Displaying items by tag: Klabin

Klabin successfully starts up the world’s first commercial-grade, concentrated sulfuric acid plant in a pulp mill

Klabin has successfully started up a sulfuric acid plant supplied by ANDRITZ at its Ortigueira/PR plant in Brazil. The plant is a world first and has the capacity to produce 150 tons of commercial-grade sulfuric acid per day from concentrated odorous gases and elemental sulfur. It serves the pulp lines at Klabin's Puma Unit and makes the site completely self-sufficient in sulfuric acid by recycling sulfur from the waste streams.

- ANDRITZ sustainable technologies enable production of commercial-grade sulfuric acid from the mill’s odorous gases, making the mill self-sufficient in sulfuric acid

- The plant is part of the ANDRITZ CircleToZero product portfolio that focuses on eliminating unused side streams, creating new added-value products and laying the foundation for zero emissions and zero waste production

The sulfuric acid plant helps Klabin to control the sodium and sulfur (Na/S) balance and also the sulfidity of the mill. In addition, less sulfate will now be discharged due to the optimized Na/S balance, hence improving the efficiency of input use at the Ortigueira plant. Furthermore, there is no need in future to transport hazardous inputs such as sulfuric acid to the plant and the unit also optimizes resources overall, with a large reduction in transportation volume. As the sulfuric acid plant meets stringent air emission limits, the process significantly improves the overall footprint of the Ortigueira mill.

Klabin's Director of Projects and Engineering, João Antônio Braga, says "Operation of the sulfuric acid plant at the Puma Unit, Ortigueira, represents a significant advance in the circularity of the installation. The new plant allows the Puma Unit to be self-sufficient in sulfuric acid, with the additional option of selling any excess production to the market. This innovative technology, a first in this industry worldwide, supports our efforts to optimize productivity and is an important milestone in our ambition to achieve our sustainability goals.”

The sulfuric acid plant at Klabin’s Ortigueira facility is the first worldwide to produce commercial-grade, concentrated sulfuric acid at a pulp mill © Klabin

The sulfuric acid plant at Klabin’s Ortigueira facility is the first worldwide to produce commercial-grade, concentrated sulfuric acid at a pulp mill © Klabin

Klabin's Manager of Projects, Recovery and Utilities, Walter de Oliveira, adds "The quality parameters are being met and the sulfuric acid is being used successfully in several operations at the plant, replacing the commercial acid we were using before. Besides optimizing resources, installation of the plant brings greater independence because we do not have to rely on an external supplier for our sulfuric acid needs.”

The ANDRITZ scope of supply included technologies on EPCC basis for handling elemental sulfur, combustion of sulfur and concentrated non-condensable gases (CNCG) to form sulfur dioxide (SO2), and conversion of sulfur dioxide into concentrated sulfuric acid, as well as a flue gas treatment system.

Sulfuric acid plants are part of the company's CircleToZero initiative, which includes technologies that aim to reduce and/or eliminate waste from pulp mills. This global initiative for pulp and paper customers brings the continuous development and improvement of existing ANDRITZ technology solutions together with an ambitious, future innovation goal: to eliminate unused side streams, create new value-added products, and establish a foundation for zero emissions and zero waste production.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Klabin starts up its first paper machine of Puma II Project in Brazil with support from AFRY

Klabin, Brazil’s largest producer and exporter of paper for packaging, has taken an important step in its growth strategy with the start-up of the first paper machine (MP27) of the Puma II Project in Ortigueira, Paraná in Brazil. This is Klabin’s largest investment to date and AFRY has been responsible for developing and implementing the BOP (Balance of Plant) EPCM (Engineering, Procurement, Construction Management).

Brazil’s largest paper producer, Klabin, has started operating the first phase of Puma II project when paper machine (MP27) operations were started in August 2021. The capacity of MP27 is 450,000 tons annually of 100% kraftliner paper from eucalyptus fiber (Eukaliner®). Puma II project with a total investment cost of R$ 12.9 billion aims to produce 910 000 tonnes of high-quality kraftliner board annually. The project is implemented in two phases.

