Ianadmin

Metso to supply four tissue production lines for HengAn Group in China

Metso has been awarded a repeat order for four complete tissue production lines for HengAn Group in China. Two of the lines will be located at Shandong HengAn Paper Co., Ltd, in Weifang City, Shandong Province, and two at HengAn Wuhu Paper Co., Ltd, in Wuhu City, Anhui Province. Start-ups are planned to be successive with the first in December 2013 in Weifang. The value of the order will not be disclosed.

Xu Lianjie, President, HengAn: "We like to continue the relation with Metso, being active in developing the tissue machine technology."

“We are very proud that HengAn once again trusted Metso technology to support their continued growth in the tissue industry,” says Anders Björn, President, Metso Paper Karlstad.

The new lines will add another 240,000 tonnes a year of high-quality facial, toilet and towel grades to HengAn Group's total production. This will consolidate their position as China's leading tissue producer. The raw material for the new machines will be virgin pulp. The order follows the successful start-ups of four similar tissue lines at the company’s Anhai mill in Fujian Province and Weifang mill in Shandong Province in 2006, 2007, 2008 and 2009.

The order is included in Metso’s Pulp, Paper and Power fourth quarter 2012 orders received.

Technical information

Metso’s delivery will comprise four tissue production lines featuring Metso’s stock preparation equipment and Advantage DCT 200 tissue machine. Each machine will include an OptiFlo II TIS multi-layer headbox, a Metso Yankee cylinder with deep rib for highest energy efficiency, an Advantage AirCap hood, an Advantage WetDust dust management system and an Advantage SoftReel P reel. The tissue lines will also feature Metso’s new MicroBar refiner segments for short fiber refining and VacuFox polyurethane roll covers for tissue machine press sections.

The new lines will have a width of 5.6 m and an operating speed of 1,900 m/min.

HengAn is a leading, fast-growing Chinese consumer product company with a nationwide sales and distribution network. It is a fully owned subsidiary of HengAn International, whose shares are listed on the Hong Kong stock exchange. Their turnover in 2011 was approximately EUR 1.7 billion and they have 20,000 employees.

Siemens to focus its water business on automation technology in the future

Siemens has decided to reorganize its activities in the water business. The company intends to focus in the future on automation and drive solutions for the control of water applications for municipalities and industry. The Business Unit known as Siemens Water Technologies, which offers solutions for municipal and industrial water purification and wastewater treatment, is to be sold along with the corresponding service activities. "This business shows only minor synergies with our industrial portfolio, as the skills for water treatment are primarily based on chemical expertise. Instead of investing into that business, we want to gear our resources toward our core portfolio," said Siegfried Russwurm, member of the Siemens AG Managing Board and CEO of the Industry Sector. Siemens Water Technologies is active predominantly in the North American market and recently underwent a comprehensive restructuring. Strengthening Siemens' core activities is one of the five main action fields in the corporate program "Siemens 2014".

"In the future, we will concentrate our water business on solutions along our core areas of expertise in electrical engineering. These are in the automation and drive technology used to operate waterworks and sewage plants as well as sea water desalination plants," said Anton S. Huber, CEO of the Industry Automation Division at Siemens. "For the business, which is organized in the Water Technologies Business Unit, we are looking for the right buyer with a sustainable growth perspective who is willing to invest in this business and generate more synergies."

The products and services provided by Water Technologies comprise a number of different biological, chemical, and mechanical methods for the treatment of water and wastewater. The bulk of this business is geared to the standards in North America. Beyond that, the rest of the worldwide water market is highly fragmented and dominated by local solutions. The activities of the Business Unit have been put on an economically sound basis in the past 18 months and strategically geared to customers in municipalities and various industrial sectors. A large part of the portfolio is accounted for by business with municipalities with a strong regional bias toward the US and Canada, while a smaller portion comprises the treatment of process water and wastewater from industrial companies. Siemens Water Technologies also operates its own research center in Singapore, which includes a novel and extremely energy-efficient technique for electrochemical desalination of sea water. About 4,500 employees work for Siemens Water Technologies worldwide, of whom 3,000 are located in North America.

