Ianadmin

Södra commences expansion of Mörrum

The expansion of Södra Cell Mörrum has started. On 16 October, Södra's CEO Lars Idermark, together with representatives from NCC and Valmet, turned the first soil in the project.

The expansion of Södra Cell Mörrum has started. On 16 October, Södra's CEO Lars Idermark, together with representatives from NCC and Valmet, turned the first soil in the project.Earlier this year, Södra's Board of Directors decided to invest approximately SEK 700 million to increase pulp production at Södra Cell Mörrum. A new chip plant will be constructed and one of the two pulp lines will be modified.

"This is another investment that will strengthen our market position and competitiveness in market pulp. The expansion of our pulp production represents an integral part of our Group strategy and is a prerequisite for developing our business," said Idermark.

The existing facility in Mörrum currently produces 380,000 tonnes annually. The investment is expected to increase production to about 425,000 tonnes per year.

The investment includes a new chip plant and two separate wood room lines, one for softwood chips and one for hardwood chip production, and conversion of the softwood pulp line, where the existing washing facility will be replaced.

The new wood room facilities are scheduled to go into operation in December 2015 and the softwood pulp line in March 2016.

Södra Cell Mörrum currently produces high-quality pulp and is the only Södra mill to produce textile pulp, which is a rapidly growing product area. The Södra Cell business area represents one of the largest softwood pulp producers in the world and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö.

To find out more, please contact:

Stefan Sandberg, Mill Manager, Södra Cell Mörrum, tel: +46 454 555 50

Annica Gerentz, Director of Communications, Södra, tel: +46 470 894 81

NOV MONO HELPS INCREASE CAPACITY FOR PULP AND PAPER PRODUCER

The outstanding performance of NOV Mono pumps in demanding applications has again been highlighted by a recent project in Sweden. One of the country’s leading pulp and paper producers has invested in two Mono E-Range progressing cavity (PC) pumps which will be used in conjunction with the existing Mono™ equipment already in use at the plant in Stockholm.

The outstanding performance of NOV Mono pumps in demanding applications has again been highlighted by a recent project in Sweden. One of the country’s leading pulp and paper producers has invested in two Mono E-Range progressing cavity (PC) pumps which will be used in conjunction with the existing Mono™ equipment already in use at the plant in Stockholm.

Faced with the need to increase the capacity to pump coating compound from a storage vessel out to a paper coating machine, the customer approached pump solutions provider, AxFlow, who are a distributor of Mono products in Sweden. “The coating compound involved is extremely abrasive and highly viscous,” says AxFlow’s Sales Engineer in Sweden, Hans Lundkvist. “This meant that the pumps chosen had to be rugged enough to provide reliable performance and we know that Mono’s E-Range pumps would work perfectly as they are well proven in this type of application.

“As the customer already had a number of vertically mounted Mono pumps installed and was very satisfied with their performance, a pair of Mono E-Range belt-driven pumps were the obvious choice when they needed to increase capacity. The fact that they could be vertically mounted was another added benefit, as floor space was limited with this particular application.”

The coating clay in applications such as this are highly shear sensitive and can contain up to 75% solids, including kaolin, marble, carbonates and titanium oxide. It can also dry instantly, making it essential that the pumps used can prevent moisture loss, while still providing a gentle pumping action to avoid shear damage to the coating clay during transfer.

The vertically-mounted high pressure E-Range pumps offer outstanding reliability and efficiency for applications where particularly abrasive or viscous fluids are being handled. They incorporate a helical rotor turning within a resilient rubber stator, providing a smooth low shear action which ensures the integrity of the coating mix remains intact. The pumps also feature Mono’s unique Flexishaft™ drive system that provides a single component link between the rotary motion of the drive shaft and the eccentric motion of the helical rotor. The reduced number of moving parts in the drive train eliminates wear and makes lubrication unnecessary, eliminating the risk of contamination. The Flexishaft design extends routine maintenance intervals and carries a 10-year warranty.

