Ianadmin

UPM expands its forest services in Finland by offering FSC certification to forest owners

Forest owners can obtain an FSC certificate for their forests by joining the UPM group certificate. For forest owners, this is an easy way of ensuring that their forests are managed and used in a responsible and economically viable way. The first forest certification service contracts between UPM and private forest owners have already been signed. The FSC group certificate also covers the jointly-owned forests established by UPM.

"The FSC certification of privately owned forests enables UPM to widen its range of certified products. The FSC certified raw material acquired from Finnish forests can also be used to partly replace imported wood at Finnish mills," says Vice President Pekka Rajala, Wood Sourcing, North Europe.

UPM has experience of FSC certification from its own forests. Last year, UPM was granted a forest-owner-specific FSC certificate that covers the company's forests in southern Finland. UPM also offers FSC forest certification as a forest service in Uruguay and the UK. All UPM forests worldwide are certified.

"The FSC group certificate received by UPM supports our goal of developing a new forest economy. The range of services offered to forest owners will increase, forest management will become more versatile and new environmental protection practices will develop," says Timo Lehesvirta, Director, Environment, Energy and Pulp.

Forest certification is an important part of the UPM environmental strategy. The company constantly strives to increase the use of certified wood in its products. UPM uses reliable certification systems, such as FSC and PEFC. Globally, forest certification is an important tool in promoting the sustainable use of natural resources. For consumers, certification is a sign of sustainability.

“As green as it gets”: Mondi Uncoated Fine Paper re-launches the Green Range

“As green as it gets”: Mondi Uncoated Fine Paper re-launches the Green Range to celebrate new achievements in sustainable paper making

Mondi Uncoated Fine Paper (UFP) re-launched its Green Range with a new slogan that reflects the international paper manufacturer’s latest achievements and goals in sustainable paper making. Since 2006, the Green Range stands for Mondi-branded papers with a high environmental profile. It is also recognised as a channel to communicate Mondi’s efforts and initiatives in sustainable paper production and environmental issues central to the paper industry.

Mondi Uncoated Fine Paper (UFP) re-launched its Green Range with a new slogan that reflects the international paper manufacturer’s latest achievements and goals in sustainable paper making. Since 2006, the Green Range stands for Mondi-branded papers with a high environmental profile. It is also recognised as a channel to communicate Mondi’s efforts and initiatives in sustainable paper production and environmental issues central to the paper industry.

“Our new slogan, ‘As Green as it gets,’ references the expansion of the Green Range. All Mondi-branded papers now meet Green Range criteria and are FSC® or PEFC™ certified, or Totally Chlorine Free bleached (TCF), or 100% recycled. ‘As Green as it gets’ is also about Mondi’s unending drive and commitment to continually improve the eco-efficiency of our mills and papers,” explained Johannes Klumpp Marketing and Sales Director for Uncoated Fine Paper.

Responsible management of forests, reduced water and energy usage, fewer emissions to air and water, and less waste to landfill are essential elements in Mondi’s continuous journey towards sustainable development in paper production. To emphasize the eco-conscious production behind Mondi paper, the new campaign showcases tangrami paper landscapes inhabited by bees, birds and other animals, which instinctively gravitate toward the seemingly natural flora.

In addition to the key Green Range criteria, Mondi’s papers are accredited by many renowned international organizations. All  Mondi-branded papers produced in the company’s UFP mills in Austria and Slovakia are EU Ecolabel certified, a label which signifies environmental excellence for products and services that meet high environmental standards throughout their life-cycle. Moreover, products such as 100% recycled NAUTILUS® classic and the BIO TOP 3® brand are certified with the Blue Angel and Austrian Environmental Label respectively.

Mondi-branded papers produced in the company’s UFP mills in Austria and Slovakia are EU Ecolabel certified, a label which signifies environmental excellence for products and services that meet high environmental standards throughout their life-cycle. Moreover, products such as 100% recycled NAUTILUS® classic and the BIO TOP 3® brand are certified with the Blue Angel and Austrian Environmental Label respectively.

To reduce Mondi’s effects on climate change the company’s principle is first to optimise processes, reduce emissions and then offset. The company is able to calculate the total carbon footprint of each product, at each stage of the supply chain, to determine the effect of its Greenhouse Gas-reducing activities at every stage. Carbon emissions from Mondi material operations were reduced by 26% since 2004 and 4.3 million CO2e tonnes were avoided as a result of carbon sequestration at its South African plantations and through the sale of green electricity, heat and fuels; using recovered paper; and substituting natural gas with biogas.

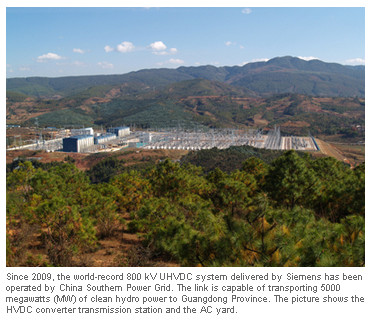

On a product level, Mondi UFP participates in the emissions reductions programme Run of River in order to offer customers 100% recycled NAUTILUS® SuperWhite and DNS® high-speed inkjet with a CO2 neutral option as well as the fully CO2 neutral Color Copy. The Run of River hydropower project results in an average annual CO2 reduction of approximately 230,000 tonnes of CO2 equivalents.

