Displaying items by tag: valmet

Valmet and Australian Paper sign a multi-year maintenance technical support agreement for Maryvale Mill

Valmet and Australian Paper have signed a multi-year agreement for Valmet to provide maintenance technical support at the Maryvale Mill in Victoria, Australia. The new technical support agreement (TSA) which will focus on providing onsite maintenance technical advice and expertise to the mill's maintenance organization, replaces the old maintenance agreements between Valmet and Australian Paper. The agreement came into effect on August 1, 2015.

Peter Williams, COO of Australian Paper, and Pierre de Villiers, Vice President Sales, Australia and New Zealand from Valmet.

The Maryvale Mill has three pulp lines, five papermaking machines, an elemental chlorine free bleach plant, pulp lapping machine, deinked pulp line, finishing facility and a waste paper processing plant. Valmet's TSA resources will be located within the mills power and recovery, fibre lines, paper mill and central maintenance areas.

"The new agreement builds on the partnership between Australian Paper and Valmet, providing long term technical input into Australian Paper's maintenance operation allowing for continuous improvement and development programs to be identified and implemented along with specific Pulp & Paper knowledge and knowhow," says Peter Williams, COO of Australian Paper.

"Australian Paper has developed continue to develop the Maryvale Mill to ensure its long term sustainability and profitability as a domestic producer of fine paper and packaging grades. The Technical Service Agreement provides the needed alignment to meet these objectives, reinforces the high level cooperation and commitment between our organizations and provides the platform to move our customer's performance forward," says Pierre de Villiers, Vice President Sales, Australia and New Zealand, Valmet.

Information about the customer Australian Paper

Australian Paper is Australia's largest manufacturer of fine papers for print and office applications and produces high-quality packaging papers. Australian Paper employs over 1,400 Australians and supplies more than 600,000 tonnes of product within Australia and around the world. Australian Paper is part of Nippon Paper Group that consists of approximately 180 affiliates and related companies. The Maryvale Mill is Australia's largest integrated fine paper-making and packaging papers complex, producing more than 500,000 tonnes of paper every year.

For further information, please contact:

Pierre de Villiers, Vice President, Sales, Australia and New Zealand, Valmet, tel. +61 417 055 564

Miikka Kettunen, Senior Manager, Maintenance Agreements, Asia Pacific, Services business line, Valmet, tel. +62 811 871 1571

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to acquire tissue rewinder business from Massimiliano Corsini srl. Italy to strengthen its product portfolio

Valmet and Massimiliano Corsini srl. have signed a Sale and Purchase Agreement of MC Paper Machinery and Focus Rewinding business to Valmet on July 31, 2015. The acquisition is estimated to be completed by August 6, 2015.

Valmet and Massimiliano Corsini srl. have signed a Sale and Purchase Agreement of MC Paper Machinery and Focus Rewinding business to Valmet on July 31, 2015. The acquisition is estimated to be completed by August 6, 2015.

The acquired operations mainly supply rewinders for tissue and non-woven machines. In the past years the net sales of the acquired business has been around EUR 10 million. The operations employ 33 people and are located in Pescia, close to Lucca, Italy.

Combination of Valmet and MC Paper Machinery creates complete customer offering

As a result of the acquisition, Valmet will have a more extensive product portfolio and becomes a stronger technology and services company in its field. The acquisition strengthens Valmet's competitiveness by combining tissue making equipment from stock preparation to rewinding, process know-how, automation and services into one customer value-adding entity.

Valmet and MC Paper Machinery have had a long-term partnership and a large amount of MC Paper rewinders have been installed in connection to Valmet tissue machines.

The company being acquired is a strong business, with established customer relations and a high level of technology and know-how, including the successful Focus technology. During the last 20 years MC Paper Machinery has become world leading in designing and manufacturing rewinding plants specifically devoted to the field of non-woven and tissue paper.

Through the acquisition, Valmet strengthens its offering and continues to develop its business.

Strengthened tissue market position

"Valmet and MC Paper Machinery share the same determination to offer leading technologies, with highest customer satisfaction. Through the acquisition, Valmet will become a technology and service company with a wider offering of high technology equipment for tissue production. By combining tissue paper and re-winding machinery with process know-how, automation and services and global presence from both companies, we can serve the tissue producers even better than before and move our customers' performance forward," says Anders Björn, Vice President of Valmet's Tissue Mills Business Unit.