Siemens Industry Automation will continue as before to operate the business with solutions for the control, management, and instrumentation of water processes, which is part of the Industrial Automation Systems Business Unit. Essentially, these are solutions based on the Simatic PCS7 process control system and process instruments such as flow, pressure, and level meters. There is also drive technology – for pipelines, pumps, and agitators, for example – that are marketed by the Siemens Drive Technologies Division. This portfolio of products is used by municipal sewage treatment plants and waterworks and by industrial companies in such diverse sectors as automotive, mining, chemicals, electronics manufacturing, oil and gas, food production, and pharmaceuticals.

Pöyry supervises the construction of the Xayaburi hydropower project as Government of Lao Engineer

Pöyry's Energy Business Group has been awarded a technical consultancy services assignment for the Xayaburi hydro power plant project in Lao PDR. Pöyry works as the Government of Lao Engineer in the project. Pöyry will support the Government of Lao and the project owner Xayaburi Power Company Limited during the 8-year implementation period by reviewing the design and supervising the construction of the project. The parties have agreed not to disclose the value of the assignment. The project will be included in Pöyry's fourth quarter 2012 order stock.

The project is a state-of-the-art run-of-river plant, with no large reservoir. The installed capacity of 1,285 MW is generated by 8 Kaplan turbines. The design includes multiple fish passages, fish-friendly turbines, low level outlet gates for sediment flushing and navigation locks for shipping to minimise possible adverse environmental and social effects of the plant. The energy production of the plant is sufficient to provide clean electricity to nearly 1 million people in Lao PDR and 3 million people in Thailand.

In 2011 Pöyry acted as a technical consultant to the Government of Lao preparing a technical comparison between the original Xayaburi hydropower project design and the recommendations of the Mekong River Commission. In that technical comparison, Pöyry made several specific recommendations to improve the sustainability of the scheme including additional environmental studies, installation of additional fish ladders and other measures to improve fish migration as well as technical design modifications to improve the sediment and nutrients handling. After this, Pöyry has worked as the Government of Lao Engineer during the development of the project to oversee the implementation of the proposed recommendations. The Government of Lao and Xayaburi Power Company Limited have confirmed that the recommendations made by Pöyry will be incorporated in the project design.

"Large infrastructure projects such as hydropower plants raise a variety of sustainability related questions among stakeholders. However, the Xayaburi hydropower plant, as an example, will provide CO2-free renewable energy for about 4 million people in South East Asia. The lifespan of a run-off river power plant can reach up to 100 years and during this period it will provide affordable clean renewable energy to Lao PDR and Thailand, replacing fossil fuels, improving reliability of power supply and helping to advance Lao PDR out of the "Least Developed" category of nations. Through this assignment Pöyry is committed to monitor the construction of the hydropower plant and its compliance with the Mekong River Commission guidelines, including the proposed technical design improvements and additional studies. I believe that by first reviewing the project's technical design and now overseeing the project implementation we can actively and positively contribute in careful implementation of the first hydro power project in the lower Mekong river", says Ari Asikainen, President, Energy business group.

The project is available on www.poyry.com

NewPage Disclosure Statement Approved

NewPage Corporation (the Company) announced today that the Disclosure Statement for its Fourth Amended Chapter 11 Plan (the Plan) has been approved by the U.S. Bankruptcy Court for the District of Delaware. The Court's approval of the Disclosure Statement allows the Company to begin the Plan voting process, leading to a confirmation hearing scheduled for mid-December and the Company's expected emergence from bankruptcy before the end of the year.

NewPage Corporation (the Company) announced today that the Disclosure Statement for its Fourth Amended Chapter 11 Plan (the Plan) has been approved by the U.S. Bankruptcy Court for the District of Delaware. The Court's approval of the Disclosure Statement allows the Company to begin the Plan voting process, leading to a confirmation hearing scheduled for mid-December and the Company's expected emergence from bankruptcy before the end of the year.

