Super User

ANDRITZ improves pulp mill performance at Mondi Frantschach, Austria

International technology group ANDRITZ has successfully improved performance of the pulp mill at Mondi Frantschach by implementing new advanced process controls.

The target was to reduce the variability of Kappa, an indication of the lignin content in the pulp, in order to run the process a step closer to its maximum specification limits. This measure leads to higher production efficiency in the mill because less wood is needed to produce the same amount of pulp.

As part of the optimization project, ANDRITZ Automation commissioned and fine-tuned three advanced process controls (APCs) in Mondi´s continuous cooking process. The controls implemented, including the chip level control for digester and impregnation vessel, the digester H-factor control (kinetic model for the rate of delignification in kraft pulping) and the blow-flow consistency control, were fully developed with Metris X – the distributed control system (DCS) developed by ANDRITZ Automation to simplify operational complexity, lower project risk, and improve plant performance. Metris X is a key application of the Metris UX Platform, a state-of-the-art digitalization platform that enables full functionality and support for industrial plants throughout their entire life cycle.

View of Mondi Frantschach’s continuous digester, where the optimization was performed © ANDRITZ

View of Mondi Frantschach’s continuous digester, where the optimization was performed © ANDRITZ

ANDRITZ’s scope of supply included the analysis of data correlated to Kappa, return of investment (ROI) calculations, an evaluation of the cooking process, instrumentation, and former Kappa control, performing of trials on the actual process, and the commissioning, start-up and fine-tuning of an advanced process control solution for Kappa stabilization.

The solution delivered proved better than the former system in all instances, showing that ANDRITZ Automation is capable of delivering the results promised.

Mondi Frantschach would like to point out that the fruitful working cooperation between the Mondi Frantschach team and ANDRITZ Automation was a key factor in this great achievement of further improving the complex kraft pulping process.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ AUTOMATION

ANDRITZ Automation covers the entire project life cycle of the plant. Starting with project management, hardware and software development, through installation works, commissioning, and operator training, to maintenance and design work for extensions and improvements. With the Metris technology brand, ANDRITZ Automation offers a wide range of digitization products that customers can use individually and in combinations for their own essential and sustainable benefit. The proprietary Metris UX platform adds significant value to the planning, operation, asset management, maintenance, and optimization of production plants and the associated supply chains. The division has around 2,000 employees and is active in over 100 locations.

Valmet signs an extensive distributed control systems and digitalization development agreement with Mercer International

Mercer International and Valmet have signed a long-term agreement to accelerate Mercer’s global digital transformation program. The implementation of the agreement starts with the replacement of distributed control systems (DCS) at the Mercer Peace River pulp mill in Alberta and the Mercer Celgar pulp mill in British Columbia, Canada with the Valmet DNA Automation System.

Valmet DNA is a single automation system for process, machine, drives and quality controls. Its intuitive user interface makes the most meaningful information available to users based on their roles – regardless of their location, enabling collaboration and real-time performance optimization based on data analytics anywhere and anytime.

“We wanted a partner that can provide a strong DCS solution but at the same time help improve our performance through better data utilization, improved internal benchmarking and collaboration across all our sites. We chose Valmet because of their expertise in pulp combined with extensive automation offering and strong digitalization capabilities,” says Christoph Grewe-Franze, CIO, Mercer International.

Valmet DNA’s new user interface enables real-time performance optimization and collaboration between different user groups regardless of their location.

Valmet DNA’s new user interface enables real-time performance optimization and collaboration between different user groups regardless of their location.

Mercer will benefit from better and connected DCS data communication and analysis of real-time performance across all their operations. This will improve diagnostics and troubleshooting while reducing redundancies and downtime. A solid foundation for advanced data utilization with integrated industrial internet connectivity, global collaboration, operational consistency and continuity will be realized.

