Ianadmin

Valmet to invest in a new services center in Asia-Pacific

Valmet has decided to build a new services center in Indonesia, which is one of the key markets in Asia-Pacific for Valmet's products and services. The new service center will be located in the Jakarta area on the island of Java, and it will be fully operational at the beginning of 2017.

Valmet has decided to build a new services center in Indonesia, which is one of the key markets in Asia-Pacific for Valmet's products and services. The new service center will be located in the Jakarta area on the island of Java, and it will be fully operational at the beginning of 2017.

"We see good opportunities for services growth in the Asia-Pacific area. After the investment, we'll be able to provide our Asia-Pacific pulp, paper and energy customers with a much wider services offering. Our offering will expand to include roll services, boiler services, fiber workshop services, mill improvement solutions, paper machine clothing, and filter fabrics," says Jukka Tiitinen, Business Line President, Services at Valmet.

Strengthening local presence

"This investment supports Valmet's activities in the area to a great extent. We are present close to where our customers operate. We deliver environmentally sound technologies and services and promote sustainable development in every way. Customers' performance improvements and competitiveness are key issues for us," points out Hannu T. Pietilä, Area President, Asia-Pacific at Valmet.

The center will serve Valmet's pulp, paper and energy customers throughout the Asia-Pacific area. Valmet has a large installed base in the area, providing a good platform for services to grow.

Today, Valmet operates Asia-Pacific service centers in Thailand, South Korea and Australia.

"The new service center in Indonesia will bring us significantly closer to the customers in the area," concludes Tiitinen.

For more information, please contact:

Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 433 0937

Hannu T. Pietilä, Area President, Asia-Pacific, Valmet, tel. +66 81 862 1122

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Miltenberg PM 7: New energy-efficient tissue process line from Voith successfully in operation

A new process line was successfully put into operation at the Miltenberg paper mill and headquarters of Fripa Papierfabrik Albert Friedrich KG in the middle of November 2014. The goal of the tissue manufacturer was to maintain a modern and efficient system that is equipped with the latest resource-conserving and energy-saving Voith technology. The NipcoFlex T shoe press had special significance here, as it reduces the need for thermal energy by up to 20% due to the high dry content after the press. At the same time it is ideally suited for production of soft paper and thus meets the high quality requirements of Fripa.

The PM 7 is designed for a paper width of 2,700 mm and in the future will produce toilet paper and paper towels from 100% virgin pulp at a working speed of 2,100 m/min. With this production capacity, the Miltenberg PM 7 is currently one of the most capable tissue machines in the world. Voith delivered the entire process line to Fripa: from stock preparation and the approach flow system, the tissue machine, auxiliary equipment and system accessories all the way to automation, electrification and engineering. In addition, extensive services and replacement parts were included in the delivery, such as the entire clothing package which is ideally coordinated with the requirements of shoe press technology.

The centerpiece of the new PM 7 is the EvoDry Y Yankee cylinder with the new NipcoFlex T shoe press technology. Other energy-efficient components include the IntensaPulper and the TwinFlo refiner with Pluralis refiner fillings in stock preparation, the innovative approach flow system with the newly developed IntegraGuard headbox screen, the MasterJet T headbox as well as dryer hoods and air systems perfectly coordinated with the production process.

“Voith stood by us as a genuine partner during the planning and processing of the project, and with the PM 7 has delivered an innovative system. Of particular importance to us were maximally optimized energy consumption, moderate operating costs, low water and waste water values and a high level of paper softness. The new PM 7 meets all these requirements,” explains Fripa Managing Director Andreas Noack.

The roots of Fripa Papierfabrik Albert Friedrich KG go back to 1911. The company offers high-quality sanitary paper that meets the constantly growing demands for hygiene in modern society. Fripa is a sought-after tissue producer in the international sanitary paper market and is known for its special flexibility and reliability.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Valmet to supply the new machine for folding boxboard production at Metsä Board's Husum mill in Sweden

Metsä Board Corporation has selected Valmet as the supplier for its new folding boxboard production line at Husum mill, Sweden. The new machine will produce high-quality folding boxboard with an annual capacity of 400,000 tons. The start-up of the machine is scheduled for the beginning of 2016.