On a product level, Mondi UFP participates in the emissions reductions programme Run of River in order to offer customers 100% recycled NAUTILUS® SuperWhite and DNS® high-speed inkjet with a CO2 neutral option as well as the fully CO2 neutral Color Copy. The Run of River hydropower project results in an average annual CO2 reduction of approximately 230,000 tonnes of CO2 equivalents.

To increase awareness about environmental issues related to the pulp and paper industry and the environmental labels found on Mondi papers, the company regularly hosts Green Events and developed an online learning tool called the Green Modules (www.mondigroup.com/greenmodules), which is now available in German, English and Italian. For every person who reads the Green Modules, Mondi donates 1 euro to the NGO OroVerde’s reforestation project “Guatemala – Tree for Tree”. 1 euro equals 1 tree planted. If you answer the Green Module Quiz correctly, Mondi will donate 10 Euros to the project.

To learn more about Mondi’s infinite journey in sustainable paper production, eco-labels, or carbon neutral topics visit: www.mondigroup.com/gogreen.

Mondi Environmental Facts

- Mondi plants roughly 32 million trees each year.

- 100% of Mondi owned forests in Russia and South Africa are FSC certified

- 25% of Mondi landholdings are set aside for conservation (roughly 572,000 hectares).

- 93% of electricity used in Mondi plants is produced internally and 57% of Mondi’s total fuel consumption of our material operations was from renewable resources 61% of wood and fibre purchased by Mondi is FSC or PEFC certified. The rest meets the FSC’s Controlled Wood standard or the PEFC Mandatory Guide for the Avoidance of Controversial Timber, ensuring that no wood is sourced from controversial sources.

Ahlstrom acquires Munktell to accelerate growth in advanced filtration materials

Ahlstrom, a global high performance materials company, has today signed an agreement to acquire the Sweden-based Munktell Filter AB as a strategic step to grow the advanced filtration business particularly in life science and laboratory applications.

Under the agreement, Ahlstrom will acquire 100 percent of the shares in Munktell Filter AB, as well as its holdings in Munktell & Filtrak GmbH, Filtres Fioroni SA and Munktell Inc. The enterprise value of the transaction is approximately EUR 20 million, including the planned subsequent buyouts of minority interests. Through the transaction, Ahlstrom will become a global leader in life science and laboratory media filtration.

According to Jan Lång, President & CEO, the acquisition reinforces Ahlstrom's leadership in filtration material markets worldwide. "There is a clear strategic fit with Munktell and Ahlstrom, and the transaction allows us to strengthen our product portfolio in advanced filtration materials. This move is a prime example of our focus on new type of high performance materials business with attractive future growth potential."

"When we combine Munktell's strong position in the European advanced filtration market with our solid presence in North America, we will gain access to new markets geographically. Driven by global changes in demographics, life science and laboratory filtration are lucrative growth areas for us," added Tommi Björnman, Executive Vice President, Filtration.

Munktell is based in Falun, Sweden and it has production sites in Germany and Sweden, a joint venture in France, as well as a sales office in the U.S. The company's net sales amounted to approximately EUR 15 million and operating profit margin was roughly 15% in 2011. It employs some 100 people. Munktell produces filtration materials mainly for life science and laboratory applications. End-use examples include new born screening, laboratory media filtration, filter materials for pollution control, as well as testing materials used by medical, sugar and beverage industries.

Munktell will be integrated into Ahlstrom's Filtration business area. The acquisition is expected to be completed by the end of October 2012 and is subject to customary regulatory approvals.

Ahlstrom is the global leader of filtration materials with 11 production sites producing filtration materials across four continents.ANDRITZ Küsters presents new calender technology for textiles customers

ANDRITZ Küsters, one of the leading suppliers worldwide of calender technology for the textiles, nonwovens, and paper industries, has developed an innovative calender concept for the growth market technical textiles, incorporating proven technologies from the production of paper and nonwovens. The new teXcal trike technology (patent application is ongoing) will be available for customer trials in a pilot plant at the technical center of ANDRITZ Küsters in Krefeld, Germany, as from the end of this year.

ANDRITZ Küsters, one of the leading suppliers worldwide of calender technology for the textiles, nonwovens, and paper industries, has developed an innovative calender concept for the growth market technical textiles, incorporating proven technologies from the production of paper and nonwovens. The new teXcal trike technology (patent application is ongoing) will be available for customer trials in a pilot plant at the technical center of ANDRITZ Küsters in Krefeld, Germany, as from the end of this year.

