Ian Melin-Jones

Gardner Denver Acquires Runtech Systems

Gardner Denver Holdings Inc. (NYSE: GDI), a leading global provider of mission-critical flow control and compression equipment, announced that it has acquired Runtech Systems Oy for a net purchase price of approximately $93 million funded by cash on hand. Based in Kolho, Finland, Runtech is a leading global manufacturer of turbo vacuum technology systems and optimization solutions for use in a variety of process-oriented industrial end markets. Runtech will be part of Gardner Denver’s Industrials Segment.

“Runtech is a market-leader with a history of innovation, excellent customer relationships and strong talent with deep market expertise,” said Vicente Reynal, Gardner Denver’s CEO. “This transaction is aligned with our strategy of leveraging core, mission-critical technologies to drive growth and build additional value at acquired companies. Runtech’s technology will enable expansion into new and attractive markets. It is a great addition to the Gardner Denver family,” added Reynal.

“Runtech is a market-leader with a history of innovation, excellent customer relationships and strong talent with deep market expertise,” said Vicente Reynal, Gardner Denver’s CEO. “This transaction is aligned with our strategy of leveraging core, mission-critical technologies to drive growth and build additional value at acquired companies. Runtech’s technology will enable expansion into new and attractive markets. It is a great addition to the Gardner Denver family,” added Reynal.

“This is an exciting time for our customers and employees,” said Kimmo Loippo, Chairman and co-founder of Runtech. “Both companies are aligned, with an entrepreneurial mindset and a passion for developing innovative customer-focused solutions,” added Loippo. Juha Karvinen, co-founder and developer of EcoFlow™ and Eco-Pump™ said, “Together our combined capabilities will further expand the technology to broader flow control, vacuum and pressure solutions for the betterment of our customers.”

For more information, visit: www.gardnerdenver.com

European paper industry’s trade complaint against Turkey upheld in European Commission report

The EU has today released a report related to a Trade Barrier Regulation ("TBR") investigation launched following a complaint submitted by CEPI, the European association representing the paper industry. The report upheld the complaint finding that the measures imposed by Turkey on the imports of certain varieties of paper such as office paper, books, envelopes and paper used for direct mail marketing (otherwise known as uncoated wood free (“UWF”) paper) from the EU were inconsistent with both WTO and the EU–Turkey Customs Union rules.

“CEPI takes pride in its strong commitment to free trade with its partners. The decision by the Turkish authorities to remove these unfair measures is applaudable; however this issue should never have been escalated in the first place. It is our expectation that the Turkish authorities stand by their obligations under the EU-Turkey Customs Union Agreement in the future” says Sylvain Lhôte, Director General at CEPI.

“CEPI takes pride in its strong commitment to free trade with its partners. The decision by the Turkish authorities to remove these unfair measures is applaudable; however this issue should never have been escalated in the first place. It is our expectation that the Turkish authorities stand by their obligations under the EU-Turkey Customs Union Agreement in the future” says Sylvain Lhôte, Director General at CEPI.

In advance of the Commission’s publication of the report Turkey pre-emptively removed the unfair trade measures. With this in mind, the EU has decided not to pursue the matter further. The industry will however remain vigilant that similar measures do not hinder the free flow of trade between the EU and Turkey in the future, particularly in light of the modernisation of the EU-Turkey Customs Union Agreement.

Background to the trade complaint:

Following an inconclusive safeguard investigation on UWF imports in 2014-2015, Turkey extended in 2016 an existing import licensing system which targeted €150 million of EU exports of UWF paper products.The Turkish non-automatic import licensing system with regard to UWF paper was based on an arbitrary price threshold and created a significant and unfair obstacle to EU-Turkey trade. The contested system posed a clear violation of WTO and the EU-Turkey Customs Union Agreement. The European paper industry already exports 22% of its produce outside the EU and will continue to remain an advocate for free trade and take a firm stance where this is put at risk.