The Company also was authorized to enter into a commitment letter and related fee letters for its exit financing, consisting of a $500 million term loan facility led by Goldman Sachs Lending Partners LLC and a $350 million revolving credit facility led by J.P. Morgan Securities LLC.

"The approval of our Disclosure Statement represents a significant achievement and another important step for the Company and its stakeholders," said George Martin, president and chief executive officer of NewPage. "We look forward to implementing the Plan upon emergence later this year with the financing and liquidity needed to support our operations."

The Company filed the fourth amendment to its Plan and related Disclosure Statement on November 7, 2012. A copy of the Plan and Disclosure Statement is available at www.kccllc.net/NewPage.

Votes on the Plan must be received by the Company's voting agent, Kurtzman Carson Consultants, LLC, by December 10, 2012, unless the deadline is extended. Solicitation materials are expected to be mailed to all creditors entitled to vote on the Plan by November 15, 2012. A hearing to consider confirmation of the Plan is currently scheduled for December 13, 2012, at 12:00 noon Eastern Time.

This press release is for informational purposes only and is not a solicitation to accept or reject the Plan. The Disclosure Statement, along with ballots and other solicitation materials, will be distributed directly to those creditors of the Company who are entitled to vote to accept or reject the Plan pursuant to the Disclosure Statement.

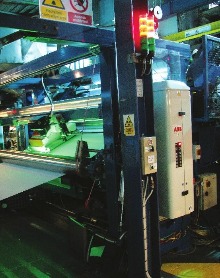

ABB and Arjowiggins team together on Stoneywood’s PM10 Machine

Transparency is key to improving performance.

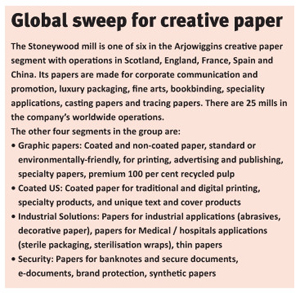

A project to upgrade the PM10 machine at the stoneywood fine paper mill of Arjowiggins in Scotland has transformed its operation. Vince Maynard Editor of Pulp Paper & Logistics Magazine was there to see the project signed off.

Real-time information about the operational performance of any paper-making line is key to improving quality and productivity.

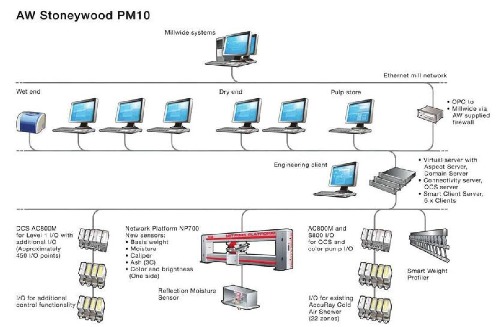

When hardware upgrades were installed at one of the four lines at the Stoneywood fine paper mill operated by Argowiggins near Aberdeen in Scotland, a parallel project to install state-of-the-art quality-control systems provided new-found transparency into the line’s improved performance.

In a collaborative QCS/DCS project with ABB worth £1 million, the improvements to the PM10 machine – capable of sophisticated processes such as watermarking and colour variations – demonstrated how new life can be injected into an already well-established process.

At the end of May, the six- month project was signed off to the satisfaction of development engineer Ian Kilgour, along with documentation that showed the positive effects of the hardware improvements.

In April, PPL magazine was exclusively invited to witness the outcome of the project. While in the PM10 control room mill operations manager Alex McAllan entered with charts showing the production improvements, key performance indicators that spoke for themselves. Time taken for a total change was down by 12 percent; weight and moisture change down by 13.2 per cent and an impressive reduction in breaks.

In April, PPL magazine was exclusively invited to witness the outcome of the project. While in the PM10 control room mill operations manager Alex McAllan entered with charts showing the production improvements, key performance indicators that spoke for themselves. Time taken for a total change was down by 12 percent; weight and moisture change down by 13.2 per cent and an impressive reduction in breaks.