“We are happy to continue our long-time collaboration with Mercer International with this significant agreement. We have a full automation and digitalization offering to manage and optimize processes, including cloud connectivity, analytical applications, and full support both locally and remotely to serve the needs of our customers in various industries. We are delighted to build these capabilities together with Mercer to increase their competitiveness,” says Sami Riekkola, President, Automation business line, Valmet.

About Mercer

Mercer International Inc., is a diversified global producer of forest products, bioproducts, and green electricity with operations in Germany, Canada, the United States, and Australia with a consolidated annual production capacity of approximately 2.2 million tonnes of kraft pulp and 550 million board feet of softwood lumber.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Intesa Sanpaolo and SACE support sustainable development of Lucart

Lucart, one of the most important European paper groups, known for, among other things, the brands Tenderly, Grazie Natural and Tutto Pannocarta, and Intesa Sanpaolo have signed a financing agreement for an amount of 10 million euros backed by a SACE Green Guarantee.

The financing is aimed at supporting Lucart Group's growth and development plan from an ESG (Environmental, Social and Governance) and circular economy perspective. The credit facility has a pricing mechanism linked to the achievement of specific sustainability targets. These objectives include, on the one hand, completion of the Castelnuovo di Garfagnana (LU) production line, which will enable the company to increase its use of alternative packaging, and, on the other, greater recovery of Tetra Pak® type poly-coupled food cartons at the Diecimo (LU) plant.

The transaction was concluded by Intesa Sanpaolo's IMI Corporate & Investment Banking Division, led by Mauro Micillo with the support of the Circular Economy Desk of Intesa Sanpaolo Innovation Centre, a company dedicated to innovation and to the spread of circular economy.

The transaction was concluded by Intesa Sanpaolo's IMI Corporate & Investment Banking Division, led by Mauro Micillo with the support of the Circular Economy Desk of Intesa Sanpaolo Innovation Centre, a company dedicated to innovation and to the spread of circular economy.

The financing is part of Lucart Group's strategy, which for years has adopted a sustainable development model aimed at optimising the use of raw materials and reducing waste by transforming it into new resources, in line with the principles of circular economy. Lucart is in fact the only tissue mill capable of recovering all the components of beverage cartons: both the fibrous part, which is converted into paper products of the Natural lines, and the aluminium and polyethylene part, converted into other objects such as pallets for transporting goods.

Thanks to their positive impact in terms of mitigating climate change, the financed projects meet the objectives of the Green New Deal, the plan for a modern, circular, sustainable and resilient Europe. In this context, SACE plays a central role in the implementation of the Green New Deal in Italian territory, as envisaged by the "Simplification" Decree Law of July 2020 (76/2020). The company led by Pierfrancesco Latini, can now issue “green guarantees” for domestic projects that encourage the transition to an economy with a lower environmental impact, integrate production cycles with low-emission technologies for the production of sustainable goods and services and promote initiatives aimed at developing new and greener modes of transport. Since the entry into force of the Decree, a team of specialists has been set up across the various corporate functions, encompassing different and complementary professional skills, capable of responding comprehensively to the needs of these new SACE operations. The deal in support of Lucart was concluded thanks to the commitment of the Florence office, one of SACE's 14 local offices in Italy, and the Green Task Force, set up to respond to the needs of the new operations linked to the Green New Deal.

"Lucart Group is a top Italian and international player that has embraced environmental sustainability issues for a some time," commented Richard Zatta, Head of Global Corporate at Intesa Sanpaolo's IMI Corporate & Investment Banking Division. "This transaction confirms Intesa Sanpaolo's commitment to boosting and concretely supporting the Green and Circular Economy by sustaining the development plans of companies in this area".

"We are proud," stressed Mario Bruni, Head of Mid Corporate at SACE, "to continue to support the growth of a key player like Lucart and to work alongside it in its sustainable development plans. With our involvement, the company will be able to pursue important objectives of environmental protection and circular economy in line with the objectives of the NRRP. SACE thus continues to play a leading role in Italy's ecological transition".