Valmet's Interim Review January 1 - June 30, 2015: Strong start for Automation as part of Valmet - profitability reached the targeted range in Q2/2015

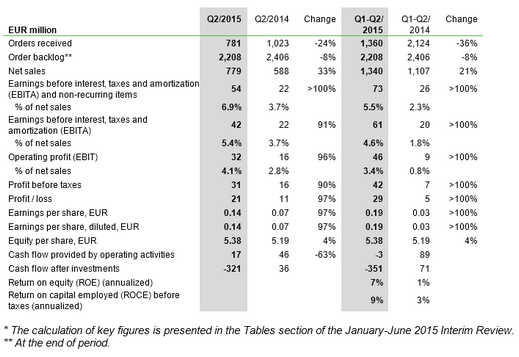

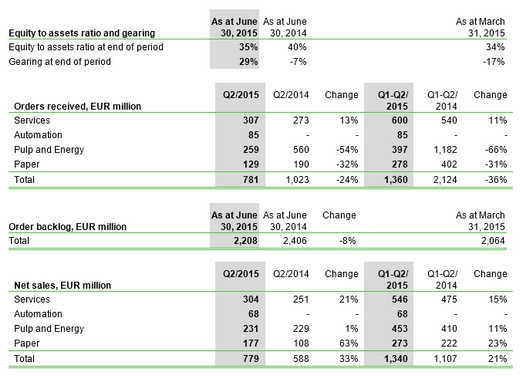

Figures in brackets, unless otherwise stated, refer to the comparison period, i.e. the same period of the previous year. Automation has been consolidated into Valmet's financials since April 1, 2015, when the acquisition of Automation was completed.

April-June 2015: Strong start for Automation - Valmet's EBITA more than doubled

- Orders received decreased to EUR 781 million (EUR 1,023 million).

- Orders received increased in the Services business line and decreased in the Pulp and Energy, and Paper business lines.

- Net sales increased to EUR 779 million (EUR 588 million).

- Net sales increased in the Paper, and Services business lines and remained at the previous year's level in the Pulp and Energy business line.

- Automation contributed to net sales by EUR 68 million.

- Earnings before interest, taxes and amortization (EBITA) and non-recurring items were EUR 54 million (EUR 22 million), and the corresponding EBITA margin was 6.9 percent (3.7%).

- Profitability improved due to the higher level of net sales, improved gross profit, and the acquisition of Automation.

- Earnings per share were EUR 0.14 (EUR 0.07).

- Non-recurring items amounted to EUR -12 million (EUR 0 million), of which costs related to acquisition of Automation amounted to approximately EUR 10 million.

- Cash flow provided by operating activities was EUR 17 million (EUR 46 million).

January-June 2015: EBITA more than doubled - continued good development in Services

- Orders received decreased to EUR 1,360 million (EUR 2,124 million).

- Orders received increased in the Services business line and declined from the high levels in H1/2014 in the Pulp and Energy, and Paper business lines.

- Net sales increased to EUR 1,340 million (EUR 1,107 million).

- Net sales increased in Services, Pulp and Energy, and Paper business lines.

- Automation contributed to net sales by EUR 68 million.

- Earnings before interest, taxes and amortization (EBITA) and non-recurring items were EUR 73 million (EUR 26 million), and the corresponding EBITA margin was 5.5 percent (2.3%).

- Profitability improved due to the higher level of net sales, improved gross profit, and the acquisition of Automation.

- Earnings per share were EUR 0.19 (EUR 0.03).

- Non-recurring items amounted to EUR -12 million (EUR -6 million), of which costs related to acquisition of Automation amounted to approximately EUR 10 million.

- Cash flow provided by operating activities was EUR -3 million (EUR 89 million).

Valmet reiterates its guidance for 2015

Valmet is reiterating its guidance presented on February 6, 2015 in which Valmet estimates that, including the acquisition of Process Automation Systems, net sales in 2015 will increase in comparison with 2014 (EUR 2,473 million) and EBITA before non-recurring items in 2015 will increase in comparison with 2014 (EUR 106 million).