For more information, please contact Bernard Lombard, Industrial Policy Director at This email address is being protected from spambots. You need JavaScript enabled to view it. or by phone at (+32) 2 627 49 22

Valmet's new innovative online solution improves lime mud moisture measurement

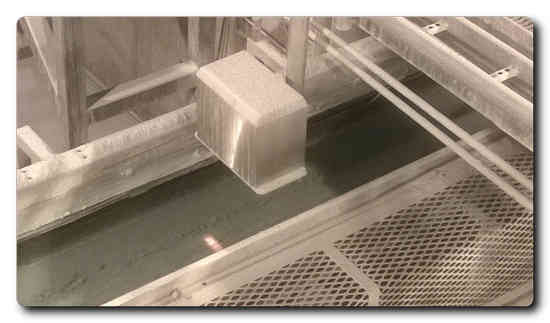

Valmet has developed an innovative online solution for measuring lime mud moisture - Valmet Lime Mud Moisture Measurement. It can be used to monitor lime mud filter performance on the conveyor belt to improve lime mud quality. The new solution is also applicable as a feedforward measurement for lime kiln power control. Through more accurate power control, it is possible to optimize energy consumption and gain significant energy savings.

"The problem with laboratory measurements is that samples are taken so seldom that measurement data cannot be used for power control. It is possible only with an online measurement," says Timo Laurila, Business Manager, Recovery Analyzers and Advanced Process Controls, Automation, Valmet.

Valmet Lime Mud Moisture Measurement

Valmet Lime Mud Moisture Measurement

Valmet Lime Mud Moisture Measurement is a non-contacting measurement that provides the moisture content of lime mud. It features an infrared sensor with a special optical design, resulting in excellent measurement accuracy. The solution is based on Valmet's long experience in moisture measurement technology.

Excellent results reported by pulp mills

This new lime mud moisture measurement has already proven its capabilities in pulp mills. According to customers, its correlation with laboratory measurements has either been on a very high level or the lime mud moisture measurement is even more accurate. Lime mud filter operations can be seen immediately in the moisture measurement level. Moisture sensor cleaning is not needed, not even in a dusty environment. The measurement can be used in lime filter maintenance planning, too.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.2 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Standard & Poor’s Ratings Services upgraded Metsä Board Corporation to investment grade

Standard & Poor’s Ratings Services has upgraded Metsä Board Corporation's issuer credit rating to investment grade, from BB+ to BBB-. The outlook of the rating is stable.

The upgrade reflects Metsä Board’s strong performance in 2017 and the expectation of strong cash flows in the coming years. The stability of Metsä Board’s business operations is supported by solid and long-lasting customer relationships as well as the strong market position.

The upgrade reflects Metsä Board’s strong performance in 2017 and the expectation of strong cash flows in the coming years. The stability of Metsä Board’s business operations is supported by solid and long-lasting customer relationships as well as the strong market position.

At the same time, Standard & Poor’s raises the ratings of Metsä Board’s senior unsecured bonds, maturing in 2019 and 2027, from BB+ to BBB-.

The upgrade does not have an impact on Metsä Board’s current financing costs.

Further information:

Jussi Noponen, CFO, tel. +358 10 465 4913

Katri Sundström, VP, Investor Relations, tel. +358 400 976 333

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards including folding boxboards, food service boards and white kraftliners. Our lightweight paperboards are developed to provide better, safer and more sustainable solutions for consumer goods as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests.The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants.

In 2017, the company’s sales totalled EUR 1.8 billion, and it has approximately 2,350 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Essity restructures in Chile

Essity is restructuring its production facility in Santiago, Chile, to further improve quality and cost for the Consumer Tissue and Professional Hygiene businesses in the country. These measures are aligned with the company’s strategy to optimize the production footprint to increase cost and capital efficiency and further increase value creation in the Consumer Tissue and Professional Hygiene business areas.

The restructuring measures include the closure of one tissue machine and two converting lines.

The restructuring measures include the closure of one tissue machine and two converting lines.

The restructuring costs amount to approximately SEK 140m, and will be recognized as an item affecting comparability in the first quarter of 2018. Approximately SEK 30m of these costs are expected to impact cash flow.

For additional information, please contact:

Henrik Sjöström, Media Relations Manager, +46 8 788 51 36, This email address is being protected from spambots. You need JavaScript enabled to view it.