Klabin's Puma II Project’s first phase has started operations with engineering, procurement, and project management support from AFRY. During the first phase, AFRY has been responsible for developing and implementing the BOP (Balance of Plant) EPCM (Engineering, Procurement, Construction Management) scope, which included the engineering and project management services of the complementary plants and interconnections between the process islands. AFRY has been involved with the Puma I and II projects since its inception, being also responsible for carrying out the conceptual study and the basic engineering.

Klabin's Puma II Project’s first phase has started operations with engineering, procurement, and project management support from AFRY. During the first phase, AFRY has been responsible for developing and implementing the BOP (Balance of Plant) EPCM (Engineering, Procurement, Construction Management) scope, which included the engineering and project management services of the complementary plants and interconnections between the process islands. AFRY has been involved with the Puma I and II projects since its inception, being also responsible for carrying out the conceptual study and the basic engineering.

“AFRY's joint action with Klabin, reflects a long-standing, trusting partnership that will help us to supply the market at a time of strong demand for packaging,” says Francisco Razzolini, Executive Director of Industrial Technology, Innovation and Sustainability of Klabin.

“We are very proud to be part of a project on the scale of the Puma II, bringing our expertise in engineering and contributing with the most advanced technologies from a sustainability perspective,” says Fábio Bellotti da Fonseca, President of AFRY Process Industries in Americas. “The bioindustry has a fundamental role in the transition towards sustainable economy, and the Puma II project is a reference into this direction, generating value for all project parties”.

AFRY is a European leader in engineering, design, and advisory services, with a global reach. We accelerate the transition towards a sustainable society.

We are 16,000 devoted experts in infrastructure, industry, energy and digitalisation, creating sustainable solutions for generations to come.

Making Future - www.AFRY.com

Klabin supports sustainable practices through issue of green bonds abroad

Sustainability is in Klabin's DNA, and to sustain its investments in these practices, the company recently (September 2017) raised funds in the international market through its first issue of green bonds amounting to around R$ 1.6 billion, maturing in 10 years. The company, which pioneered the adoption of sustainable practices, is a benchmark in sustainable development and its issue received the "High Standard" rating from consulting firm Sustainalytics. The offering drew significant investor interest, with demand exceeding the offer of green bonds sevenfold.

Sustainability governance at Klabin is strongly structured and functions on four key pillars: Sustainability Committee; Sustainability Commission; Sustainability and Communication Department; and a working group on impacts of climate change, all with the mission to raise the level of transparency across the company and structure its actions.

Sustainability governance at Klabin is strongly structured and functions on four key pillars: Sustainability Committee; Sustainability Commission; Sustainability and Communication Department; and a working group on impacts of climate change, all with the mission to raise the level of transparency across the company and structure its actions.

Klabin has been, for three years, prominently featured in the Carbon Disclosure Project (CDP), an international organization that analyzes companies' efforts to minimize and manage the environmental impacts of their operations. In 2016, it was elected "Sustainable Company of the Year" and the most sustainable company in the paper and pulp sector by Guia Exame de Sustentabilidade. Moreover, since 2014, it has been included in the portfolios of the Corporate Sustainability Index (ISE) and Carbon Efficient Index (ICO2) of the São Paulo Stock Exchange (BM&FBovespa).

The issue of green bonds strengthens initiatives under Klabin's sustainable strategic planning and is in synergy with the company’s Vision and commitments to its Sustainability Policy.

