Displaying items by tag: BTG

BTG Instruments launches the new BT-55 series

BTG Instruments launches the new BT-55 series of brightness transmitters for monitoring and control of bleaching chemicals, optical brightening agents and dyes in mechanical and chemical pulps, recycled fiber and paper machine applications. The BT-55 series comprises three versions – BT-5500, BT-5510 and BT-5520 – hence meeting all installation requirements.

The transmitters feature a unique low-maintenance probe and are standardly equipped with a UV light source for fluorescence measurement.

They are intended for

optimizing chemical addition,

minimizing product variability and

reducing operational costs.

As part of BTG’s easier, smaller, smarter, lighter product range the BT-55 series is designed to help papermakers rapidly improve their process and significantly save costs.

BTG awarded the Gold Prize (Palme d’Or) for Innovation by ATIP

BTG is the proud winner of this year’s ATIP Innovation Gold Prize. The award was received for the TCR-2512/2502 “Peak TOTASH In-line transmitter for measurement of total consistency and ash content”.

From left to right the BTG team: Bernard Rodriguez, Didier Conjeaud, Philippe Genest, Gwénaël Tartarat-Bardet, and Claude Vallier.

In pulp preparation, for the consistency range of 0.5 to 14%, current technology uses different measuring principles:

* Total consistency by optical or microwave principle: in-line measurement

* Ash content by optical (depolarized retro-diffusion) principle: on-line measurement

* Consistency by shear-force principle (rotating or blade): in-line measurement The measurement of total consistency and ash content hence necessitates the use of several measurement probes.

BTG’s innovation TCR-2502 / TCR-2512 use one unique measurement principle to very precisely and separately evaluate:

BTG’s innovation TCR-2502 / TCR-2512 use one unique measurement principle to very precisely and separately evaluate:

* Total consistency in the range of 0.5 – 12%

* Filler content in the range of 1 – 70%

* Fiber consistency in the range of 0.4 – 10%.

This method is applicable in each step of the papermaking process. The technology allows financial gains of 50 up to 300 k€ per year: from the pulper to the machine chest for pulp, waste water and slurries

Some examples:

* After the pulper: filler control through raw material selection

* Waste water treatment, deinking: productivity optimization through filler content management

* Refining: energy savings through precise and true calculation of the specific energy on the fiber

* Mixing chest: precise substitution of fibers by filler. Improved use of broke through the control of filler content

* Headbox: reduced basis weight variation

* Effluent treatment: precise evaluation of fiber loss and slurry optimization

BTG at ABTCP 2011, Booth 92, Street 2/B

Mütek™ SZP-10 System Zeta Potential

Our highlight at ABTCP 2011 is the new Mütek™ SZP-10 System Zeta Potential for measuring the surface charge of fibers, pigments and other solid materials. It is the lightest and most accurate zeta potential lab device on the market and convinces with easy handling and a total weight of less than 20 kg. The SZP-10 is the successor to the widely popular SZP-06 and can be used to assess chemical additives such as wet strength resins, sizing agents or dispersants in a papermaking process without extensive sample preparation. These characteristics has made the Mütek SZP a standard tool for chemical suppliers and papermakers alike.

In addition, BTG experts are there for you to assist in reaching your goals and discuss our:

- Universal optical transmitters for ash and fiber consistency

- High-performance metering and doctoring blades and rods for coated paper and tissue

- Holistic concepts such as Total Tissue Capability (TTC) and Integrated Coating Capability (ICC)

- Expertise in the fiberline

- Cooperation with partners like Honeywell

Visit BTG at ABTCP 2011 on booth 92 to see how we can help improve your bottom line!

TH Lim appointed Asian Pacific Sales Manager for BTG Instruments

BTG is pleased to announce that effective May 13, 2011 Mr. Thong Hiang Lim has assumed the role of Regional Sales Manager, BTG Instruments ASPAC.

