Super User

Rottneros decides on environmental investments at Vallvik Mill

Rottneros’ Board has decided on investments to reduce emissions to water at Vallvik Mill. The investments amount to a total of SEK 33 million and are linked to the mill's updated environmental permit, which has now gained legal force, allowing an annual pulp production of 255,000 tons.

The decision means that a number of measures will be taken to reduce emissions to water. They will be implemented during the mill's annual maintenance shutdown in 2021. The majority of them are aimed at increasing the proportion of emissions treated in the mill's biological treatment plant, as well as improving the efficiency of the fiberline and thereby minimizing emissions from the bleaching process.

The decision means that a number of measures will be taken to reduce emissions to water. They will be implemented during the mill's annual maintenance shutdown in 2021. The majority of them are aimed at increasing the proportion of emissions treated in the mill's biological treatment plant, as well as improving the efficiency of the fiberline and thereby minimizing emissions from the bleaching process.

"The investments mean that the Group takes further important steps towards a more sustainable Rottneros and that the process for a renewed environmental permit for Vallvik Mill is completed," says Lennart Eberleh, President and CEO, Rottneros.

Rottneros is an independent producer of market pulp. The Group comprises the parent company Rottneros AB, listed on Nasdaq Stockholm, and its subsidiaries Rottneros Bruk AB and Vallviks Bruk AB with operations involving the production and sale of market pulp. The Group also includes Rottneros Packaging AB, which manufactures fibre trays, the wood procurement company Rottneros Baltic SIA in Latvia and the forest operator Nykvist Skogs AB. The Group has about 315 employees and had a turnover of approximately SEK 2,4 billion in the 2019 financial year.

SCA to increase Kraftliner price by €50 per tonne

SCA will increase the price of White and Brown Kraftliner by €50 per tonne. The new price is valid for deliveries from February 1, 2021.

“The market is characterized by a very strong demand for Kraftliner” says Mikael Frölander, Vice President Sales & Marketing Containerboard.

“The market is characterized by a very strong demand for Kraftliner” says Mikael Frölander, Vice President Sales & Marketing Containerboard.

For further information, please contact:

Björn Lyngfelt, SVP Communications, tel, +46 70 626 82 23

Mikael Frölander, VP Sales & Marketing Containerboard, tel +46 70 616 81 10

The core of SCA’s business is the forest, Europe's largest private forest holding. Around this unique resource, we have built a well-developed value chain based on renewable raw material from our own and others’ forests. We offer paper for packaging and print, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. 2018 the forest products company SCA had approximately 4,000 employees and sales amounted to approximately SEK 1617 bn (EUR 1,8 bn). SCA was founded in 1929 and has its headquarters in Sundsvall, Sweden. More information at www.sca.com.

ABB completes large-scale remote commissioning of winder drives for major paper producer in India

Paperboard and specialty paper producer ITC achieves greater uptime, improved reliability and better runnability through major upgrades completed in a short timeframe

ABB has completed a large-scale remote commissioning of winder drives, upgrading and commissioning PM5 installations at ITC’s Paperboards and Specialty Papers Division mill in south-central India.

This project included upgrading the mill’s complete winder drive system to ABB’s latest ACS880 drives, AC motors, AC800M controller and process panel, as well as ensuring that all new assets were fully commissioned and ready for operation.

Following studies of the existing machine, detailed task planning, and numerous checks on the safety aspects of every task, ABB’s domain expertise helped the team complete the commissioning in just three days.

ABB has completed a major winder drive system upgrade with remote commissioning

ABB has completed a major winder drive system upgrade with remote commissioning

ITC engineers conducted a series of installations, hardware and I/O checks, and reporting of field challenges. Team feedback indicated the user-friendly ABB system assisted with this site work.

As a result of the drives upgrade, ITC will benefit from more accurate winder controls, including inertia compensation calculation, loss compensation, accurate load share and tension, while also experiencing higher operating speeds, with improved uptime and reliability.