More information about Klabin's projects that were selected in each category available for Green Bonds can be obtained from the Sustainalytics report: http://www.sustainalytics.com/wp-content/uploads/2017/09/Klabin-Green-Bond-Framework-and-Opinion-08302017_FINAL.pdf. Updates on the allocation of funds will be made annually on Klabin's Investor Relations website: http://ri.klabin.com.br/

The Notes have not been and will not be registered under the Securities Act, or any state securities laws, and they may not be offered or sold in the United States absent registration or an applicable exemption from the registration requirements of the Securities Act. This notice does not constitute an offer to sell the Notes or the solicitation of an offer to buy the securities. Any public offering of securities to be made in the United States will be made by means of a prospectus that may be obtained from Klabin and that will contain detailed information about the company and management, as well as financial statements.

About Klabin

Klabin is the largest producer and exporter of paper for packaging in Brazil, the only company in the country to offer a one-stop solution in hardwood, softwood and fluff pulp, and the leader in corrugated board packaging and industrial bags markets. Founded in 1899, it has 17 industrial units in Brazil and one in Argentina.

With its entire management guided by sustainable development, Klabin pursues integrated and responsible growth that combines profitability, social development and environmental commitment. Klabin has been a component of the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (BM&FBovespa) since 2014. It is also a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, and seeks suppliers and business partners that share its values of ethics, transparency and respect for the principles of sustainability.

Learn more at www.klabin.com.br

Klabin earns Leadership Status from Carbon Disclosure Project

The company participated in three of the platform’s programs:Climate Change, Water and Forests

Klabin, Brazil's largest paper producer and exporter and the leading manufacturer of corrugated board packaging and industrial bags, was classified as a Climate Disclosure Leader by the Carbon Disclosure Project (CDP) in the categories Climate Change and Forest with scores of “A-”. These scores mean that the company adopts some of the best practices on the platform and has implemented a series of actions to manage climate change in its own operations and those of third parties.A non-profit international organization, CDP analyzes and recognizes the efforts of companies around the world to manage the environmental impacts of their activities.

In the Water category, the company attained "Management" status with a score of "B".The progress of each company is categorized as follows:information disclosure (D- and D), awareness (C- and C), management (B- and B) and leadership (A and A-).Klabin's results are above the industry average and CDP noted that the company is measuring its impacts with the aim of reducing them, setting new targets and implementing strategic policies and structures to support adequate measures.Klabin’s initiatives include monitoring all of its water withdrawals, reducing the impact and improving the performance of its wastewater treatment and establishing a commitment to the UN Sustainable Development Goals related directly to water.

In the Water category, the company attained "Management" status with a score of "B".The progress of each company is categorized as follows:information disclosure (D- and D), awareness (C- and C), management (B- and B) and leadership (A and A-).Klabin's results are above the industry average and CDP noted that the company is measuring its impacts with the aim of reducing them, setting new targets and implementing strategic policies and structures to support adequate measures.Klabin’s initiatives include monitoring all of its water withdrawals, reducing the impact and improving the performance of its wastewater treatment and establishing a commitment to the UN Sustainable Development Goals related directly to water.

In Climate Change, CDP made specific notes about Klabin's results, which it classified as excellent.The score achieved by the company positions it two levels above the industry average and the Brazilian average.The Leadership level attest to the existence of significant activities related to emission reduction targets and verified emissions data.Klabin has a Climate Committee that discusses, plans and carries out actions related to anticipating weather events and maintains a strategic agenda for low-impact air emissions; received the Gold seal from the GHG Protocol, a program of the Center for Sustainability Studies (GVces) of the Getúlio Vargas Foundation (FGV); and has air emission standards focused on the production of clean energy.

In the Forest category, Klabin achieved advances in actions to ensure a value chain free of deforestation, with its practices were considered the best in deforestation risk management.Klabin, whose forest stewardship practices are a global reference in yields, was the first company in the southern hemisphere to receive an international certification attesting to its responsible and economically feasible forest management practices that promote healthy relationships with local communities and to it being a pioneer in promoting forest certification for small rural partner producers.

