Displaying items by tag: valmet

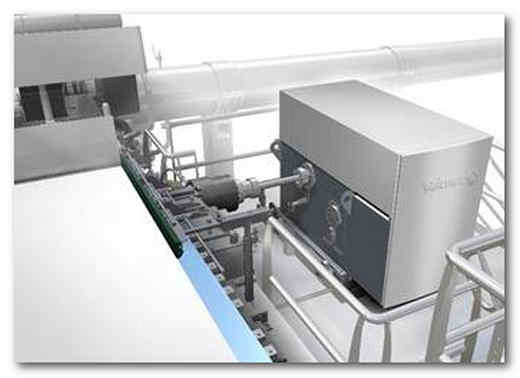

Valmet's breast roll shaker improves board and paper quality

Valmet has introduced its new FormMaster 120 for board and paper machine forming sections. It has proven to offer better board and paper quality with a smoother surface and better printability with reduced raw material costs and lower power consumption.

Improved formation and strength properties

Valmet's new FormMaster 120 improves paper and board formation through even longer strokes and higher shaking force than its predecessor. This self-balancing breast roll shaker can achieve the same strength properties with a lower basis weight, improving the visual appearance of the final product.

With an axial shaking force of 120 kN - double that of the original FormMaster - the new FormMaster 120 improves strength properties and formation by optimizing fiber web structure on the wire. FormMaster 120 makes it possible to use less refining energy, minimize starch usage and reduce calendering, while still achieving the same final quality of board and paper.

FormMaster 120 provides the best stroke length on the market for a large range of breast roll weights.

Best stroke length on the market

"FormMaster 120 is an excellent tool for paper machine operators to optimize the properties of their board and paper. The extended stroke length, achieved with this new breast roll shaker, is key to improved formation and available with a wide range of shaking frequencies," says Pekka Hirsilä, Product Sales Manager at Valmet.

Maintenance issues were also addressed in the design of FormMaster 120 by improving access to the main maintenance points. Customers all over the world have found FormMaster 120 safe, easy and reliable to use and maintain.

Further information, please contact:

Pekka Hirsilä, Product Sales Manager, Paper Technology Sales, Valmet, tel. +358 10 672 6626,

Markku Pohjola, Senior Chief Engineer, Paper Mills, Valmet, tel. +358 10 672 6354,

Valmet receives repeat order for two new tissue production lines from Lee & Man Paper Manufacturing in China

Valmet will supply two Advantage DCT tissue production lines and related automation systems to one of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd. The start-up of the two new lines is planned to take place in late 2016.

Valmet will supply two Advantage DCT tissue production lines and related automation systems to one of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd. The start-up of the two new lines is planned to take place in late 2016.

The order is included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

The Valmet's Advantage DCT 200HS tissue lines to be delivered are designed for production of high quality tissue products. The new tissue lines will fulfill the high requirements for effective technology and sustainability set by Lee & Man. In 2014, the company ordered an Advantage DCT 200HS tissue line which is planned to start up at the Chongqing mill later this year.

"We see Valmet as strategic partner in the development of our tissue business. Their position as market leader in tissue machinery made us confident to repeat our previous order with Valmet", says Raymond Lee, Chairman of the Board, Lee & Man.

"We are very pleased that Lee & Man have decided to extend the cooperation we started with the delivery of the first tissue machine to Chongqing mill. As seen from earlier installations, it is possible to reach significant drying energy savings and highest paper quality by combining the Advantage ViscoNip press with a cast alloy Yankee cylinder and steam heated Advantage AirCap hood. We also see this order as confirmation of the winning concept," says Svenerik Olsson, Director, Tissue Mills Business Unit, Valmet China.

Valmet's Advantage DCT concept is well established on the market and has proven to enable cost- and energy-efficient production of high quality tissue products.

Technical information about the delivery

The new tissue machines will have a width of 5.6 m and a design speed of 2,000 m/min. Each machine will produce 60.000 tons of toilet and facial tissue per year, using virgin wood pulp and bleached bamboo fiber as raw material.

