Ian Melin-Jones

Cristini Diagnostic Systems will be present at the MIAC Show in Lucca

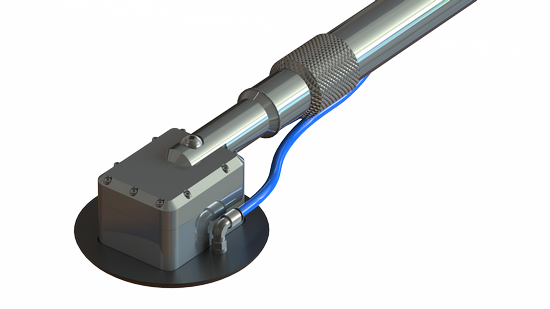

SmartScan™ LM, a new compact microwave sensor for measuring the humidity in the sheet will be presented.

SmartScan™ LM is a sensor based on ultra-short microwaves, for the accurate measurement of humidity in the sheet on low weights and humidity, typical of post-size positions.

SmartScan™ LM complete the SmartScan™ family targeted for the press section already on the market, a success installed in numerous machines across Europe and North America.

SmartScan™ sensors are engineered to overcome the typical limits of the NIR (Near Infrared) technologies. This new generation of sensors is characterized by the most compact construction on the market, with single side measurement. These characteristics and the absence of reflectors and/or sensors on the reverse side of the sheet, allows a wider freedom in installation solutions than all the sensors currently on the market.

Cristini Diagnostic Systems will be present at stand 110.

Brigl & Bergmeister announces 11% price increase on all deliveries effective January 1st 2019.

This measure is inevitable and aimed to partially offset the continuous and extreme increase of raw material cost over the previous months.

This measure is inevitable and aimed to partially offset the continuous and extreme increase of raw material cost over the previous months.

Our experience of the past two years has shown that especially the pulp market remains very volatile and unpredictable. To protect the mutual interest of our customers and us we could offer longer price validities only when they are indexed on the market pulp price.

In addition to the cost increase in raw material, the energy market also expects a sharp price increase which will remain an additional challenge to our industry.

We would like to kindly emphasize and assure our customers and partners in the supply chain that we have taken all internal measures to optimise our cost and efficiency ensuring the lowest possible effect on our product pricing.

Innovative Testing Equipment for the Corrugated Board Industry

Emtec Electronic attends the Corrugated Week in Indianapolis, USA

For the first time, emtec Electronic GmbH will attend the Corrugated Week in Indianapolis, USA from September 24th to 27th 2018, together with its US representative Technidyne Corporation. At exhibition booth no. 848 the company will present innovative testing instruments for the corrugated board industry.

The special EST12 Surface & Sizing Tester determines those surface parameters of paper and board, which are relevant for the converting process, in particular the surface sizing / hydrophobicity and surface porosity. With its help, converting properties, such as printability, gluability, coatability and dusting tendency can be predicted. It enables the optimal runnability during the finishing or converting process of paper/board. An according modular system PDA.C02 Penetration Dynamics Analyzer for more applications is available.

Alongside with the EST12, emtec will have the CAS touch! and FPA touch! on display. These instruments represent the most-modern charge measuring systems for the wet-end in paper and board production and are used to measure the interaction between particles or fibers with additives and process chemicals in the pulp suspension. The use of both instruments in the production process helps to optimize the utilization of chemicals with the objective to stabilize the process, to improve the product quality and to reduce cost.

The new measuring method to measure the mineral filler content of the ACA Ash Content Analyzer, is nondestructive, quick, easy and accurate. Typical mineral filler and pigment content in paper and board, such as calcium carbonate, kaolin/ talcum, titanium dioxide, and the total mineral filler content in percent are determined. It enables optimal process control due to instant availability of measuring results, and helps to narrow down the specifications for the filler content in the finished product and therefore to optimize the consumption of fillers.

Additionally, emtec Electronic will inform about its DSS Dimension Stability System, a modular measuring system for the investigation of the dimension stability of paper, board and foils in one-sided contact with temperature or liquids. The WSD module Wet Stretch Dynamics Analyzer measures the dynamics of the change in dimension of paper under one- sided liquid contact. And the HSA module Heat Shrinkage Analyzer predicts the dimension stability of paper, board and foils in contact with high temperature during the converting process.

