Ianadmin

Life-size paper tribute marking 400 years since Shakespeare’s death

A life-size art installation featuring more than a dozen of Shakespeare’s most famous creations handcrafted from paper and cardboard, is causing much ado about ‘something’.

The show at Birmingham City University which displays scale models over six feet tall, a three-meter-high balcony and even a walk-in tavern, has been made as a tribute to mark 400 years since the Bard’s death.

Each piece in the installation was individually crafted by 22 first year students from the University’s Design for Theatre, Performance and Events degree course.

They used techniques learned on the course to sculpt 780 meters of corrugated cardboard and nearly 5,000 meters of brown paper into the entire setting and characters.

Among the figures on show are a likeness of William Shakespeare writing at his desk and full size replicas of some of theatre’s most famous names – including Richard III, Romeo and Juliet, King Lear and Caliban.

The exhibition took nearly three weeks to create, with students working day and night to make each setting, character and item from scratch, as well as selecting music and lighting to complement each element.

The installation housed in the Shell space at the University’s Parkside building in Birmingham city centre is open to the public until Friday February 26.

Hollie Wright, Module Leader for the project, said:

"The project is a simple yet extremely effective approach to experiential learning. We want the first year students to engage with fundamental principles associated with performance design including scale, narrative, space, light, sound, audience and collaboration; as well as abilities that are difficult to teach like tenacity and determination.

“The project begins with students researching and responding individually to a given theme – which this year was Shakespeare – ideas are pitched and a final one is chosen to realise to full scale out of these basic materials.

“We have full confidence in the students’ research, skills and abilities to reach this to the high level presented, so that the ownership of the project is entirely student led.”

The tavern in the installation is intended to replicate London’s historic Gorge Inn, where history’s most famous playwright is believed to have penned many of his works.

Traditional Elizabethan music plays throughout the exhibition hall alongside words taken from ‘Two Noble Kinsmen’ – Shakespeare’s final play – as a poignant tribute to his lasting legacy.

The Shakespeare Birthplace Trust helped students research the project and visited the installation to select a number of characters and settings which will be taken away and displayed across Shakespeare’s hometown of Stratford-upon-Avon when the project ends.

Marie Brennan, Creative Programmes Manager for The Shakespeare Birthplace Trust, said:

"The remit of the Shakespeare Birthplace Trust is to help the world’s understanding of the life and works of Shakespeare.

“It’s very rare that you get an art installation that really looks at the times that Shakespeare was writing in as well as looking at new interpretations of his own work, so it's really an unusual and creative concept to bring those two together into one installation.

“We're delighted with this collaboration and we're really excited, that in this important year, we've got something we can show our guests from all over the world."

- With over 23,500 students from 80 countries, Birmingham City University is a large, diverse and increasingly popular place to study. The University puts students at the heart of everything it does, giving them the best opportunities for future success.

Nomination Committee proposal for the Board ahead of the 2016 SCA Annual General Meeting

The Nomination Committee of Svenska Cellulosa Aktiebolaget SCA proposes that the following Board members be re-elected: Pär Boman, Annemarie Gardshol, Magnus Groth, Bert Nordberg, Louise Julian Svanberg and Barbara Milian Thoralfsson. Leif Johansson has declined re-election. The Nomination Committee proposes that Ewa Björling, Maija-Liisa Friman and Johan Malmquist be elected as new Board members. The Nomination Committee also proposes that Pär Boman be re-elected as Chairman of the Board. Information about the Board members nominated for re-election is available on SCA’s website.

Ewa Björling is a Med. Dr. Sci. and Associate Professor from the Karolinska Institute. She served as the Minister for Trade from 2007 to 2014 and Minister for Nordic Cooperation from 2010 to 2014. Ewa is a member of the Board of Biogaia AB and Mobilaris AB, and former Board member of the Swedish National Insurance Office and the Swedish International Development Cooperation Agency (SIDA).

Ewa Björling is a Med. Dr. Sci. and Associate Professor from the Karolinska Institute. She served as the Minister for Trade from 2007 to 2014 and Minister for Nordic Cooperation from 2010 to 2014. Ewa is a member of the Board of Biogaia AB and Mobilaris AB, and former Board member of the Swedish National Insurance Office and the Swedish International Development Cooperation Agency (SIDA).