Valmet's scope of delivery will comprise complete tissue production lines featuring stock preparation systems and Advantage DCT 200HS tissue machines. The machines will be equipped with OptiFlo headbox and cast alloy Yankee cylinders. The machines will also be featured with the well proven Advantage tissue technology including ViscoNip press, steam heated AirCap hood, WetDust dust system and a SoftReel P reel. Basic engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

The delivery will also include an automation package from Valmet with Valmet DCS and QCS process control system.

About the customer Lee & Man Paper Manufacturing

Established in 1994, Lee & Man Paper Manufacturing Ltd has grown from a small company into a leading paper and pulp manufacturer. The company's 6,500 employees are located at the company's five production sites in China. The company had a capacity of 7 million tons of container board, duplex board and tissue paper as well as 180,000 tons of pulp in 2014.

For further information, please contact:

Svenerik Olsson, Director, Tissue mills, China area, Valmet, Tel. +86 139 10171872

Krister Harnesk, Sales Manager, Tissue mills, Valmet, Tel. + 46 766 397543

Valmet to supply a tissue production line to Renova in Portugal

Valmet will supply an Advantage NTT tissue production line and an automation system to the European tissue brand Renova. Renova is the first tissue producer in Europe to invest in Valmet's Advantage NTT tissue technology for the production of textured and plain tissue products.

Image: Valmet Advantage NTT tissue machine

The new line, to be installed at the Torres Novas mill in Zibreira, Portugal, will allow Renova to increase its paper production capacity with 50%. The start-up is scheduled for the end of 2016.

The order was included in Valmet's second Quarter 2015 orders received. The value of the order is not disclosed.

"We are eager to see the result from the combination of Renova's proactive innovativeness and Valmet's sustainable Advantage NTT technology. Its flexibility provides endless possibilities to produce special designed textured tissue products," says Mr. Pereira da Silva, CEO of Renova

"Our Advantage NTT technology has established a strong market position in high efficiency innovative and flexible tissue production. We are excited to support Renova to bring their tissue products to the next level. We are looking forward to working with Renova and making this project a benchmark on the European tissue market," says Jan Erikson, VP Tissue Sales, Valmet.

Technical information of the delivery

The new tissue machine will have a design speed of 1 800 m/min in textured mode and 2,000 m/min in plain mode. The production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of delivery comprises a complete tissue production line including an Advantage NTT tissue machine, with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including, an AirCap hood with a WetDust system. Basic and detailed mill engineering, complete stock preparation and process ventilation are also included in the scope. Furthermore, the delivery will include a Valmet DNA Automation system.

About the customer Renova

Renova is a European brand of high quality and innovative products. Available in more than 60 countries it offers colorful designs and new functional solutions through stylish and environmental friendly tissue consumer products.

For further information, please contact:

Jan Eriksson, Vice President Sales Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

Bernhard Glifberg, Sales Manager, Valmet Tissue Mills Business Unit, tel. +46 705 17 14 27

Valmet maintains its position among the world's sustainability leaders

Valmet has been included in the Dow Jones Sustainability Index (DJSI) for the second consecutive year. The DJSI is a sustainability index family which includes the global sustainability leaders across industries. Valmet was listed both in the Dow Jones Sustainability World and Europe indices.

Valmet has been included in the Dow Jones Sustainability Index (DJSI) for the second consecutive year. The DJSI is a sustainability index family which includes the global sustainability leaders across industries. Valmet was listed both in the Dow Jones Sustainability World and Europe indices.

"Being included in the Dow Jones Sustainability Index for the second year in a row is an excellent achievement for Valmet. It shows that we have been able to constantly improve our sustainability performance. We have systematically proceeded with our sustainability agenda and continued to nurture our shared values and global operating principles which serve as a strong foundation for all of us at Valmet," says Pasi Laine, President and CEO of Valmet Corporation.