Mono’s PC pumps are regularly used in pulp and paper applications to handle a variety of aggressive liquids and slurries from coating compound and black liquor through to lime and waste sludges. Their positive displacement action allows for accurate volume control, while their rugged construction ensures long life, reliable operation and minimal downtime.

For more details on AxFlow, please visit www.axflow.com

For more details on Mono, please visit www.mono-pumps.com

AxFlow

The AxFlow Group is the largest distributor of positive displacement pumps and related products and services in Europe. The company represents world-leading suppliers, and adds considerable customer value by industrial know-how, fast and reliable deliveries and a wide range of technical services.

Established in 1989, AxFlow has continually focused on meeting the needs of, primarily, process industries across Europe. Our ambition is to meet the needs of local industry while, at the same time, offering one strategic distribution and customer service solution across Europe.

This has resulted in stable growth and unequalled presence in the fragmented European market.

NOV Mono Group

NOV Mono is a division of National Oilwell Varco. It comprises a group of specialist companies offering progressing cavity pumps, artificial lift systems, industrial mixers, heat exchangers, grinders, screens and aftermarket replacement parts and services, across a broad spectrum of industrial sectors including water and wastewater, oil and gas, chemical, pulp and paper, food and beverage and agriculture. The company first began manufacturing progressing cavity pumps in 1935 and industrial mixers in 1952, giving it a heritage of over 75 years that is built on world-renowned design, expertise and excellence. The division has over 1,600 employees and a true global reach. NOV Mono has facilities around the world including Australia, New Zealand, USA, Mexico, Singapore, China, South Africa , France and UK, which are supported by a large network of international distributor and representative partners.

National Oilwell Varco (NOV)

With its headquarters in Houston, TX USA, National Oilwell Varco has over 170 years’ experience as a leader in the design, manufacture and sale of equipment and components used in oil and gas drilling and production operations, the provision of oilfield services, and supply chain integration services to the oil and gas industry. It has more than 100 subsidiaries and over 63,000 employees at over 1,200 sites around the world, plus annual revenues in excess of $20 billion.

Kemira expands production capacity at San Giorgio site in Italy

Kemira will make a multimillion investment in a production line expansion of process and functional chemistries at San Giorgio site in Italy. The production starts in the beginning of the year 2015 and reaches the full production capacity by the end of March, 2015.

Kemira will make a multimillion investment in a production line expansion of process and functional chemistries at San Giorgio site in Italy. The production starts in the beginning of the year 2015 and reaches the full production capacity by the end of March, 2015.

"San Giorgio investment secures us a sustainable and cost effective manufacturing capability and we can effectively fulfill our customer needs and requirements in terms of strength aids and tissue specialties", says Roberto Zulian, Manager, Business Development, EMEA. "The strategic location of the plant ensures our ability to efficiently serve all the major European tissue and board customers, especially in Italy, Germany, Eastern European countries, Turkey and the Middle East."

The investment includes two separate production lines for anionic and cationic products which will produce FennoBond strength chemistries for tissue and also board customers. FennoBond technologies enhance tissue paper dry and wet tensile, and are most typically used for home towel, napkin and handkerchief consumer products. The key Kemira products include FennoBond 3300E, FennoBond 46 and FennoBond 85E.

"Kemira's San Giorgio investment is an important step in becoming a significant supplier for the tissue industry in EMEA region", says Antti Matula, Head of Marketing & Product Lines, Paper, EMEA. "This investment ensures delivery of high quality products to Kemira's valued customers."

