Displaying items by tag: valmet

Valmet supplied Cogeneration system inaugurated at the Lucart Castelnuovo tissue mill

The Lucart Castelnuovo di Garfagnana tissue mill, part of the Lucart Group, has officially inaugurated its first Cogeneration system with Integrated EcoRecovery system, developed and supplied by Valmet. The installation is part of Lucart Group's about 4 million EUR investment for upgrading the mill.

Valmet presenting Lucart representatives with a silk-screen printing of the Cogeneration system. From left Roberto Benzi, Mill Manager, Lucart Castelnuovo, Danilo Calamari, Technology Manager Paper Mill, Lucart Group, Franco Pasquini, Engineering Manager, Lucart Group and Luigino Furlan, Vice President DCD Technology Unit, Valmet.

The Cogeneration system integrates a gas turbine with a yankee hood air system and a waste heat steam generator, covering all the electricity and steam needs of the site. This way the gas turbine flue gases are used to dry the paper without any further gas consumption. The system improves the energy efficiency and reduces greenhouse gas emissions significantly. In addition, drying costs in the tissue production are decreased significantly.

Valmet's solution was a perfect match with Lucart Group's objectives. "The Integrated Cogeneration technology is totally consistent with our company mission, which focuses on environmental sustainability and respect. Furthermore, we have appreciated Valmet's capability in finding and sharing possible solutions - Valmet people were always there when we needed it and this made a difference," says Franco Pasquini, Engineering Director of Lucart.

In his introduction speech at the opening ceremony Luigino Furlan, Vice President DCD Technology Unit of Valmet, highlighted how the success of this project is due greatly to the teamwork between Lucart and Valmet. "The people who envisioned, shared, built and implemented this project and the special relationship established between the teams, represent the corner stones for this achievement. Mutual trust between Lucart and Valmet has been established and the path to continued partnership is paved," Furlan said in his speech.

Technical description

The Cogeneration equipment supplied by Valmet includes a new air system with fans, burners, dampers, ducting and instrumentation for the existing hood. Furthermore the delivery comprises a heat recovery steam generator, an air/air heat recovery and an air/water heat recovery system.

The results of the installation are remarkable: using its exhaust fumes, the cogeneration gas turbine performs all the drying for the entire tissue production, covering the thermal energy of the hood air system (with burners off) and producing the steam needed for the Yankee cylinder.

The Cogeneration system will reduce the natural gas consumption by 15-20% per year which correlates to an estimated reduction of CO2 emissions by 7,000 tons /year as well as NOx to air by 3.5 tons / year.

Valmet delivered Cogeneration system at the Lucart Castelnuovo tissue millAbout the customer Lucart Castelnuovo

Lucart Castelnuovo is part of the Lucart Group, Italy, which operates six paper mills, including ten paper machines and 54 converting lines. The company employs 1.200 people and has a yearly production of 300.000 tons of Paper and a turnover of 400 million EUR per year

For further information, please contact:

Luigino Furlan, Vice President Dry Creped Drying Technology Unit, Valmet, tel. +39 348 8907828

Marco De Luca, Product Sales Manager, Package Sales Air Systems, Valmet, tel. +39 348 4110273

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to upgrade evaporators at Södra Cell, Mönsterås pulp mill in Sweden

Valmet will supply an upgrade of the evaporation plant at Södra Cell's Mönsterås pulp mill in Sweden. The upgrade will unload the capacity of the existing evaporation line No 1 and improve steam economy by increasing the capacity of the existing evaporation line No 2. The delivery is scheduled for autumn 2016.

The value of the order will not be disclosed. However, a project of this type and scope is typically valued at around EUR 10 million. The order is included in Valmet's second quarter 2015 orders received.

TUBEL replacing damaged lamellas at Mönsterås mill.

The new order follows a similar major evaporation plant upgrade of the Södra Cell, Värö mill, which was awarded to Valmet last year together with upgrades of most process areas in the same mill.

"We are looking forward to this project and are satisfied with the technical concept Valmet has offered us. This will improve the function of the evaporation plant, increase the energy efficiency and increase our profit," says Jonas Olander, Project Leader at Södra Cell Mönsterås.