Johan Karlsson, Vice President Investor Relations, +46 8 788 51 30, This email address is being protected from spambots. You need JavaScript enabled to view it.

Essity is a leading global hygiene and health company dedicated to improving well-being through our products and solutions, essentials for everyday life. The name Essity stems from the words essentials and necessities. Our sustainable business model creates value for people and nature. Sales are conducted in approximately 150 countries under the leading global brands TENA and Tork, and other strong brands, such as Jobst, Leukoplast, Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. Essity has about 48,000 employees and net sales in 2017 amounted to approximately SEK 109bn (EUR 11.3bn). The headquarters is located in Stockholm, Sweden, and the company is listed on Nasdaq Stockholm. More information at www.essity.com

Digitalisation: Contributing to profitable growth from forest to customers

Projects are supported that enable Stora Enso to explore and harness new technologies and capabilities and steer wider deployment.

Deep in the era of digitalisation and such disruptive technologies as advanced analytics, Internet of Things, artificial intelligence, blockchain and robotic process automation, Stora Enso is looking at opportunities for digitalisation throughout the value chain. Digital themes include smart operations, transparent supply chain, digital customer experience, new smart products and services as well as internal business processes. The aim: speed up the company’s transformation.

CIO and Head of Digitalisation in Stora EnsoSome immediate steps to drive digitalisation in the company have included a Digitalisation Fund, a startup Accelerator Programme, internal innovation tool, external business partnerships and cooperations to gain more cross-industry learning, as well as theme specific excellence groups. Through the Digitalisation Fund, projects are supported that enable Stora Enso to explore and harness new technologies and capabilities and steer wider deployment after prototyping to get full scale benefits.

CIO and Head of Digitalisation in Stora EnsoSome immediate steps to drive digitalisation in the company have included a Digitalisation Fund, a startup Accelerator Programme, internal innovation tool, external business partnerships and cooperations to gain more cross-industry learning, as well as theme specific excellence groups. Through the Digitalisation Fund, projects are supported that enable Stora Enso to explore and harness new technologies and capabilities and steer wider deployment after prototyping to get full scale benefits.

“The Digitalisation Fund is an important engine in the company’s development," says Teemu Salmi, Stora Enso's CIO and Head of Digitalisation. “What’s more, we have 25 000 potential innovators within Stora Enso through our diverse employee base, and the fund helps us realise their best ideas."

Every year, the Stora Enso Digitalisation Fund opens up for EUR 10 million in investment in employee initiated projects. From forest to customers, for example, these digitalisation projects include the use of advanced analytics to identify unplanned stops, smart wearables to enhance employee safety, augmented reality to view maintenance needs of running machinery, drones to capture forest or wood yard inventory data and trials of self-driving vehicles. Stora Enso also has projects focused on enhancing the customer experience, such as design tools, calculator apps, remote service, AI advisors and intelligent packages.

“There are so many possibilities – and benefits. In production, using big data to predict web (board as well as paper) breaks helps us to avoid costly disruptions. A common mobile solution for plant maintenance can help to increase efficiency and precision in mill operations, support preventive maintenance and improve warehouse handling,” continues Teemu. “At harvesting sites, digitally scanning trees provides an effective way to identify what tree is best suited for what product. In packaging, digital RFID tags enable us to track packages in the logistics chain and guarantee the authenticity of the packaged product. Incorporating our cloud solution, we can offer our customers a one-stop-shop to digitalise their supply chain.”

“An important point to make is that innovation does not take place in isolation, but rather in ecosystems with niche partners and collaborations with customers, suppliers and research organisations. The Stora Enso Accelerator Programme has also given us the invaluable opportunity to work side by side with startups to learn how we can further increase the pace of innovation within the company and find new commercial products and services. This programme has been focused significantly on digitalisation,” adds Teemu.

About Stora Enso

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people and are publicly listed in Helsinki (STEAV, STERV) and Stockholm (STE A, STE R).

