Displaying items by tag: AFT

AFT is pleased to announce the official opening of a new sales office in Saint Petersburg, Russia

While AFT has been active in Russia for about 30 years, strong growth in recent years led to the decision of opening our own sales representative office to better meet the needs of our clients.

The new location in Saint Petersburg will strengthen AFT's presence and position in the Russian and CIS markets for pulp and paper wear parts and equipment, as well as allow us to explore these markets for new opportunities. The Saint Petersburg team is led by Roman Smorgunov, Sales Manager and Julia Babenko, Head of Administration, who will be responsible for managing all operations and support functions.

From left to right: Roman Smorgunov, Julia Babenko, Sergei Korostelev, Lyubov Lyubimova

From left to right: Roman Smorgunov, Julia Babenko, Sergei Korostelev, Lyubov Lyubimova

As we aim to further expand our presence in the pulp and paper industry in Russia, the new office will provide better service to our existing clients as well as boost AFT sales on a global scale.

The office is located in the VANT business center on the Neva River and offers dedicated space for meeting with clients, partners, and our sales and delivery specialists who will be pleased to provide any support related to sales in Russia, CIS countries and the neighboring states. The office contact information can be found on our website at www.aft-global.com. For more information, please email us at This email address is being protected from spambots. You need JavaScript enabled to view it..

About AFT:

AFT is a global supplier specializing in stock preparation, screening, refining and paper machine approach flow systems. With over 110 years of experience in manufacturing and supplying tailored solutions, we respond to the needs of our customers and help improve performance with trademarked advancements such as Finebar ultra low intensity refining, Powerwave energy efficient screening, POM wet end systems, and more.

Global teamwork: AFT’s growing advantage

The Pulp and Paper Industry just gained an advocate for teamwork, naming Jacques Beauchemin as President and CEO of AFT. In his previous position as CFO, Jacques was instrumental in helping to acquire two of AFT’s largest innovations with Finebar and POM. He has built a reputation for fostering teamwork within the organization, travelling regularly to AFT’s five manufacturing sites and promoting global collaboration.

Jacques BeaucheminSays Jacques: “My focus is to strengthen our teams, built around core capabilities. Each person in our company has the support to grow and continuously improve; together we have a strong work force. We are doing more to understand our customer’s needs and bring opportunities for personal growth to our employees. We want big picture thinkers who understand customer processes, good collaborators, and individuals who can multi-task. That’s the essence of a great team.

Jacques BeaucheminSays Jacques: “My focus is to strengthen our teams, built around core capabilities. Each person in our company has the support to grow and continuously improve; together we have a strong work force. We are doing more to understand our customer’s needs and bring opportunities for personal growth to our employees. We want big picture thinkers who understand customer processes, good collaborators, and individuals who can multi-task. That’s the essence of a great team.

One recent example for key change has been to unify our global project management and service teams. This change presents a single face to our customers and strengthens our internal collaboration. It is at times a challenge to stay locally focused while being globally collaborative within the organization; my past leadership with our global information technology team will help. Our support needs to be at the same high level for customers located around the world."

Follow this link for more of Jacques interview as he steps in to lead AFT: http://ow.ly/JEa030kVnr1

AFT (Aikawa Fiber Technologies) receives Approach Systems order for new BillerudKorsnäs board machine in Gruvön, Sweden

BillerudKorsnäs has selected AFT (Aikawa Fiber Technologies) to supply a compact POM System for all three layers of their new 550,000 tonnes per year board machine at the Gruvön mill in Sweden.

According to Timo Koivisto , Vice President, Process and Equipment Solutions for AFT, “Compact and highly efficient, POM® paper machine wet end and headbox screening will deliver superior cleanliness in a compact package. The simple POM System, with its small footprint, has become the de facto alternative to traditional complex approach flow, eliminating capital and high operating costs.”

The order includes a complete POM System for all three layers and headbox screening, including:

- 3 - POMix stock processors

- 9 - POMp degassers

- 3 - POMLock drop legs

- 11- MaxFlow Headbox screens

- Cascade cleaning system, process pumps and auxiliaries plus associated basic engineering.

