possible energy consumption.

"The new lines bring a welcome contribution of 240.000 tons of new capacity to our production of consumer products. They will fulfill our requirements for new capacity. The Valmet Advantage DCT Technology's capability to produce high quality tissue with low energy consumption will also support our targets of environmental efficiency and providing high quality tissue products on the market" says Raymond Lee, Chairman, Lee & Man Paper.

Lee & Man tissue line start-up team

"To start-up four machines in three months was a big challenge and is a record hard to beat. Thanks to the well proven technology, great team work and hard effort from everyone involved the machines started up efficiently and even ahead of schedule," says Svenerik Olsson, Director China Tissue, Valmet.

Technical information

Valmet's scope of delivery comprised four complete tissue production lines featuring stock preparation systems and Advantage DCT 200HS tissue machines. The machines are equipped with OptiFlo headboxes and cast alloy Yankee cylinders. They are also featured with the well proven Advantage tissue technology including ViscoNip press, steam heated AirCap hood, WetDust dust system and a SoftReel P reel. Stock preparation equipment, basic engineering, installation supervision, training, start-up and commissioning were also included in the delivery. The delivery also included an automation package with Valmet DCS and QCS process control systems.

The new tissue machines have a width of 5.6 m and a design speed of 2,000 m/min. They will have an annual production of 60.000 tons each of toilet and facial tissue per year, using virgin wood pulp and bleached bamboo fiber as raw material.

About the customer Lee & Man Paper Manufacturing

Established in 1994, Lee & Man Paper Manufacturing Ltd has grown from a small company into a leading paper and pulp manufacturer. The company's 6,500 employees are located at the company's five production sites in China. The company had a capacity of 7 million tons of container board, duplex board and tissue paper as well as 180,000 tons of pulp in 2014.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Taison Group reconfirms A.Celli technology.

By early 2017, Shanghai Taison Pulp-Making (Group) CO., LTD. (Taison Group) and A.Celli Paper will be in cooperation once again. Taison Group ordered 4 of Tissue Rewinders from A.Celli to be installed in its Jiangxi mill site.

These new Tissue Rewinders have a 5600-mm format and aworking speed of 1000 mpm; they are equipped with 4 unwind stands, calendar, slitter system, winding system, dust removal system, etc. Just a year after the order of 3 Tissue Rewinders of the same model by Taison Group, this new repeat order is a further confirmation that A.Celli Paper is a reliable, expert and professional partner.

So far, A.Celli Paper has supplied 1 Tissue Machine Line and 14 Rewinders to Taison Group. The Tissue Machine Line, with its 2850-mm format and a design speed of up to 2000 mpm, is located in the Chongqing Tongnan mill and is running smoothly; 5 Paper Rewinders are located in the Zhejiang Haiyan mill; two 5800-mm Paper Rewinders are located in the Anhui Maanshan mill; three 5600-mm Tissue Rewinders will soon be installed in its Guizhou Chishui mill, and these 4 newly ordered ones will be installed in its Jiangxi Jiujiang mill in 2017.

Shanghai Taison Pulp-Making

Shanghai Taison Pulp-Making (Group) Co., Ltd based in Shanghai, China, is a large comprehensive international group enterprise integrating forestry, pulp-making, plastic packaging, timber processing, real estate and trading.

China’s Guangdong Shaoneng orders new 26,000 tpy tissue unit from A.Celli Paper.

In the fourth quarter of 2016, A.Celli Paper won the chance to cooperate with GuangDong ShaoNeng Group Co., Ltd.

For the first time, ShaoNeng Group ordered a Tissue Machine line from A.Celli Paper, the scope of supply including a stock preparation system, electrical & drive system, DCS & QCS, accessory equipment and the Tissue Machine itself, in a 2850-mm format and operation speed up to 1600 mpm. Capacity is up to 26,000 tpy.

This new Tissue Machine will be located in Nanxiong Shaoneng Group’s subordinate mill, Nanxiong Zhuji Paper Mill, as its TM02, using virgin wood pulp or bamboo pulp as raw material. During the offer process, after a thorough reference survey, internal discussions that deeply studied and compared all suppliers’ technical and performance capabilities and supplier reliability, Shaoneng Group executives chose A.Celli as its partner.

A.Celli Paper will adopt the most advanced technology and leading edge manufacturing process design to deliver this Tissue Machine line. This project is expected to be placed into operation in the second half of 2017.