"We are very pleased with the support that Sace and Intesa Sanpaolo will be giving our projects. Their commitment to the sustainable economy dovetails perfectly with our dedication to applying circular business models through a strategic plan to increase the recovery of raw materials to 60%," commented Andrea Fano, Chief Financial Officer of Lucart Group. "Another important goal is to get to 100% recycled and/or compostable packaging by 2030, on all our production lines".

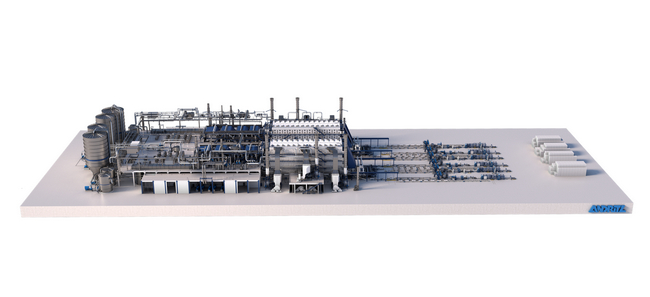

ANDRITZ pulp drying lines at Bracell’s “STAR” project, Brazil, achieve new production world records

The pulp drying plant at Bracell’s “STAR” project in Lençóis Paulista, São Paulo, consisting of two identical pulp drying lines (L2A and L2B) supplied by ANDRITZ, has achieved new production world records.

On December 18, 2021, the L2A pulp drying line reached a total output of 4,672.5 air dry tons per day, which is a production world record on a single line. In terms of specific drying capacity, this corresponds to 456 tons per day and meter of working width produced on an ANDRITZ drying line for a sheet width of 10.24 meters.

Moreover, on December 18, 2021, the L2A and L2B pulp drying lines achieved a total of 8,897.4 air dry tons per day on both lines together, which is a new mill-wide capacity world record.

ANDRITZ pulp drying plant at Bracell’s “STAR” project, Brazil, achieves new production world record © ANDRITZ

ANDRITZ pulp drying plant at Bracell’s “STAR” project, Brazil, achieves new production world record © ANDRITZ

Both records were set during the first four months after start-up. This impressive performance was made possible by ANDRITZ’s leading and proven EvoDry pulp drying system, whose energy-efficient pulp drying is based on the high-capacity Twin Wire Former technology, includes airborne dryers, cutter-layboy and baling lines, and is equipped with the Metris DryQ smart pulp drying solution.

Bracell’s “STAR” project at the mill in Lençóis Paulista is one of the largest and most sustainable pulp mills in the world, meeting the highest environmental standards. It features two flexible, environmentally friendly hardwood fiberlines for a capacity of 2.6 to 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp made from sustainably cultivated eucalyptus.

These outstanding results are based on the combination of customer and supplier partnership, good plant management and technology as well as excellent planning and implementation.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient, and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

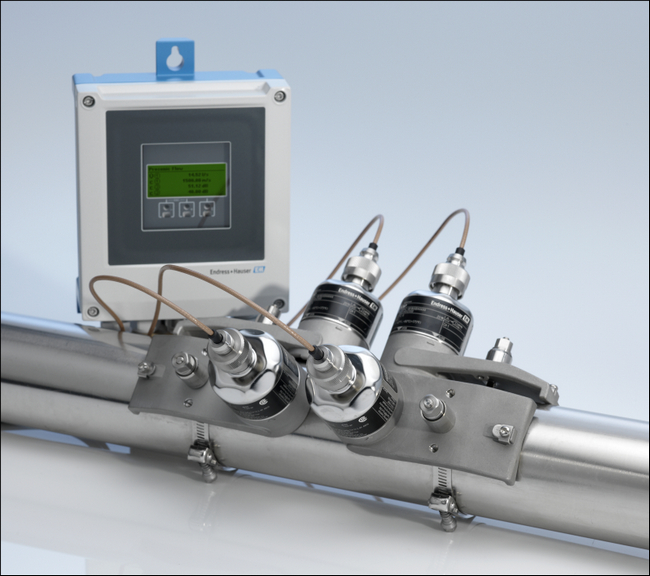

Endress+Hauser launches advanced clamp-on flowmeter unit for water, wastewater, and other process industry applications.

