Ianadmin

Clearwater Paper Announces Proposed Offering of Senior Notes

Clearwater Paper Corporation (NYSE:CLW) has announced a proposed offering of $250 million aggregate principal amount of senior notes due 2023.

Clearwater Paper Corporation (NYSE:CLW) has announced a proposed offering of $250 million aggregate principal amount of senior notes due 2023.

Clearwater Paper intends to use approximately $163.9 million of the net proceeds to redeem all of its outstanding 10.625% Senior Notes due 2016. The remaining net proceeds are expected to be used to purchase shares of the Company's common stock pursuant to the Company's $100 millionstock repurchase program separately announced today.

As the offering is a private placement, the notes will be offered and sold only to qualified institutional buyers in reliance on Rule 144A under the Securities Act of 1933 (the "Securities Act") and to certain non-U.S. persons in transactions outside the United States in reliance on Regulation S under the Securities Act. The notes to be offered have not been registered under the Securities Act or any state securities laws and may not be offered or sold in the United States absent registration or an applicable exemption from registration requirements.

This press release does not constitute an offer to sell or the solicitation of an offer to buy any of the notes nor shall there be any sale of the notes in any jurisdiction in which such offer, solicitation or sale would be unlawful. This news release is being issued pursuant to and in accordance with Rule 135c under the Securities Act.

This press release contains information about pending transactions, and there can be no assurance that these transactions will be completed.

Source: Clearwater Paper Corporation

Clearwater Paper Board of Directors Announces $100 Million Stock Repurchase Authorization

Clearwater Paper Corporation (NYSE:CLW) has announced that its board of directors has authorized the repurchase of up to $100 million of the company's common stock, reflecting the company's strong balance sheet and positive outlook on its business. This authorization follows the completion of the company's previous $30 million stock repurchase authorization implemented by the board in July 2011.Clearwater Paper expects to fund the repurchases through available cash resources, including a portion of the proceeds of a proposed senior notes offering announced separately today.

Clearwater Paper Corporation (NYSE:CLW) has announced that its board of directors has authorized the repurchase of up to $100 million of the company's common stock, reflecting the company's strong balance sheet and positive outlook on its business. This authorization follows the completion of the company's previous $30 million stock repurchase authorization implemented by the board in July 2011.Clearwater Paper expects to fund the repurchases through available cash resources, including a portion of the proceeds of a proposed senior notes offering announced separately today.

"This stock repurchase program, which we intend to fully execute in 2013, emphasizes the board's ongoing commitment to enhancing shareholder value," said Linda K. Massman, president and chief executive officer. "With the successful start-up of our Shelby TAD paper machine, Clearwater Paperis poised to generate significant discretionary free cash flow. We are now focused on operational execution in the near term and upon completion of the stock repurchase program, we plan to return approximately 50% of discretionary free cash flow to our shareholders over the 2014 and 2015 timeframe."

The repurchase program authorizes the company to purchase its common stock from time to time through open market purchases, negotiated transactions or other means, including accelerated stock repurchases and 10b5-1 trading plans in accordance with applicable securities laws and other restrictions. The company has no obligation to repurchase stock under this program and may suspend or terminate the program at any time.

Source: Clearwater Paper Corporation

One step closer to wood-based carbon fibres

On 18 December, Ylva Nordström defended her licentiate thesis “Development of softwood kraft lignin based carbon fibers” at Luleå Technical University. The work was carried out within the LigniCarb project at Innventia and demonstrates promising research findings with carbon fibres from softwood lignin, a raw material which has been considered impossible to process into precursor fibres.

Polymer composites designed for high-performance applications are mostly based on carbon fibre reinforcement, produced from fossil originating raw materials such as poly(acrylonitrile) and pitch (petroleum- or coal-based). As of today, lignin has proved to be one of the most promising alternatives. Lignin is a substance that is found in wood but is removed during kraft pulp production. Thanks to LignoBoost technology*, the pulp mill can extract extremely pure lignin which could be used and thus increasing the access to a raw material for carbon fibre. Previous research has mainly focused on the use of hardwood lignin which is easier to meltspin. However, the presented work by Ylva Nordström states that precursor fibres also can be produced from kraft lignin from softwood, which is the most common industrial wood raw material in the northern hemisphere, such as the Nordic region and North America.

The aim of this work was to find a way for melt spinning of softwood kraft lignin which was managed by adding small amounts of low-molecular lignin. Both unfractionated hardwood and softwood lignin were used with addition of their fractionated counterparts acting as softening agents. As previously reported in Ida Norberg’s PhD thesis, the stabilisation step in the process was also further developed as a first step towards a process optimised for softwood kraft lignin based carbon fibres. In Ylva Nordström’s work, mechanical characterisation of the final carbon fibres was carried out. The experimental results and predictions showed a good fit, although the strength of the produced fibres is still significantly lower than that of commercially available carbon fibres

“This thesis reports the first mechanical characterisation of softwood kraft lignin based CFs. This will hopefully enable further process optimisation”, says Ylva Nordström.

