Ianadmin

Imperial Bag & Paper Co., LLC Announces the Acquisition of Goldman Paper Company Inc.

Imperial Bag & Paper Co., LLC (“Imperial”), the largest single-location food service and janitorial supplies distributor in the United States, announced the acquisition of Goldman Paper Co Inc. While Imperial and Goldman will continue to operate under their respective names and managerial staff, the combined businesses are expected to generate in excess of $375 million in annual revenue and operate from more than a half million square feet of distribution space.

Imperial Bag & Paper Co., LLC (“Imperial”), the largest single-location food service and janitorial supplies distributor in the United States, announced the acquisition of Goldman Paper Co Inc. While Imperial and Goldman will continue to operate under their respective names and managerial staff, the combined businesses are expected to generate in excess of $375 million in annual revenue and operate from more than a half million square feet of distribution space.

“We are continuing to look for strategic acquisitions to focus on our growth plan in order to continue to offer Imperial's high level of service to our ever growing customer base.”

“This acquisition was a step in efficiency for Imperial as our goal is to deliver the same service and quality to all customers throughout the Northeast,” said Jason Tillis, President of Imperial. “We welcome the Goldman staff to the Imperial team.”

Robert Tillis, CEO of Imperial, stated, “The acquisition of Goldman Paper will take Imperial’s capabilities and efficiencies to the New England area as we continue to strive to be the most responsive and knowledgeable foodservice, disposables and janitorial supplies distributor in the country.

“We are continuing to look for strategic acquisitions to focus on our growth plan in order to continue to offer Imperial's high level of service to our ever growing customer base.”

"We look forward to being able to provide the same service along with a newly expanded variety in product offerings to the existing Goldman customer base," said Barry Goldman, President of Goldman.

Goldman Paper is Imperial’s seventh acquisition since CEO Robert Tillis bought the 80-year-old company in 2007.

BillerudKorsnäs makes substantial sustainability investments in Gävle

BillerudKorsnäs´ Board of Directors has authorized an investment of over 450 MSEK for environmental improvements at the production unit in Gävle.

BillerudKorsnäs´ Board of Directors has authorized an investment of over 450 MSEK for environmental improvements at the production unit in Gävle.

The investment includes a new sedimentation basin, developments in the pulp mill and a large number of related water-saving measures. This will be implemented in 2014 and 2015 and will be completed by the beginning of 2016.

- This is an important environmental investment for Gävle completely in line with the vision that our products shall have a minimal environmental impact and the best possible function in order to contribute to a sustainable future, says Christer Simrén, COO at BillerudKorsnäs

In addition to the environmental benefits, improved water quality and reduced use of electricity, the quality of the products will increase. This investment follows on the energy-related investments made in 2012 which greatly improved the production unit's sustainability performance in terms of energy efficiency and reduction of fossil fuel use.

PulPaper 2014 - End of Show Report

The 8th edition of PulPaper was held in Helsinki 3-5 June, 2014. The three eventful days once again confirmed PulPaper's status as the world's premier and most progressive meeting place for the industry. Just like it set out to, the event enabled participants to share knowledge, innovation and new ideas with each other and created a platform to meet, network, do business and stay updated.

The 8th edition of PulPaper was held in Helsinki 3-5 June, 2014. The three eventful days once again confirmed PulPaper's status as the world's premier and most progressive meeting place for the industry. Just like it set out to, the event enabled participants to share knowledge, innovation and new ideas with each other and created a platform to meet, network, do business and stay updated.

For first time exhibitor Richter Karhula, PulPaper was a great success. – Richter has been active on the German market for over 40 years. After having taken over the Karhula plant a year ago we wanted to get better known in the Northern market, says Dirk Richter, General Manager of Richter GmbH&Co KG. - By exhibiting at PulPaper, we made many new and valuable contacts in the Finnish market. The arrangement was very well implemented and we had a great time in Helsinki with customers and colleagues. We feel even more at home in the Finnish market now and hold a very positive attitude towards the future.

