Ian Melin-Jones

BASF increases its presence in growing African markets

BASF is increasing its presence in the growing African markets. Today, December 7, 2011, the company will open a new office in Nairobi, Kenya, to serve customers in East Africa and Sub-Sahara .

“Africa is a huge continent with a wealth of raw materials and a growing population. At the same time, the dynamically growing economy has enormous potential for BASF. Through establishing a stronger local presence we will be able to even further support our customers and to enhance BASF's market position,” said Jacques Delmoitiez, President, responsible for BASF's business in Europe, the Middle East and Africa.

The company’s target is to more than double sales in Africa by 2020. Its sales, excluding oil and gas, were around €1 billion in 2010.

The sale of innovative construction chemicals for the booming construction industry in the urban areas of East Africa is one of the main focuses of activity, as is the distribution of crop protection products that increase crop yields. At the same time, BASF is expanding its business in the consumer sector with products such as ingredients for personal care products and laundry detergents as well as pharmaceuticalingredients. Here, the company is profiting from a growing middle class with rising consumer aspirations.

BASF is also developing solutions to the pressing challenges that affect large parts of Africa. For the private housing sector, BASF supplies insulating materials such as Neopor®. Another key project is the fight against vitamin A deficiency. Too little vitamin A can cause blindness and makes people more prone to infections. Staple foods, such as cooking oil and flour, are therefore fortified with vitamin A with the help of BASF.

Supporting important social projects

“Our engagement in East Africa ensures that everyone benefits – our customers, the local population and BASF. We want to be good neighbors at all our sites worldwide. This is why we are supporting important social projects in Kenya,” said Peter van den Hoek, head of newly established unit Market Development Africa. Furthermore, van der Hoek will be Managing Director of the Nairobi-based subsidiary BASF East Africa Ltd.

In Kibera, Nairobi, BASF is supporting a project in cooperation with the United Nations Human Settlements Program (UN-HABITAT) and local partners. The Kibera Soweto East Resource Centre provides physiotherapy and occupational therapy for handicapped children and medical care for babies and infants. There is a counseling center which offers HIV tests to patients. The staff of the center also provides training for handicapped children and young adults. BASF wants to use its engagement to improve the prospects of the people living in Kibera.

To alleviate the immediate suffering caused by the drought in East Africa, BASF has supplied emergency aid to the refugee camp in Dadaab via the United Nations High Commission for Refugees (UNHCR). Also, this year’s Christmas collection by the BASF Social Foundation will be used to support the population in Kenya affected by the drought. A joint project with UN HABITAT and the Kenyan government aims to improve the water supply through the Daua River in order to cope better with the drought in future. BASF employees in Germany are encouraged to donate to this project during the month of December. BASF has already forwarded an advance of €100,000.

source: BASF

Temple-Inland Approve Merger with International Paper

Temple-Inland Inc. announced that at its Special Meeting of Stockholders held today, Temple-Inland stockholders voted to approve the adoption of the merger agreement with International Paper Company (IP), with 86,908,118 shares of Temple-Inland common stock voting in favor of the merger, representing over 98 percent of the shares voted. All other matters submitted to a vote of the stockholders were also approved.

Completion of the merger is subject to other customary closing conditions, including the receipt of regulatory approval.

About Temple-Inland Inc.

Temple-Inland Inc. is a manufacturing company focused on corrugated packaging and building products. The fully integrated corrugated packaging operation consists of 7 mills and 57 converting facilities. The building products operation manufactures a diverse line of building products for new home construction, commercial and repair and remodeling markets. Temple-Inland's address on the World Wide Web is www.templeinland.com.

SOURCE: Temple-Inland Inc.

FITNIR ANALYZERS gains further traction in the Canadian pulp market

FITNIR Analyzers has gained further traction in the Canadian pulp market as two pulp mills chose the company's equipment for process control optimization.

Mercer International's Zelstoff Celgar mill, located near Castlegar, B.C., will be implementing FITNIR's fully automated, online analyzer to optimize its recausticizer controls. "Over the past six months we have been trialing a FITNIR analyzer and have already benefited from significantly reduced operational costs and improved quality," says process engineer, Shawn Russell. "The results obtained from the demo were the deciding factor in moving forward to purchase a full scale system."

The mill used to rely on a manual titration methodology for its recaust area. Now, Celgar will be able to automatically test more frequently from six sample lines once the FITNIR system has been implemented. Implementation will begin in December.