Proline Prosonic Flow W 400 provides a reliable liquid flow solution with ease of installation and user-friendliness for a variety of liquid measurement applications.

Prosonic Flow W 400 brings the modern technology of Endress+Hauser’s Proline device series to clamp-on ultrasonic flowmeters. The W 400 clamp-on and I 400 insertion units provide comprehensive process monitoring with long-term cost efficiency and extensive diagnostics. These sensors pair with Endress+Hauser’s Proline 400 transmitter to provide a complete flow metering solution.

For decades, users in many process industries have turned to ultrasonic clamp-on instruments for convenient flow measurement. This trend continues, but with growing requirements for instrument data. Prosonic Flow W 400 addresses this and other issues by providing reliable measurements of process parameters, along with a host of additional information.

The flowmeter uses a nonintrusive, clamp-on measurement method, with its ultrasonic sensors mounted directly on a pipe’s exterior. This provides safe measurement of many fluids, independent of their conductivity or other properties. This includes corrosive, abrasive, and toxic fluids, making this flowmeter ideal for monitoring countless processes.

Because neither piping nor process flow are interrupted, clamp-on flowmeters can be easily used for retrofitting at any time. They are suitable for low- or high-pressure applications, on pipes smaller than an inch in diameter, and up to 160 inches, such as those encountered in water distribution.

This size range illustrates the Prosonic Flow W 400 measurement solution’s versatility. It can be used to measure flow, monitor processes, verify previously installed flowmeters, detect leaks in a pipeline, and for other applications.

The flowmeter’s IP68 Type 6P submergence-rated ultrasonic sensors provide long-term and reliable operation, requiring little maintenance. This makes them suitable for use in harsh process and ambient conditions, able to withstand temperatures from –40 to +266 °F.

Web server eases installation and operation

The Proline 400 transmitter includes a built-in web server, so users can access process, diagnostic, configuration, and other instrument data via any device capable of hosting a web browser, such as a laptop, smartphone, or tablet.

The transmitter provides targeted parameterization of measuring points, and it saves time during commissioning, maintenance, and service. Its LCD display and web-based operating tool each show real-time measurement quality—good, acceptable, or bad—to provide key status information at a glance.

FlowDC function for high performance despite flow disturbance

Piping systems in the process industry often have multiple fittings and elbows that disturb the flow profile and, along with it, the accuracy of ultrasonic flow measurement. The Prosonic Flow W 400 solution is optionally available with Endress+Hauser’s FlowDC function, which detects and corrects for the effects of flow disturbance. This ensures measurement accuracy even in the presence of a short pipe inlet run, for example when significantly reduced from the standard 15 pipe diameters down to two. The FlowDC function increases flexibility for equipping new or retrofitted systems with clamp-on flowmeters.

Heartbeat Technology increases measurement integrity

Heartbeat Technology—a testing function integrated into all Endress+Hauser Proline measuring devices—provides instrumentation self-diagnostics, along with traceable measurement verification during operation. This technology monitors for changes to the instrument electronics and sensors caused by extreme environmental or process conditions, increasing measurement integrity.

Fit for almost any application

Prosonic Flow W 400 can be mounted on a wide variety of pipe types and materials with or without lining, including metal—e.g., steel or cast iron—plastic, glass-fiber-reinforced plastic, and composite materials. A maintenance-free contact medium, called a coupling pad, provides optimum sound transmission between sensor surface and the pipe, and the resulting high signal strength ensures stable measurement results and long-term reliability. These clamp-on flow sensors are available in multiple ultrasonic frequencies ranging from 0.3 to 5 MHz, optimized for application pipe size, pipe material, and fluid.