Metsä Board Corporation has selected Valmet as the supplier for its new folding boxboard production line at Husum mill, Sweden. The new machine will produce high-quality folding boxboard with an annual capacity of 400,000 tons. The start-up of the machine is scheduled for the beginning of 2016.

The order is included in Valmet's fourth quarter 2014 orders received. The value of this size of an order is typically around EUR 60-70 million and it is part of Metsä Board's EUR 170 million investment in the mill.

"We selected Valmet as the technology provider for this strategic project because of their advanced and competitive solutions for high-quality folding boxboard production and our long history of working with Valmet," says Mika Joukio, CEO of Metsä Board.

"This important order from Metsä Board is a good continuation for the active order year for Valmet. I am delighted that Metsä Board trusted us on this significant strategic project. It is a strong token of the competitiveness of our new OptiConcept M paper and board machine concept. The order has an important employment impact for us especially in Jyväskylä, Finland," says Pasi Laine, the President and CEO of Valmet.

Technical information of Valmet's delivery

Valmet's delivery includes a wet end of the latest OptiConcept M design with headboxes, forming section and press section, as well as a rebuild of the off-machine coater, winder and the roll wrapping line. The wet end area of the machine features innovative OptiConcept M frame construction without the need for cantilever beams for fabric changes. The fabric changes will be carried out by means of fabric insertion units, which Valmet has sold 120 units globally so far.

"The wet end area introduces newest design which also adds safety and machine usability. The winder will be rebuilt with our unique dual unwind station for maximum capacity," summarizes Mikko Tani, Area Vice President, Sales and Marketing, Valmet.

The 6660 mm-wide (trim) machine, BM 1, will produce folding boxboard (FBB) grades in the basis weight range of 180-350 g/m2 at a design speed of 1000m/min.

About Metsä Board

Metsä Board is Europe's leading producer of folding boxboard and the world's leading manufacturer of coated white-top fresh forest fibre linerboards. It offers premium solutions for consumer and retail packaging. The company's sales network serves mainly brand owners, carton printers, corrugated packaging manufacturers, printers and merchants. Metsä Board is part of Metsä Group and its shares are listed on the NASDAQ OMX Helsinki. In 2013, the company's sales totalled approximately EUR 2.0 billion. The company has approximately 3,100 employees.

For further information, please contact:

Jari Vähäpesola President, Paper Business Line, Valmet, tel. +358 10 672 5260

Mikko Tani, Area Vice President, Sales and Marketing, Valmet, tel. +358 40 518 0567

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet reaches top result in fiberboard line Defibrator system sales in China

Valmet has during 2014 increased its fiberboard line Defibrator system market share in China. With a total order value of about EUR 12 million Valmet is now the leading supplier of Defibrator systems in the country.

Valmet has during 2014 increased its fiberboard line Defibrator system market share in China. With a total order value of about EUR 12 million Valmet is now the leading supplier of Defibrator systems in the country.

"Our target has been to become the leading supplier of Defibrator systems in China by the end of 2014, and now we have around 60 percent share of the market. We are really very pleased with what we have achieved during this year", says Aki Niemi, Area President, China, Valmet.

The received orders are a mixture of upgrades and new machinery, and have come both from old and new customers for Valmet. A great deal of efforts has been put into developing the production processes and machines to improve the process results, specially focusing on energy savings and environmental factors.

"A development project is ongoing and we will introduce a new and further improved system on the market very soon. We are grateful for all the orders we've been entrusted with and will keep improving our technology to meet also future demands," says Yutong Feng, Vice President of Pulp and Energy Business Line for Valmet in China.

"But we are not just looking for sales, we are looking for a life-long relationship with our customers in which we can develop and grow together. This is the beginning of our journey", Feng continues.

Information about Valmet's Defibrator system

The Defibrator system is an essential part in a fiberboard line. Valmet's defibrators are known for their reliability and provide high-quality, homogenous fiber material. The material from Valmet's system has a minimum of shives and low fines content, which is a prerequisite for successful fiberboard production.