For more information, please contact

Kemira Oyj

Roberto Zulian, Manager, Business Development, EMEA

+39 335 603 9824

Antti Matula, Head of Marketing & Product Lines, Paper, EMEA

+49 171 196 1641

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2013, Kemira had annual revenue of EUR 2.2 billion and around 4,500 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

BASF to divest global textile chemicals business to Archroma

BASF and Archroma have agreed on the sale of BASF’s global textile chemicals business to Archroma, a supplier of specialty chemicals to the textile, paper and emulsions industries. Archroma is a portfolio company of SK Capital Partners, a private investment firm with focus on the specialty materials, chemicals and healthcare sectors. It is planned to integrate the business into the Archroma Textile Chemicals Specialties business. Currently, the textile chemicals business is part of BASF’s Performance Chemicals division. The transaction is subject to approval by the relevant antitrust authorities and the closing is expected to take place in the first quarter of 2015. The parties have agreed not to disclose financial details.

BASF and Archroma have agreed on the sale of BASF’s global textile chemicals business to Archroma, a supplier of specialty chemicals to the textile, paper and emulsions industries. Archroma is a portfolio company of SK Capital Partners, a private investment firm with focus on the specialty materials, chemicals and healthcare sectors. It is planned to integrate the business into the Archroma Textile Chemicals Specialties business. Currently, the textile chemicals business is part of BASF’s Performance Chemicals division. The transaction is subject to approval by the relevant antitrust authorities and the closing is expected to take place in the first quarter of 2015. The parties have agreed not to disclose financial details.

- Business to become part of Archroma’s Textile Specialties

- BASF’s Performance Products segment further sharpens focus on growth-driven customer industries

The transaction comprises the global textile chemicals business, as well as the legal entity BASF Pakistan (Private) Ltd., Karachi. About 290 positions globally are in the scope of the transaction, thereof approximately 230 in Asia. This step is in line with BASF’s strategy of actively managing its portfolio and it will further sharpen the focus of the Performance Products segment on growth driven customer industries.

“In a very competitive and highly fragmented market, we have successfully positioned the textile chemicals business as one of the leading global textile suppliers. The current consolidation process of the industry means that a critical mass is necessary to grow the business successfully. We see positive future growth prospects for the business under the umbrella of Archroma, building on the expertise and professionalism of our textile chemicals team,” said Hans W. Reiners, President of BASF’s Performance Chemicals division.

The textile chemicals business of BASF offers solutions to the full textile processing value chain, which includes a portfolio for pre-treatment, printing, finishing and coating. The business has a global presence with a strong focus on Asian growth markets, and is headquartered in Singapore.

About BASF

At BASF, we create chemistry – and have been doing so for 150 years. Our portfolio ranges from chemicals, plastics, performance products and crop protection products to oil and gas. As the world’s leading chemical company, we combine economic success with environmental protection and social responsibility. Through science and innovation, we enable our customers in nearly every industry to meet the current and future needs of society. Our products and solutions contribute to conserving resources, ensuring nutrition and improving quality of life. We have summed up this contribution in our corporate purpose: We create chemistry for a sustainable future. BASF had sales of about €74 billion in 2013 and over 112,000 employees as of the end of the year. BASF shares are traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (AN). Further information on BASF is available on the Internet at www.basf.com.

About Archroma

Archroma is a global color and specialty chemicals company committed to innovation, world-class quality standards, high service levels, cost-efficiency and sustainability. Archroma is headquartered in Reinach near Basel, Switzerland, and operates with approximately 3,000 employees over 35 countries. Through its three businesses: Textile Specialties, Paper Solutions and Emulsion Products, Archroma delivers specialized performance and color solutions to meet customer needs in their local markets. Archroma helps people fulfill their desire for products that appeal to their emotions and senses for a greater life experience, by developing beauty- and performance-improving technologies applied to everyday products. Products enhanced, colors enhanced, performance enhanced – “Life enhanced”. www.archroma.com

ANDRITZ to supply new waste-to-energy power plant to Riikinvoima Oy, Finland

International technology Group ANDRITZ has been selected by the local utility company Riikinvoima Oy to supply a waste-to-energy power plant to Leppävirta, Finland. Start-up is scheduled for the fourth quarter of 2016.