Valmet to supply a repeat order of three winders for Shanying International in China

Valmet will supply three winders for Shanying International Holdings Co., Ltd., in the city of Jingzhou in Hubei province, China. The order is following the delivery of the Valmet OptiConcept M board machine (PM 21) announced in December 2017 and earlier winder deliveries to company's Ma'anshan site. The capacity of the three winders will cover the production of two board machines. The start-ups of the winders are scheduled for the end of the year 2018.

The order is included in Valmet's first quarter of 2018 orders received. The value of the order will not be disclosed. The value of an order of this type is typically EUR 10-20 million.

OptiWin Drum winder

OptiWin Drum winder

"We have a long and good relationship with Shanying. Valmet is supplying or has delivered already six paper or board machines for this customer - the latest ones being the orders of the testliner machine PM 21 and two earlier started-up container board lines in Ma'anshan. Valmet has also just recently announced a waste-fired boiler delivery for Shanying International Holdings. These earlier projects and strong track record with winders convinced the customer to choose Valmet," says Mikko Osara, Vice President of Board and Paper Mills Business Unit at Valmet.

Technical details about the delivery

Valmet's delivery includes three high-capacity OptiWin Drum two-drum compact winders. They are repeat orders of three similar OptiWin Drum winders delivered at the Ma'anshan site in 2014. Valmet's winding concept brings flexibility for the mill's two production lines with high capacity potential as well as smart drive controls and optimization.

The winders are designed for basis weight range of 80-170 g/m2 and design speed of 3,000 m/min.

About the customer Shanying International

Shanying International Holdings Co., Ltd., formerly Anhui Shanying Paper Industry Co., Ltd., is a China-based company, principally engaged in the manufacture and distribution of paper products. The Company's main products consist of various packaging paper boards, newsprint paper, corrugated cardboard boxes, culture paper and other paper products, which are marketed under the brand name of Shanying. The Company distributes its products within domestic markets, with eastern China as its main market.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.2 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Archroma introduces Leucophor® MT, a new cost-effective optical brightening agent for high whiteness surface applications

Archroma, a global leader in color and specialty chemicals, has just announced the introduction of Leucophor® MT liq, a new tetrasulfonated optical brightening agent (OBA) modified to give high whiteness performance in surface applications.

The application of optical brighteners to the surface of paper is usually done by using either hexasulfonated OBAs, when high whiteness levels are required, or tetrasulfonated OBAs, when standard levels of whiteness are sufficient.

With the increasing costs of some of the key raw materials needed to manufacture hexasulfonated OBAs, Archroma asked its R&D experts to develop a tetrasulfonated agent for surface applications that would give comparable levels of whiteness to hexasulfonated grades.

The outcome is Leucophor® MT liq, a REACH-registered, urea-free, modified tetrasulfonated OBA that offers papermakers a new, cost-effective option to achieve high whiteness levels in a surface application, especially at the size press.

Leucophor® MT liq is produced in Archroma’s OBA production facility near Barcelona, Spain, which was extended in 2017 to raise capacity to meet the demands of its European customers.

Andrew Jackson, Product Manager OBAs, Archroma Packaging & Paper Specialties, commented: “With Leucophor® MT liq, we are able to offer a new alternative to both standard tetrasulfonated and hexasulfonated optical brighteners for use in surface applications. This new portfolio option underlines once again Archroma’s continuous commitment to delivering innovation and cost efficiency to our customers, and confirms our position as the leading supplier of OBAs to the paper industry.”

Leucophor® IS A TRADEMARK OF ARCHROMA REGISTERED IN MANY COUNTRIES.

© 2018 Archroma

About Archroma

Archroma is a global color and specialty chemicals company headquartered in Reinach near Basel, Switzerland. It operates with 3,000 employees over 35 countries and with 24 production sites. Its three businesses – Brand & Performance Textile Specialties, Packaging & Paper Specialties, and Coatings, Adhesives & Sealants – deliver specialized performance and color solutions to meet customers’ needs in their local markets, touching and coloring people’s lives every day, everywhere.

Archroma is passionate about delivering leading and innovative solutions, enhancing people’s lives and respecting the planet. The company is committed to challenging the status quo in the deep belief that it can make its industry sustainable; an approach reflected in its innovations, world-class quality standards, high service levels and cost-efficiency. Products enhanced, colors enhanced, performance enhanced – “Life enhanced”.