Since 2006, Klabin has been involved in the Carbon Disclosure Project's global initiative, which facilitates dialogue between investors and companies seeking to minimize the environmental impacts of their business in light of climate change.As part of this effort, in 2015, Klabin was recognized as the company with the Best Practice of Natural Capital Management by the CDP.In 2014, it was selected as one of the companies that most encourages good stewardship practices, which encompass controlling impacts and actions through supplier engagement and the certification and traceability of its wood as a means to guarantee a deforestation-free value chain.

CDP has the largest and most complete global environmental disclosure system for companies, cities, states and regions, enabling them to better measure and manage their environmental impacts.With a network of investors and buyers, companies and political decision-makers use the CDP's data and considerations to make better decisions, manage risks and capitalize on opportunities.

About Klabin

Klabin is Brazil's largest paper producer and exporter and the leading manufacturer of paper and board for packaging, corrugated board packaging and industrial bags. Founded in 1899, it has 16 industrial units in Brazil and one in Argentina. Klabin is organized into four business units: Forestry, Pulp (hardwood, softwood and fluff pulp), Paper (paperboard, kraft paper and recycled) and Packaging (corrugated board and industrial bags).

The company’s management is entirely oriented towards Sustainable Development in the pursuit of integrated and responsible growth that combines profitability, social development and commitment to the environment. Klabin has been included in the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (BM&FBovespa) since 2014. It is also a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, and seeks suppliers and business partners that adopt the same values of ethics, transparency and respect for the principles of sustainability. Learn more at: www.klabin.com.br

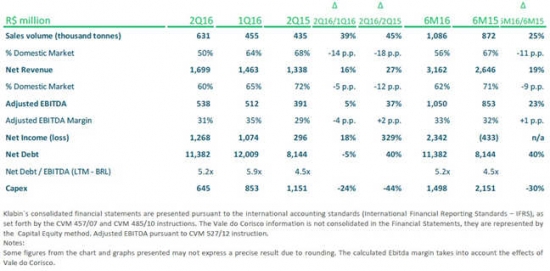

Klabin launches sales of pulp from its Puma Unit and posts EBITDA growth of 37% in 2Q16

Klabin, Brazil’s largest packaging paper producer and exporter and leading manufacturer of corrugated board packaging and industrial bags, reported its 20th straight quarter of growth, with adjusted EBITDA (earnings before interest, tax, depreciation and amortization) in the second quarter of 2016 of R$538 million, or 37% higher than in the second quarter of 2015. Net revenue including wood sales amounted to R$1,699 million, advancing 27% on the prior-year period.

- Adjusted EBITDA amounted to R$538 million in the second quarter of 2016, an increase of 37% from the same period of 2015.

- Net sales revenue in the second quarter advanced 27% on the prior-year period to R$1,699 million.

- In March, Klabin successfully commissioned its Puma Unit in Ortigueira, Paraná. Pulp production continued to ramp up during the quarter, with sales corresponding to 50% of the mill’s nominal capacity.

The second-quarter results benefitted from the commencement of pulp sales by the Puma Unit, which marked a new phase in the Company’s growth. The unit’s operations are ramping up within the established learning curve and contributed 181,000 tons to pulp sales volume in the period, with 165,000 tons of hardwood pulp and the remainder softwood pulp, generating revenue of R$286 million.

Klabin’s sales volume in the second quarter amounted to 631,000 tons (excluding wood), or 45% higher than in the same period last year. In addition to the additional pulp volume in the period, the Company registered 4% growth in sales of paper and packaging, which reached 450,000 tons. This growth was supported by the expansion in production capacity, the debottlenecking actions carried out in 2015 and the flexibility of its product mix, which allows production to be directed to various different markets.

Export volume in the quarter corresponded to 50% of total sales volume, compared to 32% in the second quarter of 2015. The increase is explained by the growth in paper exports and, especially, by the start of pulp sales.

