Displaying items by tag: siemens

Siemens at Cigré 2012: Connecting and powering the world

Siemens wins first service order for energy optimization of an industrial plant in China

Siemens to supply 300 offshore wind turbines to DONG Energy

with a capacity of 1,800 megawatts (MW). The agreement is based on the new SWT-6.0-154 direct drive wind turbine that will be installed in wind power plants off the British coast between 2014 and 2017. The world's largest rotor blade measuring 75 meters in length equaling a total rotor diameter of 154 meter will be deployed.

with a capacity of 1,800 megawatts (MW). The agreement is based on the new SWT-6.0-154 direct drive wind turbine that will be installed in wind power plants off the British coast between 2014 and 2017. The world's largest rotor blade measuring 75 meters in length equaling a total rotor diameter of 154 meter will be deployed.World's most compact Coriolis flow solution

The new generation of Coriolis flow measurement technology from Siemens Industry Automation Division is the most compact solution in the market. The digitally based flow solution Sitrans FC430 with short build-in-length is suitable for any liquid or gas application within the process industry. The new device is capable of optimizing a wide range of processes for increased productivity in industries like Chemical and Pharmaceutical. Sitrans FC430 is ideal for multi-parameter measurement and can be used in applications like fast filling, batch control, blending and dosing as well as for measurement of gases or fluids.

Sitrans FC430 features market-leading compactness, very high accuracy of 0.1 per cent, low pressure loss, extremely stable zero point and best-in-class data update with 100 Hertz high-speed signal transfer. Innovative user friendly support tools provide direct access to all operational and functional data, certificates and audit trails. Sitrans FC430 is amongst the first Coriolis flowmeters to offer SIL (Safety Integrity Level) 2 and 3 approval in hardware and software respectively, enabling maximum redundancy meeting the highest standards of safety and reliability.

The highly automated production of the Sitrans FC430 ensures a flexible supply chain for rapid responses to customer inquiries. Very short lead times for tailor-made solutions are guaranteed by assembly robots guided by sophisticated 3 D vision laser systems.

You can find more information on the Internet at: www.siemens.com/fc430

Siemens receives its first wind power order in Chile

Siemens has received an order for a total of 50 wind turbines with a combined capacity of 115 megawatts (MW) for the El Arrayán wind power plant in Chile. This wind project will be developed as a joint venture between Pattern Energy and AEI. Furthermore, the mining division of Antofagasta plc, which is the parent company of Minera Los Pelambres, the power offtaker, has purchased an equity stake in the El Arrayán project. The scope of supply encompasses delivery, installation and commissioning of 50 SWT-2.3-101 wind turbines with a power rating of 2,3 MW and a rotor diameter of 101 meters, including a five-year service and maintenance contract. Installation of the project is scheduled to begin in spring 2013, with commissioning of the wind power plant planned for early 2014.

"The El Arrayán wind power plant marks our market entry in Chile. This project also proves that we are well positioned on the global wind markets with our product portfolio. It is our goal to grow our presence in this region", said Felix Ferlemann, CEO of the Siemens Wind Power Division. The Global Wind Energy Council concluded that Chile has good wind resources from the northern deserts to the extreme South and estimates the country's wind energy potential to be around 40 Gigawatt (GW).

"The El Arrayán wind power plant marks our market entry in Chile. This project also proves that we are well positioned on the global wind markets with our product portfolio. It is our goal to grow our presence in this region", said Felix Ferlemann, CEO of the Siemens Wind Power Division. The Global Wind Energy Council concluded that Chile has good wind resources from the northern deserts to the extreme South and estimates the country's wind energy potential to be around 40 Gigawatt (GW).

The El Arrayán Wind Farm is located approximately 400 kilometers north of Santiago on the coast of the Coquimbo IV Region. Once completed, it will be the largest wind project in Chile and provide clean and renewable energy to power the equivalent of up to 200,000 average households.

Other Siemens wind orders in South America include three projects with a combined capacity of nearly 300 megawatts (MW) in Brazil, which will be installed in 2012 and 2013. These contracts were secured during the last two years. The 2.3 wind turbines are the workhorses of Siemens` portfolio. At the end of 2011 more than 3,700 units were installed globally.

