Displaying items by tag: voith paper

Magma and MagmaHigh: New Dryer Fabrics from Voith for the High-temperature Range

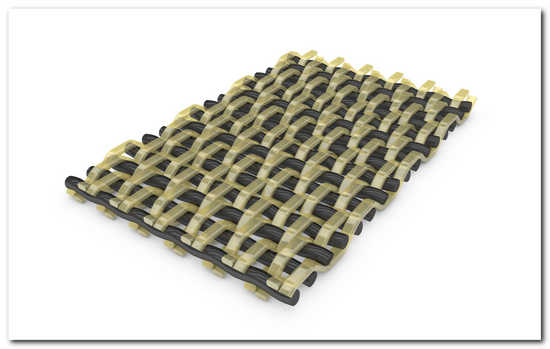

Voith has enhanced its CleanWeave product range with the new Magma and MagmaHigh dryer fabrics. Magma dryer fabrics are made from hydrolysis-resistant PPS which ensures performance in the hottest dryer positions.

- Heat-resistant material for high-temperature ranges

- Clean machine run due to proven weave pattern

- Predictable servicing schedule for cost-efficient operation

Extreme temperatures in some paper machines put dryer fabrics under severe stress and call for special material properties. Hydrolysis-resistant PPS reduces the stress on the fabric, allows service intervals to be properly planned and thus prevents unscheduled machine downtimes. Moreover, both Magma and MagmaHigh use the weave pattern that has already proven effective in the CleanWeave product range. The weave structure features industry low internal void volume, which significantly reduces dirt within the fabric. Due to its relatively low number of yarn crossover points, this compact weave pattern makes surface cleaning easier and ensures constant air permeability. This guarantees that the fabric maintains its air permeability for optimum drying and web running properties over its entire service life.

The superior reliability of Magma and MagmaHigh dryer fabrics makes planning easier and ultimately leads to more efficient and economic paper machine operation. As well as the dryer fabrics, Voith offers excellent service support and associated consultancy services.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