The annual evaluation conducted by a Swiss investment specialist RobecoSAM comprehensively reviews the company's performance with regard to social, environmental and financial factors. In total 317 companies were included in the DJSI World for 2015-2016. In addition to Valmet, three other companies from Finland are included in the World index this year.

About the Dow Jones Sustainability Indices

The DJSI is the world's leading sustainability index family. It serves as a benchmark for investors who are committed to ethical investing and review companies' sustainability performance as part of their analyses. The company inclusion is based on a best-in-class approach, which means that the indices only include the top ranked companies within each industry.

For further information, please contact:

Anu Salonsaari-Posti, SVP, Marketing, Communications and Sustainability, Valmet, tel. +358 50 453 4262

Laura Puustjärvi, Head of Sustainability, Valmet, tel. +358 50 337 4473

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet and Stora Enso Kvarnsveden sign multi-year consumables and roll service agreement

Valmet and Stora Enso Kvarnsveden have signed a five-year (three plus two) agreement on the supply of paper machine and fiber line consumables including clothing, doctor blades, refiner segments, winder consumables and selected roll covers. The agreement also includes local roll maintenance operations next to Kvarnsveden's site at Borlänge. The agreement is valid as of July 1, 2015.

Valmet and Stora Enso Kvarnsveden have signed a five-year (three plus two) agreement on the supply of paper machine and fiber line consumables including clothing, doctor blades, refiner segments, winder consumables and selected roll covers. The agreement also includes local roll maintenance operations next to Kvarnsveden's site at Borlänge. The agreement is valid as of July 1, 2015.

Technical support for maintenance and production is part of the agreement. The performance of consumables is optimized by taking advantage of remote analytics and the skills of Valmet's technology experts. In addition, Valmet will keep a ready stock of consumables for Kvarnsveden. This total cost of ownership agreement (TCO) is an exclusive agreement with a fixed monthly fee. The value of the agreement has not been disclosed.

Optimizing consumable performance and simplifying daily operations

The agreement provides a framework for long-term collaboration between Kvarnsveden and Valmet. The aim is to improve the efficiency of daily operations and decrease costs for both partners. Fixed monthly invoicing increases cost predictability.

"With our advanced services offering Valmet's goal is to continuously simplify our customers' daily operations, reduce the consumption of consumables and find cost efficient solutions. I am convinced that we will exceed Kvarnsveden's expectations of us," says Per Holm, Vice President, Sales, Scandinavia at Valmet.

Information about the customer Stora Enso and the Kvarnsveden Mill

Stora Enso is the global rethinker of the paper, biomaterials, wood products and packaging industry. The company produces chemical pulp, paper and board, corrugated packaging and sawn wood products. The Kvarnsveden Mill produces improved newsprint and magazine paper on three paper machines. The production capacity is approximately 720,000 tons per year.

Further information, please contact:

Per Holm, Vice President, Sales, Scandinavia, Valmet, tel. +46 705 17 13 88,

Peter Lindgren, Sales Manager, Consumable Solutions, Scandinavia, Valmet, tel. +46 54 17 11 38

Juha Ojala, Senior Manager, Concept Development, Services, Valmet, tel. +358 40 702 9117

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply a tissue production line to Resolute Forest Products in the United States

Resolute Forest Products Inc. has selected Valmet's Advantage NTT tissue production technology and Valmet's automation solution for the new facility it is building in the United States to manufacture at-home, premium private label tissue paper, including bath and towel. The new machine will be installed at the company's mill in Calhoun (Tennessee), and start-up of the tissue production line is planned for early 2017.

Valmet Advantage NTT tissue machine

The order is included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

"We are very proud to work with Resolute on this important project, and we will deliver first-class tissue technology to their state-of-the-art facility," says Soren Eriksson, Director of Sales, Tissue Mills Business Unit, Valmet.