Maija-Liisa Friman holds a MSc. Eng. and served as CEO of Aspocomp Group Plc from 2004 to 2007. Prior to that, she served as the President of Vattenfall Oy and Gyproc Oy. Maija-Liisa is the Vice Chairman of the Board of Neste Corporation and a Board member of Finnair, LKAB and Boardman Oy. She previously served as a Board member of TeliaSonera, Rautarukki, Metso, Ekokem and Talvivaara Mining Company Plc.

Johan Malmquist holds a MSc. Econ. and served as President and CEO of Getinge from 1997 to 2015. Johan is a Board member of Elekta AB (publ), Mölnlycke Health Care AB, the Dunker Foundations, Medvisor AB and the Chalmers University of Technology Foundation. He previously served as a Board member of Getinge AB and Capio AB.

The Nomination Committee’s other proposals will be announced in the notice convening SCA’s Annual General Meeting. The Nomination Committee comprises Helena Stjernholm (AB Industrivärden), Yngve Slyngstad (Norges Bank Investment Management), Håkan Sandberg (Handelsbanken Pensionsstiftelse and others), Hans Sterte (Skandia) and Pär Boman (Chairman of the Board of SCA). Helena Stjernholm is the Chairman of the Nomination Committee.

SCA’s Annual General Meeting will be held on Thursday, April 14, 2016, at 3:00 p.m. in Aula Magna, Stockholm University, Frescativägen 6, Stockholm.

NB: Svenska Cellulosa Aktiebolaget SCA (publ) discloses the information provided herein pursuant to the Securities Markets Act (SFS 2007:528). The information was submitted for publication on February 16, 2016, at 8:15 a.m. CET.

For further information, please contact:

Helena Stjernholm, Chairman of the SCA Nomination Committee, 46 8 666 64 00

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2015 amounted to approximately SEK 115bn (EUR 12.3bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Stora Enso inaugurates new Innovation Centre for biomaterials in Stockholm

Swedish Minister for Enterprise and Innovation, Mikael Damberg, joins Stora Enso CEO, Karl-Henrik Sundström, at the official Innovation Centre inauguration.

The Innovation Centre for biomaterials will host research, application, business development and strategic marketing under one roof. By creating renewable solutions and products from second-generation biomass, such as wood, in order to replace fossil-based products, the centre is addressing societal problems such as climate change, increased urbanisation as well as water and land use issues.

“The Innovation Centre in Stockholm is another important step on the road to Stora Enso’s transformation into a renewable materials company. It will help us build on our long, worldwide tradition in forestry, which – when coupled with access to sustainable raw materials and our expertise in fibres – gives us an excellent starting point for creating solutions that will benefit our customers and end-users in various industries and markets,” says Karl-Henrik Sundström, CEO at Stora Enso.

“Specifically, the centre will help to boost innovation by identifying business opportunities in the markets for renewable materials and bio-based chemicals. We will link our own expertise with leading research centres, universities and business partners,” says Arno van de Ven, SVP, Head of Innovation in Stora Enso’s Biomaterials division.

Currently, there are 40 people working in the centre and it is estimated that by the end of 2017 it will employ around 100 people, recruited both from inside of the company as well as externally. The Innovation Centre covers 4 900 m2, with a state-of-the art laboratory area of 1 600 m2, and is located in the greater Stockholm area in Nacka, Sweden.

About Biomaterials division

Stora Enso’s Biomaterials division is a provider of pulp grades to meet the demands of various paper, board and tissue producers. The offering also includes fluff for hygiene applications and dissolving pulp for the textile industry. The mission of the Biomaterials division is to find new, innovative ways to maximise the value extractable from wood, as well as other kind of ligno-cellulosic biomasses. Through innovation, the aim is to develop into a cost and performance differentiated renewable biochemical company offering drop-in and new materials to industries we already cooperate with and industries new to Stora Enso.

For further information, please contact:

Ulrika Lilja, EVP, Head of Communications, tel. +46 72 221 92 28

Kirsi Seppäläinen, Head of Communications, Division Biomaterials, tel. +358 400 786659

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 27 000 people in more than 35 countries, and our sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market.