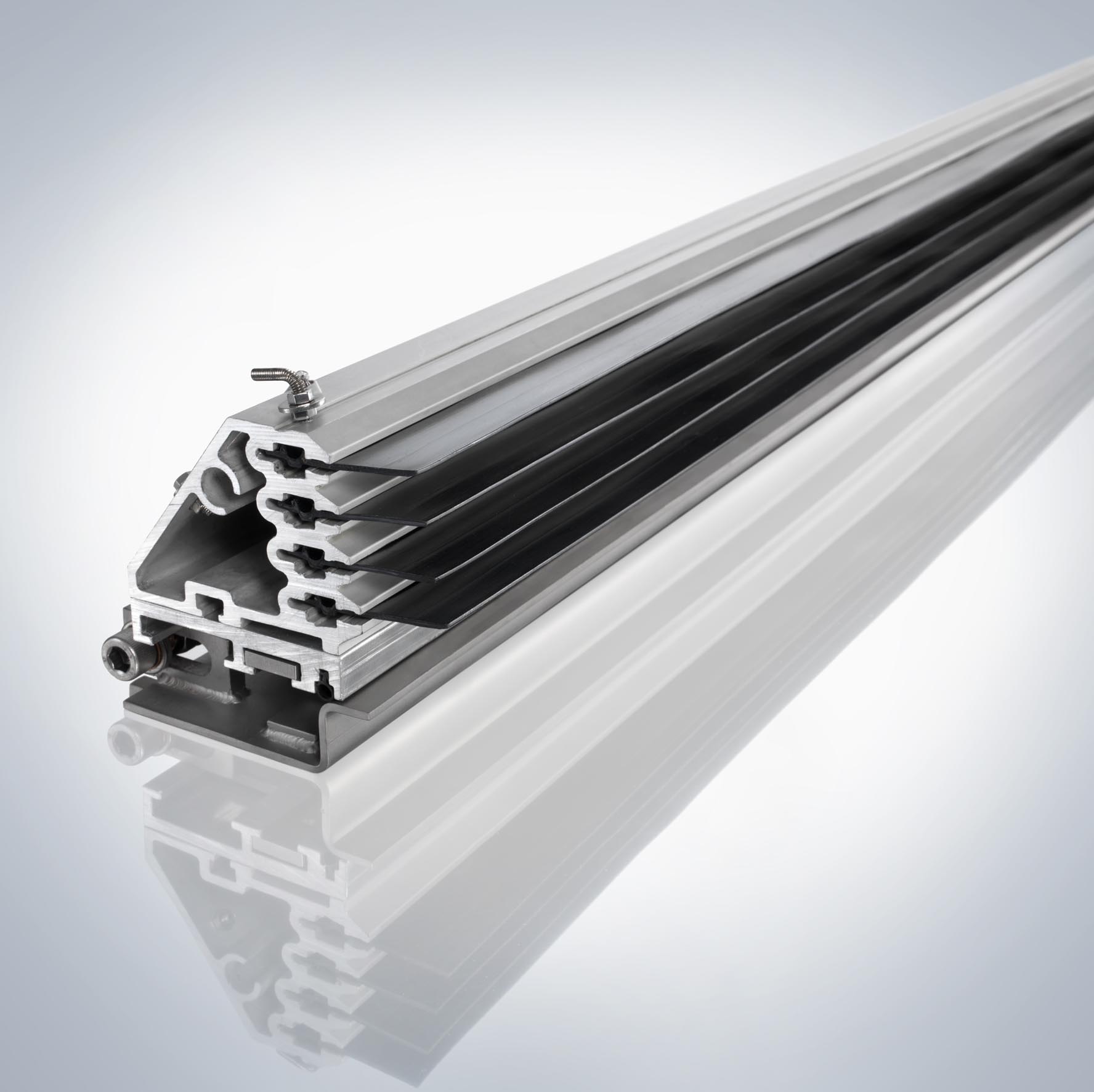

New sealing technology from Voith: upgrade for ProRelease+

Voith’s new MultiSeal Plus sealing technology improves processes in the dryer section of paper machines. Thanks to a shorter high-vacuum zone, the fabric deflection is significantly reduced and fabric wear is decreased. In addition, the adjustable SkySeal Plus sealing strips consistently optimize fabric runs and extend maintenance intervals. The entire sealing technology upgrades the web stabilization system ProRelease+ and results in better performance and an increase in machine speed.

- Reduced fabric wear thanks to minimized deflection

- Faster production speeds through an optimized vacuum zone

- Greater durability of sealing strips and easier servicing

The MultiSeal Plus is the carrier system for the SkySeal sealing strips. A key innovation is the horizontal adjustability of the new strips, which can be re-adjusted by up to 12 millimeter depending on the amount of wear. As a result, the correct distance between fabric and sealing system is guaranteed at all times. The SkySeal is available in two models with different hardness levels, which makes it easier to accommodate the characteristics and requirements of the respective paper machine. As a result the sealing strips suffer less abrasion.

The MultiSeal Plus carrier systems can be adjusted to provide an optimum seal of the release zones in the ProRelease+ sealing systems. Thanks to the new technology, the high-vacuum zone can be shortened overall. This results in an increase in runnability and reduced energy costs. The entire upgrade for ProRelease+ should be suitable for all fast-running paper machines.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

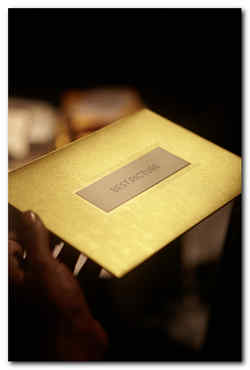

Voith and the Oscars® – a Short Story about the Night’s Glamorous Envelopes

Los Angeles. “And the Oscar goes to…“ – these magic words will once again make 24 movie stars very happy at the 88th presentation of the Academy Awards®. The famous stage at the Dolby Theater® will also feature a little piece of Voith, when the world’s entertainment industry is looking excitedly at the golden envelopes. Because the paper for the envelopes, which currently contain the presumably 24 best kept secrets of the film industry, originates from a paper machine made by Voith.