In addition to Celgar, a mill in Eastern Ontario has selected FITNIR equipment. Optimization of this mill's recausticizer operations through FITNIR Online is expected to be completed in the spring of 2012.

"These two projects are yet another demonstration of the increasing awareness and confidence that pulp mills have of FITNIR analyzers," says FITNIR Analyzer's President, Tom Sands.

FITNIR Analyzers Inc. is the exclusive distributor of FPInnovations' optically-based liquor analyzer. FITNIR's fully automated online and bench top systems provide fast and accurate measurement of a complete suite of liquor properties for process control.

Algae can give new fuel to the mills.

Without The Paper Province cluster it would not be possible for Metso

Global Timber and Wood Products Market Update

Tissue World Americas Conference

Dear Tissue Industry Professional!

The tissue business continues to grow at a very nice pace, especially in comparison with many other businesses. In the Americas, particularly, many tissue companies are in an interesting phase of expansion with growing market demand for higher quality tissue products stimulating new investments. These trends and developments will certainly be a topic of discussion when the Tissue Industry meets at Tissue World Americas in Miami Beach on March 20-23, 2012.

To help bring the wide range of topics impacting the tissue industry in North and South America into even sharper focus, we have assembled an excellent program of speakers for the Tissue World Americas conference. To be held under the theme of -

"Boosting Performance for Better Quality, Sustainability and Profitability"

the conference includes many highlights which are sure to be of interest to you:

- Senior executives from Kimberly-Clark, Greenpeace, Cascades, EcoLogo, SCA North America and more in a panel discussion on Sustainability in the Tissue Business

- Market Developments and Fiber Supply session looking deeply at Market Developments in North and South America as well as Where the Fiber for Tissue Making Will Come From

- Yankee Dryer Summit, held for the first time in Miami, covering a full day and going into critical technical details on Yankee reliability, efficiency and sustainability

- Technical sessions and workshops featuring world-leading experts giving timely, concise knowledge on key areas such as paper making, energy, converting wrapping, logistics, stock prep and other crucial topics.

- As well as the Best Networking Opportunity available to pick up ideas and solutions to the operational and profitability challenges you face in your plants and your company

|

To Register NOW --- CLICK HERE |

Here is a more detailed look at the sessions:

Main conference sessions – Wednesday to Friday

Wednesday March 21, 2012 (full day)

Conference Theme:

Boosting Performance for Better Quality, Sustainability and Profitability

Session 1: Sustainability in the Tissue Business

Steps Toward the Sustainable Value Chain for Tomorrow

Suhas Apte, Global Vice President of Sustainability, Kimberly-Clark Corporation, USA

Greenpeace: No Reason to be Afraid, Necessarily

Scott Paul, Forest Campaign Director, Greenpeace, USA

Making Sense of Environmental Certifications Programs

Suzanne Blanchet, President and CEO, Cascades Tissue, Canada

Environmental Leadership in the Tissue Paper Sector – Beyond Forest Certification

Angela Griffiths, Executive Director, EcoLogo, Canada

SCA North America, Speaker to be Named

Session 2: Market Developments and Fiber Supply

Market Developments and Trends in North and South America

Esko Uutela, Principal - Tissue, RISI, Germany

Fiber Supply – Where will fiber for tissue making come from?

Saara Söderberg, Director Global Consutling, Pöyry, Finland

Session 3: Papermaking Developments

The Chattermark Project to Reduce Operational costs at ICT Iberica, ICT and BTG

World's First Tissue Machine with a Compact Wet End with Active Degassing, POM and LC Paper

New TAD Simulator provides Tissue Makers a Competitive Edge, Ashland

Seamless Tissue Plant Concept Plus: Entry level Technology for Private Labels, Comer

New Pressing Technology for Higher Bulk and Dryness on Conventional Machines, Voith

Yankee Dryer System: Critical Asset Protection, Monitoring and Control, Nalco

Development Trends in Pressing for Tissue, Metso

Session 4: Energy Reduction and Savings

Forecasting and Validation of Fossil Fuel and Steam Savings from Tissue Machine Heat Recovery, Thermal Energy and Kruger Products

Steam Energy Reduction in Tissue Drying Process, Andritz

Significant Energy Savings with Variable Speed Vacuum Pumps in Tissue Making, Runtech Systems