GuangDong ShaoNeng Group

GuangDong ShaoNeng Group Co., Ltd. is a Listed Public Company based on renewable energy and investments in clean energy development. It was founded in June 1993, and since then, the development strategy of the company has been committed to investing in clean and renewable energy development.

Kemira increases prices of Pulp & Paper FennoSize AKD chemicals in EMEA

Kemira announces a price increase for its Pulp & Paper FennoSize AKD product line in EMEA. The adjustment will be effective immediately or as customer contracts allow.

The price increase of the AKD sizing chemicals will be approximately 5-10%, depending on the specific formulations and can differ in selected geographies. This adjustment is necessary due to significant raw material costs increases.

The price increase of the AKD sizing chemicals will be approximately 5-10%, depending on the specific formulations and can differ in selected geographies. This adjustment is necessary due to significant raw material costs increases.

More information:

Harri Eronen

VP, Sales &Technical Service, Pulp & Paper, EMEA

Tel. +491718028790

This email address is being protected from spambots. You need JavaScript enabled to view it.

Janne Silonsaari

Director, Marketing & Product Management, Pulp & Paper, EMEA,

Tel. +358504099264

This email address is being protected from spambots. You need JavaScript enabled to view it.

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers’ product quality, process and resource efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2015, Kemira had annual revenue of EUR 2.4 billion and around 4,700 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

Maximizing pump efficiency through reduced corrosion and erosion

Industrial processes across the globe require pumps to operate reliably and efficiently. The latest pump designs and coating technologies offer significant improvements in the long term performance of industrial pumps. By minimizing the effects of corrosion and erosion, users can enhance productivity and reduce running costs.

Continued research into the processes that degrade pump performance is being matched by the development of better application techniques for protective coatings. By gaining a better understanding of both the pumping process and the factors that affect it, end users can make significant improvements in their maintenance strategies.

Coating technologies offer improved performance and durability

Affected applications

Almost every industrial process involving liquids will include a pump at some point. From deep sea oil and gas to DNA sequencing, pumps are required to perform a vast range of tasks. However, no matter what the design or the size of the pump, central to every application is reliability and efficiency – minimizing down time and running costs is essential to modern industry.

For those working with large industrial pumps, often operating in harsh environmental conditions, maintaining pump performance in the face of a continuous threat from corrosion and erosion can be a particular challenge. With increased knowledge of these processes and the techniques used to tackle them, it is possible to implement a more cost effective pump refurbishment program.

Corrosion:

Corrosion is commonly defined as a chemical reaction between the component surface and the reacting fluid passing through a pump. In general a distinction is drawn between general or uniform corrosion and localized corrosion like pitting and crevice corrosion. Non-stainless materials suffer mainly from uniform corrosion whereas metals forming oxide layers that adhere to and passivate the surface are prone to localized corrosion.

In situations where erosion-corrosion is evident, specialised coatings may be the best solution

Flow Accelerated Corrosion:

Flow accelerated corrosion (FAC) describes the removal of the protective oxide layer on a metal. The speed of this process is affected by the oxygen content, the flow velocity and, to some extent, the chloride content. The formation of a calcareous layer due to high carbonate hardness of the water reduces or even prevents FAC.

The influence of oxygen can be seen in the following example: Water with an oxygen content of less than 20 ppb (parts per billion) and a flow velocity around 15 m/s will typically see a corrosion rate around 0.01 mm/year. However, increased oxygen content can see the corrosion rate rise to several mm/year, which will present a significant challenge to the process.

Fortunately FAC only poses a real issue for low carbon steels and cast iron. Increasing the chromium content or using stainless steel will largely eliminate the vulnerability to flow accelerated corrosion.

Erosion:

Pumps that are used to transfer fluids containing abrasive substances, such as sand, can experience significant levels of erosion, especially in areas with high flow velocities. This can be seen in the oil and gas industry where injection pumps are employed to force water back into the oil field and thus maintain the pressure which is needed to lift the oil to the surface. The entrained sand particles act as an abrasive and the high working pressures only serve to compound the issue.

From a pure design standpoint, pump manufacturers in this field effectively have two options to minimize the erosion:

i) Reduce the flow velocities in every part of the pump

or

ii) Design the pump in such a way that the flow velocities through the close-running clearances are low.