Gmund Treasury – this is the name of the award-worthy paper used for the Oscar® envelopes. Gmund Papier (Gmund Paper) produces the glamorous paper on its paper machine PM 407 from Voith. In 1979, the first high-quality papers made on PM 407 rolled off the production line at the Gmund paper makers. Voith originally built the machine for a Swiss paper manufacturer. After a rebuild, it was brought to Gmund at Lake Tegernsee, where it continues to make its special contribution to the Oscar® ceremony for the fifth time.

Gmund Treasury – this is the name of the award-worthy paper used for the Oscar® envelopes. Gmund Papier (Gmund Paper) produces the glamorous paper on its paper machine PM 407 from Voith. In 1979, the first high-quality papers made on PM 407 rolled off the production line at the Gmund paper makers. Voith originally built the machine for a Swiss paper manufacturer. After a rebuild, it was brought to Gmund at Lake Tegernsee, where it continues to make its special contribution to the Oscar® ceremony for the fifth time.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

Voith Paper Upgrades North American Roll Cover Plants with Investments in New Equipment and Technology

![]() Voith Paper, a long-time leader in roll covers and mechanical roll service for paper machines, has recently made significant investments in its North American roll cover facilities to support the manufacture of new products and ensure roll cover consistency and timely delivery.

Voith Paper, a long-time leader in roll covers and mechanical roll service for paper machines, has recently made significant investments in its North American roll cover facilities to support the manufacture of new products and ensure roll cover consistency and timely delivery.

Voith Paper has recently made significant investments in its North American roll cover facilities.

"We're continuously seeking to elevate the quality of our products and their performance on our customers' machines," said John Fox, President of Voith Paper North America. "To this end, we've introduced new technologies, upgraded equipment and made process improvement in all five of our North American roll cover plants."

Voith Paper's specific plant investments include:

- WebNet bonding technology incorporated into the polyurethane manufacturing process

- Technology installation and upgrades for polyurethane casting in cover manufacturing plants

- Installation of advanced work cells in all mechanical roll service plants

"By keeping our facilities on the leading edge in terms of technology and efficiency, we are able to improve value add and delivery time for our customers," Fox said.

Voith's Neenah roll covers plant continues to be the one-stop roll service center for the Midwest, providing rubber, poly, resin calender, resin press, ceramic/thermal spray cover manufacturing, as well as mechanical roll service. This facility offers a freight advantage to regional customers thanks to its breadth and depth of offerings.

In addition to Neenah, Voith Paper has roll cover plants in Springfield, Ore., West Monroe, La., Austell, Ga., and Hawkesbury, Ontario.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Contacts

Voith Paper

Terri Robinson, 001-252-265-4405

Liansheng BM 8 convinces with a stable and efficient first year of production

Stable and productive was the performance of the Voith supplied Liansheng BM 8 board machine during the first year at Fujian Liansheng Paper Industry Co., Ltd. in Zhangzhou, Fujian province, China. Convinced by the performance of the Liansheng BM 8, the Vice General Manager of Fujian Liansheng Paper Industry, Xue Rongjun, said, “Voith’s vast technological experience, high system efficiency and low operating costs are quite attractive.”

The remarkably smooth cooperation between Voith and Fujian Liansheng Paper Industry resulted in planned daily production being reached less than two months after start-up. Furthermore, daily production has continued to exceed expectations.

With a 7,300 mm wire width and 1,100 m/min design speed, the Liansheng BM 8 produces White Lined Chipboard in a basis weight range of 200 to 450 g/m² and coated White Top Testliner from 175 to 200 g/m². The yearly production will reach 700,000 tons.

With the advantage of Voith’s DF Coat curtain coating technology, which allows that virgin fibers can be replaced by secondary fibers for the coating layer, the BM 8 can produce board and packaging paper grades from 100% secondary fibers. This will help to achieve Fujian Liansheng Industry’s aims for recycling, resource conservation and sustainable development. At the same time, Voith has improved production properties so that whiteness and optical properties can be optimized as required with a much smoother surface.

Voith also delivered an automation package including the Machine Control System (MCS) and the Quality Control System (QCS). Also included in the scope of supply after start-up were fabrics, services for training, and technological support.