Initial feedback from ITC reported improved runnability and reliability, while devising a solution for remote commissioning helped to reduce unnecessary downtime.

“Our ABB team mobilized quickly and used its remote expertise to complete this large-scale commissioning project, overseeing all drive parameterization, controller and human-machine interface (HMI) programming, testing and commissioning,” said Sanath Kumar, Global Product Manager for Paper Machine Drives and Vice President and Head of Engineering for Process Industries, ABB India.

“For any paper producer, the winder is a critical machine, which directly affects production. Any delay or malfunction will completely stop paper production processes. Remote commissioning during a planned maintenance timeframe was essential to maximize uptime for ITC and avoid unnecessary production losses.”

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

Sappi Europe Media Release: Sappi Maastricht sells south-western part of the industrial estate to Belvédère Wijkontwikkelingsmaatschappij (municipality of Maastricht)

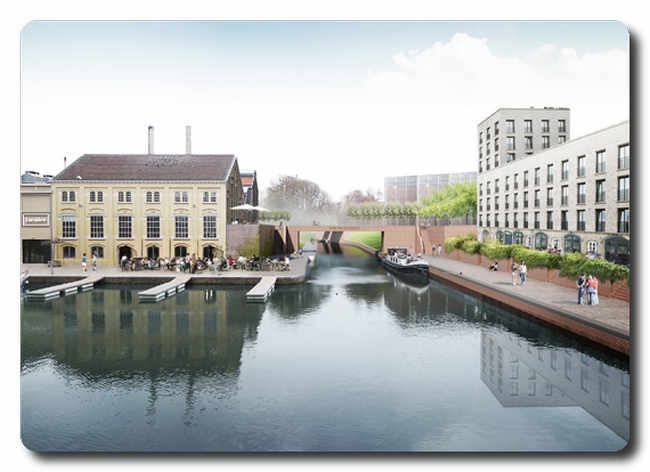

Sappi Maastricht and the Belvédère Wijkontwikkelingsmaatschappij (Neighborhood Development Company, WOM) of the Municipality of Maastricht have signed an agreement that will finalize the sale of the southwestern part of the Maastricht paper mill site to the WOM. The sale and subsequent purchase of this land creates a win-win situation for both parties as well as to the local area and will have no negative impact on employment at the Sappi site.

Investment in Sappi Maastricht

Sappi Maastricht, specialize in making coated graphical paper and have been manufacturing on the Maas site in Maastricht for 170 years (since 1850). Due to the worldwide trend for digitization within communications, the market for graphic paper is shrinking. In order to survive in this shrinking market and to guarantee continuity and employment, Sappi Maastricht started three years ago with the transition into luxury packaging board. This activity mainly takes place on the north side of the company site. The southwestern part is therefore less intensively used and was eligible for sale to the WOM. Ferdinand Koster, director of Sappi Maastricht commented: "This sale makes it possible for us to invest in the future of Sappi Maastricht. We will use the resources to improve internal logistics and additionally improve the sustainability of our production processes. "

Unique opportunity for the city

The purchase of the southwestern part of the Sappi site offers the municipality of Maastricht the opportunity to stretch the city center to the north and to further build on the Sphinxkwartier. Councilor Gert-Jan Krabbendam (Urban Development and WOM shareholder): "With this purchase we can fulfill the long-cherished wish of extending the Maasboulevard. By continuing the road around the Timmerfabriek, the Bassin bridge and Boschstraat will become more accessible. In this way we invest in the quality of life and attractiveness of the Sphinxkwartier." Councilor John Aarts (Finance and shareholder WOM) is also satisfied with the agreement:" In this way we invest twice in our city. Not only in terms of urban development, but also in the business climate and in job retention. I am delighted that Sappi is reinvesting the resources it obtains in its Maastricht mill"

New main entrance to Sappi on the north side has already been realized

During the relocation of the Noorderbrug, a new main entrance to the Sappi site has been established for freight traffic via the Commandeurslaan. The old main entrance via the small bridge on the Fransensingel will eventually be completely decommissioned to make way for the future connection between the Frontensingel and Maasboulevard.