Following the sign off, MacAllan was fulsome in his praise, complimenting ABB for the quality of the project. “The mill is very pleased with the outcome of the project,” he said “It was a great job very well executed. What is particularly pleasing is how enthusiastic the operations team on PM10 is with the system.”

As an example of how the newly-completed QCS/DCS Project offers immediate operational benefits, the way in which it highlighted the outcome of replacing earlier designs of drives was an eye-opener.

Says ABB’s Mick Cowdroy, who worked on the project with colleague Nick Evans: “ The mill upgraded two old drive units at the wet-end of the machine with two new drive units and linked them electronically to the remainder of the machine drive system, thus allowing all sections of the machine to be fully synchronised and controlled more accurately. “ This allowed the advanced controls in the ABB system to be fully optimised and generate increased production benefits through more precise speed optimisation control, faster grade, shade and brightness change control, plus fewer web breaks and faster start-up.”

The new system replaced a QCS (Accuray 1180) dating from the early 1980s and with a Taylor MOD300 (also and ABB product) was mainly used as a data gatherer for process signal for collating all the machine process data and sending it to the mill’s management Information Syetem (MIS). It was also the interface between the QCS and the MIS as the 1180 was incapable of direct linking to the outside world.

All of the machine’s process controllers were ‘stand alone’ units from a number of manufactures: Fisher ac2 (circa 1970s), Turnbull Control Systems (TCS, and eventually part of Eurotherm) were also late-1980s technology. There were two distinct models of single-loop controllers. On top of this there were a few field-mounted controllers plus Refiner KW controllers. All dating from themed-1990s

It was decided to replace all of these systems and in addition install slice lip profile actuators (to replace the manually-set ones) plus remove all Start/Stop buttons for the wet end pumps and the like.

Working with ABB on the project was the continuation of a long history of collaboration between the Stoneywood Mill and Accuray/Combustion Eng/ABB since the mid 1970s. Most recent was the successful installation of an 800xA system on the mill’s PM08 line in 2009.

Working with ABB on the project was the continuation of a long history of collaboration between the Stoneywood Mill and Accuray/Combustion Eng/ABB since the mid 1970s. Most recent was the successful installation of an 800xA system on the mill’s PM08 line in 2009.

Work on the latest project started in the spring of 2010 with Tom and Neil Gordon, of Process Instrumentation Ltd, carrying out preparatory work and then producing a User Requirment Specification (URS) with input from the mill production team, utilising their extensive knowledge of the older system’s functionality.

“The content and quality of this URS enabled the ABB project engineers to programme and configure the control system functions to a high degree of accuracy and ensure an efficient Factory Acceptance Test (FAT). The order was raised in December 2010,” said Cowdroy.

With ABB starting work at its Dundalk base in Ireland. pre-installation at Stoneywood included remote I/O panel building, installation of truncking and cabling, re-housing crew’s ‘bothy’ to enable the old one to be re-built as a wet end control room and ABB rack room, all of which was carried out between January and June 2011.

At Dundalk, the QCS Factory Acceptance Test (FAT) was completed in May 2011 by ABB Project Manager Nick Evans and QCS expert Jim Matthews, all under the supervision of Niall Gairdner from the mill’s Process Control Department. Next stage was the DCS FAT which took place at Stoneywood at the end of June 2011 along with ABB representative Lucas Hedl.again led by Gairdner.

During the annual summer shut-down at Stoneywood in July 2011 the PM10 was stopped to enable dry testing, followed by wet testing which was completed on a Sunday at the end of month. The next morning, 1 August. Stock tests took until lunch time as steam from the boiler house was raised and at 2pm a sheet went through the machine for commissioning of the drying control loops. By. 6pm saleable paper was being produced. The same machine ran all night on the same grade and from 8am the next morning the second tuning of other grades began with colour control following a few days later, but ahead of schedule.

