Ianadmin

Siemens receives 126 MW wind power plants order in Ireland

Siemens Energy has received an order for delivery and servicing of 42 direct-drive wind turbines for two onshore wind power plants. Purchaser is the Irish utility Bord na Móna. The order encompasses 28 SWT-3.0-101 direct-drive wind turbines for the Mount Lucas wind farm, located in County Offaly, around 80 kilometers west of Dublin and 14 SWT-3.0-101 direct-drive wind turbines for the Bruckana wind power plant located on the border of Kilkenny and Tipperary, around 120 kilometers south-west of Dublin. These turbines, each with a rating of 3 megawatts (MW) and a rotor diameter of 101 meters, are scheduled to begin feeding power into the grid by mid 2014. The combined capacity of both wind farms of 126 MW will be sufficient to provide ecofriendly electricity to 80,000 Irish households.

Siemens Energy has received an order for delivery and servicing of 42 direct-drive wind turbines for two onshore wind power plants. Purchaser is the Irish utility Bord na Móna. The order encompasses 28 SWT-3.0-101 direct-drive wind turbines for the Mount Lucas wind farm, located in County Offaly, around 80 kilometers west of Dublin and 14 SWT-3.0-101 direct-drive wind turbines for the Bruckana wind power plant located on the border of Kilkenny and Tipperary, around 120 kilometers south-west of Dublin. These turbines, each with a rating of 3 megawatts (MW) and a rotor diameter of 101 meters, are scheduled to begin feeding power into the grid by mid 2014. The combined capacity of both wind farms of 126 MW will be sufficient to provide ecofriendly electricity to 80,000 Irish households.

"This is the first order from Ireland for our direct-drive wind turbines. Globally, we have already sold more than 800 wind turbines of this type for on- and offshore wind power plants. With this innovative technology we contribute to the development of a sustainable energy supply in Ireland," said Felix Ferlemann, CEO of the Wind Power Division of Siemens Energy. The Republic of Ireland has excellent wind conditions. According to the Irish Wind Energy Association (IWEA), the country already has an installed wind generation capacity of about 2,000 MW today.

Siemens will supply, install and commission the 42 direct-drive turbines for the Mount Lucas and Bruckana wind power plants and will also provide service for the plants over a period of 15 years. Long-term service programs like this offer the customers more projectable service costs and a prolonged warranty.

Wind power is part of Siemens' Environmental Portfolio. In fiscal 2011, revenue from the Portfolio totaled about €30 billion, making Siemens one of the world's largest suppliers of ecofriendly technologies. In the same period, our products and solutions enabled customers to reduce their carbon dioxide (CO2) emissions by nearly 320 million tons, an amount equal to the total annual CO2 emissions of Berlin, Delhi, Hong Kong, Istanbul, London, New York, Singapore and Tokyo.

Metso supplies the Best Bioenergy Project of the Year

The Nacogdoches Generating Facility in Sacul, Texas was awarded the 2012 Project of the Year in the Biomass category by Power Engineering Magazine at the Power-Gen international conference on December 10,2012 in Orlando, FL.

The Nacogdoches Generating Facility in Sacul, Texas was awarded the 2012 Project of the Year in the Biomass category by Power Engineering Magazine at the Power-Gen international conference on December 10,2012 in Orlando, FL.

The Nacogdoches Project represents a Metso-supplied boiler island with the world's largest BFB Boiler. The project also included Metso Automation Flow Control Devices and a Metso DNA plant-wide distributed control system.

The boiler features efficient energy conversion of a wide range of biomass. Thanks to the advanced technology of the boiler island the Nacogdoches Generating Facility is prepared to deliver electricity whenever needed.

Dave King, Area President, North America, Power business line, Metso, explains that "the Nacogdoches project is a success since it plays a key role in preparing the City of Austin to meet its goals for sustainable power generation. Furthermore, this project would never have been possible if not for the excellent track record of Metso's existing global BFB base, and the ability to design a utility-grade biomass boiler capable of low emissions and high availability.