The Fujian Liansheng Paper Industry Co., Ltd. was founded in 2005 and is located in Fujian, China. The paper manufacturer produces 2,000,000 tons of board and different paper grades annually for the Chinese market.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Pyrox and PyroxHigh: Voith launches new dryer fabrics onto the market

With Pyrox and PyroxHigh Voith is launching two new heat-resistant dryer fabrics onto the market. They are part of the CleanWeave family of dryer fabrics and were especially designed for dryer sections with moderately high temperatures. Pyrox fabrics are made from a blend of hydrolysis resistant PPS and abrasion resistant PET materials. Like the entire CleanWeave product family, Pyrox and PyroxHigh is produced from SynStron yarn, a material developed by Voith that is especially suited for the challenging conditions of the dryer section.

The proven weave structure of CleanWeave dryer fabrics is incorporated in Pyrox and PyroxHigh. It offers a low internal void volume and minimal yarn crossover points, ensuring contamination within the fabric to be reduced. The compact fabric structure simplifies cleaning of the surface to ensure constant permeability. All CleanWeave products from Voith have a stable, easy-to-clean fabric structure which is unique in the industry. This ensures that the fabric maintains close to its original air permeability, maximizing drying and sheet handling over its entire service life.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

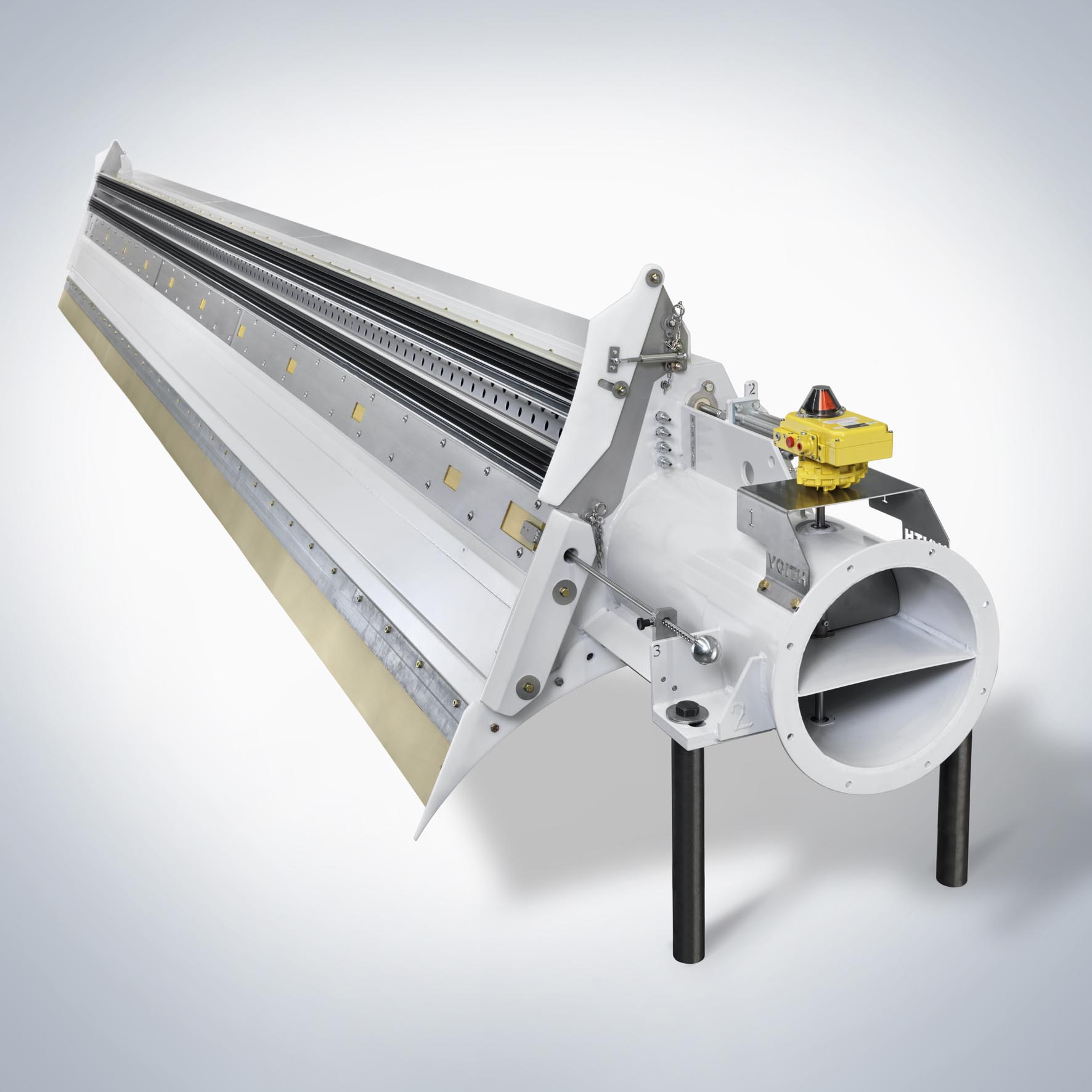

New screen element from Voith: SplitScreen substantially simplifies screw press maintenance

Voith has brought to market a new screen element for the screw press. SplitScreen is the first screen element consisting of a supporting structure and a screen plate, enabling maintenance and inspection time to be significantly reduced compared with conventional cylindrical screen baskets. In addition, investment costs over the lifetime of the screw press are much lower than for conventional screen elements.

SplitScreen comprises a split supporting body with two removable screen plates instead of one cylindrical basket. This design enables direct access to the individual screw press components without having to dismantle it completely. Whereas with previous technologies the entire press screw including screen baskets had to be lifted out using an indoor crane to get to the cylindrical screen elements, SplitScreen allows the top half of the SplitScreen to be disconnected after lifting the hood to check the condition of the plate. If the screen plate, which is a wearing part, does actually need to be replaced the lower half can also simply be turned to the top. This then gives easy access to exchange the upper and lower screen plates. At the same time this makes the press screw accessible for inspection.

With SplitScreen, the time necessary for replacing a screen element is only three to four hours instead of the average 24 to 48 hours that were previously needed. Moreover, procurement costs can be cut up to 40 percent per year after first installation, as in the event of wear only the screen plate and not the entire SplitScreen has to be changed. The large, open design of the screen area also helps improve the dewatering efficiency of the screw press.