During the annual summer shut-down at Stoneywood in July 2011 the PM10 was stopped to enable dry testing, followed by wet testing which was completed on a Sunday at the end of month. The next morning, 1 August. Stock tests took until lunch time as steam from the boiler house was raised and at 2pm a sheet went through the machine for commissioning of the drying control loops. By. 6pm saleable paper was being produced. The same machine ran all night on the same grade and from 8am the next morning the second tuning of other grades began with colour control following a few days later, but ahead of schedule.

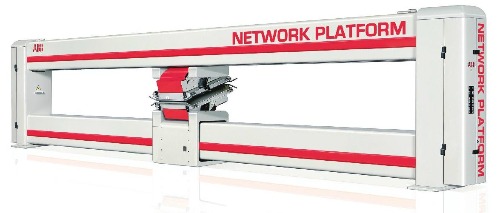

Another reason for working with ABB was the size of the scanner. Originally, ABB had suggested a direct replacement of an earlier ‘C’ frame for a later version. With very little space before the Reel-up Section the options were limited so, after an extensive review of all potential options ABB’s Network Platform 700 was chosen due to its industry-leading compact installation footprint. The result made space more available.

This greatly assisted Stoneywood in the mechanical installation of the scanner s major civil and mechanical work would have been necessary to install a Network Platform 1200. Had the NP1200, or similar, been only option this would have raised the overall project costs (ny about £250,000 or 25 per cent) but also extend the shutdown period by up to ten days with a huge knock-on effect due to lost revenue.

As an added bonus, Arjowiggins and ABB agreed to include the boiler controls within the project scope. This allowed the mill to remove the MOD30 controllers which controlled the drum level and the fuel loops. This has also been a great success. The overall result has been measurable improvements in net production, saleable paper and mill profitability. They are the result of Arjowiggins personnel having access to, and having confidence in, much more reliable and accurate information from the QCS 800xA system. The system is also automatically providing faster and more accurate measurements to the control algorithms which in turn are now calculating the required process changes much more quickly and with greater accuracy to get the process variables to target more quickly than the previous technology would have been able to accomplish.

More information from ABB, Finnabair Industrial Park, Dundalk, Co Louth, Ireland. Tel: +353 42 938 5100. Fax: +353 42 938 5124. Web: www.abb.co.uk

The above article was provided by Vince Maynard the Publisher and Editorial Director of Pulp Paper & Logistics magazine. Tel: +44 (0) 1732 505724 Web: http://www.pulppaperlogistics.com/

Resolute Forest Products Announces Two Major Investments in its Comtois and Senneterre Sawmills.

Resolute ForestProducts has announced two major investments today, totaling C$11 million, at its Comtois sawmill in Lebel-sur-Quévillon, Quebec, and its Senneterre, Quebec, sawmill.

Resolute ForestProducts has announced two major investments today, totaling C$11 million, at its Comtois sawmill in Lebel-sur-Quévillon, Quebec, and its Senneterre, Quebec, sawmill.

At the Comtois sawmill, $9 million will be invested in the construction of a new saw line. This equipment will enhance the sawmill's performance by increasing the volume of lumber produced and reducing fiber loss. The $2 million investment at the Senneterre sawmill will improve the performance of the planing complex.

Yves Laflamme, Senior Vice President, Wood Products, said that these investments will reinforce the Company's competitiveness, which is essential to maintaining jobs in the northern Québec and Abitibi-Témiscamingue regions.

"After several difficult years, we believe that these investments will put us in a good position to benefit from a turnaround in residential construction in the United States. The upgrades will consolidate our activities in both regions by creating synergies, stabilizing our operations and preserving good jobs. The investments will make our two facilities more competitive and boost their performance. We are all the more pleased and proud because today's announcement will generate substantial economic spinoffs in Abitibi-Témiscamingue and northern Quebec," he added.

Given the market outlook for lumber, Resolute Forest Products plans to focus on wood products. In this regard, President and Chief Executive Officer Richard Garneau reiterated "the Company's ongoing commitment to be a sound, strong, profitable organization that produces top-quality products and supports sustainable development." He also repeated Resolute's intention to lay the foundations for its development and growth by investing in competitive assets and promising markets in order to contribute to the organization's overall profitability.