For more information, please go to: https://eh.digital/3Kljyuf and https://eh.digital/3furcnJ

The Endress+Hauser Group

Endress+Hauser is a global leader in measurement and automation technology for process and laboratory applications. The family company, headquartered in Reinach, Switzerland, achieved net sales of over 2.6 billion euros (2.89 billion U.S. dollars) in 2020 with a total workforce of 14,000.

Endress+Hauser devices, solutions and services are at home in many industries, enabling their customers to gain valuable knowledge from their applications, to improve their products, to work economically, and to protect people and the environment.

Endress+Hauser is a reliable partner worldwide, with sales companies in 50 countries and representatives in an additional 70 countries to ensure customer support. Production facilities on four continents manufacture quickly and flexibly to the highest quality standards.

Endress+Hauser was founded in 1953 by Georg H. Endress and Ludwig Hauser. Ever since, the company has been pushing ahead with the development and use of innovative technologies, now helping to shape the industry’s digital transformation. 8,000 patents and applications protect the Group’s intellectual property.

S.TO.R.I. celebrates 50th anniversary with ten-year growth trend.

In 2021 S.TO.R.I. confirmed a ten-year growth trend during which its turnover increased by more than 25%. This result comes on the fiftieth anniversary of S.TO.R.I.’s foundation in 1972.

Owned by Toscotec, a Voith company, S.TO.R.I. is located at Toscotec’s headquarters in Lucca (Italy) and specializes in rolls maintenance services for paper and converting machines of the tissue and paper industry. Its service offer includes predictive and preventive maintenance, press roll refurbishing up to a complete rebuild, grinding, dynamic balancing, upgrade installations, non-destructive examinations, and spare parts supply.

Lorenzo Iacopi, Production Manager of S.TO.R.I., says: “In 2021 we made important investments in new machinery for crown measurement, dynamic balancing, and run tests with the aim to continue delivering state-of-the-art services to our customer base. This year, we will be able to perform run tests on cylinders to verify their working conditions while simulating the actual operating conditions of the paper machine. We have strengthened our offer with complete services packages inclusive of inspection, repairs and overhaul of press rolls and other rolls, so that paper mills can rely on accurate planning to increase their OEE and avoid unscheduled maintenance stops.”

For further information, please contact:

Lorenzo Iacopi, Production Manager, S.TO.R.I. s.r.l., This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet to supply a board machine rebuild to increase production capacity at Stora Enso’s Skoghall mill in Sweden

Valmet will supply a board machine rebuild to Stora Enso’s Skoghall mill in Sweden. The main goal of the project is to increase the production capacity of the board machine 8 (BM 8). The two-step project is planned to be completed at the second half of 2023.

The order is included in Valmet's orders received of the fourth quarter 2021. The value of the order will not be disclosed. The total value of an order of this type and delivery scope is typically around EUR 30-40 million.

In October 2021, Stora Enso announced the investment to expand the board production at Skoghall. Following the investment, the annual packaging board production at Skoghall can be increased by approximately 100,000 tonnes, to a total capacity of the mill exceeding 900,000 tonnes, subject to environmental permits. The project will be implemented through debottlenecking of one of the existing production lines, and executed in two steps, utilizing the scheduled maintenance breaks.

In October 2021, Stora Enso announced the investment to expand the board production at Skoghall. Following the investment, the annual packaging board production at Skoghall can be increased by approximately 100,000 tonnes, to a total capacity of the mill exceeding 900,000 tonnes, subject to environmental permits. The project will be implemented through debottlenecking of one of the existing production lines, and executed in two steps, utilizing the scheduled maintenance breaks.

“The investment strengthens Stora Enso’s capability to produce high-quality and cost-competitive consumer board grades within the growing core segments of liquid and food packaging,” says Marie Morin, Mill Director, Stora Enso’s Skoghall Mill.