Bekaert Solaronics to supply UniDryer® V3 infrared systems with integrated air dryers to Cartiera di Momo, Italy

Bekaert Solaronics will supply Cartiera di Momo with four infrared systems UniDryer® V3 followed by sets of air bars after each of the four coating stations on its PM1 recycled board machine.The Energy Recovery Concept is again applied to this project with the air bars directly fed by the exhaust hot air from the UniDryer® V3 systems. This concept allows even more energy savings! The installation of the systems is scheduled to take place during the 3rd quarter 2016.

The partnership between Bekaert Solaronics and Cartiera di Momo started in 1986 with the installation of three gas infrared drying systems. The objective then was the non-contact drying of recycled board for boxboard C1S production. Today, Cartiera di Momo renewed its confidence in Bekaert Solaronics to replace the existing systems.

The benefits guaranteed to the paper mill by the UniDryer® V3 with integrated air bars are many:

- machine speed will be significantly increased by 10 %;

- gas consumption will be reduced by 36 %;

- paper machine will be able to produce with 10 % more coat weight.

Moreover, thanks to the study carried out by Bekaert Solaronics, Cartiera di Momo has obtained a government subsidy for this project.

The UniDryer® V3 is a very compact system in which high performance gas infrared emitters are alternated with high temperature and velocity air nozzles. These features result in a fast heat-up, a high evaporation rate and ultimately in better product quality. Combined with the air bars, its efficiency is further improved and the gas consumption costs are optimized.

About Cartiera di Momo S.p.A

Established in 1963, Cartiera di Momo S.p.A. specializes in the production of coated multilayer cardboard packaging made with recycled fibers. The paper mill in Momo (near Novara) occupies an area of approximately 46,000 sqm. (of which 15,000 indoors), and is equipped with a 262 cm wide continuous machine. Annual production capacity is 80,000 tons, from 270 gr/ sqm up to 600 gr/ sqm. Current production includes grey back, manilla back (also for foodstuffs), coated white back and kraft back for foodstuffs.

About Bekaert and Bekaert Solaronics

Bekaert (www.bekaert.com) is a world market and technology leader in steel wire transformation and coating technologies. We aim to be the preferred supplier of our steel wire products and solutions by continuously delivering

superior value to our customers worldwide. Bekaert (Euronext Brussels: BEKB) is a global company with 30 000 employees worldwide, headquarters in Belgium and € 4 billion in annual revenue. Founded in 1967, Bekaert Solaronics supplies customized drying and heating systems based on gas and electrical infrared technology to a wide range of industries. Today, more than 1 000 systems have been installed worldwide. The company also provides maintenance services and is available to assist on upgrades or improved energy efficiency of existing systems.

Improved thermographic process analysis and characterisation of fines and fillers

Kari Hyll at Innventia defended the doctoral thesis: "Image-based quantitative infrared analysis and microparticle characterisation for pulp and paper applications" on 12 February. The project involves how to improve thermographic process analysis and characterisation of fines and fillers.

Using image-based measurement methods we are able to both analyse a greater proportion of the paper web on the machine and obtain morphological information about the particles in the stock. When it comes to measurements of the paper web, there are many benefits of using infrared thermography, which gives a temperature image of the web. However, to obtain accurate measurement values using this technology, a material property known as emittance must be known.

In the doctoral thesis work, Kari Hyll measured the emittance of fibre-based samples and investigated how it is affected by various factors that are relevant at a mill, e.g. moisture and temperature. One application was implemented where accurate temperature measurement values are essential, namely calculation of thermal energy during deformation of paper. When it comes to measuring the particles in a stock, fibre analysers have not been able to detect many fines and filler particles due to a limited image resolution.

"I have evaluated new instruments with better resolution and shown that they enable us to obtain new information about fines and filler. I have also devised and evaluated a method for differentiating between fines and filler in a mixture, something that no current instrument can do," says Kari.

The conclusion presented by Kari in their thesis is that thermographic applications requiring more exact measurement values can now be employed, fines and fillers can be measured with better resolution and a potential method for distinguishing between fines and fillers has been developed.

Kari's supervisors are Lars Mattsson, Production Engineering, KTH Royal Institute of Technology, and Hannes Vomhoff, Research Manager at Innventia.

"Evaluation and implementation of new measuring methods is a central element of Innventia's research activities, and consequently we will derive great benefit from Kari's results. For example, they will facilitate quantitative analysis of process variations with the aid of thermography. In the future we plan to link the analysis directly to the quality control system on a board machine," says Hannes Vomhoff.