Once the work is completed in the second quarter of 2013, the Company will be well equipped to reduce its conversion costs and improve product quality. Its competitive position in northern Quebec and Abitibi-Témiscamingue will be stronger, and the investments will generate positive economic spinoffs in both regions.

SOURCE: RESOLUTE FOREST PRODUCTS INC.

ABB sells its 1000th Filtercel™

ABB recently received the order for its 1000th Filtercel™, soon to be installed in a paper mill of Nine Dragons Paper Limited in China.

ABB recently received the order for its 1000th Filtercel™, soon to be installed in a paper mill of Nine Dragons Paper Limited in China.

November 8, 2012 – Over the last 20 years, ABB has installed one thousand in-line pressure filters of the Filtercel™ range in paper mills worldwide for the filtration of coating colors, pigment and starch preparations, and on stations feeding all types of paper and board machines

ABB recently successfully started up ten Filtercel™ LHP (high pressure cleaning system) on the feeding station (also designed and installed by ABB, as well as the starch preparation unit) of the new PM11 for Saica Group’s mill in Manchester, United Kingdom.

During the last two decades, the Filtercel™ has benefited from continued technological evolutions such as an integrated high-pressure cleaning system, known as the LHP version; new sealing systems with automatic wear-compensation; and increased output capacity.

Today, this evolution enables operator interventions to be significantly reduced and result in a very high uptime rate. The LHP Filtercel™ is particularly suitable for the filtering of high-requirement and varied preparations such as pigmented coating colors and starch solutions. The optimal filtering quality helps to significantly reduce the number of paper breaks on the machine and the maintenance costs. To further support equipment lifecycle management, recent improvements to the Filtercel™ can fit on filters already in service to enable their modernization.

ABB’s Process Automation division delivers industry specific solutions and services for industrial automation and plant electrification. These solutions help customers meet their critical business needs in the areas of energy efficiency, operational profitability, capital productivity, risk management, and global responsibility. Available industry specific solutions include process control, instrumentation, analytics, safety, plant optimization, telecommunications, energy management and power distribution.

UPM Raflatac expands its product range and strengthens R&D resources in China

UPM’s Label business UPM Raflatac is investing in new hotmelt adhesive mixing and coating technology at its self-adhesive labelstock factory in Changshu, China. With this in-house hotmelt manufacturing capability, UPM Raflatac will be offering label converters cutting-edge technology and expertise they require to develop cost-effective and high-quality label products. The new technology will be in use during the first quarter of 2013.

The latest hotmelt coating technology allows UPM Raflatac to expand its standard paper and film product ranges particularly in the food, retail and tyre industries as well as in variable information printing (VIP), where hotmelts provide advantages such as high initial tack and reliable adhesion on chilled, moist or rough surfaces. The new technology also enables the development of special products designed for niche markets as well as shorter runs, meeting the individual needs of brand owners.

In addition to a wider product range, UPM Raflatac’s customers will benefit from a hotmelt pilot-coating facility and strengthened local R&D capabilities. An accelerated development process will bring regionally adapted new products faster to market.

“This investment in the latest technology and local R&D development show that UPM Raflatac is committed to developing solutions that help labelstock converters in the region build their businesses and grow,” says Arto Tuomi, General Manager, UPM Raflatac China. “It also opens new opportunities for us to continually serve the market better.”

The investment is one of the biggest investments at the Changshu factory since its inauguration in 2007 and it further strengthens UPM Raflatac’s position in the competitive Asian labelstock market.

Ahlstrom announces paper release liner recycling initiative in Europe

Ahlstrom, a global high performance materials company, and a leading producer of release papers, has today announced a new initiative for recycling silicone coated paper release liners used by the pressure sensitive adhesive (PSA) label industry.

This sustainability initiative aims to collect silicone coated supercalendered papers (commonly known as "glassine") once they have been utilized as carriers of PSA labels by end-users, such as brand owners or retailers. Ahlstrom will collect the materials through one or more logistics partners and will recycle them into specialty paper production at its Osnabrück plant in Germany.