Richter Karhula attracted a lot of attention in the hall due to special marketing activities and visibility around the Messukeskus. The company works independent from any machine supplier and performs service for nearly every part of the paper machine and offers spare parts, new roll covers as well as manufacturing, repair and regeneration of rolls.

PulPaper 2014 had a final visitor figure after three days of 9428. The visitors travelled to Helsinki from 72 countries worldwide, making it the most international event of its kind. The exhibition floor hosted 453 exhibitors from 29 countries in 193 stands.

- The feedback from exhibitors, visitors and conference delegates of the event has been very positive, says Adforum CEO Marcus Bergström. - The Biofuture for Mankind and the IMPC2014 conferences offered participants highest quality content and the social activities, the Pulpaper After Work and the PI 100th anniversary Gala Evening provided guests with a great mix of entertainment and networking opportunities. We are very happy with the general outcome of PulPaper 2014 and would like to welcome everyone back to the next PulPaper event scheduled to take place in the late spring/early summer of 2018, dates to be announced.

Organisers of PulPaper 2014: Adforum, PI and AEL

PMP Group to supply an Intelli-Jet V® hydraulic headbox to Sun Paper, China

In January 2014, PMP Group – a global provider of paper and tissue technology, signed a contract with Sun Paper, China, for the delivery of an Intelli-Jet V® hydraulic headbox. PMP’s unit will be delivered to the Yanzhou mill (Shandong Province) which is the largest single pulp and paper site in China. The main goal of the project is to change the existing production profile from 1-layer to 3-layer paper products.

In January 2014, PMP Group – a global provider of paper and tissue technology, signed a contract with Sun Paper, China, for the delivery of an Intelli-Jet V® hydraulic headbox. PMP’s unit will be delivered to the Yanzhou mill (Shandong Province) which is the largest single pulp and paper site in China. The main goal of the project is to change the existing production profile from 1-layer to 3-layer paper products.

Sun Paper company is more than 30 years old and over the past decade it has managed to create a brand characterized by high quality and modern technology. Currently their total production is reaching 4 million tons. The company’s annual turnover is estimated in the amount of 30 billion RMB, however, this number is set to be increased in the upcoming 5-10 years, to 100 billion RMB. Sun paper is known for having a significant position on the Chinese market as a paper supplier, nonetheless, the company has noticed a huge potential of premium tissue products and decided to expand its market potential.

PMP Group’s scope of delivery includes a4‑channel hydraulic headbox – (Intelli-Jet V®) of 3880 mm pondside, machine controls, assembly and start-up supervision. The unit will be installed on PM#16, which produces film base paper (140-250 gsm) and has an operating speed of 600 mpm. Hydraulic headbox will include consistency profiling system, which assures excellent basis weight control, resulting with uniform paper web structure and better CD basis weight profile. Start-up is scheduled for the second half of 2014.

PMP Intelli-Jet V® hydraulic headbox is one of PMP Group’s most advanced products and is the key element in both Intelli-Technology® and Intelli-Tissue® platform. Only since the year 2000, PMP Group has sold over 100 headboxes worldwide, whereas 67 of those units are located in Asia.

Metso's new cyber security solutions boost automation system protection

With the ever-present risk of newly appearing cyber threats and malware, Metso's security business solution provides the necessary safeguards to protect automation systems from attack.

Recognizing that production control systems in the utility, manufacturing and petrochemical industries have special requirements not found in the typical corporate IT environment, Metso employs the latest security solutions to counteract emerging threats and avoid disrupted production. As well as ensuring system availability and reliability, protection from Metso can cover critical infrastructure in which safety risks and the threat of environmental non-compliance go far beyond potential monetary losses.

Metso's security business solution includes regular assessments of the security of installations with security audits to identify and help eliminate security vulnerabilities. Key risk mitigation techniques, including firewalls and virtual private networks, are supplemented with virus-protection software custom configured to the automation system.

Metso security follow-up provides security updates, including antivirus software, virus definitions and critical security patches, to ensure the highest level of protection. A back-up system service facilitates during a quick recovery from a security breach or related problem. The service can include providing and maintaining spare PC-based systems and storing a variety of essential data as needed. Metso also has the experience in virtualized server applications to take automation system reliability to a totally new level of performance.