Wind Power is part of Siemens' Environmental Portfolio. In fiscal 2011, revenue from the Portfolio totaled about €30 billion, making Siemens one of the world's largest suppliers of ecofriendly technologies. In the same period, our products and solutions enabled customers to reduce their carbon dioxide (CO2) emissions by nearly 320 million tons, an amount equal to the total annual CO2 emissions of Berlin, Delhi, Hong Kong, Istanbul, London, New York, Singapore and Tokyo.

Siemens to expand its presence in Brazil

Plans call for investment of up to $1 billion by 2017 to expand business operations

Siemens plans to expand its presence in the important growth market Brazil – setting the course for sustainable long-term growth in the country. The company intends to invest up to 1$ billion over the next five years with the aim of strengthening and expanding its business in Brazil. Investment will span the entire Siemens portfolio – comprising the Energy, Industry, Infrastructure & Cities, and Healthcare Sectors – with a special focus on localizing production and services as well as driving research and development. It also includes the necessary capital for business expansion. "We've been doing business in Brazil for more than 100 years, and we've never been more confident about its future. That's why we're investing here," noted Peter Y. Solmssen, member of the Managing Board of Siemens AG. Siemens intends to double its revenue in Brazil by 2017. "Our portfolio is geared to the country's requirements, and we're investing continuously in order to build up our capabilities," stated Paulo Stark, CEO of Siemens Brazil.

Siemens Brazil has invested about $700 million in capital expenditures and research and development in the country over the last ten years, opening eight new factories and generating 4,000 new jobs. In fiscal 2011, Siemens had some 10,000 employees and revenue of approximately $2.8 billion in Brazil.

One of the world's fastest-growing major economies, Brazil is rapidly emerging as a global economic powerhouse. "As its economy grows more complex, Brazil will require a more diverse range of products. That's why we're planning to expand our activities in areas that will be vital for the sustainable growth of the Brazilian economy," remarked Solmssen.

A large part of the planned investment will focus on future-oriented energy markets. This year, for example, Siemens will open a new research and development center in Rio de Janeiro which is geared to the oil and gas industry. The company intends to hire at least 200 highly qualified researchers and engineers to work on solutions that enhance efficiency and reliability across the oil and gas value chain.

Siemens will invest initially about $60 million to build up its brand new factory in Brazil. The factory will produce high and low voltage motors and generators for the domestic market and also for export. The initiative is aligned with the company’s strategy for energy efficient products and solutions. The production plant should be inaugurated in 2014 and when fully operational it is expected to generate around 300 direct jobs.

Siemens is also expanding its capabilities in the forward-looking smart grid market. In April, the company opened its first R&D center focused on developing smart grid solutions in Curitiba. Siemens is in the process to acquire a Brazilian Smart Grid company, a leading provider of smart metering and related services, this specialist company offers software and services designed to prevent non-technical losses (NTL) of power during distribution.

Siemens will also invest $30 million to expand its business in the Healthcare Sector in Brazil. Underscoring the Sector's strong commitment to Brazil, this investment will enable local imaging manufacturing and supply chain to be established in Joinville (in the state of Santa Catarina) – with the aim of better serving local market needs.

Siemens has been active in Brazil since 1867. Throughout the past century, the company played a key role in building and modernizing the country's infrastructure. As a result, Siemens equipment and systems currently generate 50 percent of the country's electricity, provide 30 percent of all digital diagnostics imaging and can be found in over 65 percent of all the offshore oil drilling projects implemented over the past ten years. This solid position has enabled the company to achieve sustainable growth and expand its business volume over the last five years.

Siemens - a reliable partner to the process industry for sustainable economic activity in dynamic times

At the Achema 2012 trade fair Siemens is focusing on the topic of lifecycle management. "We're demonstrating how the process industry can benefit from Siemens products, systems, solutions and services", said Axel Lorenz, Head of Process Automation for the Siemens Industry Automation Division, at a press conference in Karlsruhe, Germany. "Siemens is presenting itself to its process industry customers as a reliable partner for sustainable operations in dynamic times," according to Lorenz. The integrated portfolio of the company, he said, ensured high productivity, flexibility and efficiency throughout the entire plant and production life cycle. This could help to improve plant performance and energy efficiency and reduce the time to market. The Siemens approach to the integrated engineering of process and automation technology was groundbreaking and significantly reduced development and throughput times.