The work has primarily been carried out at Innventia, in collaboration with KTH Production Engineering, which is the department that Kari has been associated with.

For more information, please contact:

Hannes Vomhoff, Innventia, +46 (0) 8 676 74 88, This email address is being protected from spambots. You need JavaScript enabled to view it.

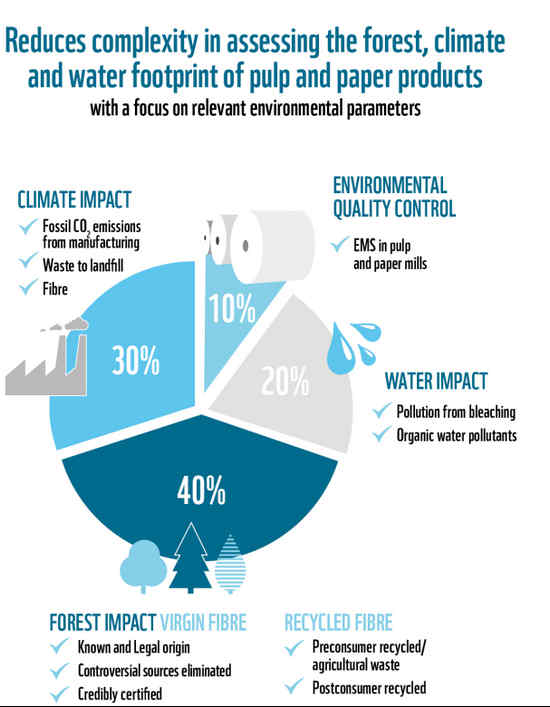

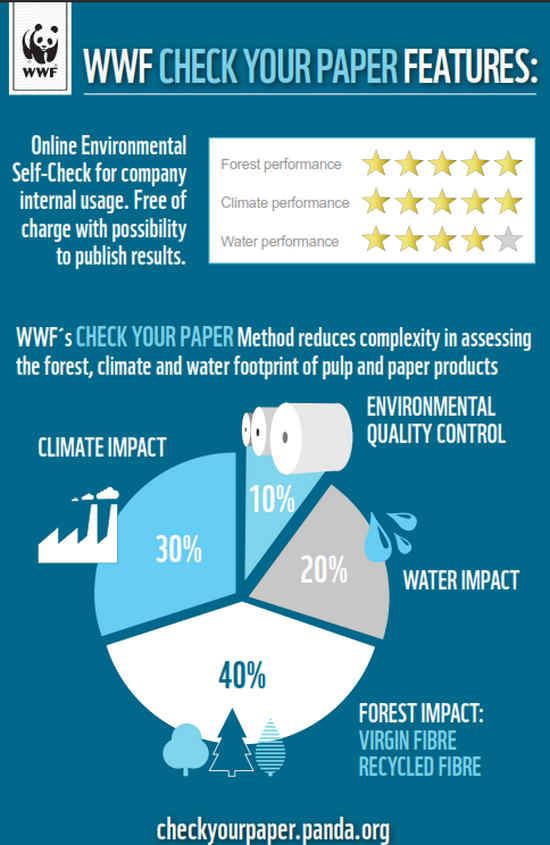

WWF offers a free online Environmental Self-Check for pulp, paper and packaging products

WWF, the conservation organisation, has developed a free and non-public management tool to assist companies along the whole pulp and paper supply chain in their efforts towards greater sustainability and credibility. The online environmental Self-Check is a valuable support tool both within companies and for communication between buyers and sellers.

Mills, merchants, agents, publishers as well as paper and print buyers can immediately benefit from the online Self-Check of the forest, water and climate performance of paper and fibre based packaging products - for entirely private or internal use. The online Self-Check on checkyourpaper.panda.org is easy to use and reduces complexity in evaluating a paper’s footprint by using relatively few, but carefully selected, environmental indicators. There are no fees or cumbersome registration procedures.

Concretely, the Self-Check tool can support a company’s internal decision making between sales, marketing, production/technical and procurement divisions. It can help to communicate the environmental performance of products to merchants and direct customers without the need for results to be made public, unless both parties want this. Printers and publishers can also request that their suppliers provide a Self-Check summary on products they intend to buy. Mills and their customers can use the tool to reduce reputational risks - for both mill brands and customer brands - and to work together towards improvements with the help of concrete indicators.