The system will come on stream in early 2019, coinciding with the start-up of BillerudKorsnäs’ new board machine.

The BillerudKorsnäs’ board machine at the Gruvön site is the company’s largest investment ever, one of the largest in Sweden in recent years. The investment of SEK 5.7 billion includes the construction of the new board machine at the Gruvön site and rebuilds in the existing pulp mill. The board machine’s annual capacity of 550,000 tonnes will make it one of the largest of its kind in the world. The machine will produce liquid packaging board, cartonboard, food service board and liner.

AFT is a global supplier specializing in recycled fiber stock preparation, screening, refining and paper machine approach flow. With over 110 years of experience in manufacturing and supplying tailored solutions, AFT helps to improve performance with trademarked advancements: Finebar- ultra low intensity refining, Powerwave- energy efficient screening, MaxiPulper- advanced pulping technologies, POM Systems and more.

AFT opens new manufacturing site in China

AFT Inc. has announced the opening of a new manufacturing facility in China -- Jiaxing AFT Manufacturing Co., Ltd. The facility is located in Zhejiang Province, west of Shanghai, on the Hangzhou Bay near an excellent transportation network of highways, railways, and shipping lanes.

AFT Inc. has announced the opening of a new manufacturing facility in China -- Jiaxing AFT Manufacturing Co., Ltd. The facility is located in Zhejiang Province, west of Shanghai, on the Hangzhou Bay near an excellent transportation network of highways, railways, and shipping lanes.

Jiaxing AFT Manufacturing will serve the dynamically growing pulp and paper market in China and joins the network of other AFT manufacturing centers in Canada, Finland, and South Korea.

Activities at the Chinese facility include the production of performance components (for screening and refining systems) as well as equipment rebuilds for screens, refiners and pulpers.

In addition to its performance components, AFT offers systems and equipment for fiber processing (virgin and recycled fiber) including screens, refiners, stock preparation, and paper machine approach flow.

According to company officials, the Chinese organization will be an area for investment over the next few years as capacity is added and capabilities of the site are expanded.

To support the new facility, a website www.aftzhongguo.com has been recently launched.

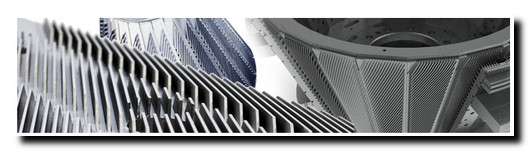

Refiner plate MiniSegment™ extends value, saves money for LC refining

AFT Finebar®, part of the global Aikawa Group, has developed the MiniSegment™ refiner plate – the latest advancement in diffusion bonded refiner plate technology. The MiniSegment allows mills to replace only the working surface of the refiner plate, reducing the overall cost of ownership.

AFT Finebar®, part of the global Aikawa Group, has developed the MiniSegment™ refiner plate – the latest advancement in diffusion bonded refiner plate technology. The MiniSegment allows mills to replace only the working surface of the refiner plate, reducing the overall cost of ownership.

The MiniSegment is installed on an Adapter Plate, which is bolted to the mounting surface using the existing refiner bolt holes. In addition to saving money by replacing only the fiber-contacting portion of the refiner plate, the MiniSegments weigh considerably less than a traditional plate, making them easy to position when bolting and safer to handle.

AFT Finebar MiniSegments can be applied to nearly any single disk, double disk, or Tridisk low consistency refiner.

Aikawa gathers forces to give papermakers a choice in stock preparation solutions

New organization under a single brand is driven by customer requests for alternatives to avoid being “boxed in” for key technologies

For many years, Aikawa Iron Works worked quietly to build its foundation as a premier supplier of stock preparation technologies in Japan. Its acquisitions of specialist companies such as AFT Screen Plates of Canada, Finebar of the USA, and POM Technology of Finland were conducted with little fanfare.

“Perhaps we have operated under-the-radar,” admits Masaki Aikawa, Chairman of the Aikawa Group. “But that has been our style. We put performance ahead of self-promotion.”