Valmet's Advantage NTT tissue production technology is designed for maximum flexibility as well as enhanced product quality and can easily change between production of conventional tissue and textured tissue in just a few hours. It has been well received by the market, and this will be the fifth NTT machine to be delivered. The first Advantage NTT line was started up in Mexico in 2013, the second line started up in the second quarter of 2015 in Chile, a third NTT line will be started up in Abu Dhabi in 2015, followed by a fourth NTT line in the U.S. in early 2016.

Technical information

The new tissue machine will have a width of 5.2 m and a design speed of 2,000 m/min. The raw material for the new line will be virgin fiber, and the production line is optimized to save energy and fiber as well as provide flexibility and product differentiation for premium quality products.

Valmet's scope of delivery will comprise a complete tissue production line, including an Advantage NTT 200HS tissue machine. The tissue machine will be equipped with a layered OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology, including an AirCap hood and a SoftReel -B. Basic mill engineering, process equipment and process ventilation are also included in the scope.

Furthermore, the delivery includes an integrated automation solution with Valmet DNA process control system, Valmet IQ scanner with IQFibre & Moisture sensor, as well as IQProfilers and a state-of-the-art web camera system for quality and reliability control. Installation supervision, training and commissioning as well as product development support are part of the delivery.

For further information, please contact:

Soren Eriksson, Director of Sales, Valmet Tissue Mills Business Unit, North America, +1 404 242 8845

Jan Erikson, Vice President, Sales, Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

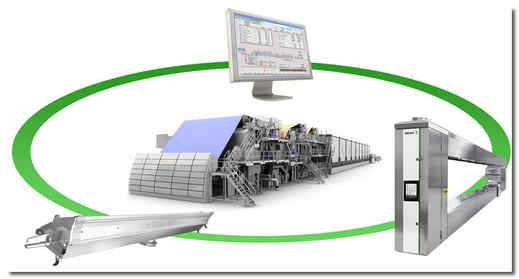

Valmet to supply analyzers and quality control system for Stora Enso's Varkaus Mill in Finland

Valmet will supply pulp mill and board machine quality management solutions for Stora Enso's Varkaus Mill in Finland. The orders are an addition to the extensive rebuild of the Varkaus mill's PM 3 fine paper machine supplied by Valmet to produce lightweight containerboard grades announced on May 13, 2014.

Valmet IQ Quality Control System

The order was included in Valmet's second quarter 2015 orders received. The value of the order is not disclosed. Typically, the order value of automation system deliveries ranges from below EUR 1 million to EUR 3 million.

"After the upgrades of both pulp mill and board machine quality management systems, the Varkaus mill will be able to fully exploit the rebuilt machine's performance potential," says Aki Korhonen, Director of Analyzers, Measurements and Performance Solutions from Valmet.

The Valmet delivery includes a Valmet Kappa Analyzer for the pulp mill and Valmet IQ quality control system (QCS) for the rebuilt board machine.

Technical details of the automation delivery

The Valmet delivery includes a Valmet Kappa Analyzer for the pulp mill. The analyzer will provide all the necessary measurements of fibers, shives and kappa number, for brown unbleached kraft production. Sampling capacity of the mill's Valmet Pulp Expert automatic pulp laboratory will also be expanded with 5 new samplers to accurately follow pulp property development in stock preparation.

The delivery also includes a new Valmet IQ quality control system (QCS) for the rebuilt board machine. With sensors for basis weight, moisture, caliper ash content and color; the IQ system features state-of-the-art machine and cross direction controls. Additionally four Valmet RM3 sensors will be supplied to measure wet end consistencies with the exclusive ability to monitor both total and true ash consistency from the process for active fines retention management. New modules will also be installed to the mill's existing Valmet Paper Lab and provide automated laboratory testing for key board quality parameters.

Information about the customer Stora Enso

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Customers include packaging, joinery and construction industries as well as publishers, printing houses and paper merchants. The Group has some 27 000 employees in more than 35 countries with sales in 2014 of EUR 10.2 billion.

