Displaying items by tag: Andritz

ANDRITZ to supply biomass pre-treatment technology for commercial-scale Project LIBERTY in the USA

International technology Group ANDRITZ, through its U.S. subsidiary ANDRITZ Inc., received an order to supply its advanced continuous biomass pre-treatment technology for the Poet-DSM Advanced Biofuels commercial-scale biofuel facility being built in Emmetsburg, Iowa, USA.

International technology Group ANDRITZ, through its U.S. subsidiary ANDRITZ Inc., received an order to supply its advanced continuous biomass pre-treatment technology for the Poet-DSM Advanced Biofuels commercial-scale biofuel facility being built in Emmetsburg, Iowa, USA.

Project LIBERTY is POET-DSM’s first commercial scale 2nd generation cellulosic ethanol plant and is under construction in Emmetsburg, Iowa. The facility will produce 20 million-gallons per year by using corn cobs, leaves, husk, and some stalk to produce renewable fuel. Construction is scheduled to be complete in the fourth quarter of 2013.

ANDRITZ’s advanced steam explosion (SteamEx) technology is a two-stage process which includes a vertical reactor, interstage washing, and continuous steam explosion. The technology will be employed to help in the pre-treatment of biomass so that it can be converted into low-cost sugars which will be used in the production of ethanol. This technology is well-proven in other industrial processes and, through extensive R&D in liquid biofuels, has been optimized by ANDRITZ to satisfy the requirements for Project LIBERTY.

ANDRITZ to supply two tissue machines with the world’s largest steel yankees to C&S Paper Yunfu, China

International technology Group ANDRITZ has received an order from C&S Paper Yunfu, Luoding, Guangdong Province, China, to supply two PrimeLineST tissue machines, each equipped with a steel yankee. Start-up is scheduled for the end of 2013.

The tissue machines have a design speed of 1,900 m/min and a width of 5.56 m. The steel yankees will be 18 ft in diameter with a shell length of 6.2 m, making them the world’s largest steel yankees for tissue. ANDRITZ’s scope of supply also includes the complete stock preparation plant as well as automation and drive systems.

These will the first PrimeLineST machines in China. The design of the PrimeLine ST is to reduce energy consumption in the drying process, which uses relatively cheap steam only. A large, high-precision steel yankee is combined with a steam-heated hood to achieve the maximum possible output at stable runnability, and this is achieved with significant cost savings.

The machinery and equipment will be manufactured at ANDRITZ’s production facilities in Europe and China. With this turnkey delivery, the PULP & PAPER business area is strengthening its position as one of the leading suppliers of tissue machines and local services in China.

ANDRITZ acquires Allied Environmental Solutions in the USA

International technology Group ANDRITZ has acquired Allied Environmental Solutions, Inc. (AES) whose headquarters is in Columbia, Maryland, USA. The company has around 40 employees and generates annual sales of approximately 30 MEUR. It was agreed not to disclose the purchase price.

International technology Group ANDRITZ has acquired Allied Environmental Solutions, Inc. (AES) whose headquarters is in Columbia, Maryland, USA. The company has around 40 employees and generates annual sales of approximately 30 MEUR. It was agreed not to disclose the purchase price.

AES – now ANDRITZ Environmental Solutions – is a leading supplier of air quality control systems for utilities and various power generating industries (e.g. fossil-fired power stations) in the USA. ANDRITZ Environmental Solutions offers a comprehensive product and service range of flue gas cleaning technologies, including Circulating Fluid Bed (CFB) scrubbers, fabric filters, wet and dry electrostatic precipitators, and Selective Catalytic Reduction (SCR) systems.

With this acquisition, ANDRITZ Energy & Environment (AE&E) is strengthening its flue gas cleaning portfolio and has entered the US market.

ANDRITZ successfully starts up the ninth tissue machine for Hengan Group, China

International technology Group ANDRITZ has successfully completed a total of four tissue machine start-ups planned for this year at Hengan Group, China. The Hengan Group is thus running nine ANDRITZ tissue machines – two of which are fitted with the largest steel yankees in operation worldwide.

International technology Group ANDRITZ has successfully completed a total of four tissue machine start-ups planned for this year at Hengan Group, China. The Hengan Group is thus running nine ANDRITZ tissue machines – two of which are fitted with the largest steel yankees in operation worldwide.