Planning for the coming years

Sappi will relocate its activities currently taking place on the sold land to the remaining Sappi site and will also undertake new construction. They estimate that they will take approximately two years to apply for the necessary permits, the internal relocations and preparations for the delivery of the sold sites and buildings.

During this time, the WOM is making preparations for the construction of the road, the housing to be built and completion of the necessary spatial procedures. The basic principle is to coordinate both schedules as closely as possible with each other. The aim is to be able to construct the new road after about two years in combination with the construction of the tram. The housing construction is expected to take place in 2025/2026, following the construction of the road.

About Sappi

Sappi is a leading global provider of sustainable woodfibre products and solutions, in the fields of Dissolving pulp, Printing papers, Packaging and speciality papers, Casting and release papers, Biomaterials and Bio-energy. As a company that relies on renewable natural resources, sustainability is at our core. Sappi European mills hold chain of custody certifications under the Forest Stewardship Council™ (FSC™ C015022) and the Programme for the Endorsement of Forest Certification™ (PEFC/07-32-76) systems. Our papers are produced in mills accredited with ISO 9001, ISO 14001, ISO 50 001 and OHSAS 18001 certification. We have EMAS registration at 5 of our 10 mills in Europe.

Sappi Europe SA is a division of Sappi Limited (JSE), headquartered in Johannesburg, South Africa, with 12,500 employees and 19 production facilities on three continents in nine countries, 37 sales offices globally, and customers in over 150 countries around the world.

Learn more about Sappi at www.sappi.com.

Emtec Electronic Showcases Innovative Approach to Measuring Tissue Softness at the 2021 Tissue Conference

Emtec’s unique invention, the TSA Tissue Softness Analyzer, provides a simple, quick, and reliable way to get objective measurements of the haptic properties of tissue paper. In this year’s Tissue Conference, hosted by Tissue Analytica in collaboration with NC State University and TAPPI, emtec gives a virtual presentation on the TSA’s measuring concept, possible applications, and customer success stories.

The Covid-19 pandemic has not only affected production, supply chains, sales, and consumer habits across industries, but also the way industry professionals gather and communicate. The tissue paper industry is no exception. That is why the 2021 Tissue Conference focuses on “Sustainability, Performance, Risks & Opportunities in Times of Pandemic” in an online event from January 12-14, starting at 9 a.m. EST. The German company emtec Electronic GmbH, one of the leading producers of special electronic measuring devices for paper, board, textiles and nonwovens, will also participate in the event and share how the use of its TSA measuring device saves time and resources.

“Especially in times of increased demand and production, such as we’ve seen during the Covid-19 pandemic, tissue paper manufacturers want to ensure the best possible quality while minimizing the waste of time and resources,” says emtec’s Global Marketing and Business Manager Alexander Gruener. “Under such conditions, sometimes even a small improvement to the process or product can yield big results.”

“Especially in times of increased demand and production, such as we’ve seen during the Covid-19 pandemic, tissue paper manufacturers want to ensure the best possible quality while minimizing the waste of time and resources,” says emtec’s Global Marketing and Business Manager Alexander Gruener. “Under such conditions, sometimes even a small improvement to the process or product can yield big results.”

In a presentation on day two of the three-day conference, Gruener explains how to use the TSA device, which is able to measure haptic properties of tissues such as softness, smoothness/structure, stiffness, compressibility and “crumple-ability”. Gruener also illustrates how the unique design of the TSA device imitates the sensory perception of the human hand. The TSA, however, is able to differentiate between three different parameters and arrive at a numeric value for a sample’s hand-feel based on softness, smoothness, and stiffness. In addition, Gruener describes current applications for use in production, including R&D, process and product optimization, quality assurance, troubleshooting, and benchmarking. One example includes a newly developed TSA test method for the evaluation of hand sheets, which was developed by industry research partners at the Munich University of Applied Sciences and featured in a study in the online journal Bioresources.