International Paper Announces Senior Leadership Retirement

International Paper have just announced the retirement of C. Cato Ealy, senior vice president, Corporate Development after 26 years with the company. His retirement will be effective December 31, 2018.

![]() Mr. Ealy joined the company in 1992 as director of Corporate Development. In June 1996, he was promoted to vice president and was elected as a senior vice president in June 2003. Mr. Ealy has been responsible for the company's acquisitions and divestitures. Most notably, he played a key role in developing and executing the company's transformation plan, which included significant divestitures and several important acquisitions transforming International Paper into a leading global packaging, pulp and paper company.

Mr. Ealy joined the company in 1992 as director of Corporate Development. In June 1996, he was promoted to vice president and was elected as a senior vice president in June 2003. Mr. Ealy has been responsible for the company's acquisitions and divestitures. Most notably, he played a key role in developing and executing the company's transformation plan, which included significant divestitures and several important acquisitions transforming International Paper into a leading global packaging, pulp and paper company.

"Cato has been a key contributor to the success of International Paper for nearly three decades helping to make IP a more sustainable and profitable company," said Mark S. Sutton, chairman and CEO. "All of us wish him the very best in retirement."

About International Paper

International Paper (NYSE: IP) is a leading global producer of renewable fiber-based packaging, pulp and paper products with manufacturing operations in North America, Latin America, Europe, North Africa, Russia and India. We produce corrugated packaging products that protect and promote goods, and enable worldwide commerce; pulp for diapers, tissue and other personal hygiene products that promote health and wellness and papers that facilitate education and communication. We are headquartered in Memphis, Tenn., and employ approximately 52,000 colleagues located in more than 24 countries. Net sales for 2017 were $22 billion. For more information about International Paper, our products and global citizenship efforts, please visit internationalpaper.com

SOURCE International Paper

Metsä Board invites you to experience the creative packaging design process live at Packaging Innovations – 13 September

Metsä Board, the leading European producer of premium fresh fibre paperboards, will present a live seminar showcasing an example of an award-winning design at Packaging Innovations and Luxury Packaging London on 13 September.

Metsä Board’s Ilkka Harju, Packaging Services Director and Mikko Spoof, Brand Director at Arctic Blue Gin will present a creative case study.This collaborative case study shows how packaging design should communicate with each part of the value chain and how it must be at the core of a brand.

Visitors are invited to join The Drinks Forum for 11.50 at The Innovation Stage to hear how the packaging for the 2018 ‘Spirit of the Year’, Arctic Blue Gin, showcases an impressive design process which optimised all aspects of the paperboard to create a stunning solution.

Metsä Board eco-barrier paperboard

Metsä Board eco-barrier paperboard

In addition, at its stand, Metsä Board will highlight its folding boxboards, white kraftliners and food service boards and full range of packaging analysis and design services – which encompass material and structural analysis as well as modification of existing packaging to a fully-customised design, complete with graphics. All these services aim to maximise packaging performance, sustainability and logistic efficiency throughout the entire value chain.

On display will be the latest addition to the range, the new eco-barrier paperboard MetsäBoard Pro FSB EB1, which is a unique product with a bio-based and biodegradable barrier treatment that is fluorochemicals-free. Other innovative and award-winning designs will be presented including Metsä Board’s SkinCare 2.0 gift box which uses fibre-based materials to replace plastic.

Packaging Services Director Metsä Board, Ilkka Harju stated; “We are looking forward to welcoming visitors to our joint presentation on the 13 September, to show them how Metsä Board can help them to achieve truly innovative, vibrant and sustainable packaging. We want to inspire brand owners, converters and designers with our fresh fibre materials and our award-winning packaging designs.”

Ricardo Domingues joins Toscotec.

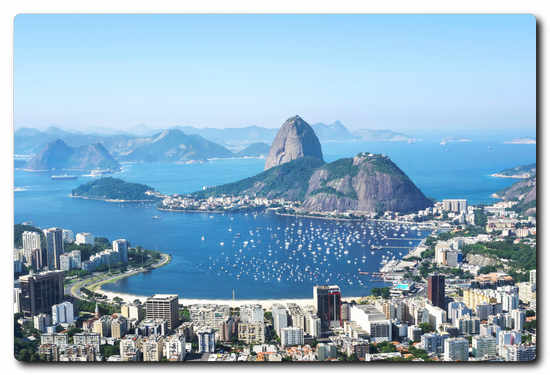

Toscotec has revealed plans to expand its tissue and paper & board businesses in Brazil. Toscotec announced that Ricardo Domingues has joined the group as Sales Manager of the Brazilian market, both for tissue and paper & board.