VALMET

Corporate Communications

For further information, please contact:

Janne Tolonen, Sales Manager, Pulp & Paper, Nordics, Automation, Valmet, tel. +358 40 566 9374

Harri Kohonen, Sales Manager, Pulp & Paper, Nordics, Automation, Valmet, tel. +358 40 748 3845

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply tenth OptiConcept M paper making line for Lee & Man in China

Valmet will supply a complete OptiConcept M containerboard production line for Lee & Man in Jiang Xi in China. The new production line is planned to produce high-quality containerboard grades out of 100 percent recycled raw materials. The start-up of the machine is scheduled for the fourth quarter of 2016.

The order is included in Valmet's third quarter 2015 orders received. The value of the order will not be disclosed. An order of this scope is typically valued around EUR 40-50 million.

"OptiConcept M has really made its breakthrough as an industry standard for paper and board manufacturing, which is proven by this repeat order from Lee & Man", says Juha Kivimaa, Director, Sales Technology in Valmet's Paper business.

"This repeat order to Valmet strengthens our long partnership in this business area. With good combination of local and imported know how Valmet has shown its capability in earlier projects. Lightweighting is a trend in containerboard business and Valmet's technology is very suitable for these grades", says Edmond Lee, CEO of Lee & Man.

The line ordered by Lee & Man will be the tenth OptiConcept M production line to be supplied by Valmet since the first delivery in 2012. In addition to Asia, Valmet has delivered OptiConcpet M lines also in North America and Europe. The compact and efficient OptiConcept M production line concept covers grades from recycled containerboards to cartonboards and fine paper.

Valmet's delivery will comprise a complete board machine with related process automation solutions, air systems and winder. The annual production capacity of the new machine will be approximately 300,000 tonnes and the design speed 1,200 m/min.

Information about the customer Lee & Man

Lee & Man Paper Manufacturing Ltd manufactures linerboard and corrugating medium grades for industrial packaging purposes. Lee & Man Paper Manufacturing Ltd has been established in 1994 and it is listed on the Hong Kong Stock Exchange. At present the company has about 7 million tons board production capacity in China.

For further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

Fan Ze, Vice President, Capital Sales in China, Valmet, tel. +86 10 6566 6600 3108

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

Valmet to rebuild Metsä Tissue's tissue machine in Raubach in Germany

Metsä Tissue has chosen Valmet's Advantage DCT concept including the Advantage ViscoNip pressing technology for the upgrade of their tissue machine TM 1 in Raubach, Germany. The start-up of the rebuilt machine is scheduled for the first half of 2016.

Metsä Tissue has chosen Valmet's Advantage DCT concept including the Advantage ViscoNip pressing technology for the upgrade of their tissue machine TM 1 in Raubach, Germany. The start-up of the rebuilt machine is scheduled for the first half of 2016.

The order was included in Valmet's second quarter, 2015 orders received. The value of the order will not be disclosed.

"Metsä Tissue is one of the leading suppliers of tissue paper products to households and professional users in Europe. We continuously develop our products, operations and production units to be able to supply high-quality tissue products and to ensure reliable deliveries to our customers. Through this tissue machine renewal in Raubach mill, we aim to enhance the product qualities as well as energy efficiency and process performance in a sustainable way. We have chosen Valmet as our partner because of Valmet's excellent reputation and strong technology know-how in tissue manufacturing," says Christoph Zeiler, Senior Vice President Tissue West Europe, Metsä Tissue.

"The most important benefits of using Valmet's Advantage ViscoNip technology are both the considerable savings in drying energy consumed and improved tissue paper quality. We are proud that Metsä Tissue has selected our well proven Advantage technology for the upgrade of TM1 in Raubach and look forward to working in close partnership to make this a successful project," says Björn Magnus, Sales Director, Tissue Mills Business Unit, EMEA, Valmet.

Technical information

The machine rebuild to be delivered by Valmet includes a new Advantage DCT wet end section with an OptiFlo Tis II headbox and an Advantage ViscoNip press for improved product quality and decreased energy consumption. A new tail threading system and sheet transfer will further advance runnability and performance. The delivery also includes key stock preparation equipment such as an Optislush Pulper and a OptiScreen machine screen.