Further information, please contact:

Jansen Shang, Senior Sales Manager, Pulp and Energy Business Line, China, Valmet tel. +86 138 0123 1944

Leif Sundberg, Sales Manager, Pulp and Energy Business Line, Valmet tel. +46 70 606 55 47

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet har omkring 1500 medarbetare i Sverige som jobbar i nära samarbete med ett stort antal kunder. I Sverige kommer tekniken i tre av fyra pappersbruk från oss. Vi har flera produktions- och R&D enheter varav de största finns i Göteborg, Karlstad och Sundsvall.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Xerium Introduces New Generation Genesis XTi and Genesis APi Calender Roll Cover Technology

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched a new generation of Genesis calender roll cover technology. Genesis XTi and Genesis APi are the latest additions to the industry-leading Genesis family of roll covers. The new Genesis covers are specifically engineered to provide improved wear resistance and fracture toughness in demanding calender applications requiring the highest gloss. In addition, due to its unique design, this cover delivers these improved factors while continuing to deliver the industry leading high ductility. Learn more about improved Genesis technology at http://www.xerium.com/news/xerium-news.aspx.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched a new generation of Genesis calender roll cover technology. Genesis XTi and Genesis APi are the latest additions to the industry-leading Genesis family of roll covers. The new Genesis covers are specifically engineered to provide improved wear resistance and fracture toughness in demanding calender applications requiring the highest gloss. In addition, due to its unique design, this cover delivers these improved factors while continuing to deliver the industry leading high ductility. Learn more about improved Genesis technology at http://www.xerium.com/news/xerium-news.aspx.

"The roll technology team is proud to unveil yet another step change in roll cover performance on these demanding calender applications. Genesis XTi and Genesis APi roll cover technologies were developed to address our customers' requests for increased life and improved roll durability," said Mr. Bill Butterfield, EVP and CTO of Xerium. "Composite calender covers operate under the most demanding load conditions for nipped roll covers and these new generations of Genesis covers have been developed to improve crack and barring resistance while ensuring maximum gloss for critical grades. We are continually striving for innovations enabling our customers to achieve new performance levels by applying our technology."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

ATLAS PAPER MILLS ANNOUNCES MERGER WITH ATLAS SOUTHEAST PAPERS

Atlas Paper Mills, LLC announced today that it has completed a merger with Atlas Southeast Papers, LLC (“Atlas Southeast”), forming a leading multi-facility integrated manufacturer of tissue paper products. The combined company will be known as Atlas Paper Holdings, Inc. (“Atlas Paper” or the “Company”). Affiliates of Peak Rock Capital, an Austin, Texas based private equity firm, acquired Atlas Paper in May, 2013 and Atlas Southeast in September, 2014, respectively.

Atlas Paper Mills, LLC announced today that it has completed a merger with Atlas Southeast Papers, LLC (“Atlas Southeast”), forming a leading multi-facility integrated manufacturer of tissue paper products. The combined company will be known as Atlas Paper Holdings, Inc. (“Atlas Paper” or the “Company”). Affiliates of Peak Rock Capital, an Austin, Texas based private equity firm, acquired Atlas Paper in May, 2013 and Atlas Southeast in September, 2014, respectively.

Headquartered in Miami, Florida, Atlas Paper is a leading manufacturer of tissue products, utilizing both virgin and recycled fiber. The Company supplies private label and branded bath tissue, facial tissue and towels, along with cocktail, dinner and dispenser napkins to a diversified mix of customers in the away-from-home and value retail channels. The Company currently operates two state-of-the-art tissue paper mills with a demonstrated capability of manufacturing a complete line of tissue products.

Jim Brown, CEO of Atlas Paper, said, “We’re very excited to add Atlas Southeast to the Atlas Paper family. The demand for our tissue products continues to strengthen, and the stellar production capabilities of the Atlas Southeast facility will help further expand our growth, diversify our end-markets, and provide high quality virgin and recycled tissue products to our customers.”