Tight with fuel consumption, generous with energy

This boiler is the largest HYBEX boiler in service, designed to produce 930,000 lbs/hr (117 kg/s) of steam and generate 100 megawatts of renewable electrical power. The entire boiler island, including air pollution control equipment and the plant-wide controls, was provided and erected by Metso under an EPC contract.

Clean and environmentally responsible power

The 100 MW capacity of the largest BFB biomass power plant in the United States can generate enough power to supply approximately 60,000 homes with electricity. The plant was built to serve a 20-year contract with Austin Energy to help meet the state's renewable portfolio standard, with the output serving the City of Austin.

The plant is fuelled entirely by non-merchantable wood biomass materials, with a base load renewable energy option that helps strengthen the nation's energy security. Abundant fuel supply in the proximity of the plant enables wood waste recycling from the local timber operations, manufacturing facilities, and municipalities. All of the fuel needed can be procured within a 75-mile radius.

During construction, extreme drought put the water supply for the facility, the Angelina River, in jeopardy - the river became completely dry and was deemed unreliable to supply the facility. Developers constructed a 10-mile water line to a nearby lake that now provides ample water to supply plant operations.

Nacogdoches has made a significant impact in the surrounding towns. During construction, more than 100 vendor contracts for services and maintenance were established, as well as 25 fuel supply contracts. The facility allowed for more than 1,000 construction jobs, which was a boost for the local economy in the 200-resident town of Sacul. The facility is also set to employ 40 full-time workers.

Each year, projects from around the world are honoured during POWER-GEN International's Projects of the Year awards gala, with many different award categories. Nacogdoches Generating Facility won the best biomass project of the year, and chosen as runner-up project was an anaerobic digester facility at the Nocton Fen Farm in the UK, developed by Cummins Power Generation.

U.S. Bankruptcy Court Confirms NewPage Chapter 11 Plan

NewPage Corporation (NewPage) has announced that the U.S. Bankruptcy Court for the District of Delaware in Wilmington has confirmed the Company's Chapter 11 Plan (the "Plan"). The Plan was accepted by the overwhelming majority of NewPage creditors entitled to vote. The Company will now proceed to close on the restructuring transactions contemplated by the Plan.

NewPage Corporation (NewPage) has announced that the U.S. Bankruptcy Court for the District of Delaware in Wilmington has confirmed the Company's Chapter 11 Plan (the "Plan"). The Plan was accepted by the overwhelming majority of NewPage creditors entitled to vote. The Company will now proceed to close on the restructuring transactions contemplated by the Plan.

"We are pleased that the Court has confirmed our Chapter 11 Plan, clearing the way for us to officially exit bankruptcy, hopefully by the end of this year," said George Martin, president and chief executive officer for NewPage. "We will exit bankruptcy with substantially less debt and new financing at lower interest rates. NewPage will be well positioned to serve the needs of our customers and compete successfully in the North American paper industry."

SOURCE NewPage Corporation

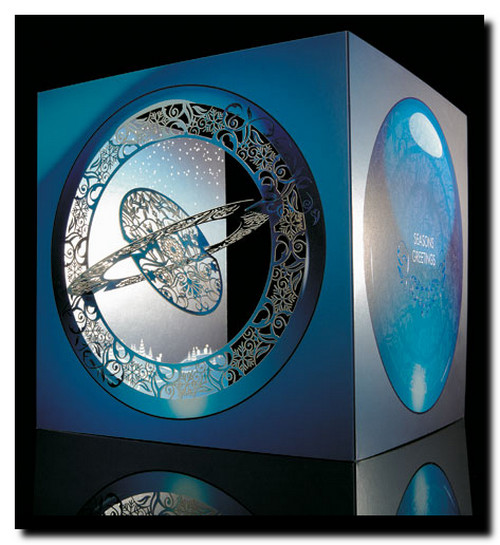

Extreme laser cutting in a stylish Christmas card

This year’s Christmas card from Iggesund Paperboard has all the requirements to be a classic that many people will keep for a long time. The van Heertum Design agency from the Netherlands has made a name for itself by not flinching from design commissions that demand both complex printing and intricate finishing.

