Displaying items by tag: acelli

iDEAL® forged YD: another new-generation Yankee has been shipped

A further confirmation for the A.Celli Group after the presentation of the patent during the “iT’s Tissue 2018” event

At the end of last December, a new 15’ iDEAL® Forged YD was shipped to the customer PartexTissue Ltd, in Bangladesh.

The latest generation Yankee is an integral part of the project for a complete turnkey plant consisting of an iDEAL-1800 Tissue Machine, a E-WIND T100 rewinder with three unwinders and the A.Celli R-WAY roll handling system.

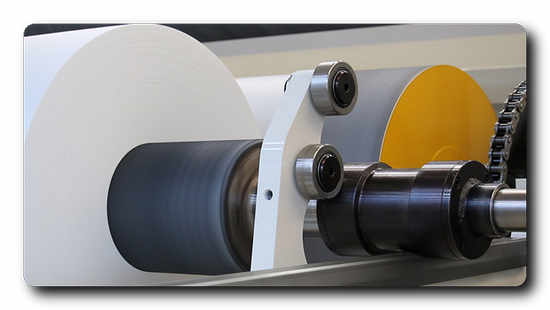

The customer has chosen a highly innovative A.Celli product, the iDEAL® forged YD, created using the new patented technology that involves the production of the dryer cylinder shell starting from a single piece of steel shaped and worked with forging and hot rolling systems.

From this particular process a homogeneous material is obtained; the unique seamless structure allows greater variation in operating pressure and definitively eliminate the risk of welding failures.

Innovation, safety, efficiency, the A.Celli Group’s basis of research.

A.Celli Paper and Global Hygiène for a turn-key tissue plant project

A.Celli Paper is pleased to begin a valuable collaboration with the French company for the supply of a complete tissue production plant.

Global Hygiène has chosen to rely on A.Celli Paper technology for the order of a complete turnkey plant to be installed in Charavines, in southeastern France.

The French company has secured the A.Celli technological excellence, from the stock preparation to the roll handling system.

The new iDEAL®1800S machine will have a 2850 mm format and an operating speed of 1800 mpm. The project also includes an E-WIND® T100 rewinder and a R-WAY® roll-handling system.

The Yankee supplied is the forged one of the latest A.Celli generation and has a diameter of 15’.

Luc Brami, CEO of Global Hygiène, said that the production of Charavines, estimated in 30.000 t/y, will cover the needs of the two Global Hygiène group’s converting plants, in Auxonne and Vern d’Anjou, consolidating the company’s leadership position in the market for hygienic products.

As usual A.Celli has given its total availability in experience and professionalism to the customer, with a full spirit of partnership.

The delivery is expected for the fourth quarter of 2019.

A.Celli Rebuilding: Shaniv Paper Industries Tissue Machine TM1 launched

In early October, the Customer Service team at A.Celli Paper launched the Tissue Machine TM1 of Shaniv Paper Industries Ltd, the second largest Israeli paper manufacturer for home use.

The operation consisted in the supply of a new reel, an innovative DCS system, a set of more efficient motors, renewed roller equipment and the relative drives. The dryer roller (Yankee Dryer) was also insulated by shielding the heads with a layer of coating.

The operation, completed by a team of qualified technicians, allowed the machine to reach the speed of 1500 mpm for the production of high quality tissue paper.

The ambitious project was carried out in full compliance with the client's expectations, which complimented the team of A.Celli Paper for the excellent work performed.

The technicians will also accompany the customer's operators during this first post-start phase, for a brief period of baby sitting based on the well-known spirit of partnership that has always distinguished the A.Celli Group.

A new A.Celli E-WIND® T80S rewinder for Fapajal

Portuguese Producer chooses A.Celli Paper for its new investment

It is with extreme satisfaction that A.Celli Paper S.p.A. announces the start of a precious collaboration with Fapajal – Fábrica De Papel Do Tojal, S.A. through the agreement for the supply of a latest-generation E-WIND® T80S rewinder for the production of tissue.

