Ianadmin

SCA and Vinda to integrate hygiene business in China

SCA, a leading global hygiene and forest products company, and the majority shareholder in China’s third-largest tissue company, Vinda International Holdings Limited (“Vinda”) is strengthening the cooperation with Vinda. SCA to transfer its hygiene business in China (Mainland China, Hong Kong and Macau) to Vinda.

SCA, a leading global hygiene and forest products company, and the majority shareholder in China’s third-largest tissue company, Vinda International Holdings Limited (“Vinda”) is strengthening the cooperation with Vinda. SCA to transfer its hygiene business in China (Mainland China, Hong Kong and Macau) to Vinda.

As part of the transaction, SCA and Vinda have signed an agreement regarding the exclusive license to market and sell the SCA brands; TENA, (incontinence products) Tork (Away from Home tissue), Tempo (consumer tissue), Libero (baby diapers), and Libresse (feminine care) in China (Mainland China,Hong Kong and Macau). With this agreement, Vinda will hold the rights to these product brands in these Chinese markets. Vinda will acquire SCA’s Dr P and Sealer brands in China.

“With its immense number of inhabitants, ageing population and low penetration of hygiene products, China is an attractive and important market with significant potential for future growth. This new cooperation and transaction will generate mutual benefits for both SCA and Vinda particularly in distribution, sales, innovation and R&D. Vinda will get access to a broader product portfolio and SCA’s brands will have the potential to reach a broader base of consumers and customers via the extensive and robust distribution network of Vinda in China,” says Jan Johansson, President and CEO of SCA.

SCA has been a shareholder in Vinda since 2007, became its majority shareholder in late 2013, and has consolidated Vinda financials since the first quarter of 2014.

SCA’s hygiene business in China (Mainland China, Hong Kong and Macau) had net sales of approximately SEK 600m in 2013. The purchase consideration amounts to HKD 1,144m (approx. SEK 1,000m) on a debt-free basis.

The agreement is subject to approval by the independent shareholders of Vinda. Vinda is listed on the Hong Kong Stock Exchange.

Europac Papel Duen͂as: PM 2 resumes operation ahead of schedule following rebuild by Voith

Following a rebuild by Voith, the PM 2 of the Europac Group (Papeles y Cartones de Europa, S.A.) was successfully restarted at its plant in Duen͂as in the Spanish Province of Palencia after just 15 days of downtime and seven days of commissioning. This meant that the machine was back in production one day sooner than planned.

Following a rebuild by Voith, the PM 2 of the Europac Group (Papeles y Cartones de Europa, S.A.) was successfully restarted at its plant in Duen͂as in the Spanish Province of Palencia after just 15 days of downtime and seven days of commissioning. This meant that the machine was back in production one day sooner than planned.

“In Voith we had a reliable partner at our side during this project. The entire rebuild was done in a very short time frame,” confirms Maria Berzosa, who is responsible for the project at Europac in Dueñas and continues: “Very quickly, the PM 2 was producing again top-quality packaging paper.”

The Europac Group had opted for a rebuild in order to produce also white coated testliner in the future. This was achieved by installing a Voith SpeedSizer, which applies a uniform, flawless film for sizing and coating, and systematically improves paper characteristics, penetration and surface coverage.

Europac chose to work with Voith because it has decades of experience and expertise in board and packaging paper machines. The SpeedSizer applicator unit supplied is one of many components from the Voith product range that has long-standing proven reliability. Europac could therefore be confident of making a reliable investment.

As well as the SpeedSizer, the scope of supply included a starch and coating colour preparation unit and a CB-Turn for non-contact turning of the paper web. The PM 2 has a production capacity of 150,000 metric tons per year of brown, white and white coated testliner at an operating speed of 1,100 m/min.

Europac Papel Duen͂as is part of the Europac Group (Papeles y Cartones de Europa, S.A.) which operates in the entire supply chain of the paper and packaging industry.