“We have developed the BM 8 at Skoghall with Stora Enso for a long time; Valmet completed a forming section rebuild with several steps at the same machine line in 2017-2020. We are happy to continue our cooperation in this project,” says Per Holm, Vice President, Sales, Scandinavia, Valmet.

Valmet’s delivery in the two-step project will include upgrades in the stock preparation system and multiple improvements in several parts of the board machine. All the machines and equipment included in Valmet’s delivery will be delivered installed.

About the customer Stora Enso

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. Stora Enso believes that everything that is made from fossil-based materials today can be made from a tree tomorrow, and it has some 23,000 employees, and sales in over 50 countries. Stora Enso’s Skoghall site in western Sweden is a modern, world-class producer of consumer packaging board, for liquid packaging and dry food packaging. Total annual production currently exceeds 800,000 tonnes of board.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

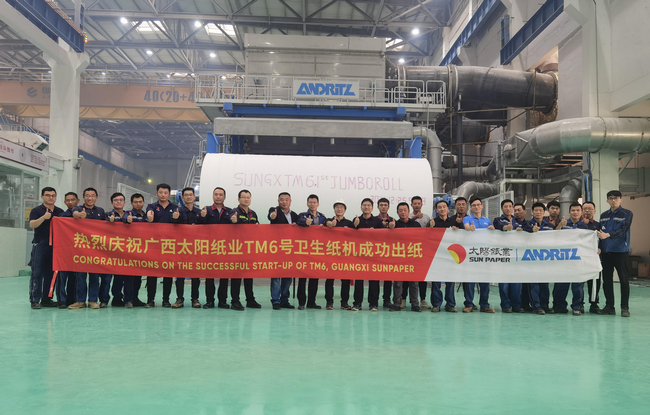

ANDRITZ successfully starts up the second of two tissue machines delivered to Guangxi Sun Paper, China

On December 25, 2021, international technology group ANDRITZ successfully started up the second of two PrimeLineTM W 2000 tissue machines delivered to Guangxi Sun Paper, China, for its mill in Beihai City, Guangxi Province.

The tissue machine (TM6) has a design speed of 2,000 m/min, a working width of 5.65 m and a capacity of 60,000 t/a, and it is equipped with energy-saving components (steel Yankee with head insulation, heat recovery system, Yankee Ecosteam system for re-evaporation). Forming fabrics and press felts by ANDRITZ Fabrics and Rolls were installed for optimum end-product quality.

Like the TM5 order, the scope of supply also included FibreSolve FSV pulpers, the paper machine approach flow systems, broke handling and fiber recovery, and automation systems.

Successful start-up of the PrimeLineTM tissue machine TM6 at Guangxi Sun Paper, China © ANDRITZ

Successful start-up of the PrimeLineTM tissue machine TM6 at Guangxi Sun Paper, China © ANDRITZ

Guangxi Sun Paper is part of the Sun Paper Group. It was founded in 2019 with the aim of establishing an integrated pulp and paper mill in Beihai City. The new greenfield mill will presumably have a total pulp and paper capacity of 3.5 million t/year and will be built in two phases over approximately four years. With this start-up, Sun Paper now has four ANDRITZ PrimeLine tissue machines successfully in operation.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up leading technologies for Klabin’s EukalinerTM brown pulp mill in Brazil

International technology group ANDRITZ has successfully started up state-of-the-art and environmentally leading pulp production and chemical recovery technologies for Klabin’s Puma II line in Ortigueira, Paraná, Brazil.

Pablo Cadaval, General Mill Manager of Klabin’s Puma Unit, says: “We are very satisfied with the way we were able to manage and finish the project and start our key equipment for the Puma II line together with ANDRITZ, despite the hardships of the COVID-19 pandemic.”

The ANDRITZ scope of supply included:

- A wood processing plant with debarking and chipping line, which can process both eucalyptus (350 m3 sob/h) and pine (400 m3 sob/h), meaning that a log truckload of wood is emptied onto the line every ten minutes.