The motif is a starry sky featuring both reindeer and celestial objects done in an extremely fine laser cut, complemented with several foils and then printed in three PMS inks. The tabs attaching the laser-cut sections to the rest of the card are so fine that they are hard to see, and it is only thanks to Invercote’s superior tear strength that the card stays in one piece.

Iggesund Paperboard has a tradition of creating intricate Christmas cards that demonstrate, and in the best cases stretch, the limits of what can be achieved with Invercote as the base material.

“We want to produce more than a Christmas card, we want designers to challenge Invercote and give us something that reflects its essence,” explains Carlo Einarsson, Director Market Communications at Iggesund Paperboard.

Each paperboard sheet was printed using three different techniques and more than 30 inks and varnishes. The printed sheets then passed through various finishing stages a total of 14 times.

“I take on these projects because I want to know how far the material can be pushed,” he says, clearly satisfied with this year’s Christmas card for Iggesund Paperboard.

The card is made of Invercote Creato 350 g/m2 and van Heertum Design VHD was responsible for both the design and implementation. The agency was assisted by a group of Dutch suppliers, such as the printers Drukkerij Tielen, Boxtel, and the foil printers Hensen Foliedrukkers, Oirschot, using foil supplied by Leonhard Kurz Benelux of Nijmegen. The characteristic laser cutting was done by Point to Paper, Waalwijk.

Frans van Heertum, founder of van Heertum Design and winner of a number of awards for sophisticated printing projects, has done large, advanced projects a number of times using Invercote as the base material. One recent project is his contribution to Iggesund’s Black Box Project, in which he printed a series of cards.

FiberMark Announces Winners for Annual Specifier Awards Competition

FiberMark, (www.fibermark.com), a global leader in manufacturing innovative, fiber-based specialty covering materials for world-leading brands, has announced the winners of its industry-renowned annual “Specifier Awards” competition.

FiberMark, (www.fibermark.com), a global leader in manufacturing innovative, fiber-based specialty covering materials for world-leading brands, has announced the winners of its industry-renowned annual “Specifier Awards” competition.

The FiberMark Specifier Awards program was inaugurated in 1992 to celebrate the best of color, texture, pattern and design innovation across a wide array of packaging, publishing, office products, graphic arts and industrial applications. Since its introduction, the Awards program has become international in scope, earning an increasing reputation as one of the industry’s most highly regarded competitions.

Among this year’s top winners were: a Gold Award for an “Audi C/D Segment Welcome Kit” submitted by Megan Henretta at RTC, designed by Rebecca Mabie and Paul Henkel; a Silver Award for a “Play Off Diaries” submitted by Yasuhiro Tokimoto, president at Jakeutsu Printing Company, Ltd., a Bronze Award for an “Organicept Deskset,” submitted by Leo Wasmer at Promocion Precisa SA DE CV, designed by Monica L. Yuen; and a Green Award for a “Lincoln Catalog,” submitted by Jack Dorsey at Latcha & Associates, designed by Amy Turnnen.

Stella Alstede, FiberMark’s Marketing Manager-Promotions, who coordinates the awards program, says that the competition has grown steadily since its inception. “This year, we received approximately 150 submissions from all over the world in many different categories of design and specification,” she notes, explaining that the entries are judged by a panel of experts from all aspects of FiberMark’s business. Specifier Award winners receive industry-wide recognition from the design and “specifier” communities, as well as notable posting on FiberMark’s Website, at www.fibermark.com/awards.