Peter Leibman, Managing Director of Peak Rock Capital, added, “Merging these two strong operating businesses is an exciting step forward for the Atlas Paper platform. We look forward to supporting the Company’s growth through organic initiatives, strategic partnerships and potential add-on acquisitions.”

ABOUT ATLAS PAPER

Atlas Paper is a Miami, Florida based manufacturer of tissue products, utilizing virgin and recycled fiber. Atlas Paper supplies private label and branded bath tissue, facial tissue, towels, and cocktail, dinner and dispenser napkins to a diversified mix of customers in the away-from-home and value retail channels. For further information about Atlas Paper, please visit www.atlaspapermills.com

ABOUT PEAK ROCK CAPITAL

Peak Rock Capital is an Austin, Texas based private equity firm that makes debt and equity investments in middle-market companies. Peak Rock focuses on investing in companies where it can support senior management in driving rapid growth and profit improvement through operational and strategic changes. Peak Rock’s principals have deep expertise in complex situations, with the ability to provide tailored capital solutions and close transactions quickly where speed and certainty are priorities. For further information about Peak Rock Capital, please visit www.peakrockcapital.com.

Test bed aiming at new 3D paper products

Innventia has been granted SEK 2.75 million from VINNOVA for the establishment of a full-scale test bed for processes that create highly deformable paper. This will enable verification of new product concepts and lead to a decrease of non-biodegradable waste streams and more energy efficient production processes.

Innventia has been granted SEK 2.75 million from VINNOVA for the establishment of a full-scale test bed for processes that create highly deformable paper. This will enable verification of new product concepts and lead to a decrease of non-biodegradable waste streams and more energy efficient production processes.

In January 2015, a rebuilding of Innventia’s FEX pilot plant with new units for producing highly deformable paper starts. The pilot units will be modular and can be used separately or together with the FEX pilot paper machine. This will be the start of a new project called PhD-paper which aims to establish a full-scale test bed for processes that create highly deformable paper. These processes will, on one hand, broaden the design window for forest based raw materials and, on the other hand, create opportunities for verification of new application areas and markets.

With the help of an industry consortium and Innventia’s gathered knowledge base and machine park, new technologies that are industrially viable will be made available for verification of new product concepts. During the project, value chains for new products as well as for commercial products with extended properties will be identified. One possible application is 3D packaging. Traditionally, paper has only been used to manufacture packages with flat surfaces. What restricts the use of paper for 3D packages, i.e. with curved surfaces, is the lack of industrial processes to produce paper material with a high level of stretchability in the cross direction.

“The idea with this investment is to enable testing of new energy efficient production concepts for paper qualities that will, for example, make it possible to replace some of today’s 3D packages in plastic and thereby reducing the amount of non-biodegradable plastic waste,” says project manager Mikael Magnusson.

The PhD-paper project runs for two years with a total budget of SEK 8.1 million of which VINNOVA, the Swedish Innovation Agency is financing 2.75 million. The project partners are Innventia, Gruppo X di X Gruppo, BillerudKorsnäs, Stora Enso and Tetra Pak.

For more information, please contact Mikael Magnusson, tel. +46 (0)768 767192, This email address is being protected from spambots. You need JavaScript enabled to view it. or Torgny Persson, Director Business area Material Processes, tel. +46 (0)768 767308, This email address is being protected from spambots. You need JavaScript enabled to view it..

Three Forces of PMP Group – The final stage

After a year of intense promotion PMP Group has entered the final stage of its Three Forces of PMP Group – Earth, Wind & Fire campaign. Metaphorical properties of forces of nature have become an inspiration for PMP Group to start a campaign which symbolizes the benefits of the company’s three major, technological lines in the P&P business – Intelli-Technology® (Earth), Intelli-Tissue® (Wind) and Phoenix Concept™ rebuilds (Fire).

After a year of intense promotion PMP Group has entered the final stage of its Three Forces of PMP Group – Earth, Wind & Fire campaign. Metaphorical properties of forces of nature have become an inspiration for PMP Group to start a campaign which symbolizes the benefits of the company’s three major, technological lines in the P&P business – Intelli-Technology® (Earth), Intelli-Tissue® (Wind) and Phoenix Concept™ rebuilds (Fire).