"We see this evaporator upgrade bringing many benefits for Mönsterås mill. Besides improving the steam economy of the plant, we are implementing dry solids content control of the firing liquor to the recovery boiler. We will also add additional washing possibility of existing heating surface areas to improve plant availability. We are happy to continue our good co-operation with Södra Cell," says Fredrik Vedin, Product Sales Manager EVAPS at Valmet.

Details about the delivery

The evaporation plant in a mill concentrates black liquor coming from the digester. In the evaporation process the evaporated water is brought back to the pulp production process in order to minimize mill's water consumption. After evaporation the concentrated black liquor is fired in the recovery boiler for steam generation and recovery of cooking chemicals.

The new Valmet equipment to be installed will be two Tube Evaporators, a Falling Film Reflux Condenser and four liquor preheaters. A substantial upgrade of the piping system and an integration and upgrade of an existing condensate treatment system will also be performed.

Over the years Valmet has assisted Mönsterås mill by making several smaller and larger upgrades of the existing evaporators. The co-operation started in 2001 when Valmet replaced damaged lamellas with TUBEL and also installed a new TUBEL Super Concentrator.

About the customer Södra Cell

Södra is an economic association with a membership base of about 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,500 people and has three business areas Södra Skog, Södra Cell and Södra Wood (former Södra Timber and Södra Interiör).

Södra Cell is one of the largest players in the world in the area of softwood pulp and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö. Södra Cell Mönsterås is Södra's biggest pulp mill with a capacity of 750,000 tonnes per year of pulp. In addition to electricity, the mill delivers district heating to the municipality of Mönsterås and to Södra's sawmill in the area. Furthermore, the mill supplies tall oil for biodiesel.

For further information, please contact:

Fredrik Vedin, Product Sales Manager EVAPS, Valmet, Tel. +46 706 45 23 55

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

Franklin Templeton Institutional, LLC's ownership in Valmet has decreased below 5%

Notification according to chapter 9, section 5 of the Securities Market Act: Franklin Templeton Institutional, LLC's ownership in Valmet has decreased below 5%

Notification according to chapter 9, section 5 of the Securities Market Act: Franklin Templeton Institutional, LLC's ownership in Valmet has decreased below 5%

Valmet Corporation (Business ID 2553019-8) has on June 10, 2015 received a notification referred to in Securities Market Act from Franklin Templeton Institutional, LLC, stating that the company's ownership and share of votes in Valmet Corporation has decreased below the threshold of 5 percent (1/20).

As a result of share transactions on June 9, 2015, the holding of Franklin Templeton Institutional, LLC decreased to 7,196,324 shares (previously 7,517,629 shares), representing an ownership of 4.80 percent (previously 5.02 percent) of Valmet Corporation's total number of shares and share of votes.

Valmet Corporation has one series of shares in which each share carries one vote. The aggregate number of shares is 149,864,619.

Further information, please contact:

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

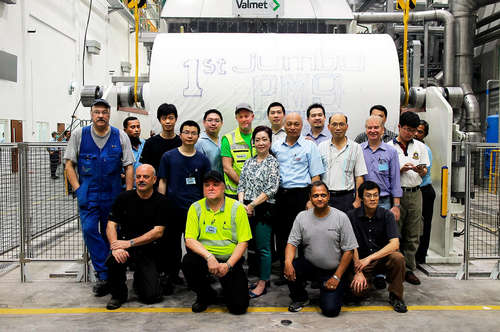

New Valmet-delivered tissue line started up at PT Suparma Tbk's mill in Indonesia

PT Suparma Tbk's new tissue line came on stream in Surabaya, Indonesia two days ahead of the schedule, on April 8. The Advantage DCT 100 tissue machine, supplied by Valmet, increases the company's production of bathroom tissue, towel and diaper tissue for the Indonesian market, by 25,000 tonnes per year. The new tissue line fulfills the company's ambition to produce sustainable products of high quality in a cost-efficient way.

"Working together with Valmet has been a priceless experience, and we learned a lot during the project. Valmet is known to be the leader in paper machinery and we are proud to own one of their machines. It is undeniable that Valmet managed to deliver a state of the art machine. During the initial run we managed to produce commercial grade tissue on the second day. It was a pleasure to work together with Valmet's team and we are pleased with the result," says Edward Sopanan, Director, PT Suparma Tbk.