More information about the 2021 Tissue Conference and the opportunity to register can be found online under tissueconference.com.

About emtec Electronic

The emtec Electronic GmbH develops, produces and distributes worldwide testing and measuring devices for the detection of relevant processing properties of paper, board, nonwoven and textile materials. The portable measuring devices enable manufacturers and converters of paper, nonwoven and textile products for example, to control and optimize the manufacturing and converting processes during ongoing production. From the wet end to the final product, the application of the devices enables an efficient process to achieve and ensure the best possible quality with the least possible effort.

For 25 years, we have relied on innovative, highly specialized measuring instruments combined with a high degree of service orientation. Since the company was founded, we have been intensively involved in scientific cooperation with institutes and companies, further developing instruments for our customers and offering a broad network in over 80 countries from our Leipzig location.

For more information about emtec Electronic, please visit our website:

Automation pioneer ABB confirmed as #1 DCS market leader

Customer focus, digital innovation and remote services were drivers for ABB’s leadership position in Distributed Control Systems (DCS) for the 21st consecutive year, according to analyst

Distributed Control Systems (DCS) are central to automation in the energy and process industries, playing a key role within Industry 4.0 and representing a global market valued at $15 billion. A recent report published by the ARC Advisory Group confirmed that, in a highly competitive landscape, ABB remains the #1 DCS market leader for the 21st year running.

Holding an overall share of 19.2%, ABB leads the field thanks to its domain knowledge in multiple industries, extensive service network and a continued investment in technology and digital solutions that meet rapidly changing customer requirements. This puts ABB more than two points ahead of the nearest DCS competitor.

The largest share of 2019 DCS market growth came from oil and gas, chemicals, mining, pharmaceuticals and biotechnology, followed by food & beverage, metals, cement, and pulp & paper. With its two main DCS offerings, ABB Ability™ System 800xA and ABB Ability™ Symphony Plus, ABB has a strong presence in each of these segments. ABB is also a leader in several of the key DCS trends identified in the report, including Modular Automation, Batch, Characterizable I/O and Remote Services.

As the DCS leader, ABB continuously develops new control benefits for customers. For example, by processing the massive amounts of data generated by the DCS, ABB continues to develop new data analytics that help customers to increase production efficiency, and leverage machine learning capabilities that improve problem predictability and extend asset life.

“I want to thank our customers for their longstanding support, helping us to shape ABB’s automation offering and expertise into what it is today,” said Bernhard Eschermann, Chief Technology Officer, ABB Industrial Automation. “Automation makes a difference in the world around us. The DCS is the backbone for much of the digitalization transforming our customers’ industries. It helps to provide many of the elements essential to modern society, such as the water we drink, the energy we consume or the materials used to build our homes.”

“During more robust economic times, process industry producers often rely on new production machinery to increase output. In the current highly demanding economic environment, customers are squeezing as much value as they can out of existing assets, running as efficiently as possible to protect profit margins. Maximizing assets and efficiencies is what DCS do,” he said. “We see it as our duty to continue to develop solutions that offer these benefits and more for our customers.”

A key focus of ABB’s annual $1.5 billion research & development investment is the further expansion of DCS and other digital and automation capabilities in the context of Industry 4.0. In July, ABB brought two new offerings to market that use DCS data with value-added applications to improve customer production availability, process performance and product quality. The ABB AbilityTM Edgenius Operations Data Manager gleans value from DCS data, while the ABB AbilityTM Genix Industrial Analytics and AI Suite combines data from operations (e.g. DCS), engineering and information technology for multi-dimensional data analytics and decision support.