Cost pressure, global competition, a constantly and rapidly changing technological backdrop, as well as increasing environmental demands are the challenges facing companies in the process industry today. "Siemens has the right answers to these challenges. We work closely and reliably with the world's leading chemical and pharmaceutical companies, so that they can gain maximum performance from their plants", said Lorenz. This was also underlined by the motto used on this year's booth at Achema: "Guiding you through change – Your trusted partner for lifecycle innovation".

At the trade fair, Siemens is showcasing its extensive range of process instrumentation and analytical systems, drive technology, process control, manufacturing execution systems and plant engineering for the entire product and plant lifecycle – from research and development, through process analysis and design, plant engineering and production, to maintenance, optimization and modernization.

At the press conference, Hans-Georg Kumpfmüller, CEO of the Siemens Sensors and Communication Business Unit, stressed the considerable importance of reliable process instrumentation and analytics, as well as the growing requirements of users for suppliers who offer a complete product portfolio for all measurement variables: "Siemens is a complete systems supplier in the field of process instrumentation and analytics. Our portfolio covers all measurement variables such as pressure, level, temperature, positioning controllers, wireless solutions, weighing systems and flow measurement. We are a leading supplier in process analytics with our gas chromatographs and our gas analyzers". According to Kumpfmüller, there will be a series of important new products at Achema for the chemical and hygiene segment of the food and beverage industry and the pharmaceutical industry, as well as a wealth of additional applications. These ranged from groundbreaking innovations in level and flow measurement technology to new gas analyzers.

Andreas Geiss, Head of Comos Industry Solutions within the Siemens Industry Automation Division, underlined the growing influence of software on the various segments of the process industry: "Plant engineering is rapidly converging with significant gains in efficiency for the users." For plant management from plant engineering to production, Siemens is presenting Comos 10 at Achema – a new version of the software with a significantly extended scope of functions, enabling even the largest volumes of data to be managed. The integration of process engineering and automation has also been taken a stage further. A new interface ensures a consistent, bidirectional exchange of information between Comos and the Simatic PCS 7 process control system.

For research and development, Siemens is presenting a clean-room solution with access control, fire protection and evacuation, as well as special solutions for laboratories such as pure and ultrapure water and automation of typical laboratory applications.

In the area of process analysis and design Siemens is highlighting the potential of continuous production in the pharmaceutical industry. Companies can expect cost savings of up to twenty percent compared with batch production. There are innovations in the Sipat process analytical technology (PAT) software. These can easily be integrated into process control solutions by original equipment manufacturers (OEMs) in the new Version 4.

The main focus in production and maintenance is Version 8 of the Simatic PCS 7 process control system with a host of new functions. The new features range from improved data exchange and a simpler engineering workflow, more powerful communication, redundancy-related and high-availability functions, to new controllers and extended software tools.

The Siemens portfolio for the chemical industry is characterized by high-performance, plant availability and process reliability, exemplified by redundancy and failsafe fieldbus communication, as well as control and maintenance concepts. Furthermore, the company is presenting simple recipe sequence controllers with the Simatic PCS 7 APF (advanced process function) add-on for flexible hybrid processes.

In the pharmaceutical sector, Siemens is presenting a modular and flexible solution based on Simatic PCS 7 for fermenters according to the ISA-S88 standard. The TIA Portal engineering framework is used consistently in the manufacture of pharmaceuticals, from the definition and planning of recipes to the control of production and filling lines. The presentation for the pharmaceutical industry is supplemented by a serialization solution which enables companies in the industry to comply with future legislation and bring greater transparency to their supply chain.

Two topics determine drive technology: firstly, energy-efficient drive solutions for pumps, fans and compressors and, secondly, Loher motors and drives for hazardous areas and extreme ambient conditions. The Siemens portfolio in production and maintenance is completed by remote services, in which the company demonstrates the options and benefits of remote-controlled automation systems.

In optimization and modernization, Siemens is highlighting its engineering, consulting and service expertise and pointing out new ways to increase efficiency: for example, by optimizing resources, by simulation or modern plant control centers. Based on the main automation vendor (MAV) concepts, as well as the Simatic PCS 7 lifecycle service agreements, the company is presenting further solutions for increased plant availability, security of investment and lower total cost of ownership (TCO) throughout the entire lifecycle.

The Siemens booth at the Achema trade fair is rounded off by an extensive range of services for both the chemical and pharmaceutical industries. These extend from technical support, maintenance and lifecycle service agreements to professional consultation on industrial safety or energy management.