Valmet's and PT Suparma's start-up team

"It is a pleasure to work with PT Suparma. The PT Suparma's team is skilled and determined, and they take pride in what they accomplish. The good interaction between our teams, from project start to installation and start-up, was the key to success," says Stefan Ziegel, Project Manager, Valmet Tissue Mills business unit.

Technical information of the new line

Valmet's delivery included a complete high-speed tissue production line featuring an Advantage DCT 100 tissue machine equipped with an OptiFlo headbox, a cast iron Yankee cylinder and an Advantage AirCap Yankee hood. Valmet has also supplied part of the stock preparation equipment as well as basic engineering, installation services and start-up of the machine.

The new line has a width of 2.75 m and an operating speed of 1,600 m/min. Raw material for the new production line is virgin fiber and recycled fiber.

Information about the customer PT Suparma Tbk

PT SuparmaTbk was founded as a paper and board producer in1976. The company established its first tissue machine in 2007 and is today a well-known supplier of high-quality board, laminated wrapping kraft and tissue paper for the Indonesian market as well as the Asian, Australian and African markets. The company employs 1,800 people and produces over 200,000 tonnes of paper per year. PT Suparma Tbk is registered on the Indonesian Stock Exchange.

For further information, please contact:

Ingmar Andersson, Sales Manager, Tissue Mills business unit, Valmet, tel. +46 705 17 13 90

Stefan Ziegel, Project Manager, Tissue Mills business unit, Valmet, tel. +46 705 17 12 31

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Successful start-up of the Valmet delivered pulp line at the CMPC Guaíba mill in Brazil

After two years of work, the new pulp line of CMPC Celulose Riograndense Ltda (CMPC) has been started-up according to schedule on May 3rd, 2015. The delivery agreement of the key technology for the new pulp line was signed by CMPC and Valmet in June 2013.

The new pulp line is an expansion to the existing Guaíba pulp mill in Rio Grande do Sul state, south of Brazil. The new line has a capacity of 1.3 million tonnes per year and can be upgraded to reach 1.5 million tonnes per year with minor investments. This is an addition to the existing capacity of the mill of 500,000 tons per year.

CMPC Guaíba pulp mill site

"Valmet's commitment was to deliver to CMPC sustainable technologies to create a world reference in efficiency and low environmental emissions. The mill is located very close to the city of Guaíba and one of the most important prerequisites was to minimize all possible impacts to the community. The project execution was a great success. This showcase demonstrates our capacity and competence to deliver a complete pulp plant in the right time and quality," says Celso Tacla, Valmet's Area President for South America.

Valmet's delivery in detail - best technologies for high yield and low operational costs

Valmet's delivery covered the main process islands of the pulp line, from the cooking plant to the bales that are shipped to final users, including the complete fiberline, pulp drying and baling, evaporation, recovery boiler, causticizing, lime kiln and an integrated automation solution and operator training simulator for all mill process areas. In addition, Valmet has also delivered a state-of-the-art non-condensable gas treatment system.

Valmet's solutions for the Guaíba project were based on the best technologies available. The capacity of the evaporation plant is the largest in operation in the world. The stationary cooler of the lime kiln brings significant savings in the fuel oil. The recovery boiler is designed for high power generation. The fiberline features industry-leading operational costs, combining high pulping yield, low chemical consumption and reduced water consumption with low effluent levels. The pulp dryer utilizes the most reliable technology to provide low steam consumption, and is equipped with high-speed baling lines.

Very good safety results at the construction phase

"We are pleased with the outstanding results in Health and Safety during the project. This sets a new benchmark for the industry. In the peak of construction Valmet had over 4,000 employees and contractor workers at the site. Since we had such a large amount of people on site and tight time schedule, safety was a top priority during the whole construction phase," says Francisco Gervasoni, Valmet's manager for Guaíba expansion project.

CMPC Celulose Riograndense Ltda is part of the Chilean group, CMPC Celulosa, one of the largest forestry-based companies in Latin America. Its mills in Chile and Brazil produces around 2.8 million tonnes of pulp per year. The new line will add 1.3 million tonnes to company's capacity.