Technology cooperation by ANDRITZ and Alucha, Spain: Innovative and environmentally friendly pyrolysis of plastic rejects

International technology Group ANDRITZ has concluded a cooperation agreement with recycling specialist Alucha, Spain, to supply new technologies and equipment for pyrolysis of rejects (waste) produced in the processing of liquid packaging board to make paper. Pyrolysis of rejects leads to reduced operating costs in industrial plants, for example in the pulp and paper industry, and makes substantial contributions towards protecting the environment.

Innovative pyrolysis process, which can also be used to treat plastic-containing rejects from the pulp and paper industry PHOTO: Andritz

By treating rejects from liquid packaging board, the fibers are recovered here and the residual fraction is separated into aluminum, gas, and oil by means of pyrolysis. While the recycled aluminum can be sold, the pyrolysis gas and oil can be used to generate heat or electricity, thus reducing the total operating costs and conserving natural resources.

Based on its extensive know-how in the reject treatment sector, ANDRITZ will act as supplier as well as sales and license partner under this cooperation agreement. Alucha is one of the leading developers worldwide of pyrolysis processes for industrial applications.

ANDRITZ AUTOMATION concludes another modernization project successfully in the process control engineering sector at Hamburger Containerboard in Pitten, Austria

ANDRITZ AUTOMATION, part of international technology group ANDRITZ, has successfully concluded complete modernization of the process control system for a steam boiler at the Hamburger Containerboard mill in Pitten, Austria.

Specifically developed design and operating concept from ANDRITZ AUTOMATION for the PM3 control room at Hamburger Containerboard, Austria "PHOTO: Andritz"

Based on the ANDRITZ “upgrade on-the-fly” concept, the complete process control system for the existing boiler, which has been operated as standby boiler since 1993 and is equipped with an S5 control system, was replaced within a very short time. Thanks to this concept and a comprehensive FAT (Factory Acceptance Test) together with the Hamburger Containerboard operating personnel, all four boilers in boiler house 3 were fired successfully five days before scheduled start-up, and high-quality steam was produced for the paper machine.

After successful upgrade of the entire PM3 and system upgrades of pulping lines 2, 3, and 4, as well as of the PM4 auxiliaries station by ANDRITZ AUTOMATION, start-up of the boiler was an important milestone for Hamburger Containerboard in bringing the mill’s entire process control system up to a uniform, modern standard. Hamburger Containerboard produces 445,000 tons of corrugated base board from 100% waste paper in Pitten.

ANDRITZ to upgrade deinking line for Danalakshmi Paper Mills, India

International technology Group ANDRITZ received an order from Danalakshmi Paper Mills to rebuild an existing pulp deinking line in Tamil Nadu, India. The upgrade aims at improving the quality of the waste paper stock used for paper production. Start-up is scheduled for April 2015.

The ANDRITZ supply to Danalakschmi, India, includes two SelectaFlot flotation units such as the one shown here. “Photo: ANDRITZ”

The scope of supply includes two SelectaFlot flotation stages, a thickener, a ModuScreen TC tailing screen, a cleaning plant, and pumps. After the rebuild, the plant will produce newsprint as well as printing and writing grades using sorted office paper, printer’s offset cuttings, coated book stock, and notebook.

Danalakshmi isone of India’s leadingnewsprint manufacturing companies, supplying newsprint grades to the local market as well as exporting its products to several countries in Asia and in Africa. The paper mill has a capacity of 40,000 tons per year.

Voith brings a new hybrid press felt onto the market

The newly developed Kinetic hybrid press felt from Voith differs from conventional press felts through its combination of a woven base structure and a non-woven yarn structure. Its modular design gives paper manufacturers the possibility of fulfilling their requirements for dewatering performance and sheet quality at the same time.