Due to an innovative 3-roll arrangement with two separately controlled system rolls, the teXcal trike calender provides outstanding productivity and flexibility in the manufacture of sophisticated technical textiles, such as sailcloth, parachute silk, breathable outdoor clothing, sunscreens, filter materials, or protective clothing. “Our customers have shown great interest in our new calender concept. We already have many inquiries to run test series, and several well-known textile finishers from many different areas of application have already invested in a teXcal trike calender,” says Tobias Schäfer, Sales Director at ANDRITZ Küsters.

ANDRITZ Küsters, a member of international technology Group ANDRITZ, is the only manufacturer worldwide to combine three different deflection-controlled roll systems in its portfolio: the swimming S-roll, the piston-supported HyCon Roll, and the Xpro roll recently presented for the first time at the ITMA trade show.

Verso Paper Corp. Announces That It Has Ended Discussions With NewPage Corporation

In this press release, all statements that are not purely historical facts are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. Forward-looking statements may be identified by the words "believe," "expect," "anticipate," "project," "plan," "estimate," "intend" and similar expressions. Forward-looking statements are based on currently available business, economic, financial and other information and reflect management's current beliefs, expectations and views with respect to future developments and their potential effects on Verso. Actual results could vary materially depending on risks and uncertainties that may affect Verso and its business. For a discussion of such risks and uncertainties, please refer to Verso's filings with the Securities and Exchange Commission. Verso assumes no obligation to update any forward-looking statement made in this press release to reflect subsequent events or circumstances or actual outcomes.

Source: Verso Paper Corp.

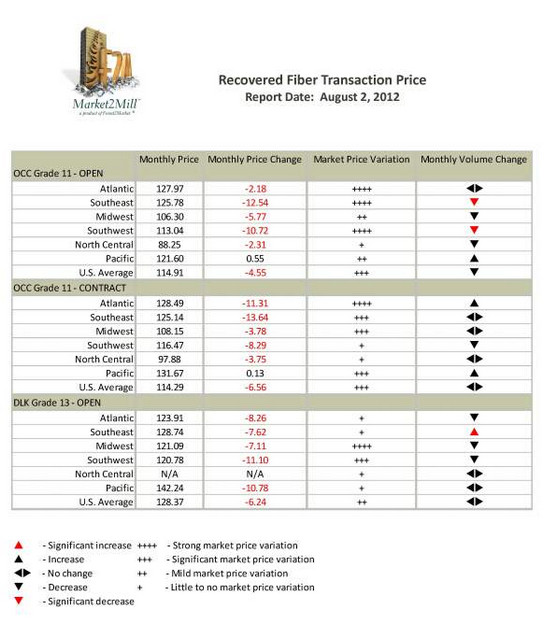

Must History Repeat Itself? Recovered Fiber Market Crashes

UPM Raflatac completes the acquisition of Gascogne’s labelstock operations in Switzerland

“UPM Raflatac has focused in recent years on growth in special labelstock products. As a result of this transaction we will strengthen our position in this product area in Europe,” says Tapio Kolunsarka, Senior Vice President, Europe, Middle-East and Africa.

UPM has today started employee consultations in Martigny in order to adjust the cost structure and organization of the factory to a sustainable level.

Metso introduces new energy-saving roll cover for boardmaking

Metso has launched PressPolar, a new polyurethane roll cover for press rolls. The cover is suitable for large and highly loaded press rolls, mainly used in boardmaking. The PressPolar cover is designed to significantly reduce the energy consumption of roll drives in the press section.

Metso has launched PressPolar, a new polyurethane roll cover for press rolls. The cover is suitable for large and highly loaded press rolls, mainly used in boardmaking. The PressPolar cover is designed to significantly reduce the energy consumption of roll drives in the press section.

New polyurethane material offers low rolling resistance

The roll drives in press sections consume remarkable amounts of energy, and also the soft roll covers on roll bodies greatly influence energy consumption. The rolling resistance of a roll cover is what affects the drive power consumption. In the PressPolar roll cover, due to the new polyurethane material, the rolling resistance is remarkably lower than that in conventional rubber and polyurethane roll covers. In addition, a roll with a PressPolar cover needs no internal water cooling. These features provide significantly reduced energy consumption.

Development of durable and long-lasting cover materials continues

Polyurethane roll covers have been well-known for their good wear resistance properties for decades. Metso continues the development in this field and the PressPolar cover offers the best durability ensuring extended service intervals and longer total roll cover lifetimes.Siemens at Cigré 2012: Connecting and powering the world

Change in Ahlstrom's Board of Directors

Nathalie Ahlström (M.Sc., Tech) has decided to tender her resignation as a member of Ahlstrom's Board of Directors due to a conflict of interest caused by her taking up a new executive position. The resignation will be effective as of Sept. 1, 2012

Ahlstrom Corporation and its Board of Directors wish to warmly thank Ms. Ahlström for her valuable contribution as a member of the Board of Directors wish her all the success in her future endeavors.

The Board of Directors will continue with six members until the next Annual General Meeting in 2013: Peter Seligson (Chairman), Pertti Korhonen (Vice Chairman), Sebastian Bondestam, Lori J. Cross, Esa Ikäheimonen and Anders Moberg.