Services saw the highest growth in relation to software and hardware in the ARC report. This trend accelerated in 2020, which created a high need for remote services. One such service, ABB AbilityTM Collaborative Operations, a remote-enabled network of ABB experts and technologies, uses many ABB DCS technologies to remotely monitor and support customer assets and processes. ABB experts in ABB Collaborative Operations centers globally are available 24/7 to assist customers. The Collaborative Operations network continues to provide remote support for customers in travel-restricted situations.

As the world looks to Smart Cities, Green Energy and Vertical Farming in support of trends such as Urbanization, ABB DCS will play a key role in ensuring their realization.

https://new.abb.com/control-systems/system-800xa

https://new.abb.com/power-generation/systems/power-plant-automation/abb-ability-symphony-plus

ARC Advisory Group

Founded in 1986, ARC Advisory Group is the leading technology research and advisory firm for industry, infrastructure, and cities due to its in-depth coverage of operational technologies (OT), engineering technologies (ET) and associated business trends. ARC’s analysts and consultants have the industry knowledge and first-hand experience to help clients find the best answers to the complex OT, ET and business issues facing organizations today. ARC provides technology suppliers with strategic market research, and helps end-user clients develop appropriate adoption strategies and select the best technology for their needs.

ABB’s Industrial Automation business area offers a broad range of products, systems, and solutions for customers in the process and hybrid industries. These include industry-specific services, as well as measurement and analytics, marine and turbocharging offerings. ABB’s Industrial Automation business is #2 in the market globally. With deep domain knowledge, experience and expertise, ABB Industrial Automation helps customers increase competitiveness, improve return on investment and run safe, smart, and sustainable operations.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

UK logistics sector faces major threats

The logistics industry, currently one of the greatest winners in the 2020 pandemic world, is under enormous threat going into 2021 as one of the UK’s prime business sectors is targeted by sophisticated cyber-destructors and intellectual property thieves.

“The logistics sector is at a major crossroad... and the real winners and losers will more accurately be defined in the next couple of years” said Robert Garbett, Founder of Drone Major Group, and one of the world’s leading advisors on the advanced capabilities of unmanned systems (drones).

“This year’s lockdowns and now the Christmas rush of pent-up demand have provided virtually all logistics companies with a rapid accelerator for growth, and most have fared extremely well. But in 2021 and beyond, there will be a massive division between those in the logistics sector who have recognised the need to embrace fast evolving new technologies, and in particular those which are safeguarded against cyber espionage, and attackers targeting their supply chains, and those logistics companies who have simply ridden the wave.”

Last month’s report by IBM’s ‘threat intelligence taskforce’ highlighted how hackers ‘probably backed by a nation state’(1) appeared to be trying to disrupt or steal information about the key processes to keep the newly approved Covid vaccines cold as they travel from factories to hospitals and doctors' offices. “The potential for disruption of supply chains is enormous” said Garbett and, “until recently, logistics organisations have felt they have been relatively safe... but the stakes are getting higher as the need for more sophisticated logistics services, such as unmanned (drone) conveyance is increasingly in demand.”

The economic significance of the logistics sector is huge. Trade association, LogisticsUK, has confirmed that there are over 194,000 logistics enterprises in the UK, with 2.6 million employed in the wider industry. The logistics sector has a £1 trillion turnover, contributing £130 billion Gross Value Added (GVA) to the UK economy, which is 10.2% of the contribution to the UK non-financial business economy.(2) In comparison, the scale of this industry is far greater than UK construction (3), energy (4) and manufacturing(5) among others.

Garbett added: “Data security at every point in a logistics system is paramount and like any IOT (internet of things) system there are many points which will need protection, and a strong culture of cyber security will need to exist to avoid the inevitable human error and threat from malicious human interference, which are the cause of the vast majority of cyber breaches in any system. Modern sophisticated logistics must create new types of infrastructure on a world stage to adapt to a rapidly evolving threat landscape.