Up till now the viewers had the opportunity to see adverts, movies and articles in regard to Wind (Intelli-Tissue®) and Fire (Phoenix Concept™). Now the time has come to present the final element – Earth (Intelli-Technology® - Platform Concept for Papermakers). This specific line is characterized by low media consumption (ECO) and high runnability – thus the green color and the connection to Mother Nature. In this specific area paper producers are offered complete paper machines for special papers (like MG), as well as highly advanced paper and board units. Product portfolio covers all key technological sections of PM: Intelli-Jet V® hydraulic headbox, dewatering unit – Intelli-Top® former, Intelli-Nip® Shoe Press, Intelli-TriNip™ press, Intelli-Sizer™ metering size press (film press), Intelli-MicroCrepe™ and an Intelli-Reel®. PMP Intelli-Technology® Platform, as a compact and flexible solution for paper & packaging producers, reflects all benefits that are associated with one of the most powerful Forces of Nature – Earth.

Entering the final stage of the Three Forces of PMP Group campaign however, does not mean its end. By fulfilling the last phase of the project the company has taken the idea to the next level and despite maintaining the general concept, developed it to meet wider expectations. New releases are planned to be implemented since the beginning of 2016 and will include all three mentioned before Forces. More information to come.

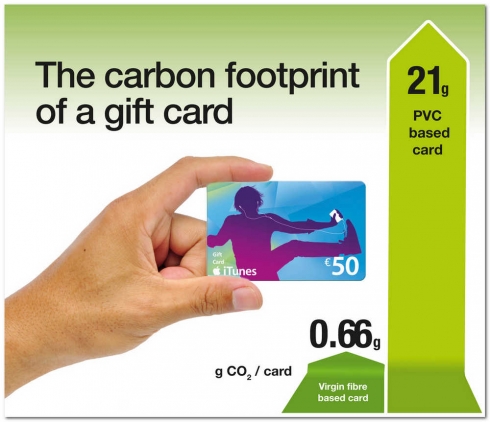

Paperboard gift cards lessen the environmental impact of Christmas

What can we give as a Christmas present when we don’t know what the other person wants? A gift card is one option that always works. But gift cards have changed over the past decade or so. What used to be a written commitment has become packaged offerings of money, experiences, music or other items, often in the form of a credit-card-sized PVC card.

How do these plastic cards in our wallets affect the environment? Estimates in the United States conclude that five new cards are produced there per inhabitant per year. The equivalent for Europe would mean the production of 2.5 billion cards annually, resulting in the emission of 52,500 tonnes of fossil carbon dioxide.

“If we replaced those plastic cards with ones made of virgin fibre paperboard, the emissions would only be one-thirtieth of what comes from making the plastic cards in the best scenario,” explains Jonas Adler, Business Development Director for Iggesund Paperboard.

In the United States a debate about the carbon emissions from all these plastic gift, discount and membership cards has been going on for some years now and has led to a growing demand for gift cards made of paperboard. This trend is now making its way to Europe.

In the United States a debate about the carbon emissions from all these plastic gift, discount and membership cards has been going on for some years now and has led to a growing demand for gift cards made of paperboard. This trend is now making its way to Europe.

“A number of American manufacturers have chosen paperboard as the base material for their cards for environmental reasons,” Adler says. “European manufacturers are now also considering the environmental effects of their choice of material. Normally Europe is ahead of the US when it comes to reducing this type of emission but in this case we are lagging behind.”

Driving the new trend is the difference in carbon footprint between the two materials. A paperboard card weighs just over half as much as a plastic card. The paperboard card leads to the release of only one-thirtieth of the amount of fossil carbon produced from making the plastic cards, based on the published values for Iggesund’s Invercote Duo paperboard and the plastics used for the cards.

Invercote Duo, which is one of Iggesund’s standard products, performs well in the card manufacturers’ processes and has been a success among American card manufacturers.

Even though the difference in emissions between the two card materials is huge, this is not the most urgent environmental issue but it can be an important symbolic step for a company to take.