Production environments can be vulnerable to attack from threats both inside and outside the organization. Today's environment of open software architecture, including networked electronic sensing, monitoring and diagnostic systems, makes the development of a threat-resistant infrastructure essential while still using the technology as a competitive advantage.

EAGLE SYSTEMS installs Eco-Eagle Cold Foil System at Farmografica in Argentina

-- Farmografica is considered be one of the leading manufacturers of

paperboard packaging in the Latin American market –

Eagle Systems, Inc., a U.S. based developer and manufacturer of foil enhancement equipment, today announced the completed installation of its Eco-Eagle Cold Foil system at the Argentinian headquarters of Farmografica S.A.., considered a top 10 paperboard manufacturer in Latin America and a top 3 in the Argentinian marketplace. The Eagle System was installed in March and operates in unison with the company’s KBA 8-color press (KBA 105 - 8 + L Model 2014).

Eagle Systems, Inc., a U.S. based developer and manufacturer of foil enhancement equipment, today announced the completed installation of its Eco-Eagle Cold Foil system at the Argentinian headquarters of Farmografica S.A.., considered a top 10 paperboard manufacturer in Latin America and a top 3 in the Argentinian marketplace. The Eagle System was installed in March and operates in unison with the company’s KBA 8-color press (KBA 105 - 8 + L Model 2014).

“The installation of this new concept of printing and finishing, opens a new door to creativity and innovation,” notes Martin Esposito, Operational Manager, Farmografica. “We’ve positioning ourselves as the only printer in Argentina with such a technology. Its impact is not only an advantage for our customer, but an incredible differentiator for our business. The Eagle System has worked perfectly, dazzling us with every new project, and making our prints pop with unprecedented finishes. Just as impressive is how easy it is to operate and its versatility. All of which has been reflected in the variety and quality of the finished work.”

Farmografica is not a packaging company, it’s a company that provides a service, the end result being a cardboard container. “Our philosophy is based on our understanding of the great hotels of the world, where the most important thing is to achieve the satisfaction of our customers, always trying to understand, help and serve. Since our customer's happiness is our happiness. Our philosophy is easily reflected in the Eagle systems. Mike King, owner and developer of the Eagle system, finds the same passion and vocation in work as we do in Farmografica,” adds Esposito.

Farmografica made the decision to include the Eagle System as a priority in their investments after extensive competitive research. “We visited two companies that were already working with Eagle. Fortunately, both of them were very open and able to speak thoroughly about it. Their response was that of overwhelming satisfaction with their new printing possibilities, while exceeding customers’ expectations. For us, Eagle Systems opens doors to new markets.”

Farmografica made the decision to include the Eagle System as a priority in their investments after extensive competitive research. “We visited two companies that were already working with Eagle. Fortunately, both of them were very open and able to speak thoroughly about it. Their response was that of overwhelming satisfaction with their new printing possibilities, while exceeding customers’ expectations. For us, Eagle Systems opens doors to new markets.”

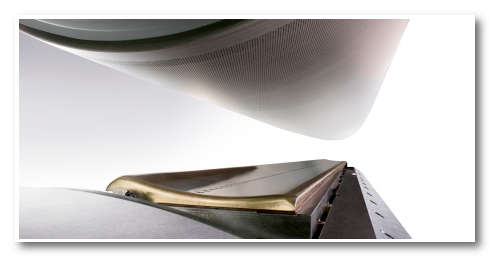

The Eco-Eagle Cold Foil System

The Eco-Eagle Cold Foil system is a value-added finishing technique for cold foil applications. The add-on system can retrofit to new or existing 28-inch up to 80-inch sheet-fed offset presses from most major press manufacturers. It offers users the flexibility to apply a single 40-inch width of foil or multiple widths of foil, in any combination, as narrow as 2- inches. This ability greatly reduces foil cost and consumption. In addition, the cold foil system operates on about the same amount of electricity as a 1,500 watt hair dryer, reducing energy demands in production environments.