ANDRITZ will supply a new waste-to-energy power plant to Leppävirta, Finland Photo:Andritz

The new plant is designed to treat 145,000 tons of waste per year coming from eight local waste management companies. The design capacity is 16 megawatts for electricity and 38 megawatts for district heating.

ANDRITZ will supply a circulating fluidized bed boiler, waste fuel treatment and flue gas cleaning systems, a steam turbine, electrification, automation, and auxiliary systems. The high efficiency of the boiler plant and the ANDRITZ technology to enhance environmental protection were decisive in the award of this order.

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,100 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long-term.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, gasification plants for energy production, flue gas cleaning plants, production equipment for biofuel (second generation) and biomass pelleting, biomass torrefaction, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

New screw press from Voith: high dewatering performance and low energy consumption, with minimum maintenance required

With the new InfiltraScrewpress, Voith is launching another product to join its BlueLine range of stock preparation machines, that impresses with its high dewatering performance, improved energy efficiency and low maintenance outlay. As part of Voith’s Compact Dispersion System it has been successfully in operation at a number of paper manufacturing sites.

With the new InfiltraScrewpress, Voith is launching another product to join its BlueLine range of stock preparation machines, that impresses with its high dewatering performance, improved energy efficiency and low maintenance outlay. As part of Voith’s Compact Dispersion System it has been successfully in operation at a number of paper manufacturing sites.

The Compact Dispersion System by Voith is a dispersion system featuring outstanding performance in the reduction of stickies and spot contamination. Further benefits are low energy consumption and space requirements, as well as high system availability. The Compact Dispersion System by Voith includes the InfiltraScrewpress, the InfibraHeater quick heating screw and the InfibraDisp disperser, which has also been newly developed. These machines also belong to the BlueLine product range.

The InfiltraScrewpress boasts a design that is more than ten times stiffer than comparable machines, complementing its low center of gravity. This ensures the machine’s very tight tolerances over the entire operation cycle, allowing high dewatering performance and minimal fiber loss to be achieved. It is equipped with a double-thread press screw. The fiber suspension is fed into the screw press at a stock consistency of 8 – 12 % and is then transported by the press screw in axial direction. The suspension is thickened by the constricting volumes between press screw and screen baskets. Excess water is discharged via the screen baskets. The filtrate can thus be pressed out of the suspension and discharged via the screen baskets of the new SplitScreen screen elements. The remaining pulp is conveyed at a stock consistency of around 30% via the outlet of the screw press to the InfibraHeater quick heating screw.

The double-thread design of the screw press provides a continuous stock discharge to the InfibraDisp disperser, resulting in a reduction of the energy consumption in downstream processes. Together with a special protective coating, a further positive effect of the even stock flow is an extended service life and low maintenance outlay.

The SplitScreen screen elements feature improved dewatering performance and markedly greater ease of maintenance. Its special design allows quick replacement of the split screen plates without time-consuming disassembly of the entire screen element. The SplitScreen screen element is used in the new screw press, but can also be installed into existing screw presses as part of a rebuild package.

Voith’s BlueLine range for the stock preparation impresses with its low consumption of energy, fibers and water.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith employs more than 43,000 people, generates € 5.7 billion in sales, operates in about 50 countries around the world and is today one of the biggest family-owned companies in Europe.

New Eco High-Speed Inkjet Paper from Mitsubishi

Mitsubishi HiTec Paper is introducing two new eco inkjet papers for high-speed printing: JETSCRIPT DT 8002 and DT 9002, which are suitable for Transactional and Transpromo communications and complete the Mitsubishi range.

The new inkjet papers have matte eco top-surfaces and are printable on both sides. They are characterized by high whiteness, excellent opacity and high smoothness. Superb drying and processing properties make it the medium of choice for high-speed inkjet printing of Transactional and Transpromo documents.

They are available in 80gsm and 90gsm. The lighter 80gsm version, DT 8002, saves postage costs and is therefore particularly suitable for mailings. Both products are specially developed and designed for use with pigment inks, but also suitable for dye inks. They are of course as FSC® Mix certified products available.