“Drones have been shown to offer a wide range of benefits to logistics operations, providing a cost-effective and environmentally responsible alternative to traditional methods, as well as relieving the burden on our already stretched road traffic system. One of the challenges, however, is the need to adopt drone technology within a disciplined, holistic strategy which supports the organisation and ‘future proofs’ what is put in place. To maintain its global competitiveness, it is now more important than ever that the UK logistics industry recognises the speed of drone technology advancement, embraces it, innovates, and stays ahead of the hackers.”

1) https://www.ibm.com/security/digital-assets/xforce-threat-intelligence-index-map/#/

(2) Further details can be found in LogisticsUK’s Logistics Report 2020: https://logistics.org.uk/logisticsreport

(4) https://www.energy-uk.org.uk/energy-industry/energy-in-the-uk.html

(5) https://www.ons.gov.uk/businessindustryandtrade/manufacturingandproductionindustry

Drone Major Group Limited

Drone Major Group is the world’s first global drone consultancy dedicated to advising companies and organisations on what can be achieved through the use of autonomous and remotely controlled systems (drones) in their operations across all environments (surface, underwater, air and space); where to acquire the technology, and how to integrate it safely and effectively into their operations.

Robert Garbett

Robert Garbett is the Founder of Drone Major Group Limited. He is also Founder and Chairman of the Drone Delivery Group, Chairman of the British Standards Institution (BSI) Committee responsible for the development of drone standards in the UK, and leads the International Standards Organisation Working Group developing the standards for the operation of unmanned air systems (UAS), both passenger and non-passenger carrying. He is the only authority to be advising on drone standards in Britain, Europe and worldwide; a leading consultant within the global drone industry and an advocate on the potential of drone technology to transform businesses and economies.

Kemira and DuPont Nutrition and Biosciences partner for development and commercialization of new breakthrough biomaterials

The two companies join forces to commercialize applications of new tailored biomaterials and biobased chemicals, based on DuPont’s breakthrough biotechnology platform. Kemira’s role in the collaboration will be to co-develop and commercialize a range of new biobased and biodegradable products across Kemira’s key product lines.

Global biotechnology giant DuPont and Kemira, a global leader in sustainable chemical solutions for water intensive industries announced today an exclusive partnership for the development and commercialization of DuPont’s enzymatic biomaterial platform technology. This collaboration will allow both partners to commercialize a range of new, biobased and biodegradable products in their respective core markets in the upcoming years.

Under the terms of the partnership Kemira will gain access to DuPont’s new and unique biomaterial technology, known as the engineered polysaccharide platform. It enables production of a variety of biomaterials that can be used to enhance sustainability, biobased content and biodegradability across different product lines and applications. The platform utilizes sustainable plant-based sugars as raw materials and proprietary enzymes catalyst for the reaction. The technology readiness of the production platform is at advanced pilot scale and the technology can be scaled up to global level.

Kemira’s role in the partnership will be to provide the application development expertise and market access required to leverage the full potential of the technology in Kemira’s core markets such as paper and board industry, water treatment as well as oil & gas industries. Kemira will be the exclusive provider of the new biomaterials to its core markets, while DuPont will continue to develop and commercialize the platform for other applications in DuPont’s own target markets.

Kemira’s role in the partnership will be to provide the application development expertise and market access required to leverage the full potential of the technology in Kemira’s core markets such as paper and board industry, water treatment as well as oil & gas industries. Kemira will be the exclusive provider of the new biomaterials to its core markets, while DuPont will continue to develop and commercialize the platform for other applications in DuPont’s own target markets.

"Our partnership with DuPont is a major milestone on our strategic journey to deliver high quality, sustainable and biobased products to our core markets. The versatility and scalability of this exciting new platform will allow us to leverage the technology across our key product lines. These new biomaterials can be used in multiple applications including municipal and industrial water treatment as well as in packaging and board applications to improve e.g. strength and barrier properties. Sustainability is one of the main drivers of Kemira’s long-term growth and our target is to reach biobased revenue of over 500 million euros by 2030.” says Antti Matula, SVP, Global Product Lines & Business Development for Kemira Pulp & Paper.