Any product designed and manufactured during the previous calendar year is eligible for submission. Entries are judged from criteria that consider color, texture, pattern and design, and their expression throughout a range of “naturally creative” materials and themes. Importantly, the judges also weigh construction quality and the relationship of the covering material to the overall product.

Voith Holds Its Own in a Difficult Environment

The Voith Group has finished the fiscal year 2012 (ending September 30) satisfactorily in a challenging market environment. The globally active family-owned company increased its Group sales by 2 percent to EUR 5.7 billion compared to the record value of the previous year. With EUR 5.7 billion, orders received were behind the excellent value of last year amounting to EUR 6.4 billion (-10 percent), which, among other things, was due to an extraordinarily high volume of major orders from the hydro power market. At EUR 6.1 billion per September 30, 2012, orders on hand were slightly above the previous record level (2011: EUR 6.0 billion).

The Voith Group has finished the fiscal year 2012 (ending September 30) satisfactorily in a challenging market environment. The globally active family-owned company increased its Group sales by 2 percent to EUR 5.7 billion compared to the record value of the previous year. With EUR 5.7 billion, orders received were behind the excellent value of last year amounting to EUR 6.4 billion (-10 percent), which, among other things, was due to an extraordinarily high volume of major orders from the hydro power market. At EUR 6.1 billion per September 30, 2012, orders on hand were slightly above the previous record level (2011: EUR 6.0 billion).

All key figures are positive, although on a lower level than in the past year. Despite the declining sales for graphic paper machines in the Group Division Voith Paper, Voith was able to generate one of the best operational results in the history of the Group. The operational result before non-recurring result was EUR 341 million (-18 percent), the net income amounted to EUR 114 million (-43 percent).

Stable thanks to broad portfolio

"The year 2011/2012 has presented Voith with massive challenges. We have worked intensively on our profitability and our future growth, and laid crucial foundations to ensure that Voith can continue to grow profitably," said Dr. Hubert Lienhard, President and CEO of the Corporate Management Board of Voith GmbH at the company's Balance Sheet Press Conference. According to Dr. Hermann Jung, Chief Financial Officer of Voith, one of the key reasons for the stable business development despite this challenging market environment is the Group's broad portfolio. "We can offset declining sales in individual markets. Because we serve five core industries that follow different cycles: energy, oil & gas, paper, raw materials, transport & automotive. This portfolio has allowed us to grow during the economic crisis in 2009. We were also able to cushion the noticeable slump in the market for graphic paper machines," stated Jung.

All Group Divisions make a positive contribution to sales and earnings

Voith Hydro, one of the world's leading complete suppliers for hydro power plant equipment, was able to increase its sales by 7 percent to EUR 1.3 billion and to raise its operational result by 11 percent to EUR 100 million. As predicted, orders received remained below the previous year, which was marked by major hydro power projects, yet still reached a good value with EUR 1.3 billion (-25 percent).

Sales at Voith Industrial Services, a leading supplier of technical services for key industries such as automotive, energy, the chemical and petrochemical sector, as well as machine construction and aerospace, rose by 9 percent to EUR 1.1 billion. A major contributor to this result was the good business in the automotive industry. The operational result increased to EUR 41 million (+1 percent).

At Voith Paper, the pioneer of the paper industry, sales declined by 5 percent to EUR 1.7 billion due to adverse market conditions. Especially new business was severely affected by the structural slump in demand for graphic paper machines: Orders received dropped by 13 percent to EUR 1.7 billion. Voith has promptly introduced a restructuring program. The negative impact resulting from these measures has already been fully absorbed in the 2012 end-of-year accounts. The operational result of Voith Paper decreased by 41 percent to EUR 84 million.

Voith Turbo, specialist for drive technology, increased its sales by 2 percent to EUR 1.6 billion. Orders received amounted to EUR 1.5 billion - a three-percent drop compared to the previous year. With EUR 151 million, the operational result of Voith Turbo continues to be on a high level, albeit below the value of the previous year (-8 percent).