“Self-Check is invaluable as a means of independent verification for the end user and will further the promotion of sustainable paper products”, said Danny Doogan, Group Sustainability Manager, Denmaur Independent Papers Ltd.

"Pulp, paper and packaging can be very green", said Rod Taylor, Director of WWF’s Global Forest Programme, “The Self-Check is a powerful and free tool to help companies improve the environmental credentials of their products”.

“We were getting a lot of positive feedback from producers and buyers about the original Check Your Paper but not all companies wanted to publish their brand results online. The new environmental Self-Check supports continual improvement efforts, however outside of the public arena”, said Emmanuelle Neyroumande, Manager of WWFs global paper work.

The environmental Self-Check is based on a simple but scientifically robust method that was developed by WWF in cooperation with scientists, paper buyers, producers and NGOs.

For further information:

Helma Brandlmaier, Senior Advisor Strategic Communications and Knowledge Management,

WWF International Tel: +43676842728219 This email address is being protected from spambots. You need JavaScript enabled to view it.

The online Self-Check on checkyourpaper.panda.org is based on a method which reduces complexity in evaluating a paper’s footprint by focusing on a limited number of important environmental indicators including fossil CO2 emissions, waste going to landfill, water pollution, how well forests supplying the fibre are managed and the use of recycled or agricultural fibre. Next to this non-public support tool for companies, Check your Paper features also a public database for pulp and paper products with high environmental standards. The public as well as the non-public interface are designed for all the main pulp and paper categories including coated and uncoated papers, newsprint, tissue, packaging and board papers, speciality papers and pulp.

About WWF

WWF is one of the world’s largest and most respected independent conservation organizations, with over 5 million supporters and a global network active in over 100 countries. WWF's mission is to stop the degradation of the earth's natural environment and to build a future in which humans live in harmony with nature, by conserving the world's biological diversity, ensuring that the use of renewable natural resources is sustainable, and promoting the reduction of pollution and wasteful consumption.

WWF´s Forests for Life Programme has a long standing track record working with companies towards continual improvement within the forest and paper sectors and to increase supply chain transparency. WWF´s Check your Paper platform is one of WWF´s Forests for Life Programme´s efforts to motivate and reward continual improvement in the forest products sector. For more information, visit www.panda.org/forests

Smithers Pira launches market reports for nonwovens fabrics industry

Smithers Pira, the worldwide authority on the paper, packaging and print industry supply chains, have just announced it is launching a line of market reports that will provide detailed information regarding the nonwoven fabrics industry. These reports, previously published by sister-organisation Smithers Apex, will complement Smithers Pira’s existing offering of market data reports as well as the company’s recognised history and expertise in materials testing and consultancy.

“Smithers Pira has developed a strong reputation for providing authoritative market intelligence and independent market insight,” said Adam Page, Director of Reports and Consultancy at Smithers Pira. “The nonwovens sector is a natural fit for Smithers Pira, and by integrating our business expertise in the pulp, paper and nonwovens industries, we can continue to meet our global customers’ research needs.”

“Smithers Pira has developed a strong reputation for providing authoritative market intelligence and independent market insight,” said Adam Page, Director of Reports and Consultancy at Smithers Pira. “The nonwovens sector is a natural fit for Smithers Pira, and by integrating our business expertise in the pulp, paper and nonwovens industries, we can continue to meet our global customers’ research needs.”

The global nonwovens market is expected to reach $50.8 billion in 2020, up from a value of $37.4 billion in 2015, according to Smithers Pira’s latest exclusive research. The market is predicted to increase by 6.3% on average year-on-year thanks to global rising demand.

Focusing on emerging sectors within the nonwovens industry, recent reports published by Smithers Pira include:

- The Future of Flushable Wipes to 2020, which explores the growth of the global flushable wipes market based on an unprecedented increase in the supply of dispersible nonwovens

- The Future of Nonwovens for Industrial Applications to 2020, which predicts that the value of industrial nonwovens consumed will total $27.4 billion, for a projected growth rate of 6.9% by the year 2020

- The Future of Cleaning and Disinfecting Wipes to 2020, which explores rising demand in hospitals and other healthcare institutions and changing consumer perceptions of disinfecting wipes as more of a necessity than a luxury product

The reports produced by Smithers Pira examine the main drivers for this growth, based on a mixture of primary author research, secondary sources and ongoing research programmes conducted by the company’s global market research team. The reports are designed to provide insightful forecasts for product managers and engineers; manufacturers; machinery suppliers; raw materials suppliers; brand owners and retailers; consultants, analysts and all those involved in the nonwovens supply chain.