However, in most cases the specifications required for the application will prevent either of these solutions from being implemented. Coatings with high erosion resistance in selected areas of the pump are a proven solution in these applications.

Where cavitation is unavoidable, a bespoke coating system should be used

Erosion-Corrosion:

In operating conditions where both erosion and corrosion are present, the degradation mechanism can become very complex and depends on the type of substrate and the fluid chemistry. Corrosion may create oxide layers with low adherence to the substrate which is prone to erosion, or erosion may damage the passive layer, leading to an activation of the surface which accelerates corrosion. In this case surface protection regimes are often the best and sole option.

Cavitation:

Most commonly seen on the pump impeller, cavitation is caused by a pressure difference, either on the pump body or the impeller. A sudden pressure drop in the fluid causes the liquid to flash to vapor when the local pressure falls below the saturation pressure for the fluid being pumped. Any vapor bubbles formed by the pressure drop are swept along the impeller vanes by the flow of the fluid. When the bubbles enter a region where the local pressure is greater than saturation pressure, the vapor bubbles abruptly collapse, creating a shockwave that, over time, can cause significant damage to the impeller and/or pump housing.

In most cases it is better to prevent cavitation rather than trying to reduce the effects on the pumping equipment. This is normally achieved by one of the three actions:

- Increase the suction head

- Lower the fluid temperature

- Decrease the Net Positive Suction Head Required (NPSHR)

For situations where cavitation is unavoidable or the pumping system suffers from internal recirculation or excessive turbulence, it may be necessary to review the pump design or minimize the potential for damage using a bespoke coating system.

Appropriate material selection

For pump manufacturers, the key is to mitigate the corrosion problems by using the most appropriate base material in the construction of the pump. For applications where the use of carbon steel or cast iron is preferred due to cost reasons, the corrosion rate can be estimated very accurately. Based on the mutually accepted corrosion rate per year, the service life of the pump can be anticipated and factored into the maintenance costs of the application.

If the expected corrosion rate is not acceptable the pump materials have to be upgraded to stainless steels which leads to higher costs. In cases where this cost increase is prohibitive, the alternative is to use advanced coatings that can be tailored to suit each application.

If stainless steel is selected for an application, the expected service life is much longer, in some cases infinite. However, this is only true as long as the appropriate stainless steel grade has been chosen for the specific application, it has been produced carefully and is used within the agreed fluid specifications. Special care is required as soon as particles are introduced into the fluid.

In this case even stainless steel becomes susceptible to corrosion due to the passive layer being damaged and the base material becoming activated, which then starts to corrode. Normally the passive layer can be re-established, but if the chloride content is too high or the pH level is too low, the material may remain in an active state and the corrosion continues. Another frequent cause of corrosion in stainless steel pumps are stagnant conditions caused by process interruptions or intermittent operation.

A further threat for stainless steel is chlorine, which is used to combat biological growth in the pump or the connected pipelines. Low level concentrations, around 2 ppm, will have little impact on stainless steel, but it is important to understand how and where the chlorine is introduced into the water flow, to avoid spot concentrations that will damage the protective layer.

Unexpected corrosion can easily negate the anticipated improvement in durability of stainless steel compared to the much cheaper carbon steel variant.

Protective coatings

It is important to determine if the application of coatings will actually improve the performance and the service life of the pump in the first instance and if the costs are really lower than a materials upgrade. In most cases pump manufacturers aim to meet the requirements of a process by using the most appropriate materials for the application and use coatings only as back-up solution.

Polymeric coatings like Fusion Bonded Epoxy can be applied to pump components using a fluidized bed or electrostatic coating. They provide a good level of corrosion protection as long as the coating isn’t damaged. As a polymer coating it is limited to low flow conditions and normally used in clean water applications where it may also improve the hydraulic performance by smoothening the pump surfaces.

However, coatings which are appropriate for pipelines may not be suitable for pump applications where the flow velocities are much higher, narrow passages concentrate the flow and moving parts can be difficult to protect. Again, some methods, such as galvanic protection, commonly used in pipework, are largely unsuitable for pumps.

In these cases coatings are applied to specific areas where increased flow rates are expected or at points where impact damage is expected, such as 90 degree bends. A hard layer is usually applied using a spray coating method such as Air Plasma Spraying (APS), or High Velocity Oxygen Fuel (HVOF) - which one will depend on the required coating thickness and composition.