BTG is pleased to announce that effective May 13, 2011 Mr. Thong Hiang Lim has assumed the role of Regional Sales Manager, BTG Instruments ASPAC.

Mr. Lim graduated from Singapore Nanyang University with a BSc in mathematics and received an MSc in computing and control engineering from Bradford University, UK. He joined the BTG group with a 30-year working experience in process control and instrumentation and has brought with him expert knowledge in sales management of various instrument and control system businesses throughout the Asia Pacific region.

Mr. Lim is located in Singapore and takes overall responsibility for BTG Instruments in the ASPAC region, excluding Japan.

Lydia Bley

General Manager Instruments

Light, compact, fast and accurate - the new Mütek SZP-10 System Zeta Potential

BTG launches Mütek SZP-10, the successor to the widely popular Mütek SZP-06. Like its industry-standard predecessor, it identifies the surface charge of fibers, pigments and other solid materials. It can be used to assess chemical additives such as dispersants, wet strength agents or coatings in a manufacturing process without extensive sample preparation (as is needed for electrophoresis, for example).

The new SZP-10 reflects feedback from our customers - chemical suppliers and R&D labs - with ten years' experience of zeta potential measurements. As a result, the new instrument is as light, compact and fast as zeta potential measuring instruments can get.

Other features which make the Mütek SZP-10 a highly reliable working companion include:

- easy handling with intuitive user guidance significantly reduced size and weight;

- quick, worry-free initialization, with pre-set parameters and automatic pressure difference adjustment;

- fast and highly accurate measurements, with zeta potential results provided within a couple of minutes;

- data transfer via USB stick into Microsoft Excel or directly into BTG software;

- a new, lighter trolley

to mention but a few.

New MarCom Manager for BTG Instruments

Lydia Bley, Vice President & General Manager – BTG Instruments, is pleased to announce the appointment of Elke Winter in a new position as the Global MarCom Manager for the Instruments Division, effective as of the 1st of April, 2011.

Lydia Bley, Vice President & General Manager – BTG Instruments, is pleased to announce the appointment of Elke Winter in a new position as the Global MarCom Manager for the Instruments Division, effective as of the 1st of April, 2011.

Visit BTG at SPCI 2011 to see how we can help improve your bottom line!

BTG, present throughout the papermaking process, is committed to helping clients achieve significant, sustainable gains in business performance, accomplished through world-class people, market-leading technologies, industry expertise and a passion for results.

Visit our booth at SPCI go get to know how BTG can assist in reaching your goals:

Reduced fiber costs, reduced consumable costs, improved tissue machine uptime and converting plant yield: all of these are possible through the application of the industry's most widely used particle charge detector, zeta potential measurement and our highly efficient equipment for the evaluation of retention aids.

Improved productivity and large savings thanks to MSP optimization - the effect of spare parts lifetime on total cost - with high-performance coating and size press rods.

Web breaks, edge build-up, flying sheet: to significantly reduce these production constraints we introduce our fines management concept based on new generation optical consistency transmitters for fiber, ash and fines.

Bulk improvement, improved fiber yield, enhanced softness and consistent quality: a reality thanks to our range of high-performance creping doctors and our unique creping blade holder, which allows for independent adjustment of linear load and creping pocket angle - while running!

In fine paper, 30% fewer intermittent scratches and lines, meaning leass scrap and better runnability and resulting in a monthly 100-ton reduction in waste through the use of high-performance coating blades.

At this year's SPCI, BTG will also be presenting our new integrated coating capability concept for overall coating optimization and reduced operating costs - as well as a new companion and that you would regret not having met... Don't miss out - visit us on booth A09:28

BTG launches an upgrade of its Kappa Number Analyzer, the KNA-5300.