Toscotec is set to consolidate its market position with the support of Domingues, who brings over 20 years of experience in the tissue and paper industry in Brazil.

Thanks to Domingues’ international expertise in design, sales and services, Toscotec is taking a new step in growing its customer base in Brazil.

Invercote and Incada - when paperboard pros get to choose

Iggesund Paperboard, which is part of the Holmen Group, has the two most valuable paperboard brands in Europe. That’s the conclusion of a brand survey done by the analyst firm Opticom International Research. Over 200 converters – companies that process paperboard into finished packaging – rank Invercote and Incada from Iggesund at the very top.

The survey encompasses converters in Germany, France, the UK, Italy, Spain, Switzerland, Belgium and the Netherlands in the packaging segments: pharmaceuticals & health care products, cosmetics & beauty, chocolate & confectionery, dry foodstuffs, frozen & chilled foods, and wines & spirits. The study has been done every second year since 2004 and Iggesund’s brands have consistently placed at the top.

“Every time we place highest in this survey we get confirmation that both our paperboard families offer what the market wants,” comments a satisfied Kenneth Nysten, Sales and Marketing Director at Iggesund. “Of course, it is particularly pleasing that the survey participants are converters, who make their living from transforming this white and lightweight paperboard into functional and elegant packaging.”

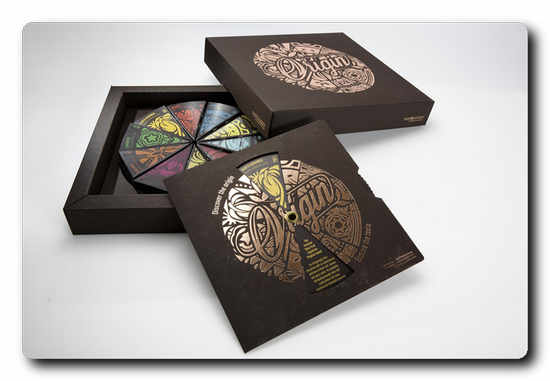

The Origin Box is made of three kinds of paper material, of which two, Invercote and Incada, are made by Iggesund Paperboard. Converter was Du Caju Printing & Packaging, Belgium.

The Origin Box is made of three kinds of paper material, of which two, Invercote and Incada, are made by Iggesund Paperboard. Converter was Du Caju Printing & Packaging, Belgium.

The survey also concludes that high quality and sustainability characteristics are becoming more and more important as selection criteria. Converters also have high expectations on properties such as printability, runnability in the conversion process, and folding properties – all of which both Invercote and Incada achieve with ease.

Iggesund and Stora Enso are perceived as leading the paperboard market with regard to sustainability, even though the majority of the respondents do not see any clear leader within the industry.

“The converters’ opinion, not least the fact that they single out runnability and product quality, reinforces our view that we are heading in the right direction. Their appreciation of our sustainability work is also important and a strong argument in favour of our products,” Nysten concludes.

Europe’s most valuable paperboard brands according to the survey:

1. Invercote (Iggesund)

2. Incada (Iggesund)

3. Tambrite (Stora Enso)

4. Ensocoat (Stora Enso)

5. Performa (Stora Enso)

6. BillerudKorsnäs (BillerudKorsnäs)

7. CKB (Stora Enso) NEW 2018

8. MetsäBoard Pro (Metsä Board) NEW 2018

9. Alaska Plus (International Paper)

10. MetsäBoard Classic (Metsä Board) NEW 2018

11. MetsäBoard Prime (Metsä Board) NEW 2018

Hygienic Tissue Mills fired up a new TT WIND-P tissue rewinder supplied by Toscotec, in South Africa.

On July 27, Hygienic Tissue Mills started up a Toscotec-supplied TT WIND-P tissue rewinder at its Pietermaritzburg mill, in eastern South Africa. This is a repeated order for Toscotec, following the supply of a MODULO-PLUS tissue machine, PM2, in 2017. The TT WIND-P slitter rewinder serves PM2, processing 100% virgin pulp and recycled paper parent rolls.