Significant increase in investments, intensive R&D activities

In fiscal 2012, Voith's investment in the sustainability of the company continued unabated. The Group increased its investment volume significantly by nearly one third above the level of the previous year, spending EUR 272 million (+29 percent), which corresponds to an investment quota of 4.8 percent of the overall Group sales. The company also increased its R&D expenditure to EUR 267 million (+3 percent), thus reaching an R&D quota of 4.7 percent.

In the business year just ended, Voith also invested heavily in the training of young people: At the company headquarters in Heidenheim Voith is building a new training center for about EUR 16 million. At the Voith location in Kunshan, China, work has begun for a training center based on the German dual training principle, in which Voith is investing approximately EUR 7 million. "We are aware that the future of Voith as technological leader largely depends on highly skilled experts, the creativity of its engineers and the readiness and the ability to invest boldly in new products and activities also in the future," said Lienhard at the Balance Sheet Press Conference.

Outlook 2013: growth expected to be restrained

In view of the ongoing difficult framework conditions, such as the Euro debt crisis, an uncertain capital market environment and subdued economic prospects on all major markets and industries, Voith anticipates that developments in 2013 will continue to be restrained. "Dealing with the changes in some of our core markets will continue to be high on our agenda also in 2013, and we cannot see any dynamic growth in 2012/2013, but we expect altogether stable business developments for the Voith Group," stated Lienhard. Based on the assumption that growth for the global economy will be moderate, the Voith CEO foresees that orders received will be at a high level, with sales and results developing at a measured pace, while the net income will improve.

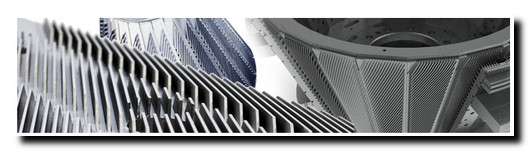

Refiner plate MiniSegment™ extends value, saves money for LC refining

AFT Finebar®, part of the global Aikawa Group, has developed the MiniSegment™ refiner plate – the latest advancement in diffusion bonded refiner plate technology. The MiniSegment allows mills to replace only the working surface of the refiner plate, reducing the overall cost of ownership.

AFT Finebar®, part of the global Aikawa Group, has developed the MiniSegment™ refiner plate – the latest advancement in diffusion bonded refiner plate technology. The MiniSegment allows mills to replace only the working surface of the refiner plate, reducing the overall cost of ownership.

The MiniSegment is installed on an Adapter Plate, which is bolted to the mounting surface using the existing refiner bolt holes. In addition to saving money by replacing only the fiber-contacting portion of the refiner plate, the MiniSegments weigh considerably less than a traditional plate, making them easy to position when bolting and safer to handle.

AFT Finebar MiniSegments can be applied to nearly any single disk, double disk, or Tridisk low consistency refiner.

UPM closes down Aureskoski further processing mill, offers support for employees

The operations at UPM Aureskoski further processing mill in Parkano, Finland will cease this month. UPM has produced interior wood panels at the mill. UPM announced in June 2012 the decision to close down the mill by the end of the year.

The operations at UPM Aureskoski further processing mill in Parkano, Finland will cease this month. UPM has produced interior wood panels at the mill. UPM announced in June 2012 the decision to close down the mill by the end of the year.

UPM has started the “From Job to Job” programme in Aureskoski in order to alleviate the effects caused by staff reductions in relation to the closing of the mill. The programme, which UPM implements in co-operation with the authorities and partner companies, includes active measures that promote employment and re-training.

Aureskoski further processing mill employs 33 people. The closure announced today is part of the decision published on 29 June 2012, including restructuring of UPM’s sawmill and further processing operations and renewal of business strategy in Finland.