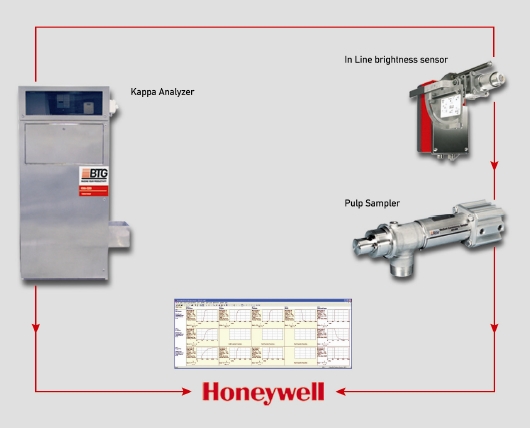

An enhanced Pulp mill solution, which reduces chemical consumption and quality variations and increases operator effectiveness, also requires modern communication with the instrumentation. BTG’s field sensors and analyzers are the window to your process and enable Honeywell’s Profit Controller® to provide best-in-class Advanced Process Control performance.

Therefore, BTG releases a new PLC and computer interface for new and existing KNA kappa analyzers. The new PLC utilizes connection to today’s most common field bus systems and allows four bus modules at one time. These include: Profibus DP, DeviceNet, CANopen, MODBUS, CS31, RCOM, Ethernet TCP/IP, PROFINET and EtherCAT. An OPC server is also provided.

Enhanced user-designated screens, graphics and diagnostics make this the most easily accessible kappa analyzer on the market. The computer interface for mill operators, instrument technicians and process engineers is Windows 7 based.

As of January, 2011 all new BTG kappa analyzers are delivered with this enhanced performance. Upgrade kits for mills, owners of the KNA-5200, will be available to take advantage of today’s new connection and communication technology.

Lydia Bley named Vice President and General Manager BTG Instruments

BTG are pleased to announce that effective March 1st Ms Lydia Bley will assume the role of Vice President and General Manager – BTG Instruments.

Ms Bley started her distinguished career in 1988 after graduating from Munich University of Applied Science with a degree in physical chemistry. After finishing her diploma thesis at the PTS she joined Mütek GmbH as product manager and developed the global market segment wet end chemistry with the Particle Charge Detector PCD-02 first.

She became shareholder and held several positions of increasing responsibility reaching General Manager in 2001, the year Mütek was acquired by BTG. From 2003 - 2006 Ms Bley operated her own consulting business and then rejoined BTG Instruments in 2007 as Product Management Director – Analyzers. In 2008 she was named Director – Product management and Innovation, assuming additional responsibility for the complete portfolio and all technology and business development activities.

Visit BTG at Tissue World Nice 2011

SEE HOW BTG CAN HELP IMPROVE BOTTOM LINE!

BTG: helping the tissue maker improve economic performance and quality, thanks to in-depth process- and customer knowledge and advanced technologies. We work hand-in-hand with the customer to develop innovative, cost-effective ways of improving his operation, replying to his specific demands and needs.

Visit booth E45 to discuss how we can help you improve your bottom line:

* Reduced fiber costs, reduced consumable costs, improved tissue machine uptime and converting plant yield: all of these are possible through the application of the industry's most widely used particle charge detector, zeta potential measurement and our highly efficient equipment for the evaluation of retention aids.

* Web breaks, edge build-up, flying sheet: to significantly reduce these production constraints we introduce our fines management concept based on new generation optical consistency transmitters for fiber, ash and fines.

* Bulk improvement, improved fiber yield, enhanced softness and consistent quality: all possible thanks to our range of high-performance creping doctors and our unique creping blade holder, which allows for independent adjustment of linear load and creping pocket angle - while running!

* Our collaborative project approach to tissue mill economic enhancement (TTC, Total Tissue Capability) drawing on a comprehensive package of equipment, specialist know-how and consumables - all geared to optimizing your tissue operation

For more information please contact

---------------------------------------------------

Lena Coquerand-Werner Communications Mgr BTG Eclépens S.A.

+41 21 866 00 61 / Fax. +41 21 866 00 61

This email address is being protected from spambots. You need JavaScript enabled to view it.

Or go to: www.btg.com