Ylva’s licentiate work was carried out within the framework of the LigniCarb/LigniCarb Add research project, with the aim of examining and demonstrating the possibilities of making carbon fibre from kraft lignin. The work constitutes a part of Innventia’s new field of research on production processes for lignin-based carbon fibres.

“There’s a lot to be gained from better equipment. Thanks to the recent promising findings in this field, investment in larger scale, more advanced equipment is now being planned,” adds Elisabeth Sjöholm, who was Ylva’s supervisor at Innventia and the project manager for LigniCarb.

*LignoBoost has been developed in partnership between Innventia and Chalmers University of Technology. The process has been successfully demonstrated at Innventia’s demonstration facility in Bäckhammar. The LignoBoost process, including patent rights, has been owned by Metso since 2008.

First Metso Advantage NTT tissue line to be started up at Fabrica De Papel San Francisco in Mexico

The Mexican tissue producer Fabrica De Papel San Francisco is preparing to start up their third Metso tissue production line. It will be the world’s first tissue line based on the Advantage NTT concept, which enables high bulk and softness properties at the same time as it provides energy savings compared to conventional or structured tissue grades.

“After operating two Metso Advantage DCT tissue machines with good experience, we are now prepared to take the next step for quality to produce tissue products with higher bulk and softness, aiming towards the top end products. The Advantage NTT concept will also bring us a higher production capacity compared to the dry crepe tissue concept,” says Dario Palma y Meza Espinoza, Director of Operations, Fabrica De Papel San Francisco.

“We have a very long and fruitful relation with Fabrica De Papel San Francisco and we are of course very excited to supply the first Advantage NTT technology and support their ambition to supply high-quality products produced with less energy and fiber. Fabrica De Papel San Francisco has a very strong and knowledgeable team,” says Jan Erikson, Vice President, Sales, Metso.

The project is proceeding according to plan and the new tissue production line will start up in Mexicali, Mexico, in the end of the second quarter of 2013.

Metso’s scope of supply comprises a complete 2.6-m-wide Advantage NTT tissue machine equipped with an OptiFlo II TIS headbox, a Metso Yankee cylinder, an Advantage AirCap yankee hood, sheet control, tail threading equipment, an Advantage WetDust dust management system and an Advantage SoftReel reel.

The new tissue line will add another 30,000 tonnes per year of bathroom tissue, napkin and towel grades to Fabrica De Papel San Francisco’s existing production.

Fabrica De Papel San Francisco already operates two Advantage tissue machines at their Mexicali facility, one of which started up in 2006 and the other in 2009. The company’s PM 4 set a then world speed record of 2,160 m/min in 2009 and their PM 5 achieved a record-breaking rapid start-up in 2009, reaching a production speed of 2,100 m/min only 12 days after start-up.

Fabrica De Papel San Francisco now operates four tissue production lines and converting facilities, delivering tissue products for the Mexican and US market.

Ahlstrom provides preliminary information on 2012 net sales and operating profit

![]() Ahlstrom, a global leader in high performance fiber-based materials, provides preliminary information on net sales and operating profit excluding non-recurring items from continuing operations for 2012.

Ahlstrom, a global leader in high performance fiber-based materials, provides preliminary information on net sales and operating profit excluding non-recurring items from continuing operations for 2012.

In 2012, net sales from continuing operations amounted to approximately EUR 1,011 million and operating profit excluding non-recurring items from continuing operations was approximately EUR 18 million.

Ahlstrom had previously expected net sales from continuing operations to be EUR 960 - 1,040 million and operating profit excluding non-recurring items from continuing operations to be EUR 22 - 32 million in 2012.

The operating profit excluding non-recurring items for 2012 is lower than the company had earlier anticipated because of weaker sales mix and volumes across all key markets towards the end of the year, as well as longer than expected production downtime taken during the last quarter.

The figures are based on unaudited preliminary financial results. Ahlstrom will publish its financial statements bulletin 2012 on January 31, 2013.

Mondi showcases expanded high-speed inkjet portfolio at the 2013 Hunkeler Innovationdays, February 11-15 in Lucerne, Switzerland

Mondi professional printing papers will be on display at stand I18 and used for print applications by various original equipment manufacturers (OEM). Mondi has sponsored Impika, CANON OCÉ, Hunkeler, HP, Kodak and KBA with digital printing papers for print demonstrations throughout the trade fair.

