Sappi’s Somerset Mill is on a mission to continually improve its reel building quality, and the ABB Optical Caliper Sensor has helped Sappi to effectively manage optimum reel-building conditions in real-time.

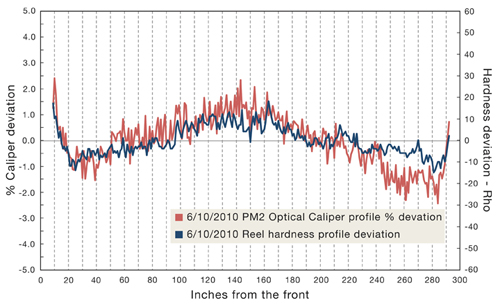

Uniform caliper is extremely important for good roll-building on coated and calendered papers. Because the paper is so dense and smooth, very little caliper profile deviation can be tolerated before the effect is seen on the hardness profile of the reel, and subsequently in the quality of the rolls coming off the winder. PM2 at Sappi’s Somerset Mill used to rely on manual off-line testing of reel hardness profiles using a hand-held hardness tester to assist with the process of troubleshooting reel-building. While this approach was sufficient to enable Sappi to meet its quality targets, the infrequency of these hardness tests represented an opportunity for Sappi to further optimize reel-building conditions, and their available manpower.

“The stability and repeatability of the Caliper Sensor allows the operator to trust the profile shape and make reel-building corrections in real-time rather than wait for an off-line hardness profile test,” says Dave Moore, Senior Process Engineer at Sappi Somerset Mill.

The Optical Caliper Sensor contacts the sheet on one side using a smooth ceramic stabilizing plate with vacuum applied by concentric rings. On the other side of the sheet is a unique optical (confocal) measurement. The confocal measurement is combined with a magnetic reference measurement, and the result is caliper measurement. The simplicity of this design provides reliable performance day after day in the harsh paper mill environment.

Even with the sensor applied very soon after the calendering process on high-gloss grades, Moore adds that, “We have not seen any sheet marking issues with this design.”

Caliper correlation within ±1% between the laboratory and the Optical Caliper Sensor was one goal of the project: “The optical sensor has met our requirement of reproducible CD profile correlation without marking the sheet surface,” reports Moore.

Equally important for Sappi was the correlation to the hand-held hardness instrument. Figure 1 shows that the correlation was good enough to allow operators to make corrections before out of specification limits were reached.

ABB has been working with the Sappi Somerset Mill to implement service and evolve its Quality Control Systems (QCS) for more than 25 years on its three paper machines. Over that period of time, ABB and Sappi have worked together to evolve the systems in a step-wise approach, with manageable capital investments.