For further information, please contact:

Celso Tacla, Area President, South America, Valmet, tel. +55 41 3341 4403

Bertel Karlstedt, President Pulp and Energy business line, Valmet, tel. +358 10 676 3026

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

Valmet makes a donation to help earthquake victims in Nepal

Valmet has made a donation to support catastrophe victims in Nepal, which was hit by a severe earthquake on Saturday, April 25. Valmet agreed to channel the EUR 10,000 contribution through a humanitarian organization, the Finnish Red Cross. The donation is targeted at first aid and rebuilding work.

Valmet has made a donation to support catastrophe victims in Nepal, which was hit by a severe earthquake on Saturday, April 25. Valmet agreed to channel the EUR 10,000 contribution through a humanitarian organization, the Finnish Red Cross. The donation is targeted at first aid and rebuilding work.

"When a catastrophe of this magnitude occurs, all support is needed. We hope that Valmet's donation helps contribute to restoring normal operations in the area," says Anu Salonsaari-Posti, Senior Vice President, Marketing and Communications, Valmet.

The Red Cross currently has 10,000 volunteers in the field to provide first aid to those injured in the earthquake and to look for survivors. The Red Cross also has aid supplies, such as blankets, tarps and cooking sets, for 40,000 people.

Earlier in December 2014, Valmet allocated part of its annual seasonal donation to the Red Cross' Disaster Relief Fund. Through the Disaster Relief Fund the Red Cross helps the victims of natural disasters and conflicts around the world by delivering supplies, such as tents, blankets, clean drinking water or an entire field hospital to the disaster areas. The Red Cross also continuously helps to fight diseases and hunger together with local volunteers.

For further information, please contact:

Anu Salonsaari-Posti, SVP, Marketing and Communications, Valmet, tel. +358 50 453 4262

Laura Puustjärvi, Head of Sustainability, Valmet, tel. +358 50 337 4473

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

Valmet inaugurated the extension of its filter fabric production and R&D center in Ovar, Portugal

Valmet has inaugurated the extension of its location in Ovar, Portugal, which has become the company's center of filter fabric production and R&D. The unit manufactures filter fabrics for solid and liquid filtration and dust filtration, as well as felts and accessories for the laundry industry.

"In addition to the production, we are concentrating our filtration-related R&D to Ovar in order to have the best knowledge and R&D equipment under one roof. This now finalized investment ensures our future competitiveness in the filtration business," says Jani P. Hämäläinen, Director of the Filtration technology unit at Valmet.

Inauguration ceremony at the Valmet Ovar site. From the left: Salvador Malheiro, Mayor of Ovar, Luciano Amaral, Head of Operations and General Manager, Ovar unit, Valmet, Pedro Mota Soares, Minister of Solidarity, Employment and Social Security and Jukka Tiitinen, Business Line President, Services, Valmet

In addition to Portugal, Valmet manufactures filter fabrics in Brazil, China, Poland, the USA, and, to some extent, in Finland.

Good growth opportunities in filter fabrics

The market for filter fabrics is versatile, as the filter fabrics are used in many different industries. Valmet is concentrating on filter fabrics for the pulp, paper, power, mining, and chemical industries, as well as the alumina, cement, and food industries. Tightening emissions standards and legislation worldwide are driving the growth in the filtration market.

"The filter fabric business is a good example of Valmet's wide services offering. We are moving our customers' performance forward by offering reliable energy and cost-effective solutions backed up with proven expertise in the field of filtration," says Jukka Tiitinen, Business Line President, Services, Valmet.

Filter fabric

For further information, please contact:

Luciano Amaral, Head of Operations and General Manager, Ovar, Fabrics business unit, Services, Valmet, tel. +351 256 579 500

Jani P. Hämäläinen, Director, Filtration technology unit, Services, Valmet, tel. +358 40 847 7587

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

European paper industry welcomes Valmet as a new partner

The Confederation of European Paper Industries (CEPI) is happy to announce a new partnership with Valmet. CEPI and Valmet have already collaborated in the past, notably on the European Paper Week. The new status will deepen an established good relationship, to include areas of common interest.