About Smithers Pira

Smithers Pira is the worldwide authority on packaging, paper and print industry supply chains. Established in 1930, Smithers Pira provides strategic and technical consulting, testing, intelligence and events to help clients gain market insights, identify opportunities, evaluate product performance and manage compliance. For more information visit www.smitherspira.com

Asia Pulp and Paper Forest Conservation Policy Report Reveals Accelerated Progress in Peatland Management

More than 3,500 canals blocked as Peatland Best Practice Management Project accelerated

Agroforestry programme rolled out to improve community welfare while supporting protection of natural forests in the supply chain

Belantara Foundation, initiated by APP, ready to manage and fund conservation projects in Indonesia

Fire prevention measures strengthened with implementation of new Integrated Fire Management Strategy

On the 3rd anniversary of the company’s Forest Conservation Policy (FCP), Asia Pulp & Paper Group (APP) announces the acceleration of their Peatland Best Practice Management Project (PBPMP).

“Looking ahead, we are ready to learn from our experience and to further collaborate with other stakeholders in our landscape, in our country, and beyond, to try to create a better world for future generations.”

The FCP, launched in February 2013, is APP’s commitment to immediately end deforestation in its supply chain and bring sustainability to the forefront of the company’s operations. Policy commitments include the ending of natural forest conversion throughout its supply chain, best practice in peatland management, and adopting a collaborative approach to resolving social issues.

Specifically, work to block over 3,500 perimeter canals to increase water levels in APP suppliers’ concessions located on peatland has recently been completed, with a total target of 7,000 dams to be built by the end of the first quarter of 2016. This is in addition to the retirement of 7,000 hectares of commercial plantation areas in Riau and South Sumatra, announced by APP in August 2015. In total, APP and its suppliers have allocated approximately 600,000 hectares for forest conservation and ecosystem restoration within its suppliers' concessions. Peatland areas are particularly vulnerable to forest fires and these initiatives to manage and protect them are a critical part of APP’s new Integrated Fire Management (IFM) strategy. The move supports efforts to significantly lower the risk of wildfires in the region.

Specifically, work to block over 3,500 perimeter canals to increase water levels in APP suppliers’ concessions located on peatland has recently been completed, with a total target of 7,000 dams to be built by the end of the first quarter of 2016. This is in addition to the retirement of 7,000 hectares of commercial plantation areas in Riau and South Sumatra, announced by APP in August 2015. In total, APP and its suppliers have allocated approximately 600,000 hectares for forest conservation and ecosystem restoration within its suppliers' concessions. Peatland areas are particularly vulnerable to forest fires and these initiatives to manage and protect them are a critical part of APP’s new Integrated Fire Management (IFM) strategy. The move supports efforts to significantly lower the risk of wildfires in the region.

Integrated Forestry and Farming System

Another forest protection initiative is the Integrated Forestry and Farming System Programme launched by APP during COP21 in Paris. The programme aims to help local communities develop alternative livelihoods to achieve economic development while also keeping Indonesia’s forests intact.

As a first step in its implementation, community members will be given equipment and support in the form of microfinance or revolving funds to help kick-start local businesses. Horticultural training will also be given to help improve community capacity in managing fruit and vegetable crops using the agroforestry system. The programme will include 500 villages across the APP supply chain with up to $10 million invested over the next five years.

Fire Management

In 2016, the company rolled out its new comprehensive new Integrated Fire Management (IFM) strategy. The strategy consists of a number of key initiatives:

- Fire management experts TREK Wildland Services from Canada and Working on Fire (WOF) from South Africa will provide 400 APP staff members and their suppliers with Incident Command System (ICS) fire training. The programme will train fire commanders on the practical application of ICS including early detection and rapid response, with the aim of increasing the ability to prevent and fight fires as early as possible.