A.Celli Paper E-WIND® T80S is a modular and fully automated rewinder, running at 1000mpm, with built-in electrical cabinets, capable of managing products that involve a specific volume, diameter and cutting format while also guaranteeing extra capacity during production peaks.

It is customisable, plug-and-play, perfectly adaptable and compatible with any standard rewinding system or complete line in the tissue sector.

Yet another confirmation for A.Celli Paper technology that is even more present and is capable of meeting the needs of different customers, promptly answering the motley production variables with flexibility.

COMPANY PROFILE

Fapajal has a paper-making tradition dating back to 1755 and is currently focussed on producing tissue paper. Headquartered in São Julião do Tojal, Loures, the Company relies on the contribution of over 150 employees and approximately 50 outsourced employees.

A.Celli E-WIND® T80S: flexibility close at hand

A.Celli Paper presents a new rewinder of high production flexibility.

The two goals were to optimise production and increase line productivity.

Both have now been achieved, limiting investment to a minimum, with E-WIND® T80S: the new rewinder designed by A. Celli Paper to respond to these very needs.

A.Celli Paper E-WIND® T80S is a modular and fully automatic entry level rewinder, with built-in electrical cabinets, capable of managing products that involve a specific volume, diameter and cutting format while also guaranteeing extra capacity during production peaks.

It is customisable, plug-and-play, perfectly adaptable and compatible with any standard rewinding system or complete line in the tissue sector.

A.Celli Paper E-WIND® T80S: flexibility for everyone!

This email address is being protected from spambots. You need JavaScript enabled to view it.

E-WIND® T200: Further success of the new generation A.Celli Rewinders

Successful start-up of a new E-WIND® T200 rewinder by A.Celli Paper in Portugal

On September 3, the E-WIND® T200 was started-up at The Navigator Company plant in Cacia, in northern Portugal.

This rewinder, which manages rolls of 5670 mm on the unwinder, with diameters up to 3000 mm and for a weight of between 11 and 40 gsm, was designed to meet all of the customer's needs, ensuring excellent performance and a maximum operating speed of 1800 mpm.

The machine, equipped with a "Full Enclosure" dust removal system, is incorporated in a self-supporting aluminium and polycarbonate structure, which permits maximum containment and the relative reduction of dust deriving from unwinding, rewinding and cutting processes.

A long track record, a high level of expertise and close customer relations have once again made it possible for A.Celli Paper to develop an important partnership, this time with The Navigator Company

iDEAL® forged YD: the first new-generation Yankee has been shipped

Since the promotional launch and presentation during the "iT's Tissue" event, the A.Celli solution has gained more recognition than ever before

A.Celli Paper is pleased to announce the start of a series of supplies of the iDEAL® Forged_YD new generation Yankee.

Specifically, in this case, we are talking about valuable collaboration with the Mexican customer Blue Tissue S.A.P.I. de C.V., sealed with an agreement for the supply of an iDEAL® Forged_YD – 16" new generation Yankee Cylinder for the Apizaco plant, in the district of Tlaxcala, Mexico.

This extraordinary result is thanks to the investment strategy of A.Celli, aimed at increasing its influence in the tissue and paper sectors with the development of highly innovative technological solutions.

iDEAL® forged YD is the new production technology conceived and patented by A.Celli Paper, characterised by a cylinder with a shell made from a single piece of steel that is shaped and worked with hot forging and rolling systems.

The result is a highly innovative and seamless product that stands out for its exceptional quality of manufacture.

The uniform material and the unique structure, free from processing stress, allow for greater variation in operating pressure and definitively eliminate the risk of breakage.

A.Celli Paper iDEAL® forged YD: the future of Steel Yankee Dryers!

For more information, please contact us.