The Eco-Eagle system provides the benefits of high-quality performance and reliability, as well as efficient machine-ability and cost effectiveness. Spot or overall foil coverage is printed inline and then overprinted at standard press speeds. The process uses standard printing plates and features setup times of less than 10 minutes. Eco-Eagle is completely automated thereby eliminating the human interface and operator/machine intervention.

Metso stabilizes Burgo Ardennes mill bleaching process

Metso’s Bleaching Optimization selected by Burgo Ardennes mill in Belgium has smoothed out bleach plant operation and demonstrated an 8.7% savings in bleaching chemicals with improved brightness stability. A continuous improvement program extends the gains for the mill.

Following a detailed process control audit by Metso, improvements have been achieved by a successful implementation of advanced controls based on new Metso Kappa Q and Metso Cormec 5 analyzers. The mill produces 400,000 t/y of mixed hardwood bleached kraft pulp, which presented a particular control challenge. Metso’s team effectively implemented the control based on in-depth knowledge of the process and how to deal with disturbances.

Ever since the project was completed in summer 2013, stability has been maintained and augmented by a continuing Performance Service Agreement (PSA). After initial commissioning, the controls have been adapted to significantly higher production rates in the latter part of 2013. The service includes process monitoring though a link to Metso and 24/7 telephone help services. Daily and monthly remote diagnostic reporting by Metso outlined specific process improvements that were implemented with positive results. Improvements in chemical utilization are continuing.

Eric Bazzoni, Fiber Line Production Manager, sums up the mill’s objectives and results achieved: “Our goal with the new measurements and controls was to stabilize the process and reduce costs. Now, we have a big advantage because we can achieve the right brightness even at higher production rates. Before, it was difficult to achieve stability from shift to shift, as operators would manually change parameters. Now, the control system adjusts by itself, and the parameters are the same. We do not have any off-specification pulp.”

He points out that chemical consumption is kept to a minimum since the chemical residual of chlorine dioxide after the bleaching towers is at a very low level. Additionally, there are no problems with off-gassing that might cause health, safety and environmental problems.

Pierre Carnevali, Mill Projects Project Manager, adds his thoughts on the controls implementation: “I am impressed that the Metso engineers have adapted the controls to our own process, giving us a tailor-made control solution for our mill.”

Regarding continuing process performance services, Bazzoni finds this a useful tool, as it gives a concise report on key control objectives and uncovers any problems. Carnevali adds, “The reports tell us if we are in a good control range or not, and if we are consuming the right amount of chemicals.”

Pls feel free to ask for more information. We also appreciate your feedback in all automation related issues.

Metso's automation technology for the world's most technologically advanced and enviro friendly recycling mill

Advanced solutions improve sustainability in producing lightweight packaging paper

Pratt Industries has chosen a large automation package from Metso for its new PM 16 packaging paper production line, which will be located at the 100% recycled paper mill currently under construction in Valparaiso, Indiana, US. Once completed in the first quarter of 2015, this mill will be the world's most technologically advanced and environmentally friendly mill.

Pratt Industries has chosen a large automation package from Metso for its new PM 16 packaging paper production line, which will be located at the 100% recycled paper mill currently under construction in Valparaiso, Indiana, US. Once completed in the first quarter of 2015, this mill will be the world's most technologically advanced and environmentally friendly mill.

Metso's delivery scope to the site includes the Metso DNA automation system and a Metso IQ quality control system equipped with a Metso IQ Dilution Profiler for a dilution headbox and a Metso IQ Moisturizer system for moisture profiling.

Automation plays a significant role in improving the sustainable performance in papermaking. With advanced solutions, it is possible to increase the energy and materials efficiency as well as reduce water consumption through process stabilization and optimization. Metso has a solid track record in these areas.

"This mill will be a showcase of 21st century recycling technology, resulting in the best performing recycled paper on the market," says Anthony Pratt, Chairman of Pratt Industries. "At capacity, the mill will save the equivalent of some 20,000 trees and divert up to 3,500 cubic yards of waste from landfills every day. That's enough trees to cover almost 15 football fields and enough waste to fill 90 garbage trucks every 24 hours."

The deliveries will take place in 2014.