The newly developed Kinetic hybrid press felt from Voith differs from conventional press felts through its combination of a woven base structure and a non-woven yarn structure. Its modular design gives paper manufacturers the possibility of fulfilling their requirements for dewatering performance and sheet quality at the same time.

The non-woven yarn structure of Kinetic can be positioned both in machine as well as in cross direction and is designed for fineness and accuracy. Thanks to this structure, Kinetic has a large number of contact points, which provides for up to 20% more efficient dewatering of the paper web. The woven base structure can consist of up to threelayers depending on the water volume of the paper machine. Their composition facilitates stability and long running times. The combination of both concepts unites endurance and precision.

This hybrid structure offers better visual paper characteristics and accelerated start-up times. The cross profile of the paper web is also improved. Kinetic has almost no tendency to markings, compacting or contamination and thus increases the entire operative performance. Quicker start-up times, an extended service life and improved surface characteristics of the paper make Kinetic clearly more economical and thus more efficient than conventional woven or non-woven press felts.

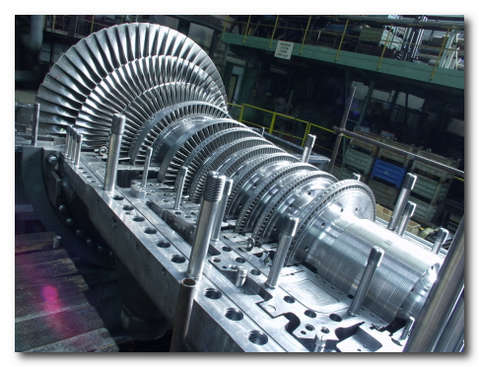

Södra chooses Doosan Skoda as turbine supplier for Värö

Södra Cell has chosen Doosan Skoda Power to supply a turbine for the expansion of the Värö Pulp Mill.

Södra Cell has chosen Doosan Skoda Power to supply a turbine for the expansion of the Värö Pulp Mill.

Doosan Skoda Power has been commissioned to supply a complete turbine installation consisting of a turbine, generator and other equipment. The turbine is a 60MW condensing turbine and it will be an important part of Södra's expansion of the Värö Pulp Mill. The new turbine safeguards the expanded mill's electricity generation and surplus electricity will be supplied to the national grid. This means Södra will be able to increase deliveries of 'green electricity' which is replacing fossil fuels in the community.

"We chose Doosan Skoda to supply our new turbine because they made us a highly competitive offer. We've also been extremely satisfied with the turbine from Doosan Skoda that we started in 2007," explained Jonas Eriksson, Mill Manager at Södra Cell Värö.

Södra has already commissioned Sweco for construction design, NCC for groundworks, installation and construction work, Valmet for process equipment and Raumaster for storage and transportation equipment for wood chips and bark.

Doosan Skoda Power is a Czech company that sells equipment and services for all kinds of installations and specialises in steam turbines and heat exchangers it designs itself. The company belongs to Korean industrial group Doosan Heavy Industries & Construction.

UPM to become exclusive distributor of Domtar’s BioChoice™ lignin in Europe

UPM and Domtar have entered into an agreement for UPM to become the exclusive distributor of Domtar’s BioChoice™ lignin in Europe. BioChoice™ is produced at Domtar’s biorefinery in Plymouth, North Carolina, US. The agreement takes effect on 1 August 2014.

UPM and Domtar have entered into an agreement for UPM to become the exclusive distributor of Domtar’s BioChoice™ lignin in Europe. BioChoice™ is produced at Domtar’s biorefinery in Plymouth, North Carolina, US. The agreement takes effect on 1 August 2014.

BioChoice™ lignin is a by-product of the kraft pulping process. It is a 100 % biobased sustainable alternative to replace fossil based products. BioChoice™ lignin holds the USDA Certified Biobased product label.

“Our lignin-separating process is groundbreaking, allowing us to offer high-quality kraft lignin in commercial quantities. UPM is an ideal partner for Domtar in many ways. They have a strong presence in the European market and also years of experience with biomaterials”, said Richard Mullen, Domtar, Vice President Market Development and Analysis.