SplitScreen is a standard feature of Voith's new InfiltraScrewpress. All conventional screen elements of Voith’s Thune screw press as well as screw presses from other manufacturers can be converted to SplitScreen.

The new screen element has already been successfully installed more than a dozen times worldwide and has also been retrofitted to conventional screw presses six times to date. The product is proving effective in the field and customers that have installed SplitScreen are very satisfied with its performance.

SplitScreen is a component of Voith’s BlueLine product range that has been developed for stock preparation. BlueLine products are known for their low consumption of energy, fibers and water.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Voith Paper plans to bundle European activities

The significantly reduced market volume for new machines and major rebuilds has resulted in a difficult situation at Voith Paper, especially in the projects business. With this in mind, the Management Board of Voith Paper today presented a plan for a package of measures, which is intended to adapt the company's European structure to the market conditions.

The significantly reduced market volume for new machines and major rebuilds has resulted in a difficult situation at Voith Paper, especially in the projects business. With this in mind, the Management Board of Voith Paper today presented a plan for a package of measures, which is intended to adapt the company's European structure to the market conditions.

- Long-term diminished market volume for new machines and major rebuilds

- Concentration of the paper machine business in Heidenheim and stock preparation in Ravensburg planned

- Goal is a lean, customer-focused organization

- Planned reduction of approximately 1,000 jobs worldwide

“The market volume for new systems has shrunk in half. This is going to stay that way, which means that revenues from this market will not be coming back,” says Voith Paper CEO Bertram Staudenmaier. “The consequences for our new machines and rebuilds business are significant. In this much smaller market, we are faced with strong competition and price pressure. The decline in order volume in recent years has had a very strong effect on capacity utilization, sales, and profits. Therefore, we must adapt to the changed market conditions.”

Planned is a bundling of the European paper machine business in the Heidenheim location and the stock preparation activities in Ravensburg. This will be accompanied by the termination of the paper activities in St. Pölten, Austria (reduction of approximately 150 jobs) as well as the closure of the locations in Krefeld and Neuwied (with a reduction of approximately 200 jobs and a transfer of remaining activities to Heidenheim). Also planned is an adjustment of the capacities in Ravensburg (reduction of approximately 150 jobs) with a closure of the manufacturing currently located there. In the future, the Ravensburg location will be operated exclusively as a competence center for stock preparation and roll services. Also planned is a reduction of approximately 300 jobs at the Heidenheim location, which will also affect employees in manufacturing. Overall, the package of measures plans a global reduction of around 1,000 jobs at Voith Paper.