Mondi’s focus on the digital printing market continues into 2013. At Hunkeler Innovationsdays, the international packaging and paper producer will present its expanded high-speed inkjet portfolio, which comprises a comprehensive offering of grammages and shades for this growing market.

Mondi’s focus on the digital printing market continues into 2013. At Hunkeler Innovationsdays, the international packaging and paper producer will present its expanded high-speed inkjet portfolio, which comprises a comprehensive offering of grammages and shades for this growing market.

“In the past year, we have expanded Mondi’s high-speed inkjet portfolio to offer more variety and greater options for businesses and printers. Current printing demands, with applications that vary from transpromo and direct mail to book printing, require a portfolio that offers a wide range of optics, haptics, environmental options and accreditations,” says Johannes Klummp, Marketing and Sales Director for Mondi Uncoated Fine Paper.

At stand I18, Mondi will feature its smooth, high-white, recycled, off-white and coated high-speed inkjet papers optimised for both dye and pigment inks. These include DNS® high-speed inkjet CF (coated feel), DNS® high-speed inkjet NF (natural feel), 100% recycled NAUTILUS® high-speed inkjet, BIO TOP 3® high-speed inkjet and DNS® enhanced color inkjet, which is Mondi’s first high-speed inkjet paper with a pigment-coated inkjet surface.

Klummp adds, “BIO TOP 3® high-speed inkjet, for example, is our off-white recommendation for book printing. It is a TCF paper with no optical brightening agents and has a natural uncoated feel. On the other hand, DNS® high-speed inkjet CF could be the perfect fit for stylized marketing applications that require a high-white, smooth coated feel.”

Hunkeler Innovationdays also marks the debut of DNS® enhanced color inkjet to a broader professional printing market. As a pigmented paper, DNS® enhanced color inkjet delivers a higher colour density, allowing dye inks to reach density levels comparable to pigment ink. The inclusion of a pigmented grade to Mondi’s high-speed inkjet portfolio adds a further dimension to an already varied assortment.

With the growing demand for CO2 offsetting within the printing industry, Mondi also offers a CO2 neutral option for all high-speed inkjet papers as well as 100% recycled NAUTILUS® SuperWhite. Mondi’s colour laser paper Color Copy is fully CO2 neutral.

All Mondi-branded papers are part of the Green Range of eco-conscious papers that are FSC® or PEFC™ certified, 100% recycled or TCF (totally chlorine free). More information about Mondi’s complete digital printing portfolio is available at www.mondigroup.com/printing.

Nalco and Wetend Technologies Ltd Reach Patent Agreement

Nalco, an Ecolab company based in the U.S., and Wetend Technologies Ltd, a technology and innovation company based in Finland, have reached a global patent settlement agreement that includes the dismissal of a current lawsuit between the two companies. The terms of the settlement are confidential.

Both Nalco and Wetend Technologies operate globally and have businesses that serve forest products-based process industries, including paper and board mills. The patent dispute involved the use of process mixing technologies for the forest products industry.

Going forward, the companies will collaborate to provide injection mixing technologies to their customers that provide superior environmental results, including the elimination of use of fresh water, reduced use of energy and chemicals and reduced carbon dioxide emissions.

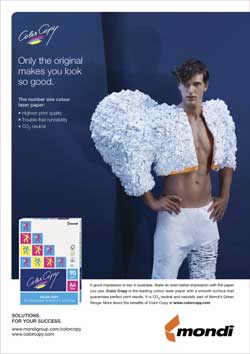

A paper with flair: Mondi’s 2013 Color Copy campaign brings haute couture to the modern office

The launch of Mondi’s 2013 Color Copy campaign showcases haute couture made from Color Copy and offers a chance to win trips to the world’s fashion capitals

International packaging and paper manufacturer Mondi launched its new haute couture Color Copy campaign with the slogan, “Only the original makes you look so good”. Color Copy has led the way as an original on the market since its launch in 1989 as the world’s first paper specially developed for digital colour laser systems and more recently as the first CO2 neutral digital colour laser paper. Mondi’s new campaign features six haute couture designs made from Color Copy through a collaboration with design students from the University of Art and Design in Linz together with the Hetzendorf fashion school in Vienna, Austria. From these six designs, two will be used in the Color Copy advertisements throughout 2013. The campaign kicks-off with an online game (www.colorcopy.com) that will run until 30 June 2013, which features all six designs and gives participants a chance to win one of 100 iTunes vouchers and one of three trips to the world’s fashion capitals: Milan, Paris and New York.