Short-term outlook

General economic outlook

Global growth is projected at 3.3 percent in 2015, marginally lower than in 2014, with a gradual pickup in advanced economies and a slowdown in emerging market and developing economies. In 2016, growth is expected to strengthen to 3.8 percent. The distribution of risks to global economic activity is still tilted to the downside. Near-term risks include increased financial market volatility and disruptive asset price shifts, while lower potential output. (International Monetary Fund, July 9, 2015)

Short-term market outlook

Valmet is reiterating its short-term market outlook presented on April 29, 2015. Valmet estimates that activity in pulp, and board and paper markets will remain on a good level. The activity in the services, tissue, and automation markets is estimated to remain satisfactory. The activity in the energy markets is expected to remain weak.

President and CEO Pasi Laine: Together with Automation, Valmet becomes a stronger company

When the acquisition of Process Automation Systems was completed on April 1, 2015, Valmet got its fourth business line, called Automation. Our customers appreciate that we have reunited the automation expertise with paper, pulp, and power plant technology and process know-how, within the same company. This change has energized and motivated our employees too.

Automation had a strong start as a part of Valmet, and over time I believe that we can achieve even greater benefits through good internal cooperation. With an integrated sales process, harmonized project execution, wider offering and enhanced product development, we will be able to serve our customers even better than before. All in all, Valmet will become a stronger company.

Valmet's performance in the second quarter of 2015 was solid: net sales increased, profitability improved and the EBITA margin reached our targeted range. Good development continued in the Services business line. Additionally we are continuing our focus on cost control and successful project execution.

In addition to expanding Valmet's offering, the automation business somewhat decreases cyclicality of Valmet's businesses. On annual level the automation business is typically fairly stable, thus increasing the stability and visibility of Valmet's business.

Key figures*

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet's Interim Review January 1 - June 30, 2015

Publishing of Valmet Corporation's Interim Review for January-June 2015 on July 30, 2015

Valmet Corporation's Interim Review for January 1 - June 30, 2015 will be published on Thursday, July 30, 2015 at approximately 3:00 p.m. Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

Valmet Corporation's Interim Review for January 1 - June 30, 2015 will be published on Thursday, July 30, 2015 at approximately 3:00 p.m. Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

Invitation to conference call and audiocast

Valmet will arrange a conference call and an audiocast in English for analysts, investors, and media on Thursday, July 30, 2015 at 4:00 p.m. Finnish time (EET). President and CEO Pasi Laine and CFO Markku Honkasalo will be presenting Valmet's Interim Review.

Conference call participants are requested to dial in at least five minutes prior to the start of the conference, at 3:55 p.m. (EET), at +44 1452 553430. The participants will be asked to provide the following event passcode: 1719244

The audiocast can be followed live at www.valmet.com/webcasts. The live audiocast starts at 4:00 p.m. (EET) and a recording of the audiocast will be available shortly after the event at the same address.

It is possible to ask questions at the conference call after the presentations by the President and CEO, and the CFO. At the audiocast, written questions can also be sent via a chat function.

The event can also be followed in Twitter at www.twitter.com/valmetir.

Further information, please contact:

Hanna-Maria Heikkinen, VP, Investor Relations, Valmet, tel. +358 10 672 0007

For media: Anu Salonsaari-Posti, SVP, Marketing & Communications, Valmet, tel. +358 10 672 0033

VALMET CORPORATION

Markku Honkasalo

CFO

Hanna-Maria Heikkinen

VP, Investor Relations

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet delivers white liquor handling system to BillerudKorsnäs's pulp mill in Skärblacka, Sweden

Valmet will deliver a white liquor handling system to BillerudKorsnäs's pulp mill in Skärblacka, Sweden. The start-up of the rebuilt plant is planned in June 2016.

The order is included in Valmet's second quarter 2015 orders received and the value of the order will not be disclosed.

"Previously Valmet has delivered a recovery boiler rebuild and a new evaporation plant to the Skärblacka mill. This upgrade will enable a production capacity increase, as existing equipment has become too small and is in a need of extensive maintenance," says Thomas Malmqvist, Sales Manager Pulp and Energy, from Valmet.