- Two new aircraft with state-of-the-art thermal imaging cameras will help gather hotspot data with far greater accuracy than satellite imaging. Information will be distributed in near real time to APP’s in house Geographic Information System (GIS) and distributed to field staff within 15 minutes, allowing rapid response to emerging fire threats.

- New fire patrol route maps based on past fire occurrence and local risk factors to ensure that firefighters are closely mapped to identified risks.

- Two medium lift helicopters capable of carrying up to 3,500 litres of water to improve the sheer speed and power of APP’s waterbombing capabilities.

Belantara Foundation

Since committing to a landscape approach in 2015, the company has worked to establish a platform to help manage and fund landscape conservation programmes in Indonesia. As a result of these efforts, APP has initiated the Belantara Foundation. Today we announce the newly appointed Advisory Board, consisting of widely respected individuals drawn from the government, non-profit and corporate sectors. With the Foundation’s personnel, full working remit and due diligence processes in place, Belantara is now ready to work together with other key stakeholders in the landscape to help support the protection and restoration of Indonesia’s forests.

Belantara Foundation will work with communities, civil society, government and businesses to help ensure a careful balance is found between economic development, the livelihoods of people in local communities and environmental conservation. This involves overseeing natural forest restoration and endangered species protection and conducting studies to strengthen sustainable landscape management. In addition, the Foundation will support community empowerment and local economic development, especially in areas that rely heavily on natural resources.

By coordinating and collaborating with different stakeholders, Belantara will help to ensure that different initiatives are aligned and information is shared. Belantara will also fund landscape conservation initiatives aligned to the Foundation’s objectives.

Social Commitments

During 2015, APP continued work to resolve social conflict in its supply chain, while also strengthening the implementation of Free Prior and Informed Consent (FPIC). This includes a commitment to implement FPIC in areas where new developments are proposed, as well as revisions to the FPIC protocol to expand its scope to include high impact activities on developed plantation areas. Over the last year, the FPIC process has been completed for both the new OKI mill development and PT Karawang Ekawana Nugraha (PT KEN), an APP Ecosystem Restoration forest concession in South Sumatra.

Aida Greenbury, Managing Director of Sustainability and Stakeholder Engagement at APP said,

“On the third anniversary of our Forest Conservation Policy launch we are pleased to report that our continued work to implement the policy, together with efforts to align our ambitions with those of other actors in Indonesia’s forests have resulted in tangible progress. We now have the building blocks for a sustainable model of forest and pulp and paper operations whereby forests are protected, communities empowered and our supply chains strengthened.

"Looking ahead, we are ready to learn from our experience and to further collaborate with other stakeholders in our landscape, in our country, and beyond, to try to create a better world for future generations."

You can find full details of APP’s FCP progress report https://www.asiapulppaper.com/sustainability/vision-2020/forest-conservation-policy.

About APP-Indonesia

Asia Pulp & Paper Group (APP) is a trade name for a group of pulp and paper manufacturing companies. APP is responsible for delivering quality products to meet the growing global demand for tissue, packaging and paper. On any given day, our products find their way into the hands of consumers in various branded forms all over the world.

Started in 1972 with Tjiwi Kimia producing caustic soda, now we run nine mills located in Java and Sumatra islands with an annual combined pulp, paper, packaging product and converting capacity of over 9 million tons. Today, APP markets its products in more than 120 countries across six continents.

Over the years, we have expanded our operations significantly through the acquisition and expansion of several of our pulp and paper mills. It’s our commitment to customer satisfaction that enables us to grow our share in paper sales worldwide and broaden our presence through offices in many countries. We believe ‘tradition and modernity go hand in hand’ which means we value long term relationships as part of our Eastern traditions, while we also are eager to embrace the modern values of innovation and efficiency.

Maintaining the integrity of our supply chain is also crucial to APP’s operations. APP launched its Sustainability Roadmap Vision 2020 in June 2012 and its Forest Conservation Policy in February 2013, to further improve its environmental performance, biodiversity conservation, and protection of community rights. Key objectives of this roadmap are to ensure that its pulpwood suppliers adopt High Conservation Value (HCV) and High Carbon Stock (HCS) protection, peatland protection, and be 100% Sustainable Forest Management (SFM) certified by 2020.