International Paper Reaches Agreement to Sell Temple-Inland Building Products Division for $750 Million

International Paper has announced that it has reached an agreement to sell its Temple-Inland Building Products division to Georgia-Pacific LLC for $750 million in cash, subject to certain pre-and post-closing adjustments. The assets to be sold include 16 manufacturing facilities - five solid wood mills, four particleboard plants, two medium-density fiberboard plants, one fiberboard plant and four gypsum wallboard plants.

International Paper has announced that it has reached an agreement to sell its Temple-Inland Building Products division to Georgia-Pacific LLC for $750 million in cash, subject to certain pre-and post-closing adjustments. The assets to be sold include 16 manufacturing facilities - five solid wood mills, four particleboard plants, two medium-density fiberboard plants, one fiberboard plant and four gypsum wallboard plants.

"While not core to IP's strategy, Temple-Inland Building Products is an industry leader," said John Faraci, Chairman and Chief Executive Officer. "I am pleased to have reached a deal that recognizes the strength of the business and provides excellent value for IP shareowners."

Temple-Inland Building Products facilities are located across eight states, primarily in the southeastern and eastern portions of the United States, with access to five of the top 12 housing markets.

The transaction is expected to be completed in the first quarter of 2013, subject to satisfaction of various closing conditions, including obtaining required governmental approvals. IP intends to use the proceeds from the sale to reduce its debt.

Additionally, the Company announced its intention to report a new (Non-GAAP) adjusted EPS measure, 'Operating Earnings' beginning with our fourth quarter 2012 earnings release. Operating earnings is defined as earnings from continuing operations (GAAP) excluding special items and non-operating pension expense, which is impacted by changes in interest rates and plan returns. Significant declines in interest rates over the past several years have caused an extraordinary increase in certain components of pension expense that the Company considers to be unrelated to underlying operating performance. This move will thereby reduce the volatility in earnings from non operational factors and improve the transparency of the performance of current operations. For the nine-month period ended Sept. 30, 2012, non-operating pension expense was approximately $.18 per share on a continuing operations basis. The Company will provide further information concerning the new reporting format with our next quarterly earnings release.

SOURCE International Paper

Ahlstrom completes its release paper range for premium self-adhesive graphics

![]() Ahlstrom, a global high performance fiber-based materials company, has completed its range of Silco(TM) Flat release papers for Pressure Sensitive Adhesive (PSA) graphics, with the addition of newly developed products for the most demanding graphics applications and for plotter cut films.

Ahlstrom, a global high performance fiber-based materials company, has completed its range of Silco(TM) Flat release papers for Pressure Sensitive Adhesive (PSA) graphics, with the addition of newly developed products for the most demanding graphics applications and for plotter cut films.

Large format self-adhesive graphics are applied on large surfaces to create appealing decoration or advertising in architecture, retail, vehicles or exhibitions. Release liners used for such laminates need to be specially designed to perform well during lamination, printing or plotter cutting, in order to deliver outstanding visual effect once the film has been applied on the surface.

As a leading global release papers supplier, Ahlstrom has developed through the years a range of sustainable paper products for PSA graphic laminates, supplied to the key players in this industry. To be aligned with the latest advances in printing and cutting technologies, the Ahlstrom Silco(TM) Flat range was recently enlarged with new high performance materials.

Ahlstrom Silco(TM) Flat Premium has been developed for the most demanding graphic applications. Its increased top and backside smoothness enhance the vinyl film glossiness while its backside moisture barrier ensures outstanding planarity for faultless performance during printing.

Additionally, Ahlstrom Silco(TM) Flat HB has been designed specifically for plotter cut films. Its high internal bond enables a cut with a high degree of precision, even with the most complex shapes or smallest letters. Its high top side smoothness delivers a high gloss and avoids orange peel effect, ensuring perfect finish of the most sensitive vinyls or thin transparent films.

Made of natural fibers, release papers are the most sustainable release liner substrates. Entirely based on renewable raw materials, they are derived from responsible forestry, are recyclable and biodegradable.