Details about the delivery

The new equipment that Valmet will install are a white liquor filter of type PDW and a causticizer tank. The white liquor filter produces a clear white liquor which increases the efficiency and availability in the pulping process. The separation of white liquor from lime mud is done by pressure filtration. After the rebuild the white liquor plant will have a capacity of 5 200 m3 per day.

About the customer BillerudKorsnäs and Skärblacka mill

BillerudKorsnäs is a leading company within renewable packaging materials. Together with their partners, they create smart packaging solutions. The company has about 4 300 employees and eight production units, one of which is the Skärblacka mill.

Skärblacka mill develops and produces everything from highly porous sack paper to fluting and white machine glazed kraft paper. Production capacity of the mill is 430 000 tonnes/year.

For further information, please contact:

Thomas Malmqvist, Sales Manager, Pulp and Energy Business Line, Valmet, Tel. +46 70 310 53 22

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply winding technology for Parenco's paper machine grade conversion rebuild

Valmet will supply Parenco B. V. with high capacity winder for company's containerboard making line PM2 in Renkum, Netherlands. The PM2 was shut down in 2009 by mill's earlier owner due to declining demand of newsprint paper. Now, the machine will be converted to produce testliner and fluting grades, which are used in containerboards. The converted PM2 is scheduled to start-up during the third quarter of 2016.

The order is included in Valmet's second quarter 2015 orders received. The value of the order will not be disclosed.

Valmet OptiWin Drum high capacity winder

"Valmet's winding technology enables high capacity and reliable production of lightweight packaging board. The proof of this is our strong reference base in Europe. Our OptiWin two drum winders are well suited for multiple grades and models are available for all machine widths", says Kenneth Åkerlund, Product Manager, Winders and Reels, from Valmet.

Technical information about the delivery

Parenco's PM2 has a trim width of 8.5 m. After the conversion it will produce testliner and fluting grades at a capacity of around 385,000 tonnes/yr.

Valmet's delivery includes a fully automated OptiWin two-drum winder comprisingcore feeding, automatic set change and an end gluing device. Valmet's delivery also includes parent roll handling system, fully automatic roll marking and roll conveyor system, automatic core cutting and core handling system as well as related pulper and air systems and machine control system.

About the customer Parenco

Parenco B. V., located in the Netherlands, has a yearly turnover of approximately EUR 140 million and the company operates two paper machines PM1 and PM2 in their Renkum mill. Parenco has over 200 employees. Since October 2012 the company has been owned by H2 Equity Partners.

Further information, please contact:

Kenneth Åkerlund, Product Manager, Winders and Reels, tel. + 358 40 865 6287

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills Business Unit, tel. +358 40 744 8182

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd. Valmet to supply OptiConcept M fine paper making line for APRIL in Indonesia

Valmet will supply an OptiConcept M fine paper production line for APRIL Group's Pangkalan Kerinci site in Riau Province in Indonesia. The new production line is planned to produce top quality digital-ready fine papers and it will increase the company's capability to produce value-added products from renewable resources. The start-up of the new machine is scheduled for the third quarter of 2016.

The order was included in Valmet's first quarter 2015 orders received. The value of the order will not be disclosed.

The first Valmet OptiConcept M line designed for fine paper production

OptiConcept M is Valmet's modular board and paper making concept, which enables significant savings in energy, water and raw material usage. The concept has been acknowledged in Finnish Design competition in 2014.

The new PM3 for APRIL is Valmet's first OptiConcept M delivery in Indonesia. This is also the first time when the latest OptiConcept M technology is utilized in fine paper production.

"This technology investment increases our ability to meet the growing global demand for premium PaperOneTM products, APRIL Group's flagship paper brand. The deployment will enable new product diversification in response to consumer demand for high-value digital paper products in particular," says Tony Wenas, Managing Director of APRIL Group Indonesia Operations.

"Valmet OptiConcept M focuses on low operating costs combined with energy-efficient and flexible production of high-quality paper grades. The technological innovations we have made, play a key role in achieving the overall efficiency of the production line," says Jari Vähäpesola, President of Paper Business Line, Valmet.

Valmet's delivery includes a complete fine papermaking line from stock preparation to reel with related automation systems. A new winder is also included in the delivery. The new 7.1 m-wide (wire) machine will produce woodfree uncoated paper grades in the basis weight range of 40-120 g/m2. The production capacity of the machine will be approximately 900 tonnes per day and the design speed 1,400 m/min.