In April 2014, APP launched its commitment to support the protection and restoration of one million hectares of forest in Indonesia. In line with that commitment, by 2015 APP and its suppliers have allocated approximately 600,000 hectares for conservation within its suppliers’ concessions and for ecosystem restoration.

World Fibre Outlook 2030: Global consumption of papermaking fibre and specialty pulps has grown by 125% since 1980

The new global pulp market study “World Fibre Outlook up to 2030” by Pöyry Management Consulting details how global consumption of papermaking fibre and specialty pulps has grown from 185 million tonnes in 1980 to 416 million tonnes in 2014 – representing a growth of 125%.

The new global pulp market study “World Fibre Outlook up to 2030” by Pöyry Management Consulting details how global consumption of papermaking fibre and specialty pulps has grown from 185 million tonnes in 1980 to 416 million tonnes in 2014 – representing a growth of 125%.

The past 35 years have witnessed major changes in the paper industry’s fibre furnish. The recovered paper industry has seen a 28% increase in its share of the market, with global consumption levelling at 233 million tonnes in 2014. During the same period, the share of wood pulp has declined by 27% with global consumption amounting to 167 million tonnes in 2014.

According to the Pöyry study which looks at ten geographic regions and ten product areas including papermaking and specialty fibre grades, global demand for paper and paperboard is forecast to grow by 1.0%/a in the long term, from about 400 million tonnes in 2014 to 467 million tonnes by 2030. This growth is driven by the emerging markets with Asia accounting for 95% of global incremental paper and paperboard consumption during 2014-2030.

The global papermaking fibre market is facing profound changes with China’s economy starting to slow down and uncertainty growing in other parts of the world. The study by Pöyry provides insights into this increasingly turbulent market and notes that with paper market slow-down, coupled with the combination of several new pulp lines coming on stream at close intervals to each other, the global pulp industry is facing a real risk of value destruction.

Pöyry forecast that maintaining equilibrium despite the evolving new large-scale supply will be one of the key challenges for the pulp industry towards the 2020s. The report highlights that there is a strong need for restructuring within the global pulp industry and supply/demand balances will inevitably then be restored over time.

The study proposes that investments made ahead of demand in low cost areas will inevitably lead to exits of higher cost suppliers. Meanwhile, over-capacity in the lower sections of the supply curve will result in declining equilibrium prices and lowered producer surplus, thus affecting all players in the market.

The “World Fibre Outlook up to 2030” study provides a strategic platform and essential business information for all business participants, including pulp and paper companies, chemicals, machinery and related suppliers, investors, financiers, institutions, pulp traders, logistics companies and other interest groups.

Link to order form:

http://www.poyry.com/sites/default/files/wfo_up_to_2030_brochure_web.pdf

Kadant Awarded $7 Million in Orders for Fiber Processing Systems

![]() Kadant Inc. (NYSE:KAI) announced it received orders totaling $7 million from two paper producers in North America for chemical pulping equipment and a recycled fiber processing line. The chemical pulping equipment will be used to recover chemicals in the kraft pulping process and the recycled fiber processing system for the production of linerboard. The orders were booked in the fourth quarter of 2015 and are expected to ship in 2016.

Kadant Inc. (NYSE:KAI) announced it received orders totaling $7 million from two paper producers in North America for chemical pulping equipment and a recycled fiber processing line. The chemical pulping equipment will be used to recover chemicals in the kraft pulping process and the recycled fiber processing system for the production of linerboard. The orders were booked in the fourth quarter of 2015 and are expected to ship in 2016.

“We are pleased to have been selected to supply the fiber processing system for these significant projects which reinforces our leading position in both chemical pulping equipment and recycled fiber processing systems used in the production of packaging”

“We are pleased to have been selected to supply the fiber processing system for these significant projects which reinforces our leading position in both chemical pulping equipment and recycled fiber processing systems used in the production of packaging,” said Jonathan W. Painter, president and chief executive officer of Kadant.

About Kadant

Kadant Inc. is a global supplier of high-value, critical components and engineered systems used in process industries worldwide. The Company’s products, technologies, and services play an integral role in enhancing process efficiency, optimizing energy utilization, and maximizing productivity in resource-intensive industries. Kadant is based in Westford, Massachusetts, with revenues of $402 million in fiscal 2014 and 1,800 employees in 18 countries worldwide. For more information, visit www.kadant.com.