International packaging and paper manufacturer Mondi launched its new haute couture Color Copy campaign with the slogan, “Only the original makes you look so good”. Color Copy has led the way as an original on the market since its launch in 1989 as the world’s first paper specially developed for digital colour laser systems and more recently as the first CO2 neutral digital colour laser paper. Mondi’s new campaign features six haute couture designs made from Color Copy through a collaboration with design students from the University of Art and Design in Linz together with the Hetzendorf fashion school in Vienna, Austria. From these six designs, two will be used in the Color Copy advertisements throughout 2013. The campaign kicks-off with an online game (www.colorcopy.com) that will run until 30 June 2013, which features all six designs and gives participants a chance to win one of 100 iTunes vouchers and one of three trips to the world’s fashion capitals: Milan, Paris and New York.

“Our new Color Copy campaign is about making a good impression with high-quality print outs, whether for an important office presentation, a photo book or marketing collateral. In short, when your printed material looks good, you look good,” explains Johannes Klumpp, Marketing and Sales Director for Mondi Uncoated Fine Paper, Europe and International.

The students selected various grammages from the entire Color Copy portfolio, experimenting with the potential offered by using different weights and textures. Over the last 21 years, the Color Copy portfolio has grown to include a broad range of shades and textures with Color Copy, Color Copy style, Color Copy coated glossy, Color Copy coated silk and Color Copy indigo, an HP 3-star certified paper for HP Indigo digital presses. Using Color Copy papers as the base material for their designs, the students explored the medium’s potential and versatility by washing, ironing and using papier mache, for example, to achieve their sartorial concepts. In the end, Mondi selected six final designs for a high-fashion photo shoot with renowned photographer Mark Glassner.

“Color Copy’s optimum smooth surface is key for delivering outstanding print quality. Furthermore, the even toner adhesion, brilliant colour reproduction and natural contrasts achieved make it an ideal medium for our haute couture marketing material,” Klumpp adds.

“Color Copy’s optimum smooth surface is key for delivering outstanding print quality. Furthermore, the even toner adhesion, brilliant colour reproduction and natural contrasts achieved make it an ideal medium for our haute couture marketing material,” Klumpp adds.

The Color Copy advertisements for 2013 feature designs by Miriam Kohlhofer and Moritz Gottschalk. All haute couture designs created for the campaign are featured in the online game (www.colorcopy.com) and the behind-the-scenes video showing the making of the campaign (www.youtube.com/TheGreenrange).

Color Copy is part of Mondi’s eco-conscious Green Range and is CO2 neutral, FSC® certified, and bears the EU Ecolabel – a symbol for products and services deemed to have a lesser impact on the environment. More information about the Color Copy portfolio and the 2013 campaign is available at www.mondigroup.com/colorcopy.

International Paper Finalizes Transaction with Grupo Orsa in Brazil

International Paper and Brazilian corrugated packaging producer Jari Celulose, Embalagens e Papel S.A., a Grupo Orsa company, have finalized the formation of Orsa International Paper Embalagens S.A. The new entity, in which IP will hold a 75 percent stake, includes three containerboard mills and four box plants, which make up Jari's former industrial packaging assets. Today's closing completes the transaction announced in October of 2012.

International Paper and Brazilian corrugated packaging producer Jari Celulose, Embalagens e Papel S.A., a Grupo Orsa company, have finalized the formation of Orsa International Paper Embalagens S.A. The new entity, in which IP will hold a 75 percent stake, includes three containerboard mills and four box plants, which make up Jari's former industrial packaging assets. Today's closing completes the transaction announced in October of 2012.

"International Paper has been in Brazil for over 50 years and we are excited about this partnership as a platform to enter the corrugated packaging business in this strategic region," said John Faraci, Chairman and Chief Executive Officer. "This investment fits our strategy to grow our packaging business globally and allocate capital to opportunities that deliver returns well above our cost of capital."

The value of IP's investment is approximately $470 million at today's exchange rate.

Papcel to build a paper mill for Zavod Gazetnoy Bumagi in Belarus for €69 million

Papcel to build a paper mill for Zavod Gazetnoy Bumagi in Belarus for €69 million

Czech equipment producer Papcel signed the biggest contract in its history with Belarusian pulp and paper concern Zavod Gazetnoy Bumagi located in Shklov (Mogilyov region) on delivery of a complex line for production of fancy papers.

In the opened tender the company PAPCEL Litovel has defeated some very important competitors in the pulp and paper industry, including Voith and some Chinese companies, and will build up a new key-ready paper mill in Belarus.

The €69-million contract is the biggest project ever signed in Papcel’s history.

The scope of this delivery is a complete paper mill for production of 30,000 tons of fancy papers per year. Construction will start in March 2013, the mill will be launched in January 2015.