Capital Expenditure

Klabin invested R$649 million in the second quarter of year, with the highlight the investment of R$505 million in the new pulp mill in Ortigueira, Paraná. Capital expenditure to sustain the industrial operations came to R$99 million. Meanwhile, R$34 million was allocated to the forestry operations and R$11 million to special projects and capacity-expansion projects.

Financial Highlights

About Klabin

Klabin is Brazil's largest paper producer and exporter and the leading manufacturer of paper and board for packaging, corrugated board packaging, industrial bags and timber in logs. Founded in 1899, it has 15 industrial units in Brazil and one in Argentina. Klabin is organized into four business units: Forestry, Pulp, Paper (paperboard, kraft paper and recycled) and Packaging (corrugated board and industrial bags).

Management of the company is entirely oriented towards sustainable development, in the pursuit of integrated and responsible growth that combines profitability, social development and a commitment to the environment. Klabin has been included in the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (BM&FBovespa) since 2014. It is also a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, and seeks suppliers and business partners that adopt the same values of ethics, transparency and respect for the principles of sustainability.

Learn more at www.klabin.com.br

Klabin inaugurates its new pulp mill in Paraná state

The Puma Unit is the largest investment ever in the company’s 117-year history

Klabin, Brazil's largest paper producer and exporterand the leading manufacturer of paper and board for packaging, corrugated board packaging and industrial bags, has just inaugurated its new pulp mill located in Ortigueira, Paraná.The Puma Unit represents an important mark in the company’s new growth cycle.With the new mill, Klabin becomes a fiber solutions company by being the only one in Brazil to produce, at the same plant, bleached pulp from hardwood fibers, bleached pulp from softwood fibers and fluff pulp.

The inauguration ceremony was attended by Brazil’s acting president, Michel Temer, the governor of Paraná, Beto Richa, the mayor of Ortigueira, Lourdes Banach, as well as representatives from federal, state and local governments, rural producers, business partners and clients.The guests were welcomed by Klabin’s chairman of the board, Paulo Galvão, and other directors, and by the company’s CEO, Fabio Schvartsman, and its other executive officers.

“It’s imperative for a country of continental dimensions, like Brazil, to have a solid and competitive industrial sector.And Klabin shares this vision.It’s at the core of our corporate DNA,” said Galvão during the inauguration ceremony.According to Israel Klabin, who also sits on the company’s board, “the project that most inspires us is the one to develop sustainably.The one to create an environment of stability that allows us to think further ahead and benefit a greater number of stakeholders.”

The highest private-sector investment ever made in the state of Paraná, the project required total investment of R$8.5 billion, including infrastructure and recoverable taxes, and construction was completed in 24 months and within the initial budget.The Puma Unit will have annual production capacity of 1.5 million tons of pulp, with 1.1 million tons of bleached hardwood pulp (eucalyptus) and 400,000 tons of bleached softwood pulp (pine), a portion of which will be converted into fluff pulp.With power generation capacity of 270 MWavg and 150 MW of surplus power, which is sufficient to supply a city with a population of 500,000, the new operation further improves Klabin’s electricity self-sufficiency.The Puma Unit reinforces Klabin’s commitment to best sustainability practices by combining high forest productivity, efficient production and logistics operations and last-generation environmental technology.

“Puma is a Brazilian experience in excellence and boldness that we hope will serve as an example for the country that we want for our children and grandchildren.It reinforces Klabin’s already globally recognized commitment to the environment.And it shows that you can invest in projects that are concerned with social aspects, with this concern translated into dozens of projects involving health, education, housing and recreation,” said Schvartsman during the ceremony.

Klabin’s hardwood pulp is marketed under the brand LyptusCel™, while its softwood pulp was christened PineCel™.Called PineFluff™, Klabin’s fluff pulp, which for the first time in Brazil is produced on a large scale from softwood pulp, gives the domestic market the possibility of substituting imports of this raw material, which is an important input in the manufacture of diapers, disposable sanitary pads and other absorbent products.