From January to September of this year, two PrimeLine W8 tissue machines were started up at the Chongqing mill and two PrimeLine TM W6 tissue machines at the Jinjiang mill, all ahead of the time schedule. All four orders included the supply of the complete stock preparation and machine control systems. The steel yankees of PM15 and PM16 are the largest for tissue operating anywhere in the world. With a diameter of 4.9 m and a shell length of 6.2 m, they provide for safe and energy-efficient machine operation.

The ANDRITZ PULP & PAPER business area, which manufactures its tissue machine components in Europe and China and is confirming its position as one of the leading suppliers of tissue machines and local services in China with the start-ups for the Hengan Group, will be presenting its latest tissue technology at Tissue World Asia in Shanghai (November 14-16) and at Tissue World Barcelona (March 19-21, 2013).

ANDRITZ to supply stock preparation systems for Fujian Liansheng Paper, China

International technology Group ANDRITZ has received an order to supply stock preparation systems for the new board machine to Fujian Liansheng Paper Co. Ltd., located in Longhai, Zhangzhou City, Fujian Province, China. Start-up is scheduled for end of 2013.

International technology Group ANDRITZ has received an order to supply stock preparation systems for the new board machine to Fujian Liansheng Paper Co. Ltd., located in Longhai, Zhangzhou City, Fujian Province, China. Start-up is scheduled for end of 2013.

The scope of supply for this new board machine which will produce 600,000 t/a coated board and white top test liner comprises:

- 250 t/d virgin fiber line (Northern Bleached Kraft Pulp/Leaf Bleached Kraft Pulp, Northern Unbleached Kraft Pulp) for the top ply,

- 350 t/d OMG/MOW/old books line (Old Magazines/Mixed Office Waste) for the under top ply,

- components for the 1,300 t/d mixed waste line for the filler ply,

- 260 t/d ONP line (Old Newsprint Pulp) for the back ply,

- sludge dewatering system and reject treatment components for the recycled fiber lines,

- four-layer paper machine approach system,

- save-all disc filter,

- under the machine pulper system (all in all eight pulping/slushing units),

- basic engineering, supervision of erection, commissioning, start-up and training as well as spare and wear part packages for the entire equipment supply.

With this important order, ANDRITZ PULP & PAPER is once again confirming its position as leading stock preparation system and equipment supplier in China.

ANDRITZ Biax to supply another MESIM film stretching line to China

After successful start-up of the worldwide largest and fastest MESIM film stretching line for a customer in Europe at the beginning of this year, international technology Group ANDRITZ has received the order to supply another MESIM line. Chinese film manufacturer Zhejiang Nanyang Technology Co., Ltd., Taizhou, ordered a 5.1 m wide line for the production of various PET films in a range from 2-75 µ. Start-up is scheduled for the first quarter of 2014.

After successful start-up of the worldwide largest and fastest MESIM film stretching line for a customer in Europe at the beginning of this year, international technology Group ANDRITZ has received the order to supply another MESIM line. Chinese film manufacturer Zhejiang Nanyang Technology Co., Ltd., Taizhou, ordered a 5.1 m wide line for the production of various PET films in a range from 2-75 µ. Start-up is scheduled for the first quarter of 2014.

MESIM (Mechanical Simultaneous Stretching System) is a stretching technology patented by ANDRITZ Biax. The stretching variable process in both the longitudinal and transverse directions takes place simultaneously in only one step. The stretching area can be adjusted over a wide range while in operation to suit all kind of polymers (PET, PP, PA, PI, PEEK, COC, PC, and many others). The MESIM film products have outstanding optical and physical properties and are used for high-quality applications (for example, in the food packaging and entertainment industries).

Zhejiang Nanyang Technology manufactures smooth, rough, and metalized polypropylene films for various types of capacitors as well as PET films for different products.

ANDRITZ Küsters presents new calender technology for textiles customers

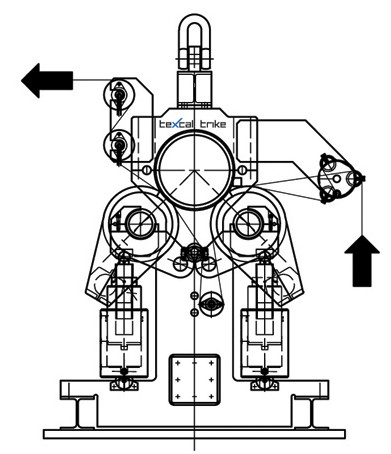

ANDRITZ Küsters, one of the leading suppliers worldwide of calender technology for the textiles, nonwovens, and paper industries, has developed an innovative calender concept for the growth market technical textiles, incorporating proven technologies from the production of paper and nonwovens. The new teXcal trike technology (patent application is ongoing) will be available for customer trials in a pilot plant at the technical center of ANDRITZ Küsters in Krefeld, Germany, as from the end of this year.