Glassine paper release liners will be picked-up at no cost from end-users anywhere in Germany, Belgium, Luxemburg and the Netherlands, provided a minimum quantity of two tons per load. Avery Dennison Label and Packaging Materials Division will support this initiative and utilizes its contacts across the value chain in order to make label printers and brand owners aware sof this new opportunity.

Ahlstrom's recycling capacity will be sufficient to absorb release liner waste of a significant number of end-users. The initiative increases the recycling options available in the market and will help divert paper liner waste from landfill or incineration, while increasing the quantities recycled into paper.

"Thanks to Ahlstrom Osnabrück's convenient location in north-western Germany and the support of Avery Dennison, we trust this program will offer PSA label end-users an opportunity to increase their overall environmental performance" says Daniele Borlatto, Executive Vice President, Label and Processing. "Such programs also reinforce the position of paper as a uniquely sustainable material for the PSA industry"

Avery Dennison Label and Packaging Materials Division supports this initiative, as engaging local value chain partners is essential in driving self-sustaining waste recycling programs for the self-adhesive industry.

Ahlstrom is a global leading producer of release papers for the PSA industry. It operates five release papers production sites located in Europe (4) and South America (1). All of them are ISO 14001, FSC(TM) and PEFC(TM) Chain of Custody certified, and are part of Ahlstrom's Label and Processing business area.

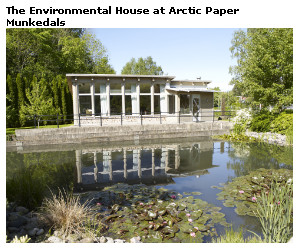

Arctic Paper Munkedals AB nominated for EMAS Awards 2012

Life is impossible without an adequate supply of clean water. Watercourses provide drinking water as well as process water for manufacturing. They are also habitats for a wide variety of flora and fauna and contribute to preserving biological diversity. Sound water management is vital. The European Commission is proud to accept Sweden's nomination for the EMAS Awards 2012 – Arctic Paper Munkedals AB. Together with 26 other companies and organizations, Arctic Paper Munkedals AB has been nominated for an award for “Water Management (including water efficiency and water quality)”, which is the EMAS Award topic for 2012.

Life is impossible without an adequate supply of clean water. Watercourses provide drinking water as well as process water for manufacturing. They are also habitats for a wide variety of flora and fauna and contribute to preserving biological diversity. Sound water management is vital. The European Commission is proud to accept Sweden's nomination for the EMAS Awards 2012 – Arctic Paper Munkedals AB. Together with 26 other companies and organizations, Arctic Paper Munkedals AB has been nominated for an award for “Water Management (including water efficiency and water quality)”, which is the EMAS Award topic for 2012.

The Swedish Environmental Management Council has nominated Arctic Paper Munkedals AB for the EMAS Awards 2012. An EMAS Award is the most prestigious award in environmental management and is only presented to top-performing companies and public authorities. According to an announcement from the European Commission, "The nominees have demonstrated their dedication in the field of water management". The winners for 2012 will be announced at the official EMAS Awards ceremony, which will take place on November 29, 2012 in Brussels, Belgium.

"At Arctic Paper Munkedals we have been working with water management and efficient water usage for many years as a part of our environmental strategy," says Anders Fransson, Group Technical and Environmental Coordinator at Arctic Paper. He continues: "We are honoured to receive this nomination in recognition of our efforts and achievements so far. We know our mill in Munkedal Sweden is one of most efficient mills in the world when it comes to efficient water usage. The nomination is an inspiration to us all to continue developing our way of working and set our sights even higher for the future."

All nominees for the Award can be found at the Facebook page of the Sustainable Production & Consumption Unit of the Directorate-General for the Environment at the European Commission, where the nominees in each category are announced.

You can also find a list of all nominees arranged according to category on the EMAS Awards website (http://ec.europa.eu/environment/emas/emasawards/nominees.htm). More information about the exemplary ways in which the nominees are managing their water use will also be presented on the website shortly.