- The HERBTM recovery boiler from ANDRITZ, which has a capacity of 3,300 tds/d with high steam parameters of 103 bar(a) and 502°C to maximize power generation. It is equipped with the autonomous Smart sootblowing control solution that combines Smart sensors (HEWI) and controls to ensure the cleanability period, a higher availability of the boiler, as well as greater operating safety.

- A power boiler based on ANDRITZ EcoFluid bubbling fluidized bed (BFB) technology with a steam production capacity of 220 t/h. It is combined with the recovery boiler to form a “boiler island”, and some of the auxiliary equipment is shared between the two boilers. This provides savings in investment and operating costs.

- A complete white liquor plant consisting of a recausticizing plant (5,000 m3/d) and an ANDRITZ LimeKiln (450 t/d) with a multi-fuel burner.

The new power boiler combined with the recovery boiler form a “boiler island”, providing savings in investment and operating costs. © ANDRITZ

The new power boiler combined with the recovery boiler form a “boiler island”, providing savings in investment and operating costs. © ANDRITZ

The excellent business relationship between ANDRITZ and Klabin was once again confirmed when the Puma II EukalinerTM production line started up successfully during the fourth quarter of 2021, almost on schedule regardless of the worldwide pandemic.

Francisco Razzolini, Klabin's Director of Industrial Technology, Innovation and Sustainability, says: "Klabin, along with its partners, has extensive expertise in creating solutions that contribute to the processes of pulp and packaging paper production. ANDRITZ is one of the great examples, which – besides being fundamental to the entire production area – also proves to be a reference in optimizing processes, with cutting-edge technology."

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

About KLABIN

Klabin is Brazil’s largest producer and exporter of packaging paper, the only company in the country to offer one-stop shop solutions in hardwood, softwood and fluff pulp, as well as the leader in the corrugated board packaging and industrial bags markets. Founded in 1899, it has 24 industrial units in Brazil and one in Argentina.

Its entire management is guided by sustainable development, pursuing integrated and responsible growth that combines profitability, social development and environmental commitment. Since 2014, Klabin has been a part of the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (B3), and in 2020, it was included in two portfolios of the Down Jones Sustainability Index: the World Index and the Emerging Markets Index. As a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, Klabin seeks suppliers and business partners who share its values of ethics, transparency and respect for the principles of sustainability.

A.Celli starts up a complete turnkey Tissue plant at Partex Star Group in Bangladesh

A.Celli Paper successfully started up in December 2021 the turnkey Tissue plant supplied to Partex Star Group.

The line, installed for the production of bulky and soft Tissue with high levels of absorbency, includes a low-consumption complete stock preparation from 100% pure cellulose pulp, the “Control and Automation System”, the ancillary services and the field equipment.

The scope also includes a new iDEAL® Tissue machine with a width of 2800mm at the pope reel and a maximum operating speed of 1800 m/min, a 15-foot forged steel Yankee Dryer, an E-WIND® T100 three-ply Tissue slitter rewinder and, finally, a reel handling system.

Mr. Shamsul Arefin Chowdhury, collaborator of A.Celli Group, says, “It was extremely satisfying to produce the first Jumbo Roll with A.Celli Tissue machine. We at Partex Tissue Ltd. would like to thank A.Celli for the state-of-the-art technology and services they provided us with, which allowed for a wonderful start up without any sheet breaking. All of this was possible despite the COVID 19 pandemic situation and the consequent limitations.”

PARTEX STAR GROUP - COMPANY PROFILE

Partex Star Group is one of the largest Bangladeshi private sector enterprises. The Group, the then Partex Group, started its journey in 1962 thanks to Mr. M.A. Hashem and currently owns and operates more than twenty-five manufacturing, service and trading companies. The goal of the group is to offer the best value to its customers through its products and services for the consumer durable and FMCG markets.