Making 100% High Pressure Steam with a new Post Combustor on Hood exhaust, Novimpianti

--------------------------------------------------------------------------------------------------------------------------------------------------------

Thursday March 22, 2012 (full day)

Session 5: Converting, Packaging, Wrapping and Logistics

Colored Laminating Glues for Design Embossing, Kapp-Chemie

TCO: Total Cost of Ownership Analysis Spells Informed Investment, Futura

6 Different Products are just One Click Away, CMG

Compact Packaging of Tissue Paper, Optima

Overall Equipment Effectiveness: How Next Generation Automation Gives Real Improvements,Schneider Equipment

Conveying Lines: Optimizing Energy, Maintenance, Product Quality and Safety, Pulsar

New Concepts in Robotic Palletizing: Product Handling Methods, Multiple SKU Management and Flexibility, E80

New Robotic Bundler Combines Packaging and Palletizing Technology, W+D Langhammer

Reducing Costs and Improving Operations with Automatic Guided Vehicles, JBT Corp.

Workshops on various areas such as Printing, Web Handling and Knives and Blades

The program of speakers for these workshops is presently under development. More details will be coming soon.

--------------------------------------------------------------------------------------------------------------------------------------------------------

Friday March 23, 2012 (half day)

Session 6: Stock Prep

First Mill Experience with a new High Efficiency Compact Refiner, Metso

New Insights into the Application of High-yield Pulp in Tissue and Towel, Tembec/FP/Kruger

Compression Refining, Flexible Fibres and low Fines Content, Wageningen UR

Evaluation of Furnishes for Tissue: New Research Results on Suction Box Dewatering and Pressing, Karlstad University

Session 7: Auxiliary Topics in Tissue Making

Improve Operator Safety and Reduce Downtime with Automatic Web Marking on a Tissue Line, Ryeco

Studies Reveal Unnecessary Fiber, Energy and Water Losses, Tecumseth Filtration

Guarding Operations - Engineering Safety for Tissue Converting Lines, SEACON

Recognized Standard Locations for Dust Concentration Testing,Brunnschweiler

Maintaining Optimum Performance of Tissue Machine Clothing, Dubois Chemicals

Ecolab and Nalco Complete Merger

Shareholders from both Ecolab Inc. and Nalco Holding Company overwhelmingly approved the merger of the two companies on November 30. The merger became effective on December 1, 2011, creating the global leader in water, hygiene and energy services, offering premier product solutions, the industry’s largest and best-trained sales and service force, coverage in more than 160 countries, and 2011 annualized sales of more than $11 billion.

- For financial information about Ecolab Inc, please visit the Ecolab Investor website.

- For more information about the strengths of the combined company please visit one.ecolab-nalco.com.

Brief Merger FAQ

What is the effective date of Ecolab's purchase of Nalco?

Effective December 1, 2011, a wholly-owned subsidiary of Ecolab was merged with and into Nalco Holding Company. At the time of the merger, Nalco common stock was cancelled.

What will Nalco shareholders receive?

The former shareholders of Nalco will receive either (i) 0.7005 shares of Ecolab Common stock, or (ii) $38.80 cash, without interest, in exchange for one share of Nalco Common Stock, subject to the adjustment and reallocation provisions of the Agreement and Plan of Merger dated as of July 19, 2011. For questions or assistance with the election process, shareholders can call MacKenzie Partners, Nalco's Information Agent, toll-free at 1-800-322-2885 or 212-929-5500 (collect). The election period ends December 7, 2011 at 5 pm ET.

How do I exchange my Nalco stock for the merger consideration?

If your Nalco shares are held in a bank or brokerage account, please contact your bank or broker for information regarding the exchange. Nalco's shareholders of record received a Letter of Transmittal from Computershare, the merger Exchange Agent, together with specific instructions. Nalco's shareholders of record may call Computershare at 1-800-546-5141 or 781-575-2765 for assistance.

When will Nalco shareholders receive payment for their shares?

Nalco shareholders whose shares are held by a bank or a brokerage firm should contact that firm with any questions. Nalco's shareholders of record may call Computershare at 1-800-546-5141 or 781-575-2765 for assistance.

Indenture Compliance

The reports below present required financial information disclosures to bondholders for Nalco Holdings LLC, Nalco Company and subsidiaries relating to Senior Notes issued in May of 2009 that will mature in May of 2017.