“This new technology will transform industrial products, providing sustainable material options for a range of important end use markets,” said Christian Lenges, Venture Director for Biomaterials, DuPont Nutrition & Biosciences. “We are thrilled to be entering the development and commercialization phase with Kemira, and to provide access to a range of new biomaterials which are scalable on a global level, renewable and even higher-performing compared to traditional materials.”

Enzymatic polymerization process technology

The DuPont enzymatic polymerization process technology applies biotechnology tools to access sugar-based biopolymers (polysaccharides) at an industrial scale to enable broad material applications. The underlying new material innovation – for the first time – allows for the controlled enzymatic polymerization of sugar (sucrose) into glucose polymers (polysaccharides) under controlled, enzyme catalyzed polymerization conditions. This approach enables the specific and designed synthesis of nature-identical polysaccharides with high purity, controlled structural material properties and morphologies.

Kemira is a global chemicals company serving customers in water intensive industries. We provide best suited products and expertise to improve our customers’ product quality, process and resource efficiency. Our focus is on pulp & paper, oil & gas and water treatment. In 2019, Kemira had annual revenue of around EUR 2.7 billion and over 5,000 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd. www.kemira.com

DuPont Nutrition & Biosciences applies expert science to advance market-driven, healthy and sustainable solutions for the food, beverage, dietary supplement and pharmaceutical industries. We also use cutting-edge biotechnology across a range of markets to advance bio-based solutions to meet the needs of a growing population, while protecting our environment for future generations. We are innovative solvers who help our customers turn challenges into high-value business opportunities. For more information: www.dupontnutritionandbiosciences.com.

DuPont (NYSE: DD) is a global innovation leader with technology-based materials, ingredients and solutions that help transform industries and everyday life. Our employees apply diverse science and expertise to help customers advance their best ideas and deliver essential innovations in key markets including electronics, transportation, construction, water, health and wellness, food, and worker safety. More information can be found at www.dupont.com. Investors can access information included on the Investor Relations section of the website at www.investors.dupont.com

For more information, please contact:

Kemira Oyj

Mikko Pohjala, Vice President, Investor Relations

Tel. +358 40 838 0709

This email address is being protected from spambots. You need JavaScript enabled to view it.

Kemira Oyj

Antti Matula, Senior Vice President, Global Product Lines & Business Development

Tel: +358 50 570 3576

This email address is being protected from spambots. You need JavaScript enabled to view it.

DuPont

Richard Donovan

+33 (0) 6 71 58 98 54

This email address is being protected from spambots. You need JavaScript enabled to view it.

Toscotec to supply three tissue rebuild projects

Toscotec will deliver three tissue machine rebuilds located at different mills to a confidential global producer.

Toscotec will rebuild the drying sections of two tissue machines, as well as the wet end and winding sections of another machine. The drying section rebuilds include the supply of two Toscotec’s third-generation-design TT SYD Steel Yankee Dryers, steam and condensate systems, and high efficiency TT Hoods, including one newly optimized combustion system. The energy efficiency given by the integration of the steel Yankee and the hoods will result in a significant reduction of the tissue machines’ thermal consumption.

The other project requires the modification of the approach flow and fiber recovery systems and the complete rebuild of the machine’s wire and pope reel sections.

The provision of expert services, including engineering, dismantling of old equipment, erection, commissioning, start-up, and training, ensures a complete package for the rebuilds.

Since the start-up of its first TT SYD in 2000, Toscotec is the forerunner and world leading manufacturer of Steel Yankee Dryers boasting close to 230 TT SYDs sold and over 200 currently operating in five continents.

These two new TT SYDs will replace the mills’ existing Yankee dryers. Toscotec holds the record as the manufacturer who supplied all of the SYD replacements that took place in Europe to date.