With DT 8002 and DT 9002 Mitsubishi is responding to the needs of its customers and the market, and completes the wide JETSCRIPT range. Inkjet Papers for all applications from one source - only from Mitsubishi HiTec Paper.

For further information and samples, please contact This email address is being protected from spambots. You need JavaScript enabled to view it.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's most important manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality thermal papers (thermoscript), digital imaging papers (jetscript), carbonless papers (giroform) and label papers (supercote) at two tradition-rich locations in Bielefeld and Flensburg.

Each factory stands out for integrated paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of speciality papers featuring a modular system for every application – and is a highly capable partner whenever customised coated communication paper solutions are required.

UPM papers on show at World Publishing Expo 2014

World Publishing Expo 2014, starting today 13th October in Amsterdam has gathered 8000 decision-makers from 80 countries for the largest international event for news publishers and suppliers. UPM is present at the exhibition and showing its strong commitment to paper and publishing industry.

World Publishing Expo 2014, starting today 13th October in Amsterdam has gathered 8000 decision-makers from 80 countries for the largest international event for news publishers and suppliers. UPM is present at the exhibition and showing its strong commitment to paper and publishing industry.

“We are happy to be back after a few years’ absence and use the opportunity to meet our customers and show our commitment to newspaper publishing and coldset printing. The publishing industry is in the middle of a transformation, but paper still has a vital role in today’s media mix,” says Ken Ehrnrooth, Head of Sales at UPM Paper ENA, Newspaper Publishing.

Your Smart Choice

This year’s main theme ‘UPM paper – Your Smart Choice’ highlights UPM’s commitment to paper and to the publishing industry, and underlines UPM’s continuous development in this field.

“UPM has a profound understanding of the publishing industry and the needs of our customers - and our product range is geared towards meeting these requirements,” says Ehrnrooth. "We take pride in providing consistent quality, reliable deliveries and innovative solutions for our customers. That’s what our customer promise 'UPM paper – Your Smart Choice' is all about.”

In addition, UPM has a strongly driven continuous improvement process, to make sure that its offering will be competitive coupled with strong performance in safety, environment and quality.

A Briter Approach

At the World Publishing Expo 2014 UPM introduces an even more comprehensive range of machine finished grades meeting publishers’ future needs for end uses such as supplements, inserts, flyers, books and catalogues.

UPM Brite 80 C is the latest newcomer to UPM’s product range for coldset web offset printing.

“UPM Brite 80 offers an interesting alternative for publishers and printers who wish to stand out from the competition with improved added value papers,” Ehrnrooth says.

UPM Brite 80 completes the already wide range of UPM’s 100% recycled grades. Thanks to its raw material base, office papers, the grade generates unique brightness gains with minimal environmental impact.

UPM invites you to visit stand 11.415 at the World Publishing Expo on 13-15 October in Amsterdam.

For further information please contact:

Ken Ehrnrooth, Head of Sales, Newspaper Publishing, UPM Paper ENA, tel. +358 2041 50731, email This email address is being protected from spambots. You need JavaScript enabled to view it.

World Publishing Expo gathers 300 exhibiting companies and 8000 decision-makers from 80 countries. The World Publishing Expo 2014 is the largest international meeting for news publishers and suppliers. To learn more about WPE please visit: www.worldpublishingexpo.com

UPM Paper ENA in brief

UPM Paper ENA (Europe & North America) provides magazine paper, newsprint and fine papers for a wide range of end-uses. The main customers are publishers, retailers, printers, advertisers and distributors.The annual paper production capacity is about 10.2 million tonnes manufactured in 18 modern and efficient paper mills in Germany, Finland, France, the United Kingdom, Austria and the United States. www.upmpaper.com

UPM in brief

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 21,000 people and its annual sales are approximately € 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com