The TT WIND-P slitter rewinder features 2 unwind stands and handles parent rolls of 2750 mm sheet trim and 2500 mm diameter, with a design speed of 1500 mpm. The pneumatically loaded slitting system has a minimum width of 150 mm. Toscotec supplied the complete electrification and control system, and the sectional drive system. The scope of supply also included the erection supervision, commissioning, start-up assistance, and on-site training.

Toscotec Start-up & Service Engineer David Ponte commented, “It was one of the fastest commissioning I have seen for a rewinder. The TT WIND reached its maximum speed in record time with a final product that was already sellable. Thanks to the great cooperation of Hygienic Tissue’s team, we completed fine tuning in two days with the machine running at top speed”.

Hygienic Tissue CEO Ashraf Jooma said, “On the day of start-up, we reached the maximum speed in a few hours. On this rewinder, we expect to get the same efficiency that we have on the MODULO-PLUS machine. High efficiency and consumption reduction are our priorities, and we are happy with the results we are getting in both areas”.

Matteo Giorgio Marrano, Toscotec Area Sales Manager said: “the TT WIND-P rewinder completed the scope of supply of a MODULO-PLUS tissue line that has been running efficiently for nearly one year and a half. This is a new achievement for Toscotec in the South African market, which has been growing steadily in the last few years. Hygienic Tissue’s strong focus on energy savings matches our mission of tailoring the design of high performing tissue machines to the mill’s specific working conditions, in order to optimize energy usage. The good performance of the slitter rewinder goes into this direction”.

A.Celli Safety Upgrade: safety first!

The best choice to manage the adaptation and compliance of industrial machinery or plants.

The A.Celli Group has always retained technological developments and the safety aspects of machines to be its key growth factors. The Group’s approach to occupational safety is a foundational theme for the company, and the high number of plants sold throughout the world in relationship with a practically inexistent history of accidents on the job is the most evident proof of this philosophy.

Today, the complexity of industrial systems requires increasingly attentive consideration of the theme of safety. Preventing accidents on the job is not a calculation based on a single machine but an outcome of the management logic adopted throughout the production process.

And in addition to the normal risk factor, unpleasant unexpected events can arise from deficiencies at the operating phase, lack of clarity in procedures, negligence by operators or human errors. Without forgetting that year after year, international norms and directives to regulate the issue abound.

For this reason, A.Celli offers its customers the complete solution for plant modification, repair, verification and/or compliance.

The service offered includes:

- Analyses surveys and assessment of customer demands

- Engineering study on components sizing and on plant design with reference to binding norms in the country in question.

- Project management, document handling and issuing of certifications.

- Installation, commissioning and start-up

- Software modification and updating of electrical and pneumatic diagrams.

- Review of manuals and layout of new safety devices.

- 24/7 technical support hotline

- 12-month warranty from the date of completion of the modifications.

The best choice to manage the adaptation and compliance of industrial machinery or plants.

So what are you waiting for?

Contact A.Celli Customer Service (This email address is being protected from spambots. You need JavaScript enabled to view it.) for a quick consultancy or a dedicated case study.

Mitsubishi HiTec Paper welcomes 25 new apprentices

On August 1st 2018, twenty-five new trainees launched their professional career at Mitsubishi HiTec Paper’s mills in Bielefeld and Flensburg. Among them are eleven paper technologists, six machine and plant operators, two industrial clerks, three industrial mechanics, two electronics technicians and one electronic for automation technology.

Our new apprentices at the Bielefeld mill

Our new apprentices at the Bielefeld mill

An exciting time awaits the new apprentices (15 at the Bielefeld plant and 10 at the Flensburg plant) with many new experiences over the next few years: whether it will be on the large paper machines, the ultra-modern coating machines or in the management and distribution of the globally acting manufacturer of coated specialty papers.

Our new apprentices at the Flensburg mill

Our new apprentices at the Flensburg mill

For Mitsubishi HiTec Paper, the training of young people has always been a high priority. "Competitive production and worldwide sales of our high-quality specialty papers is only possible with well-trained specialists" says Andreas Born, Head of Training in Bielefeld. “And we are pleased to provide this training in-house!”