The new mill’s operations were commissioned in March, with production of the first pulp bale, which already held Chain of Custody certification from FSC® - Forest Stewardship Council® (FSC-C129105).April marked the mill’s first shipment, with 20,000 tons of hardwood pulp departing the Port of Paranaguá destined for China.To export production from the Puma Unit, Klabin developed a Logistics Unit in Paranaguá that allows for the use of rail and highway freight solutions.With this new structure, the company expects to distribute 1 million tons of pulp every year.More than 90% of the mill’s production has already been sold.

With built-up area of 200 hectares, which is equivalent to 200 football fields, the construction project involved around 40,000 workers.In all phases of the project, the company prioritized the use of local labor.Today, the new unit is responsible for 1,400 direct and indirect jobs, considering both the industrial and forestry operations, and contributes to the local community through social actions, vocational training programs and projects to promote regional development.During the investment phase, R$700 million in taxes were generated, and with its startup, the mill will generate annual tax receipts of R$300 million.

To determine its social investments, in 2012, Klabin conducted a social diagnosis of the municipalities of Ortigueira, Imbaú and Telêmaco Borba, which represents the new mill’s direct area of influence.Through a broad participatory process that involved the many different stakeholders in urban and rural areas, it developed the Puma Project’s Social and Environmental Action Plan, which comprises various initiatives in the areas of health, education, culture, recreation, the environment, family farming, etc.

The plan’s infrastructure projects included paving roads in the districts of Campina and Minuano, improvements to the Strategic road and building a new bridge to connect the left and right banks of the Tibagi River.Klabin also built a 23.5-km rail branch connecting the mill to the Central do Paraná Railroad.The average distance between forest area and the Puma Unit is 72 km, assuring the mill a high level of competitiveness.Klabin’s forestry operation in the Telêmaco and Ortigueira region, which is one of the world’s largest, supplies both its Monte Alegre and Puma units.Klabin built 100 km of power transmission lines for the new mill, which features the world’s two largest power generation turbines to be manufactured for the pulp and paper industry.

About Klabin

Klabin is Brazil's largest paper producer and exporter and the leading manufacturer of paper and board for packaging, corrugated board packaging, industrial bags and timber in logs. Founded in 1899, it has 15 industrial units in Brazil and one in Argentina. Klabin is organized into four business units: Forestry, Pulp, Paper (paperboard, kraft paper and recycled) and Packaging (corrugated board and industrial bags).

Management of the company is entirely oriented towards sustainable development, in the pursuit of integrated and responsible growth that combines profitability, social development and a commitment to the environment. Klabin has been included in the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (BM&FBovespa) since 2014. It is also a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, and seeks suppliers and business partners that adopt the same values of ethics, transparency and respect for the principles of sustainability.

Learn more at www.klabin.com.br.

Klabin posts 18th consecutive quarter of improved results

Klabin, Brazil’s largest packaging paper producer and exporter, and leading manufacturer of corrugated board packaging and industrial sacks, posted adjusted EBITDA (earnings before, interest, taxes, depreciation and amortization) of R$2.0 billion in 2015, for growth of 15% compared to 2014. In the fourth quarter, adjusted EBITDA stood at R$603 million, increasing 25% from the same period in 2014, for the 18th consecutive quarter of growth.

Klabin, Brazil’s largest packaging paper producer and exporter, and leading manufacturer of corrugated board packaging and industrial sacks, posted adjusted EBITDA (earnings before, interest, taxes, depreciation and amortization) of R$2.0 billion in 2015, for growth of 15% compared to 2014. In the fourth quarter, adjusted EBITDA stood at R$603 million, increasing 25% from the same period in 2014, for the 18th consecutive quarter of growth.

- Adjusted EBITDA of R$2.0 billion in 2015, up 15% from 2014.

- Net revenue of R$5.7 billion in 2015, for growth of 16% on 2014.

- Fourth-quarter adjusted EBITDA of R$603 million, up 25% from the year-ago period.