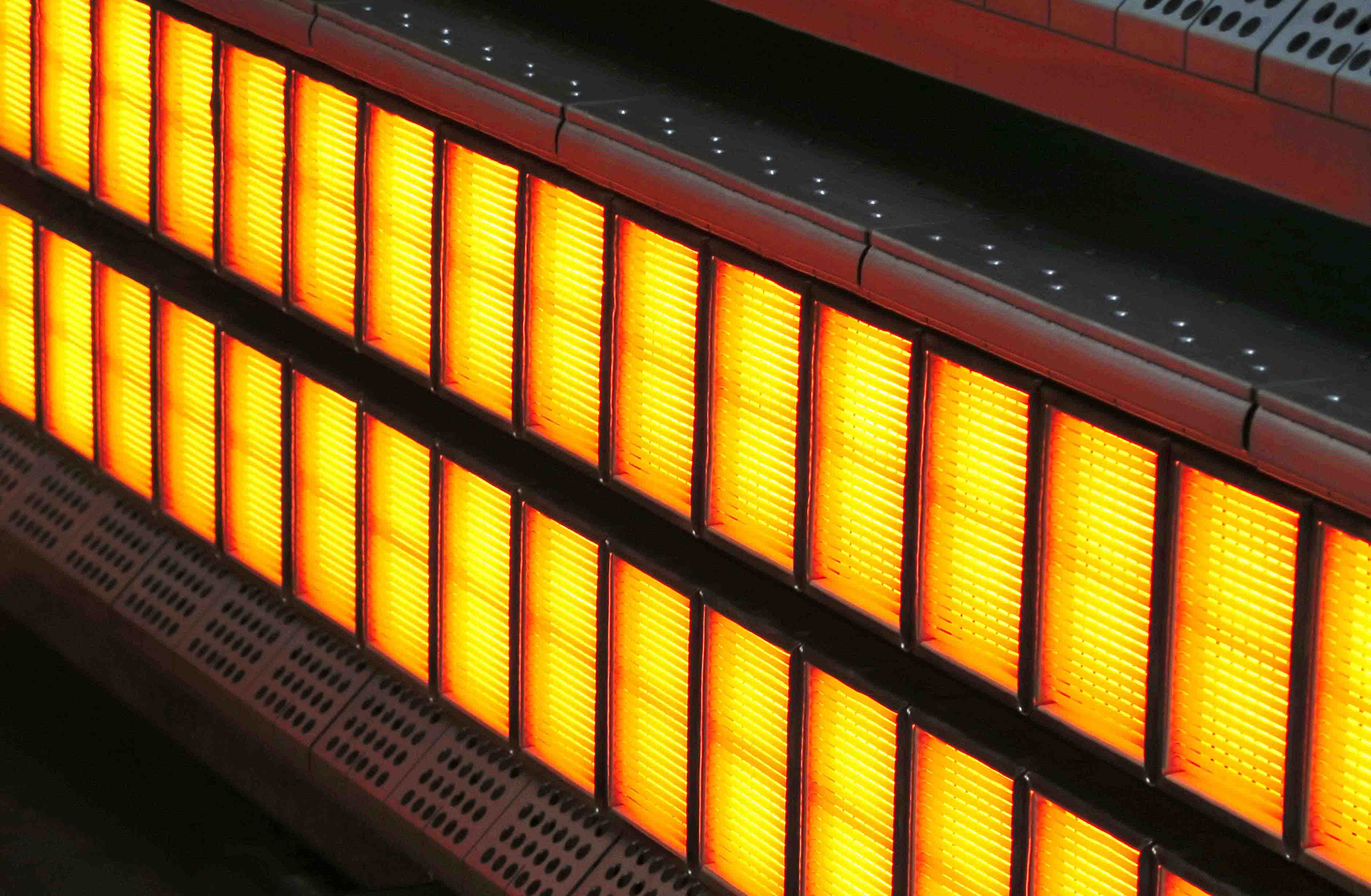

Bekaert Solaronics installs GemDryer® and Energy Recovery System at Metsä Board Tako, Finland

Bekaert Solaronics installed a GemDryer® system with Gem12E emitters at Metsä Board Tako in Finland. The delivery includes also an Energy Recovery System (ERS) to be linked to the air dryer.