In pursuit of higher performance and recognition, the Aikawa Group is announcing a name change and a new, consolidated global organization. “This is in response to our customers’ requests,” Aikawa admits. “They want alternatives to the packaged offerings of the ‘Big Box’ major suppliers. They prefer the freedom to select the best single equipment, with the expertise to put systems together when required.”

The new organization is being consolidated outside of Japan under the umbrella of Aikawa Fiber Technologies (AFT), which is guided by Michael Stephens, President and a 35-year veteran of the pulp and paper industry.

Stephens says that AFT is being structured into teams to serve the three major customer groups for Aikawa outside Japan: screen manufacturers (original equipment manufacturers) who contract with AFT for manufacturing of screen cylinders, plates, and rotors; mills who order these engineered wear parts directly from the company; and mills looking for technical solutions for fiber processing, stock preparation, and machine approach applications.

“Each of these customer groups has unique needs that often times are addressed separately,” Stephens says. “But there are also occasions where customers need solutions that cross over from capital equipment to engineered wear parts to process/systems knowledge. When this happens, we don’t want to confuse our customers with separate interfaces or separate companies with different ways of working.”

According to Stephens, in the contract manufacturing segment, AFT produces more screen cylinders than any manufacturer in the world. Stephens explains, “Most of the OEMs are customers of ours and we give them preferred pricing based on volume. The focus here is on high-precision, low-cost manufacturing that is private-labeled for OEMs.”

The fiber processing and stock preparation solutions are a combination of Aikawa technologies and the technologies of the former POM Technology Oy of Finland, which Aikawa acquired. POM has a patented compact wet end technology for paper machines. Timo Koivisto, formerly the head of POM Technology, is responsible for AFT’s Process/Equipment Solutions team.

The transition from separate companies to a unified AFT organization is currently underway and will be completed by year’s end, according to Stephens. Key management decisions will be announced in the near future.

AFT makes major contribution to UBC's new LC refining research facility

A new low-consistency (LC) refiner system donated to the Pulp and Paper Centre at the University of British Columbia (UBC) was started up in August, marking another milestone in the University's research program to enhance paper quality and reduce energy consumption.

It also marked a milestone in what has been described as one of the longest industry/academic partnerships at the university (over 25 years), according to James Olson, a professor in the Mechanical Engineering Department at UBC and a member of the Advanced Papermaking Initiative.

Advanced Fiber Technologies (AFT) contributed the key process equipment to enable UBC to expand its capabilities in LC refining -- a technology that is now being exploited by the world's leading papermakers to significantly improve the energy efficiency of mechanical pulp production, according to Olson.

"We are now starting up the most state-of-the-art, university-based LC refining facility in the world," Olson says. "We are grateful to AFT for helping us move into this important research area."

A member of the Aikawa Group, AFT designs and manufactures screening components and Finebar® refiner plates for the worldwide pulp and paper industry. To UBC, the company donated a 16-inch Aikawa AWW single-disc LC refiner plus Finebar refiner plates to process a full range of hardwood, softwood, and recycled fibers.

The Natural Sciences and Engineering Research Council of Canada (NSERC) provided funding to purchase ancillary equipment and West Fraser Mills in British Columbia donated a 150 HP motor to drive the refiner.

"AFT has consistently contributed to R&D to fully understand the science of screening," says Dr. Robert Gooding, vice -president of technology at AFT. "This most recent contribution underscores our commitment to LC refining research."

Gooding explains that while LC refining remains essential to a wide range of papermaking applications, it has taken on a new level of importance for mechanical pulping due to its reduced energy requirements.

After a short "learning curve" to understand the complexities and nuances of the new facility, fundamental research and development will begin in earnest. The LC refining facility will allow UBC to test new ideas and concepts for pre-treatment, power reduction strategies, advanced controls, and the impact on paper surface qualities. "Of course, we will be eager to perform sponsored research for pulp product development to help the industry further improve its paper products," Olson says.

Gooding adds that AFT will also utilize the facility for fundamental research on plate geometries and power-gap relationships, as well as supporting customer trials.