Summary Disclosure September 30, 2011

Summary Disclosure June 30, 2011

Summary Disclosure, March 31, 2011

Summary Disclosure December 31, 2010

Summary Disclosure September 30, 2010

Summary Disclosure June 30, 2010

Summary Disclosure, March 31, 2010

Summary Disclosure December 31, 2009

Summary Disclosure September 30, 2009

Summary Disclosure June 30, 2009

Walki-4E technology: a new, sustainable way of producing RFID antennas

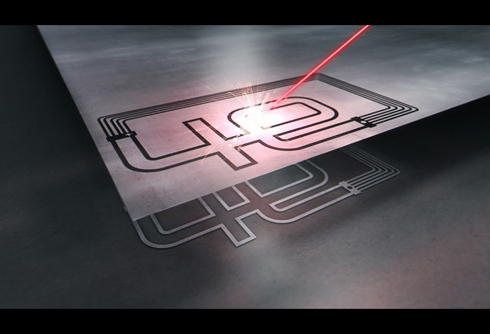

The manufacturing of RFID antennas through the process of etching is now being challenged by a new patented technology: Walki-4E, a new way of producing flexible circuit boards efficiently and sustainably. This is possible through a dry production process, involving no liquid chemicals and using paper as the substrate. It also allows for computer to antenna production and extremely accurate laser cutting of the circuit board patterns.

Walki-4E technology is a new way of producing flexible circuit boards using a dry process and paper as the substrate, the first real alternative to the wet, chemical based process of etching.

The traditional way of producing RFID antennas by etching has for a long period undergone only modest development. Walki, a leading producer of technical laminates, looked for ways to simplify the manufacturing process, while making use of their knowledge in lamination.

“We think that Walki-4E technology is the first feasible alternative to etching and that it will bring new dimensions of cost efficiency and sustainability to the industry,” says Sami Liponkoski, Global Product Manager at Walki.

In brief, the idea is to make a special laminate of aluminium and paper substrate, then aluminium foil is cut in patterns using a laser.

The technology can be used for any production of flexible circuits boards, ranging from RFID antennas to boards for radiators and flexible displays. The first product to be launched using Walki-4E technology is Walki-Pantenna, a UHF RFID antenna.

One step shorter

The four E’s of Walki-4E stand for efficient, exact, economical and ecological. Compared with etching, the technology eliminates a whole step from the tag production process or from the converter’s process, thus combining efficiency and economy.

“Since paper is used as a substrate, the RFID manufacturers can leave out the insertion of the PET inlay into paper, a necessary step when the antenna has been produced by etching. Moreover, the computer to antenna production method speeds up design and development, an advantage especially when it comes to producing short series, involving a fewer number of antennas,” Sami Liponkoski says.

Cost efficiency comes hand-in-hand with environmental benefits. The dry process does not involve any chemicals, thus resulting in process residue that is easily recyclable. The absence of liquid chemicals also leaves the RFID manufacturers with a product, the ready antenna, that is 100 % recyclable.

“Since the antenna is free from plastics, made of paper and aluminium only, it is easily recycled in a fibre recycling process, where metal detectors sort out the aluminium.” Sami Liponkoski says.

Computer to antenna production and laser cutting of the flexible board patterns allow for a speedy production process and extremely high accuracy. An example: the laser cuts with an accuracy of 20 microns while a human hair has the thickness of 100-120 microns.

Towards digitalisation

The precision of the laser cutting of the patterns allows for smaller chips, greater repeatability in the production process and higher accuracy of the antenna.

“This does not only overcome certain accuracy problems that etching brings, but also gives new possibilities for developing the antennas and the chips,” Sami Liponkoski says.

Digitalisation of the production process, i.e. computer to antenna production, brings efficiency and allows for an endless number of variations in the patterns.

“Our vision is that the antenna production eventually will be completely digital. Laser cutting can speed up the production process by ten times, and taking into account the development that laser technology undergoes every year, the possibilities of producing flexible circuit boards with lasers are almost limitless,” Sami Liponkoski says.

Walki’s first product, Walki-Pantenna, will be ready for mass production in 2012.

“We are now in the ramp-up phase for our new production line in Pietarsaari, Finland, and we are looking forward to introduction in the market. There is a lot of interest in our product and we strongly believe it has the capacity to change the industry,” Liponkoski says.