The Confederation of European Paper Industries (CEPI) is happy to announce a new partnership with Valmet. CEPI and Valmet have already collaborated in the past, notably on the European Paper Week. The new status will deepen an established good relationship, to include areas of common interest.

More specifically, Valmet will gain a clear and in-depth insight of the issues the pulp and paper industry is facing, with the opportunity to be part of CEPI’s activities with its stakeholders. CEPI will gain knowledge and expertise, building on its ever-strong eco-system around industry suppliers with the ultimate goal of strenghtening its innovation agenda. “Valmet and CEPI have a lot to gain from this partnership. It is a priviledge to collaborate with such a highly-valued industry supplier and we are very excited to see where this partnership will lead us”, says Marco Mensink, CEPI’s Director General.

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet’s services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Their strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

This is the second new partnership for CEPI in 2015, with Pöyry having joined the programme in March. The partnership programme, launched in 2011, currently includes Buckman, Pöyry, Omya, Valmet and Voith. It is open to machine and chemical suppliers active in the pulp, paper or board industry with a direct link to paper manufacturing.

For more information, please contact Annie Xystouris at This email address is being protected from spambots. You need JavaScript enabled to view it. mobile phone: +32(0)486243642.

Two new Valmet-supplied tissue lines started up at Hayat Kimya in Turkey and Russia

Hayat Kimya's new Advantage DCT 200TS tissue line, PM5, was started up in March 2015 by a joint Valmet and Hayat Kimya team. The new line, at the Mersin mill in Turkey, came smoothly on stream according to schedule and produced sellable paper from the very start.

This was the second start-up for the same team in three months, as Hayat Kimya's PM4 at the new Alabuga mill in Tartarstan, Russia was started up in December 2014. The time schedule was very tight but the paper was on reel as expected with good paper properties.

"This was for most of us, the third and fourth tissue line installation we have started together. During the years we have developed a mutual respect and high confidence in each other, which makes the coordination of the assembly and all commissioning activities very smooth and together we make things happen," says Rolf Tellack, Project Manager, Valmet.

"We share the same excitement with everyone who has contributed with patience and determination to make these projects successful. Even though the conditions were very different between the Russian and the Turkish installations both machines started up on time and are now producing top quality paper at high speed," says Lütfi Aydin, Director Paper Group, Hayat Kimya.

Hayat Kimya has now four tissue lines supplied by Valmet in their machine fleet and one more to start up in 2016. Recently the company announced the rebuild of their PM1 which means that all their tissue lines will be operating with the Advantage DCT technology from Valmet.

Hayat Kimya and Valmet team celebrating the PM5 start-up at the Mersin mill in Turkey

Hayat Kimya and Valmet team celebrating the PM4 start-up at the Alabuga mill in Tartarstan, Russia

Technical information

Both tissue machines have a width of 5.6 m and a design speed of 2,200 m/min. The design capacity for each machine is 70,000 tonnes a year. Both machines will produce high-quality facial, toilet and towel grades from virgin fiber and are optimized to save energy and enhance final product quality.

The two tissue production lines feature stock preparation systems and Advantage DCT 200TS tissue machines. The machines are equipped with OptiFlo headboxes and Valmet cast alloy Yankee cylinders as well as the Advantage technology including ViscoNip press, AirCap hood prepared for co-generation, WetDust sytem, sheet transfer system and SoftReel reel. The delivery also included an extensive automation package with Valmet DNA, process controls and Valmet IQ quality controls. Complete engineering, supervision, training, start-up and commissioning was also included in the delivery.

Information about the customer Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 350,000 tonnes and a converting capacity of 200,000 tonnes per year. Through new investment and ongoing projects the total production capacity of Hayat Kimya will reach 420,000 tonnes.