Valmet OptiConcept M for fine paper production.

Information about the customer APRIL

APRIL (Asia Pacific Resources International Limited) manufactures and supplies fiber, pulp, and paper. The company serves customers through a sales and marketing network in Indonesia, India, Japan, China, Europe, and internationally. The company was founded in 1993 and is based in Singapore with manufacturing operations in Kerinci in Riau Province. APRIL Group currently exports its paper products to 75 countries.

For further information, please contact:

Jari Vähäpesola, President, Paper Business Line, Valmet, tel. +358 10 672 5260

Aki Niemi, Area President, China, Valmet, tel. +86 150 2669 2016

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet receives two more orders from Kotkamills in Finland, both for automation technology

Valmet has received two orders for automation technology from Kotkamills Oy in Finland to complement the major order for key technology for a paper machine conversion project announced in April. The first new order includes wet end automation solutions for Kotkamills' magazine paper production line PM 2 that will be rebuilt and converted to produce packaging board. The second order includes analyzers and advanced process controls for the pulp mill.

The startup of the rebuilt paper machine with new wet end automation is scheduled for the second quarter of 2016. The pulp mill quality improvement project, with new automation solutions is ongoing.

These orders are included in Valmet's second quarter 2015 orders received. The value of the orders is not disclosed. Typically, the order value of automation system deliveries ranges from below EUR 1 million to EUR 3 million.

"One automation platform, from quality, process and machine controls to sectional drive controls, helps us get a good start-up for the project and high availability after the project phase. Our existing know-how of the Valmet DNA system, common spare parts and our service contract with Valmet provide us with many benefits. Having one supplier for the automation system, application and field engineering of the board machine will streamline our work during the project," says Jari Mäkelä, Automation Project Manager, Kotkamills Oy.

"Today, automation solutions are very important tools for the operators and maintenance staff in ensuring maximum line availability and efficiency. Valmet's automation system and know-how enable fully integrated machine controls from headbox to reel. We have had many successful projects with Kotkamills in the past, and this delivery further strengthens our long cooperation," says Ari Pinjamaa, Vice President, Nordics, Valmet's Automation business line.

Technical information about the delivery

The automation delivery for the paper machine PM2 includes Valmet DNA machine and drive controls as well as a Valmet IQ Dilution Profiler. The latter is a profile control system for advanced positioning of the headbox valves to achieve the best possible weight profiles. All the solutions will be integrated within the Valmet DNAautomation system, which is included in the order earlier announced.

The automation delivery for the pulp mill includes Valmet Continuous Cooking Optimizers for both digesters, a Valmet Kappa Analyzer, Valmet Causticizing Optimizer and a Valmet Recovery Liquor Analyzer. All these solutions enable the mill to improve pulp quality and provide significant economic benefits.

Information about the customer Kotkamills

Kotkamills specializes in laminating paper, matt coated bulky paper and sawn products. It is 100% owned by Eagle Industries Oy, a company owned by MB Funds, Nordic Mezzanine, Elo Mutual Pension Insurance Company, Finnish Industry Investment and company management. MB Funds is the majority shareholder.

For further information, please contact:

Ari Pinjamaa, Vice President, Nordics, Automation, Valmet, Tel. +358 40 708 9666

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet's strategy and financial targets unchanged and reconfirmed by the Board of Directors

Valmet's strategy and financial targets, which were announced on September 3, 2013 and reconfirmed on July 31, 2014, have been reconfirmed by Valmet's Board of Directors, and thus remain unchanged.

Valmet's strategy and financial targets, which were announced on September 3, 2013 and reconfirmed on July 31, 2014, have been reconfirmed by Valmet's Board of Directors, and thus remain unchanged.

Strategy

Valmet's mission is to convert renewable resources into sustainable results. The company continues to focus on developing and supplying competitive technology and services to the pulp, paper and energy industries. Valmet is committed to moving its customers' performance forward.

Valmet seeks to achieve its strategic targets by pursuing the following Must-Win initiatives: customer excellence, leader in technology and innovation, excellence in processes, and winning team. Valmet's vision is to become the global champion in serving its customers.