Solutions for complete turnkey systems

A.Celli Paper is pleased to announce its participation in the cycle of conferences of the twenty-fifth edition of the MIAC – International Exhibition of Paper Industry, which will be held in October 2018 (on the 10th, 11th and 12th) at the Lucca Fiere Exhibition Centre.

The company’s contribution to the MIAC TISSUE CONFERENCE – First Session, is titled “Turnkey Solution: A.Celli Paper’s answer for a more efficient production system“, and is scheduled to take place at 4:45 pm on October 10th, 2018. Anyone wishing to attend needs to pre-register through the official channels of MIAC 2018.

Daniele Checcacci (Head of Sales Capital at A.Celli Paper S.p.A.) will talk about A.Celli Paper’s solutions for complete turnkey systems: from the Tissue Ideal® machines to the E-WIND® rewinders and Roll Handling & Packaging systems R-Way®, for complete, optimised and customised management of the production process that allows the company to further strengthen relations with its esteemed customers.

A.Celli Paper will also be delighted to welcome you to stand 1 and show you the latest in its Research & Development, as well as the extensive range of services provided in the field of industrial automation – Industry 4.0

For any further information and/or to make an appointment at A.Celli’s stand, contact us This email address is being protected from spambots. You need JavaScript enabled to view it..

Successful start-up of the Yibin Paper TM2-iDEAL® Tissue Machine

The TM2-iDEAL® Tissue machine at Yibin Paper was successfully started-up on September 15, 2018, after an intense period of installation and commissioning. The TM2 is designed for a design speed of 1800m/min, an operating speed of 1600 m/min, and an untrimmed roll width of 2850 mm.

The scope of supply for the tissue machine consists of an Approach Flow system, acomplete set of Cresent Former tissue machines, a MCS control system, an Air system and a Dust Removal system.

The start-up and subsequent running-in all went smoothly. Yibin expressed great satisfaction with the result and were also very praising of A.Celli's professional work.

The TM2 which was successfully started-up was the first in a big order for five sets of iDEAL® Tissue machines. The remaining four sets are scheduled to be started up by the end of 2018.

By that time, the production capacity of tissue paper will be 120,000 tons/year.

YIBIN PAPER INDUSTRY CO. LTD COMPANY PROFILE

Yibin Paper Co.,Ltd. founded in 1944, which was formerly known as "China Paper Mill".

The main products include high-grade paper cup base paper (high bulk, medium bulk) and bamboo pulp board.

Yibin Paper New Zone has built a new 200,000 tons/year bamboo pulp production line, a 200,000 tons/year paper cup base paper production line and there is another production line of 120,000 tons/year of tissue paper to be built.

A.Celli Nonwovens & Fujian Nanfang textile for a project of great success

The first fully automatic plant installed at Fujiang Nanfang by A.Celli Nonwovens has been successfully commissioned.

The commissioning of the line on schedule is without doubt an important first step towards a close collaboration between A.Celli Nonwovens and this leading group.

The scope of supply is a Master Roll Winder, a Rewinder with Slittomatic® automatic knife positioning system, an Automatic Shaft Handling system and a fully automatic Roll Handling & Packaging system equipped with two robots.

The feather in the cap of this project is the innovative DSS (Defect Stop Management) system integrated with the Roll handling system for the segregation and removal of defects during the production cycle.

With this new supply, A.Celli Nonwovens has gone one step further in securing its success in China, and offers its client significant advantages in terms of quality and productivity of the line and conquering the Chinse market, which is of particular interest.

Fujian Nanfang Textile Co., Ltd. - Company Overview

Fujian Nanfang Textile Co., Ltd. manufactures and sells textile products in China. The company offers cotton yarns, cotton cloth, polyurethane (PU), leather fabrics, PU leather, and non-woven fabrics, as well as environmental filter materials and knitted fabrics. It is also involved in the provision of textile products technology services, as well as the import and export of textile accessories and textile products. The company is based in Nanping, China.