An extensive package of services including engineering, installation of the tissue machine, supervision, training, commissioning and start-up is also included in the delivery.

Information about the customer Metsä Tissue

Metsä Tissue is one of the leading tissue paper products suppliers to households and professionals in Europe and the world's leading supplier of baking and cooking papers. Metsä Tissue is part of Metsä Group, which is a forest industry group focusing on tissue and cooking papers, fresh forest fibre paperboards, pulp, wood products, and wood supply and forest services. Its high-quality products combine renewable raw materials, customer-orientation, sustainable development and innovation. Metsä Group's sales totalled EUR 5 billion in 2014, and it employs approximately 10,500 people. The Group operates in some 30 countries.

For further information, please contact:

Jan Erikson, Vice President, Sales, Tissue Mills business unit, Valmet, tel. +46 70 517 14 90

Björn Magnus, Sales Director, EMEA, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet supplies main equipment to the pulp mill project of Huanggang Chenming Pulp & Paper Co., Ltd. in China

Valmet will supply main equipment to Huanggang Chenming Pulp & Paper's new pulp mill located in the city of Huanggang in Hubei province, China. The pulp mill is designed for flexible production to respond to market developments. The pulp line can be run to produce softwood kraft pulp and dissolving pulp depending on the market needs. The new mill is expected to start up in 2017. Valmet's delivery includes the main equipment excluding only some specific process parts.

Valmet will supply main equipment to Huanggang Chenming Pulp & Paper's new pulp mill located in the city of Huanggang in Hubei province, China. The pulp mill is designed for flexible production to respond to market developments. The pulp line can be run to produce softwood kraft pulp and dissolving pulp depending on the market needs. The new mill is expected to start up in 2017. Valmet's delivery includes the main equipment excluding only some specific process parts.

The value of the order is about EUR 110 million. The order is included in Valmet's third quarter orders received.

"Huanggang will be our new business location, where we plan to have a three-phase investment. This pulp mill investment is the first phase. We have been cooperating with Valmet close to 20 years. Our people trust Valmet's know-how and its service spirit. We are happy to select Valmet as the main equipment supplier to this project," says Mr. Chen Hongguo, Chairman of Chenming Group.

"Huanggang pulp mill project offers both our engineering and production personnel work in the Nordics, Asia Pacific and China. This pulp mill will be the world's largest dissolving pulp producer, and the order shows the customer's trust on Valmet's know-how in pulp and dissolving pulp technology," says Bertel Karlstedt, President of Valmet's Pulp and Energy Business Line.

Details of Valmet's delivery

Valmet's delivery presents state-of-the art technology in optimizing mill production, tailor making of dissolving grades, maximizing energy efficiency and minimizing environmental impact. The delivery includes specific equipment and services for wood handling and pulp drying areas, hardwood and softwood multi-grade fiber line (excluding cooking), high dry solids evaporation plant, high power recovery boiler with integrated crystallization system, biomass gasification, lime kiln and recausticizing.

In addition to the delivered equipment, the delivery includes process and basic engineering, detail engineering services and virtual site training simulator for selected areas as well as installation and start-up advisory services.

In parallel with the Huanggang supply contract, Chenming and Valmet agreed on the delivery of a separate non-condensable gas incinerator for the Chenming Group's Zhanjiang mill.

Information about the customer Huanggang Chenming

Huanggang Chenming Pulp and Paper is part of Shandong Chenming Paper Group Co., Ltd, which is one of the leading paper manufacturers in China. The group's activities include afforestation, pulp making, and paper manufacturing. Chenming Group is listed on both the China and Hong Kong stock exchanges. The company has more than 10 production sites around China. The group's annual paper production capacity is 6 million tons and it has about 13,000 employees.

For further information, please contact:

Bertel Karlstedt, President, Pulp and Energy, Valmet, tel. +358 10 676 3026

Yutong Feng, Vice President, Pulp and Energy, China, Valmet, tel. +86 1360 108 9397

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.