“For a company that issues hundreds of thousands of plastic cards, the difference in environmental impact is great enough that it cannot be ignored,” comments Ola Buhrman, Technical Product Manager of the card product line. “Our experiences from the US and the fact that we have a standard product which functions like clockwork in the processes make us very competitive. And it’s technically easy for card producers to switch materials.”

He emphasises that Invercote Duo meets ISO/IEC 7810 and 7811, which specifies the dimensional stability and flatness required for the gift cards to function in a card reader. Invercote can handle complex printing processes and finishing steps like embossing, and it is not difficult to integrate a magnetic strip or a chip. For extra durability a bio-degradable coating layer can be applied.

Invercote is made at Iggesund Mill in Sweden. Bioenergy supplies more than 98 per cent of the mill’s energy needs and Invercote has one of the smallest carbon footprints on the paperboard market. In 2012 Iggesund Paperboard had its highest production level ever while simultaneously having the lowest emissions of environmentally harmful substances since it began manufacturing paper products almost a century ago.

“Yet another advantage of Invercote is that it can be supplied made from certified raw material and it is certified compostable in accordance with the EN 13432 standard,” Jonas Adler concludes. “All in all, it’s a perfect base material for all gift card manufacturers who want to minimise their environmental impact.”

TENCEL® Plant in Lenzing: Positive Scorecard in the Six-Month Ramp-up Phase

The track record of the new TENCEL® fiber production plant at the Lenzing site in Upper Austria during the initial six-month ramp-up phase has been a positive one.

Proud of the successful half-year track record of the new TENCEL® fiber plant in Lenzing: TENCEL® Plant Manager Franz Bauhofer, Board Member Robert van de Kerkhof (CCO) and Head of TENCEL® Operations Andrew Ronchetti.

“The plant has already successfully operated at full capacity and in a trouble-free manner for the past months, and the quality of the manufactured fibers fulfills our high expectations”, says Peter Untersperger, Chief Executive Officer of Lenzing AG. “Our new second generation TENCEL® fiber production facility is a technological milestone for lyocell technology, and proof that we are several years ahead of all our competitors.” It enables more than 67,000 tons of TENCEL® fibers to be manufactured p.a. by one jumbo production line. This significantly increases efficiency compared to the existing technology.

Lenzing is still the only company in the world with the capability of implementing the complex lyocell technology on an industrial scale and mastering safety requirements. “Over the past few years TENCEL® has secured a permanent place on the market for a whole range of attractive applications”, says Lenzing Management Board member and Chief Commercial Officer (CCO) Robert van de Kerkhof. “TENCEL® can exploit its advantages in the apparel, home textile and innovative technical segments. The fiber offers good breathing properties, excellent wearing comfort, high fiber strength and above all its environmentally-compatible production on the basis of the natural raw material, wood. For these reasons TENCEL® is also the premium cellulose fiber of the future”, he adds.

Both CEO Untersperger and COO van de Kerkhof emphasize the fact that Lenzing will continue to fully concentrate on TENCEL® in the coming years. “We are continuously developing this market. Our technological know-how will also help us to open up new markets”, van de Kerkhof says. For this reason, TENCEL® is and will remain a top research and development priority at Lenzing. In the past five years, Lenzing spent around EUR 100 mn on research in lyocell technology. Lenzing has already been operating several pilot lyocell facilities at the Lenzing site for 25 years. If demand for TENCEL® fibers continues to develop as satisfactorily as expected, the Lenzing Group will likely construct an additional TENCEL® jumbo production plant based on this proven technology in the medium term.

As of the end of 2014, total annual TENCEL® production capacity of the Lenzing Group amounts to about 220,000 tons manufactured at the Austrian sites in Lenzing and Heiligenkreuz, in Mobile, Alabama in the USA and in Grimsby, Great Britain. Thanks to the new “jumbo production line” at the Lenzing site, investment costs could be maintained at a very competitive level of approximately EUR 150 mn (or about EUR 2,200 per ton of capacity). This gives Lenzing the opportunity to achieve a further competitive scaling of TENCEL® fibers as a universally deployable textile and nonwoven fiber.