- Fourth-quarter export volume up 52% from the year-ago period.

- At December 2015, construction of the new pulp plant in Ortigueira, Paraná (Puma Project) registered 95% completion. Construction is on schedule and startup is planned for March 2016.

Net revenue in 2015 rose 16% from the prior year to reach R$5,688 million. In the fourth quarter of 2015, net revenue was R$1,596 million, increasing 27% compared to the same period in 2014.

Over the course of the year, Klabin increased its export volume to reach 627,000 tons in 2015, growing 15% from 2014. In the fourth quarter, export volume came to 190,000 tons, up 52% on the year-ago period.

Export growth, coupled with recent increases in production capacity at Klabin’s paper plants, resulted in total sales volume – excluding wood – of 1.8 million tons in 2015, or 3% more than in 2014.

Capital Expenditure

In 2015, Klabin invested a total of R$4,627 million, of which R$4,053 million in the Puma Project, the new pulp plant under construction in Ortigueira, Paraná. In December, construction at the Puma Project reached 95% completion, with 77% of financial disbursements already concluded. The new plant, scheduled to start up in March 2016, will have production capacity of 1.5 million tons of hardwood, softwood and fluff pulp.

Of the total investment of R$1,364 million made during the fourth quarter of 2015, R$1,195 million was allocated to the new pulp plant, R$114 million to the maintenance of operations at existing plants, R$27 million to forest operations and R$28 million to special projects and capacity expansion.

About Klabin

Klabin, Brazil's largest paper producer and exporter, is the leading manufacturer of paper and board for packaging, corrugated board packaging, industrial sacks and timber in logs. Founded in 1899, it has 14 industrial units in Brazil and one in Argentina. Klabin is organized into three business units: Forestry, Paper (paperboard, kraft paper and recycled) and Conversion (corrugated board and industrial sacks).

Klabin's management is entirely oriented towards sustainable development, and pursues integrated and responsible growth that combines profitability, social development and a commitment to the environment. Klabin is also a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, and seeks suppliers and business partners that adopt the same values of ethics, transparency and respect for the principles of sustainability.

Learn more at www.klabin.com.br

Klabin holds General Shutdown at Otacilio Costa Plant

Between the 11th and 20th of June, Klabin’s Otacilio Costa Plant (SC) will be holding its Annual General Shutdown, a compulsory procedure which consists of interrupting paper production and is intended to ensure that all the necessary maintenance for the proper functioning of the mill is carried out with quality and in safety. This is a common procedure in the pulp and paper sector and occurs every year in the company’s plants.

Between the 11th and 20th of June, Klabin’s Otacilio Costa Plant (SC) will be holding its Annual General Shutdown, a compulsory procedure which consists of interrupting paper production and is intended to ensure that all the necessary maintenance for the proper functioning of the mill is carried out with quality and in safety. This is a common procedure in the pulp and paper sector and occurs every year in the company’s plants.

During these ten days, about 50 contracted companies and 1,400 temporary workers will be involved in the General Shutdown. Among the principal activities programmed are inspections of boilers, digesters, power generation and distribution systems and production process controls. This amount of temporary workers requires logistics and infrastructure, involving transportation, lodgings and meals among other items which drive and boost the economy of the town of Otacilio Costa and the region. There are other additional benefits, such as the taxes generated for the municipality and extra movement in hotels, bars, restaurants and stores, as well as the services to assist the workers’ stay in the town.

During the days of the Shutdown, variations in odors and noise coming from the mill – especially on the 11th and 12th, at the beginning of the Shutdown, and on the 19th and the 20th, as machines start operating again – may be noticed by the community. It is important to note that these alterations cause no harm to people’s health nor to the environment.

As of this year, Klabin will have an exclusive channel available to attend the community which will function 24 hours a day. In the case of doubts concerning the environment, the community can get in touch with the company via the telephone number 0800 728 0607.