For further information, please contact:

Björn Magnus, Sales Director, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Rolf Tellack, Project Manager, Tissue Mills business unit, Valmet, tel. +46 705 62 75 65

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

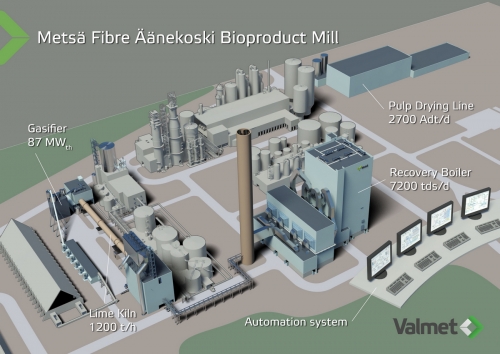

Valmet and Metsä Fibre finalized the order agreement for key technology to Äänekoski bioproduct mill

Valmet and Metsä Fibre have signed the agreement for the supply of key technology to Metsä Fibre's new Äänekoski bioproduct mill in Finland. Valmet announced the letter of intent of the delivery on February 13, 2015.

Valmet delivery includes recovery boiler, pulp drying line, gasification plant, lime kiln and a mill wide Valmet DNA automation system. The estimated value of Valmet's delivery, which includes only the core equipment supplied by Valmet, is about EUR 125-150 million. The order is included in Valmet's second quarter 2015 orders received.

The construction of the bioproduct mill will start immediately and the production at the new mill is scheduled to begin during the third quarter of 2017.

"The bioproduct mill will strengthen Metsä Group's leading position in northern softwood pulp market and will improve our profitability. We have had long term and successful cooperation with Valmet which is a strong supplier of equipment of this scale," says Ilkka Hämälä, CEO of Metsä Fibre.

Technological innovations and important employment impact

Valmet delivers leading technology for the Äänekoski bioproduct mill. The recovery boiler, pulp drying line and lime kiln will be the largest in Europe. All the equipment will have high energy efficiency.

"Our gasification technology and recovery boiler maximize the use of bioenergy and makes the pulp mill totally fossil fuel free. Valmet delivers a modern gasification plant, where bark is dried and gasified to product gas which is then used as fuel in the lime kiln. The Valmet delivered recovery boiler has multiple high power features including patented heat recovery from flue gas to combustion air enabling the mill to sell outside 1.4 times more electricity than it needs for its own operation," says Bertel Karlstedt, Pulp and Energy Business Line President from Valmet.

Valmet's delivery for the bioproduct mill will have an important employment impact on Valmet and its subcontractors. The employment impact of Valmet's project delivery is expected to be around 250 man years, out of which half in Finland mainly in Tampere, Jyväskylä, Ulvila and Raisio.

Details about Valmet's technology delivery to Metsä Fibre Äänekoski bioproduct mill

The new bioproduct mill in Äänekoski is the largest investment of the forest industry in Finland. Metsä Fibre's total investment will amount to approximately EUR 1.2 billion and the mill's annual pulp production will be approximately 1.3 million tonnes.

Valmet's delivery includes engineering, procurement, supply and construction management of a recovery boiler, a pulp drying line, a lime kiln and a gasification plant. The recovery boiler will have a capacity of 7,200 tds/d (tonnes dry solids a day). It provides steam to a turbine with 260 MW electrical capacity, which makes Metsä Fibre's recovery boiler plant the largest renewable energy production unit in Europe. The pulp drying line will have a trimmed width of 8.25 meters and a capacity of 2,700 Adt/d (air dry tonnes a day). The lime kiln will have a capacity of 1,200 t/d and will be operated by renewable fuel provided by 87 MW product gas capacity biomass gasification plant.

Valmet's automation delivery includes an extensive Valmet DNA automation and process information system covering the entire pulp mill and Valmet IQ quality control system for the pulp drying machine.

Information about the customer Metsä Fibre

Metsä Fibre is a world-leading producer of softwood pulp, whose main brand is Botnia. The company's main products are sustainably and cost-efficiently produced bleached softwood and birch pulps. Metsä Fibre has four pulp mills in Finland. Metsä Fibre's sales in 2014 totalled approximately EUR 1.3 billion, and it employs some 850 people. Metsä Fibre is part of Metsä Group.

For further information, please contact:

Bertel Karlstedt, President Pulp and Energy business line, Valmet, tel. +358 40 553 3859

Kari Remes, Vice President, Recovery, Pulp and Energy business line, Valmet, tel. +358 40 709 2015

Pasi Mäkelä, Vice President, Pulp Mill Sales, Pulp and Energy business line, Valmet, tel. +358 40 505 4199

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.