“We at UPM are truly excited about this agreement, not only because we get a great product in our offering, but also because together with Domtar we can develop the market and offer our customers sustainable, value added products for a growing variety of end uses”, said Juuso Konttinen, Vice President Biochemicals from UPM.

“Versatile use of renewable wood biomass combined with innovation and sustainability is the cornerstone of UPM’s Biofore strategy. We have developed profound know-how and for intellectual property in the area of lignin based products, e.g. resins which are typically used as binders in wood based products”, Konttinen continued.

Domtar receives 11 PPSA accolades: Safety in our business DNA

Domtar Corporation (NYSE: UFS) (TSX: UFS) is honored to have had 11 facilities recognized for safety performance excellence at the Pulp and Paper Safety Association's (PPSA) annual awards ceremony. The prizes were handed out during the PPSA's annual conference held this year in St. Petersburg, Florida, from June 22-25.

Domtar Corporation (NYSE: UFS) (TSX: UFS) is honored to have had 11 facilities recognized for safety performance excellence at the Pulp and Paper Safety Association's (PPSA) annual awards ceremony. The prizes were handed out during the PPSA's annual conference held this year in St. Petersburg, Florida, from June 22-25.

"An employee-driven safety culture is a key plank of Domtar's sustainable business strategy, and one of the important ways we live out our company values of agility, caring and innovation," noted Allan Bohn, Senior Director of Corporate Health and Safety. "So I want to congratulate our Pulp and Paper leadership, the individual site leaders and safety representatives, and especially the site employees for all their hard work and dedication that led to these PPSA honors."

The following Domtar facilities received PPSA awards:

No OSHA Recordables

- Addison, IL

- Dallas-Fort Worth, TX

- Dubois, PA

- Owensboro, KY

- Rock Hill, SC

- Washington Courthouse, OH

- Marlboro, SC

Best Record: Fine Paper Converting Plants

- Dubois, PA

Best Record: Fine Paper Mills - Large

- Ashdown Mill, Ashdown, AR

Best Record: Paper Mills - Small

- Marlboro Mill, Bennettsville, SC

Most Improved: Paper Mills - Small

- Johnsonburg Mill, Johnsonburg, PA

Catalyst Paper appoints Pierre A. Raymond to its board of directors

Catalyst Paper Corporation have announced the appointment of Pierre A. Raymond as an independent director of the company, effective immediately.

Catalyst Paper Corporation have announced the appointment of Pierre A. Raymond as an independent director of the company, effective immediately.

Leslie T. Lederer, Chairman of the Board said, "I am pleased to welcome Mr. Raymond to our Board of Directors. His extensive knowledge and understanding of corporate strategy, finance and management dealings will add a valuable perspective to the company. We look forward to benefitting from his judgment and counsel."

Mr. Raymond retired in May 2014 from Stikeman Elliott as a partner in the Montréal office. He served as Chair of the firm from 2006 to 2012 and as a member of the Partnership Board and the Executive Committee from 1997 to 2012. After he stepped down as Chair of the firm, Mr. Raymond continued to coordinate the firm's multiple country and regional initiatives and maintained a management role in the Montréal office, with a focus on client relations. His practice focused primarily on public mergers and acquisitions, securities regulation and corporate finance. Mr. Raymond was counsel to various corporations with regard to national and international securities offerings, tender offers and financings. Mr. Raymond also counselled US and European clients with respect to Québec law in connection with international privatizations, tender offers and acquisitions.

Catalyst Paper manufactures diverse specialty mechanical printing papers, newsprint and pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With three mills, located in British Columbia, Catalyst has a combined annual production capacity of 1.5 million tonnes. The company is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights Inc. as one of the 50 Best Corporate Citizens in Canada.

SOURCE: Catalyst Paper Corporation