Seventh Valmet supplied tissue line successfully started up at Hengan's mill in China, with more to come

Valmet and Hengan joined forces on January 15, 2018, to successfully start a Valmet Advantage DCT 200 tissue line at Hengan's mill in Weifang, China.

PM21 is the third of four Advantage DCT 200 lines recently ordered by Hengan. When the startup of PM22 takes place at the same mill in Weifang later this year, Hengan will have a total of eight Valmet supplied tissue production lines in operation. The other two Advantage DCT 200 machines were started in Wuhu, China, with excellent results in 2016. All three startups have been well coordinated and performed in record time, which creates a great outlook for the upcoming PM22 premiere.

The investments support Hengan's aim of strengthening their leading market position in China, while the well proven Advantage DCT Technology ensures a stable production of high-quality tissue, in this case mainly used for facial, toilet and towel grades.

Hengan is China's leading tissue producer, with a current tissue production exceeding one million tons per year. The high-performance Advantage DCT 200 trio counts for an annual capacity of least 180,000 tons of tissue products, soon to be 240,000 tons once all four production lines are started and optimized.

Valmet's and Hengan's teams in front of the newly started Advantage DCT 200 line and the first jumbo roll, in Weifang, China.

Valmet's and Hengan's teams in front of the newly started Advantage DCT 200 line and the first jumbo roll, in Weifang, China.

Technical information about the deliveries

Valmet's delivery comprises of four Advantage DCT 200 tissue production lines, featuring automation, stock preparation systems and the well-proven Advantage technology including OptiFlo headbox, Yankee, AirCap hood, WetDust dust system and SoftReel reel. The machines are 5.6 meters wide and operates at 2,000 m/min.

Information about Hengan

Hengan International Group Company Limited is an investment holding company mainly engaged in the trading of personal hygienic products. The company and its subsidiaries are principally engaged in the manufacturing, distribution and sale of personal hygiene products, including sanitary napkins, disposable diapers and tissue papers products, food and snacks products and others in the People's Republic of China, Hong Kong and certain overseas markets.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.2 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

MACDUE aims to break into the American market

MACDUE is ready to pit and is warming up the engines that will bring the Company to inaugurate soon its sales and service branch in the USA. It is dedicated to the sale of automated packaging lines and machines for tissue (towel paper rolls and folded products) and plastic products (insulating panels, food thermic boxes, trays, plates and cups) and to the after-sales service.

MACDUE aims to position itself in the US market by establishing there a branch, which is able to serve the customers closely and provide them with flexible, robust and efficient packaging solutions together with an ad hoc after-sales service.

MACDUE has a strong presence all over the world and a huge experience built up since 1981 on strong partnerships with customers and their feedback. All this allows the company, 100% Italian, to manufacture packaging machines beyond market expectations to enable customer companies to produce with maximum efficiency.

"Customers all over the world have already trusted MACDUE for its flexible, robust and efficient packaging machines. Now we are ready to introduce our Company and its range of products in the US market with the opening of a branch office in Wisconsin whose staff will manage both the sales activities and the after-sales services "- states Fiorenzo Donetti, MACDUE CEO.

It is not true then that the US market is only for big companies, it is also the seat of MACDUE; an Italian medium company, whose dimension is not indicative of the value that the company has been producing and disseminating in the world.

MACDUE will exhibit to Tissue World Miami 2018 booth G240, 21-23 March. This could be an opportunity for the US prospect customers to meet the MACDUE team, share, and gather information on their packaging machines.

MacDue was established in 1981 in Bologna, the Italian Packaging Valley.

Today MacDue is a leading manufacturer of automated packaging lines for tissue products (paper towel rolls of and folded products), EPS and XPS insulating panels, and thermoformed products such as trays, plates, and cups.

With about 6,800 machines installed worldwide, MacDue offers a complete service including consulting, design, project management, manufacturing, installation and after-sales service for its packaging lines and machines, which perfectly fit with the customer’s production process and layout. MacDue is globally connected with an extensive network of agents and dealers, one trade and service branch in North America and one production site in India that manufactures machines for the local market.