Financial targets unchanged

Valmet's financial targets remain unchanged and they are the following:

- Net sales growth to exceed market growth

- EBITA before non-recurring items: 6-9%

- Return on capital employed (pre-tax), ROCE: minimum of 15%

- Dividend payout at least 40% of net profit

Comment from Pasi Laine, President and CEO of Valmet:

"Valmet has proceeded systematically in the implementation of its strategy. The EBITA margin target of 6-9 percent is still valid, and we continue the work to reach that level. The acquisition of Automation business was an important step and now we can offer unique benefits for our customers. Valmet is committed to moving our customers' performance forward," says Pasi Laine, President and CEO of Valmet.

Further information, please contact:

Pasi Laine, President and CEO, Valmet, tel. +358 10 672 0001

Markku Honkasalo, Chief Financial Officer, Valmet, tel. +358 10 672 0008

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd. Valmet has received a repeat order for two energy recovery systems from Sofidel in Italy and Poland

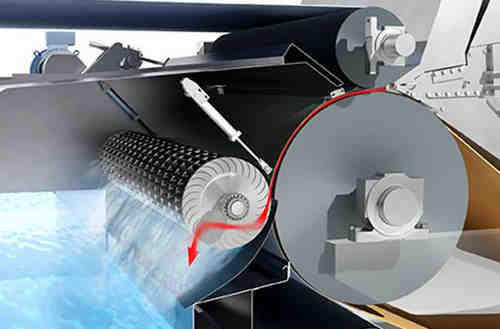

In order to increase energy efficiency of its tissue production lines, Sofidel SPA in Italy has ordered two Advantage ReTurne energy recovery systems from Valmet. The system does not only recover energy from the headbox jet power, but also returns it back to the process as electrical energy.

The order is included in Valmet's second quarter 2015 orders received. The value of the order will not be disclosed.

This will be Sofidel's second and third installation of the innovative energy saving solution and will be installed at Delicarta mill's TM2 in Italy and Delitissue mill Poland. The first Advantage ReTurne installation started up at Sofidel's Delicarta mill in Valdottavo, Italy in 2014 and proved to fully meet the expectations right from the start.

Valmet's Advantage ReTurne recovers energy from the Headbox jet stream and returns it back to the process as electrical power.

For Sofidel it is important to find new innovative solutions to reduce the environmental impact of its production. The company has joined Climate Savers, the international program promoted by WWF, to voluntarily adopt plans to reduce emissions of greenhouse gases using innovative strategies and technologies.

"The first installation of Valmet's Advantage ReTurne energy saving system has been a positive experience for us. Its energy saving capabilities turned out to be better than we hoped for. Therefore we have decided to improve the energy efficiency in two more of our tissue machines," says Simone Capuano, Vice Chief Technical Officer, Sofidel.

"Energy saving is high on our customers' agendas, and we are working hard to develop energy efficiency in our new and existing tissue making solutions. Our high expectations on the first Advantage ReTurne system were substantially exceeded. We are thus convinced that the two new installations will be as successful as the first one, and will help Sofidel reach its environmental targets," says Johan Björn, Sales Director EMEA, Valmet.

Technical information

The Advantage ReTurne energy recovery system is installed in the forming section. It is unique in that sense that it recovers 50% of the energy from the headbox drainage water and via a generator converts it into electrical power which is supplied to the sectional drives. The Advantage ReTurne does not affect the formation of the paper or the tissue making process, it is easy to handle and has low maintenance need. This new innovation is very efficient in both new and existing tissue machines.

Information about the customer Sofidel

The Sofidel Group is a world leader in the manufacture of paper for hygienic and domestic use. Established in 1966, the Group has subsidiaries in 13 countries - Italy, Spain, Sweden, the UK, Belgium, France, Croatia, Germany, Poland, Romania, Greece, Turkey and the USA - with more than 5,200 employees. With a consolidated turnover of EUR 1,771 million (2014), Sofidel is the second ranking group in Europe in terms of production capacity in the tissue sector (1,050,000 tonnes per year in 2014).

For further information, please contact:

Johan Björn, Sales Director EMEA, Valmet, Tel. +46 703 17 12 16

Jan Erikson, VP Tissue Sales, Valmet, Tel. +46 705 17 14 90

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.