PepsiCo plant to reduce up to 70% of fresh water consumption using Siemens’ integrated reuse solution

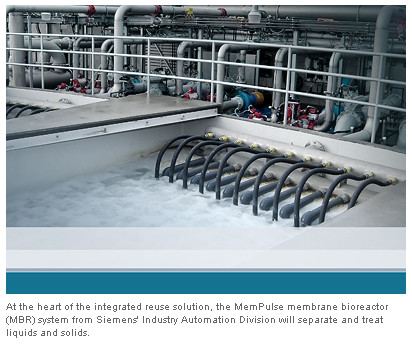

PepsiCo is installing an integrated reuse solution from Siemens Industry Automation Division at its snack food production plant in Santiago, Chile. As part of a wastewater treatment plant upgrade, the manufacturing facility is increasing its wastewater treatment capacity by 20% and incorporating environmentally beneficial technologies. The Siemens system will lower fresh water consumption by up to 70%. It is expected to become operational in April 2012.

The integrated solution from Siemens will help eventually reduce the amount of fresh water used in making potato chips and other snack food lines at the Santiago plant by an estimated two-thirds. Water savings will be accomplished by taking the initial water used in production, extracting the impurities and cycling it back into the production systems. Wastewater treated by the Siemens system will be reused in various internal manufacturing processes.

The installation is part of a corporate initiative to help standardize water reuse at PepsiCo facilities throughout South America. At the Santiago facility, most of the wastewater first passes through an extensive starch recovery system and is then screened before it moves on to primary treatment, which includes oil and grease removal. After this stage, it will flow to a MemPulse membrane bioreactor (MBR) system from Siemens that will separate and treat liquids and solids. Additionally, a remote supervision system will allow MBR performance parameters to be monitored online from Siemens' technology center in Waukesha, Wisconsin, USA. From the MBR, the water will be pretreated before it passes through tertiary treatment, including a reverse-osmosis (RO) system and a Barrier M ultraviolet (UV) disinfection system, both also from Siemens. The integrated reuse solution is more advanced than conventional wastewater treatment processes, producing consistently high-quality effluent in a smaller footprint.

While PepsiCo has used a combination of MBR and RO technologies at a few of its manufacturing facilities throughout Latin America, this marks the first known time the technology combination has been entirely offered by a single manufacturer in South America. Increasingly stringent local regulations, coupled with the company's growing green initiatives, might make using the technology combination in its processes more prevalent in the future.

MemPulse and Barrier are trademarks of Siemens and/or its affiliates in some countries

Further information about solutions for water treatment is available at:

http://www.siemens.com/water

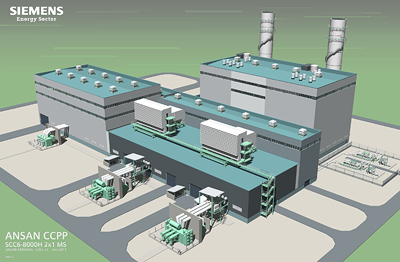

Siemens to deliver state-of-the-art power plant technology to South Korea

Siemens is again to deliver state-of-the-art power plant technology to South Korea. For the Ansan combined cycle power plant (CCPP), the company is supplying the Power Island consisting of two innovative SGT6-8000H gas turbines, one steam turbine, three generators, and two heat recovery steam generators as well as the entire instrumentation and control technology. Ansan is now the second power plant in South Korea to be equipped with the new gas turbines – SGT6-8000H – from Siemens. The customer is the South Korean Posco Engineering & Construction Co. Ltd., headquartered in Incheon, which is responsible for construction of the entire plant. The CCPP Ansan will be fueled with liquefied natural gas (LNG) and will have a gross installed electrical capacity of 834 megawatts (MW) at a gross efficiency of 61 percent. In addition to generating electricity, the plant will also provide district heating for the inhabitants of the city of Ansan, which raises the overall fuel utilization factor to over 75 percent. Commissioning is planned for the end of 2014.

The Ansan CCPP is being built in the city of the same name in Gyeonggi-Do province southwest of the capital Seoul. Siemens is constructing the core element of the plant, the so-called power block, as a turnkey project and will supply the main components – two gas turbines of type SGT6-8000H, an SST6-5000 steam turbine, and three hydrogen-cooled generators of type SGen6-2000H. Siemens is also supplying two Benson heat recovery steam generators, and the SPPA-T3000 instrumentation and control system. A long-term service agreement has also been signed for the main components.