Bekaert Solaronics installed a GemDryer® system with Gem12E emitters at Metsä Board Tako in Finland. The delivery includes also an Energy Recovery System (ERS) to be linked to the air dryer.

The objective of the investment is to replace the existing drying system while reducing the operating costs. Energy savings are guaranteed by the high efficient ERS which uses the exhaust from the infrared dryers as an energy source for the air dryers, as well as the use of new Gem12E emitters that ensure 10% gas savings for identical power transferred to the web.

Innovation and product development are key drivers for Bekaert Solaronics in order to make sure we offer the most advanced solutions to our customers in terms of low operating costs and high quality.

Gem12E benefits from the proven design of the Gem family and from two unique innovative features: the use of a second radiant screen to further improve energy recovery from hot flue gases and a solid ceramic material known for its excellent mechanical properties, optimized thanks to a specific surface treatment to efficiently operate at high temperatures (up to 1 250 °C).

About Metsä Board Tako

Metsä Board is a producer of fresh forest fiber cartonboards, manufacturer of coated white-top Kraft liners, and a major paper supplier. Metsä Board Tako is a high-quality paperboard mill located in the center of Tampere in southern Finland. Established in 1865, the mill has an annual production capacity of 250 000 tons and employs 200 people.

About Bekaert Solaronics

Bekaert Solaronics supplies customized drying and heating systems based on gas and electrical infrared technology to a wide range of industries including paper and board, converting and metal processing applications.

Today, more than 1 000 systems have been installed worldwide, of which 60% come from repeat orders with existing customers. The company provides service and maintenance options worldwide for the upgrade optimization and improves energy efficiency of existing systems.

About Bekaert

Bekaert (www.bekaert.com) is a world market and technology leader in steel wire transformation and coatings. Bekaert (Euronext Brussels: BEKB) is a global company with headquarters in Belgium, employing more than 25 000 people worldwide. Serving customers in 120 countries, Bekaert pursues sustainable profitable growth in all its activities and generated combined sales of € 4.1 billion in 2013.

Link to B2B Listing - http://www.pulp-paperworld.com/wbd/173-bekaert_solaronics

Rottneros sells the CTMP equipment of Utansjö Mill

Rottneros AB (publ) has reached an agreement to sell the CTMP equipment of the Utansjö Mill to BillerudKorsnäs.

Rottneros AB (publ) has reached an agreement to sell the CTMP equipment of the Utansjö Mill to BillerudKorsnäs.

“We are pleased that our CTMP equipment is a good fit within the large investment BillerudKorsnäs is making in Frövi and Rockhammar” says Carl-Johan Jonsson, CEO Rottneros

Rottneros’ business concept is to be an independent and flexible supplier of high-quality, customized pulp. This business concept is based on the success factors identified by the Board of Directors and management; namely, to be a company that solely concentrates on producing pulp and focuses on the requirements of its customers as well as niche ares and efficient production.

Business Concept

Rottneros' business concept is to be an independent and flexible supplier of customised and high-quality pulp. Rottneros adapts its product range to meet the needs and high expectations of customers by continuously developing its products and providing a high level of security of supply, technical support and service.

Vision

Rottneros shall be perceived as a market leader that is able to meet the needs and high expectations of pulp customers. This in turn shall result in stable profitability over the course of a business cycle set against the background of conditions within the industry.

For further information please contact:

Carl-Johan Jonsson, President and CEO Rottneros, phone +46 270-622 00

Rottneros discloses the information provided herein pursuant to the Securities Markets Act and/or the Financial Instruments Trading Act. The Information was submitted for publication on Friday, 10 October at 13:00 CET