Riccardo Gennai, Toscotec Sales Manager, says: “We take pride in the continuous evolution of TT SYD. Toscotec started up the first steel Yankee dryer in the tissue industry. TT SYD’s third-generation design enhances the machine’s drying performance and energy efficiency to a degree that it really makes us stand out in the market.”

For further information, please contact:

Riccardo Gennai, Sales Manager, Toscotec Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Mondi Ansbach steps up its customer proposition by offering more sustainable packaging solutions

Last year, Mondi, a leading global packaging and paper manufacturer, announced that it would expand its existing plant in Ansbach, Southern Germany, to become the largest heavy-duty corrugated cardboard plant in Europe. The “Ansbach 2020” project, an investment worth €30 million, is in its final stages of completion and is meeting its customers' needs with innovative sustainable packaging solutions.

- €30 million investment expands product portfolio and improves processes

- Successful installation of state of the art machinery for optimised operations

- Broader range of corrugated solutions for more specialised and sustainable customer uses

The plant successfully installed state of the art machinery, including a new corrugator, die-cutting-machine, inline-machine, paper storage, shipping facility, waste processing facility and intralogistics system. The investment is strengthening the plants position as the go-to-expert for innovative and sustainable packaging solutions in the region. Furthermore, the updated machinery results in less energy consumption and reduces the carbon footprint of the plant.

“With this investment we have been able to broaden our sector expertise offering to include not only the automotive sectors but also expand into the the construction supply, sports and leisure industry, delivering quality sustainable packaging goods,” says Markus Skiba, Managing Director, Mondi Wellpappe Ansbach.

The improvements delivered by this investment include:

- Increased production capacity, leading to shorter delivery times to customers

- Broader range of corrugated solutions for more specialised customer uses

- Enhanced product quality

The investment also includes a Customer Innovation Centre, which will offer facilities for workshops, product development, optimisation and product presentations.This hub will lead to further innovation and testing of packaging solutions to reduce their enviornmental impact and will mark the project completion in 2021.

Mondi Wellpappe Ansbach is the home of award-winning packaging solutions. In 2020, the plant developed two ScanStar award-winning transportation packaging solutions for Volvo. The team works closely with its automotive industry customers to create value-added corrugated solutions that protect heavy-duty goods such as brake boosters and headlamps, while improving processes and logistics. The ScanStar jury especially highlighted the factors cost-effectiveness, sustainability, stability and improvement in work ergonomics.

About Mondi Corrugated Solutions

Mondi Corrugated Solutions, a segment of the business unit Mondi Corrugated Packaging, is a leading supplier of corrugated packaging in Europe, with strong focus on Central and South-East Europe. In 2020 the business won three WorldStar awards, in 2019 the business won seven WorldStar Awards for innovation, to add to five won in 2018, more than any other company worldwide. Through a network of 16 plants Mondi Corrugated Packaging provides innovative design and state-of-the-art printing and gluing technology. The packaging types range from standard transit cases and heavy duty containers to upscale consumer displays. They are applied as shelf- or retail-ready solutions, transport cases or large containers when shipping FMCG's, perishables, industrial and dangerous goods as well as other products.

About Mondi

Mondi is a global leader in packaging and paper, contributing to a better world by making innovative packaging and paper solutions that are sustainable by design. Our business is fully integrated across the value chain – from managing forests and producing pulp, paper and plastic films to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is at the centre of our strategy and intrinsic in the way we do business. We lead the industry with our customer- centric approach, EcoSolutions, where we ask the right questions to find the most sustainable solution. In 2019, Mondi had revenues of €7.27 billion and underlying EBITDA of €1.66 billion.

Mondi has a premium listing on the London Stock Exchange (MNDI), and a secondary listing on the JSE Limited (MNP). Mondi is a FTSE 100 constituent, and has been included in the FTSE4Good Index Series since 2008 and the FTSE/JSE Responsible Investment Index Series since 2007.