Carbide coatings, which are deposited by using a high velocity oxy-flame, are extremely wear-resistant. Tungsten carbides in combination with cobalt, nickel or cobalt-chrome matrices are used preferably. Thanks to improvements in the powder and the thermal spray processes, the materials combine high wear-resistance and toughness with good corrosion resistance. Thermal spray coatings can be applied to most substrates, but it is a ‘line-of-sight’ process that makes the coating of complex shaped components, such as impellers, difficult.

CVD processes which are used for complex components that are difficult to coat with thermal spray create very hard surface layers, but are conducted at temperatures in excess of 850 °C. These high temperatures limit the selection of possible substrates, because structural changes and partial deformations can take place during the cooling stage.

Not all coatings are the same

The improvements in performance and durability afforded by coating systems have given rise to a large number of businesses offering a coating service. The raw materials and the basic equipment can be acquired relatively easily and used to apply coatings to a range of equipment.

However, the quality of an HVOF coating, for example, depends predominately on the spraying parameters, such as the material temperature, application velocity, application rate and the quality of the equipment used. Coatings such as these take time to apply correctly, which will inevitably impact on the final cost of the refurbishment. However, increasing the deposition rate will increase the stresses within the coating and over time this can cause the coating to degrade and fail prematurely.

The procedures and settings used by companies such as Sulzer and its coating suppliers have been developed over many years; applying extensive knowledge and experience to the process is the only way to improve it. The final procedure for each coating is closely guarded, proprietary information ensuring that every client will receive the same quality of coating across the world.

To illustrate the importance of these procedures, especially in pump applications, consider the process of installing and removing an impeller. In many situations, the impeller is heated to allow it to be installed or removed from the drive shaft. This shrink-fit procedure can cause inappropriate coatings to be damaged during a routine maintenance operation. Sulzer has ensured that its coating technologies can withstand this thermal shock and continue to deliver long-lasting corrosion protection.

Maintaining legacy equipment

Modern coating technology can be applied to legacy equipment as part of a refurbishment program that will extend the service life of a pump. Implementing a new coating as part of a refurbishment project can significantly improve the performance and reliability of existing equipment.

Ultimately, the key to a successful corrosion prevention scheme is to fully understand the application and to use all the available information to determine the most appropriate action. Working closely with experienced materials engineers enables the end user to achieve the most appropriate solution.

For those looking to refurbish an existing asset there are a number of potential improvements that can extend the service life and improve the performance of a pump. If a new pump design is required, there is an opportunity to establish not only the most appropriate base material, but also the best coating system for extended durability.

The future

As coating technologies continue to advance so end users will be able to select bespoke coatings that can be applied during the manufacturing process. However, even with the most advanced coating, there is a need to develop an application process that can be used to apply the coating to the complex internal surfaces of a cast impeller and volutes. As such, this remains the ‘holy grail’ of pump design and once this challenge is overcome, the reliability and service life of industrial pumps will be further improved.

Improvements in service intervals means reduced maintenance costs and reduced costs attributed to lost production. Together with improved efficiency, these costs of ownership can be minimized through the appropriate use of base materials, protective coatings and the implementation of better pump design to deliver a comprehensive and cost effective pump solution.

About Sulzer:

Sulzer is the leading worldwide, independent service provider for the repair and maintenance of rotating machines including turbomachinery, pumps and electro-mechanical equipment. With a global network of over 150 technically advanced manufacturing and test facilities, Sulzer offers a collaborative advantage that delivers high-quality, cost-effective, customized and turnkey solutions, providing its customers with the peace of mind to focus on their core operations.

Sulzer Rotating Equipment Services, a division of Sulzer, can accommodate all brands of rotating equipment including turbines, compressors, generators, motors and pumps. With an enviable track record, dedicated teams of on-site engineers provide best-in-class solutions to ensure that the most effective service is delivered.

Sulzer is dedicated to providing superior service solutions to a range of industries including power generation, oil and gas, hydrocarbon and chemical processing, water and air separation. Every solution is customized to suit the business needs of each application – whenever or wherever that may be.

With a long history of providing engineering service support, Sulzer is headquartered in Winterthur, Switzerland where it began in 1834. Today, with sales over US$ 3 billion and with approximately 15,000 employees, the Sulzer footprint spans across the globe. The core aim is to deliver a flexible and cost-effective service that optimizes customer operational efficiency and minimizes downtime.

For more information on Sulzer, visit www.sulzer.com