Metso - strong in the pulp and paper sector

The global pulp and paper industry is one of Metso's main customer industries. "We are a leading process performance improver, whether it is pulp and paper, mining, construction or oil and gas. We are extremely well known for our installed base within the pulp and paper industry," points out Phil Warren, Director Product Management and Support, Metso Automation USA Inc. "Today, we are number one in quality control systems, analyzers and measurements, number three in pulp & paper control systems, and number one in pulp & paper control valves. We are dedicated to maintaining and strengthening these positions."

Metso continually develops its Metso IQ quality control system to include new innovative features that improve the papermaking process and guarantee optimal end product quality. Some of the latest additions to the product family include, for example, a tool to increase profile controllability, the Metso IQ Induction Profiler with features for cross-machine caliper/gloss control, and a new online paper quality sensor, IQ Surface Measurement, to measure paper surface topography from the moving part on the paper machine.

Other newcomers in Metso's extensive portfolio include mobile phone applications in the Metso DNA automation system, intelligent maintenance services as well as new wastewater monitoring solutions.

Pratt Industries, Inc. is America's fifth largest corrugated packaging company and the world's largest privately-held 100% recycled paper and packaging company, with more than 4,400 highly-skilled, green-collar employees. Pratt was founded in the USA some 25 years ago and has today manufacturing facilities in more than 20 states. www.prattindustries.com

Successful partnership: Luohe Yinge Tissue Paper Co., Ltd. and Voith

After the installation of NipcoFlex T shoe presses in two tissue lines supplied by Voith, Luohe Yinge Tissue Paper Co., Ltd. is completely satisfied with the performance of the two systems: “The shoe presses bring outstanding results”, says QiFeng Wang, Vice General Manager at Luohe Yinge Tissue Paper. “We obtain a dry content after the press that is 5% higher than with conventional technologies. Thus we save 20% of thermal energy in the dryer section.”

In 2012, Voith delivered two identical lines for the production of tissue paper in a basis weight range of 12–30 g/m² to Luohe Yinge Tissue Paper to China. The lines include the entire stock preparation, the wet end process and the tissue machines, from the headbox to the reel.

The tissue manufacturer is very satisfied with its investment, as ShiJin Zhang, General Manager at Yinge Tissue Paper, confirms: “We can consolidate and expand our position in the Chinese market with the new machines. We are now in a position to meet the increasing requirements of our customers regarding quality and quantity and have thus achieved our aim.”

Luohe Yinge Tissue Paper Co., Ltd. was founded 20 years ago in the province of Henan, China. The Voith tissue machines are designed for an operating speed of 1,900 m/min and an annual production about 60,000 metric tons each with paper width of 5,550 mm on the reel section.

More information about shoe presses in tissue production.

Montes del Plata Pulp Mill starts operations in Uruguay

Stora Enso’s and Arauco’s joint operation Montes del Plata Pulp Mill at Punta Pereira in Uruguay has received all necessary permits from the Uruguayan authorities and is now starting up its operations.

Stora Enso’s and Arauco’s joint operation Montes del Plata Pulp Mill at Punta Pereira in Uruguay has received all necessary permits from the Uruguayan authorities and is now starting up its operations.

The state-of-the-art pulp mill has an annual production capacity of 1.3 million tonnes of bleached chemical eucalyptus pulp. The pulpwood comes mainly from Montes del Plata’s own sustainably managed plantations. In addition to producing pulp, the mill will be more than self-sufficient in energy made from biomass, producing yearly around 160 MW, of which approximately 70 MW will be sold to the national grid. The mill site has its own deepwater port for pulp exports as well as a barge wharf for incoming wood to minimise the amount of truck traffic on Uruguayan roads.

“Montes del Plata is a long-term investment, and it will be a very profitable mill, despite the delays in the construction process. We are now focusing all our efforts on achieving a smooth start-up and fast ramp-up to get the mill into full production,” says Juan Carlos Bueno, EVP, Stora Enso Biomaterials.

Stora Enso’s share of Montes del Plata pulp, 650 000 tonnes per year, will be sold as market pulp.