“This step is painful for everyone involved, but necessary in order for us to become a lean organization, especially in our projects business in Europe. We must be appropriate to the market volume and oriented towards the needs of our customers,” explains Bertram Staudenmaier.

The Management Board today informed the boards and employees of the affected locations about the plans. In the next step, Voith will hold discussions with the workers' representatives about the implementation of the reduction. The current plan expects the measures to be largely implemented by December 31, 2015.

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 39,000 employees and earns 5.3 billion euros in sales. It has locations in over 50 countries in all regions of the world and is one of the large family-owned companies in Europe.

Stora Enso: New DuoDry CC drying concept from Voith impresses in operation

DuoDry CC, the innovative drying concept from Voith, is for the first time successfully in operation. The DuoDry CC is delivered and installed in the Narew PM 5 at Stora Enso in Ostroleka, Poland. The concept impresses with its reduced curl formation caused by the drying process and lowers energy demand by increased runability of the paper machine.

CC stands for curl control and designates the latest technology for reducing curl in single-tier dryer sections, which have become especially popular on the market since the speeds of paper machines have increased. The advantage of single-tier design when compared to the two-tiered design is that the machine achieves improved runability. However, a disadvantage of the conventional single-tier design is that the paper tends to curl due to the one-sided drying.

DuoDry CC solves this problem with a smart concept that is as effective as it is simple – a vertically inverted single-tier dryer group that serves as the last group. Normally the paper web is sprayed with water on one side to fight curl. The web is dried again afterward through additional energy input. With DuoDry CC, by contrast, the thermal energy already required for drying the paper web is utilized by being fed into the inverted dryer group from the other side. Thus no additional energy is required for reducing curl. Use of this technology reduces the operating costs of the paper machine. The components used, such as web stabilizers and dryer cylinders, are products that have long been proven, which ensures the reliability of the system in operation.

Janne Myllykangas, PM area manager at Stora Enso, confirmed after the project was finalized: “The collaboration with Voith was very good. The trust formed during the negotiations has been confirmed in the execution. The decision in favor of the DuoDry CC drying system has also proved to be the right one. We are very satisfied with the performance of DuoDry CC in operation.”

The Narew PM 5 from Voith is equipped with a SpeedSizer and produces 455,000 metric tons of testliner and corrugating medium per year on a wire width of 8,600 mm.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith employs more than 43,000 people, generates € 5.7 billion in sales, operates in about 50 countries around the world and is today one of the biggest family-owned companies in Europe.

Reduced contamination: Innovative dryer fabrics from Voith

With Jade from the CleanWeave product line, Voith is bringing innovative dryer fabrics onto the market that translate reduced contamination to increased drying capacity due to their special design.

With Jade from the CleanWeave product line, Voith is bringing innovative dryer fabrics onto the market that translate reduced contamination to increased drying capacity due to their special design.

Jade dryer fabrics have minimal internal void volume and so carry significantly fewer deposits than conventional dryer fabrics. The high number of contact points and the flat yarns facilitate effective heat transfer and paper sheet handling. The compactness of the fabric structure makes both manual cleaning as well as on-line cleaning systems such as DuoCleaner Express from Voith more effective.

The SynStron yarn material used in Jade makes the dryer fabric especially effective in resisting fibrilation and so facilitates easy cleaning. Synstron is used in the entire CleanWeave product line and is noticeably more effective than conventional polyester yarns in resisting abrasion.

JadeHigh expands the product line with a more open surface ensuring stronger air flows for increased evaporation. Like all dryer fabrics in the CleanWeave product line, Jade and JadeHigh show measurable differences in their ability to maintain an easy clean structure which contribute to a more efficient drying process.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith employs more than 43,000 people, generates € 5.7 billion in sales, operates in about 50 countries around the world and is today one of the biggest family-owned companies in Europe.