South Korea enjoys a burgeoning economy, with demand for electricity annually growing at the rapid rate of 3.6 percent. In the last ten years the installed power plant capacity rose from 60 gigawatts (GW) to more than 80 GW. However, the country has few energy resources of its own and is the second largest importer of LNG in the world. Because of high gas prices, high-efficiency CCPP play a particularly important role. "Ansan is now the second power plant in South Korea that we are equipping with our ground-breaking new gas turbine technology," said Roland Fischer, CEO of the Fossil Power Generation division at Siemens Energy. "We are pleased that we are making an important contribution towards a cost-efficient and environmentally friendly power supply."

"Because of our high gas prices, the efficiency of energy conversion is very important to us. Siemens offers the to date most efficient power plant technology and is an experienced and reliable partner in the handling of projects. We are pleased to be implementing this world-class project together with Siemens," said Kwang-Jae Yoo, CEO at Posco Engineering & Construction Division.

High-efficiency combined cycle power plants are part of the Siemens environmental portfolio, with which the company earned revenues of about €30 billion in fiscal 2011. This makes Siemens one of the largest global suppliers of environmentally friendly technology. Using Siemens products and solutions, customers saved nearly 320 million metric tons of carbon dioxide (CO2) during the same time period; this figure is equivalent to the total annual CO2 emissions of Berlin, Delhi, Hong Kong, Istanbul, London, New York, Singapore and Tokyo combined.

Siemens is European patent champion in Europe

Siemens is again the uncontested leader in patent applications in Europe. According to the 2011 Patent Applicant Ranking of the European Patent Office (EPO), the company submitted 2,235 patent applications (excluding Osram: 1,994) to the EPO in calendar year 2011 to capture first place in the European patent statistics. Siemens also increased its lead over its next-ranked rivals. "I'm very proud of this achievement – it's a testimony to our employees' power of innovation. Innovations strengthen our position in international competition and create jobs," said Siemens President and CEO Peter Löscher. Löscher confirmed that Siemens will continue to invest in research and development at the current high level. In fiscal 2011, the company channeled nearly €4 billion into research and development, of which over €1 billion went to develop green technologies.

"Siemens is a great example of how to leverage innovations for business success," said EPO President Benoît Battistelli. "The company has been in the top three ever since we introduced the Top Applicant Rankings in 1997." Siemens is also increasingly innovative at the global level. The number of invention reports filed by Siemens researchers rose ten percent year-over-year to 8,600 – or almost 40 per workday. On average, each of the company's nearly 28,000 R&D employees is now reporting almost twice as many inventions as ten years ago. The number of related initial patent filings worldwide now totals nearly 4,300 or almost 20 per workday – a 15 percent increase compared to 2010, while the total number of patents granted to the company has risen from 51,300 in 2010 to 53,300.

These outstanding creative achievements are reflected in Siemens products. For example, the company's latest gas turbine has achieved an efficiency rating of 60.75 percent in combined cycle operation with a steam turbine – a current world record. In 1990, turbine efficiency was still 52 percent – nearly nine percent lower. A power plant equipped with the new Siemens turbine can supply the entire energy needs of a city of around 3.5 million inhabitants. This means that – due to its increased efficiency – it can provide electricity to half a million more people than its counterpart in 1990 and without additional CO2 emissions. The plant can also go from shutdown to 500 megawatts within half an hour. This quick start-up capability is important if wind and solar systems are to be used to feed electricity into power grids as part of the current energy transformation. The new combined cycle plants can step in at short notice if wind forces suddenly diminish or clouds obscure the sun.

Another example – this time in the healthcare field – is of particular importance to patients. Developed by Siemens, the new Biograph mMR is the first device to combine the two opposed technologies magnetic resonance imaging (MRI) and positron emission tomography (PET) in a single system. By providing much more precise images of processes within the human body, the Biograph mMR is making diagnoses more accurate. For patients, this means gentler and more individual therapies and better outcomes.

Further information is available at: www.siemens.com/press/patent-applicant-ranking.

The figures for invention reports and patent applications are calculated on the basis of continuing operations – that is, excluding Osram and Siemens IT Solutions and Services.