ANDRITZ Küsters, one of the leading suppliers worldwide of calender technology for the textiles, nonwovens, and paper industries, has developed an innovative calender concept for the growth market technical textiles, incorporating proven technologies from the production of paper and nonwovens. The new teXcal trike technology (patent application is ongoing) will be available for customer trials in a pilot plant at the technical center of ANDRITZ Küsters in Krefeld, Germany, as from the end of this year.

Due to an innovative 3-roll arrangement with two separately controlled system rolls, the teXcal trike calender provides outstanding productivity and flexibility in the manufacture of sophisticated technical textiles, such as sailcloth, parachute silk, breathable outdoor clothing, sunscreens, filter materials, or protective clothing. “Our customers have shown great interest in our new calender concept. We already have many inquiries to run test series, and several well-known textile finishers from many different areas of application have already invested in a teXcal trike calender,” says Tobias Schäfer, Sales Director at ANDRITZ Küsters.

ANDRITZ Küsters, a member of international technology Group ANDRITZ, is the only manufacturer worldwide to combine three different deflection-controlled roll systems in its portfolio: the swimming S-roll, the piston-supported HyCon Roll, and the Xpro roll recently presented for the first time at the ITMA trade show.

ANDRITZ to supply fiber preparation system for new board plant in Russian Federation.

International technology Group ANDRITZ has received an order to supply a raw material preparation system for a new MDF production line being built by LLC Kastamonu Integrated Wood Industry, Russian Federation, a subsidiary of Kastamonu Integrated Wood Industry, Turkey. Start-up is scheduled for the third quarter of 2013.

International technology Group ANDRITZ has received an order to supply a raw material preparation system for a new MDF production line being built by LLC Kastamonu Integrated Wood Industry, Russian Federation, a subsidiary of Kastamonu Integrated Wood Industry, Turkey. Start-up is scheduled for the third quarter of 2013.

ANDRITZ’s scope of supply includes the debarking (RotaBarker), chipping, and screening equipment as well as a pressurized refining system with a design capacity of approximately 1,440 t/d.

Kastamonu Integrated Wood Industry is a leading supplier of high-quality MDF and particle boards for the furniture and building industry (for example laminate flooring, skirtings, doorskin, or honeycomb board) with an annual production capacity of 3.5 million m3.

ANDRITZ to supply key components for testliner and corrugated medium machine

International technology Group ANDRITZ will deliver the paper machine approach, a save-all disc filter for fiber recovery, two PrimeFlow headboxes, and a PrimeDry  Hard 2 roll calender for the new testliner and corrugated medium machine at Sichuan F. Source Paper, China. Start-up is scheduled for September 2013.

Hard 2 roll calender for the new testliner and corrugated medium machine at Sichuan F. Source Paper, China. Start-up is scheduled for September 2013.

At a design speed of 650 m/min and a width of 4.9 m, the machine achieves an annual capacity of 150,000 t. The ANDRITZ headbox is of compact design and easy to install, which are decisive criteria especially for rebuilds. The PrimeCal Hard calender optimizes precalendering and final calendering of all paper and board grades.

With this order, the PULP & PAPER business area, which manufactures its paper machine components in Europe and China, is further strengthening its position as one of the leading suppliers of machines and local services in China.

International technology Group ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, solid-liquid separation in the municipal and industrial sectors, the steel industry, and the production of animal feed and biomass pellets.

In addition, ANDRITZ offers technologies for certain other sectors including automation, pumps, machinery for nonwovens and plastic films, steam boiler plants, biomass boilers and gasification plants for energy generation, flue gas cleaning plants, plants for the production of panelboards (MDF), thermal sludge utilization, and torrefaction plants.

The publicly listed company is headquartered in Graz, Austria, has a staff of more than 17,400 employees, and operates over 180 production sites as well as service and sales companies all around the world.

ANDRITZ presents its nonwovens solutions for the production of technical textiles