Ianadmin

Minerals Technologies Signs Agreement with Jianghe Paper for the Construction of a Satellite PCC Facility in China

Minerals Technologies Inc. has announced that it has signed an agreement with Henan Jianghe Paper Co., Ltd. for the construction of a 22,000-metric ton satellite precipitated calcium carbonate (PCC) plant at Jianghe Paper's papermaking facility in Jiaozuo City, Henan Province, China. Jianghe Paper, a privately owned paper company, is one of the largest carbonless and thermal papermakers in China with annual production of approximately 220,000 metric tons per year.

Minerals Technologies Inc. has announced that it has signed an agreement with Henan Jianghe Paper Co., Ltd. for the construction of a 22,000-metric ton satellite precipitated calcium carbonate (PCC) plant at Jianghe Paper's papermaking facility in Jiaozuo City, Henan Province, China. Jianghe Paper, a privately owned paper company, is one of the largest carbonless and thermal papermakers in China with annual production of approximately 220,000 metric tons per year.

The satellite facility, which will produce PCC as a filler pigment for Jianghe Paper, will become operational in the first quarter of 2014.

"Minerals Technologies is very pleased to provide our PCC to a fine company like Jianghe Paper," said Joseph C. Muscari, chairman and chief executive officer. "This agreement, our second in China in the last two months, adds momentum to our geographic expansion strategy, and brings the number of satellite plants we have in China to five."

PCC is a specialty pigment for filling and coating high-quality paper. By substituting Minerals Technologies' PCC for more expensive wood fiber, customers are able to produce brighter, higher quality paper at lower cost. In 1986, Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills and the concept was a major factor in revolutionizing papermaking in North America. Today, the company has 59 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

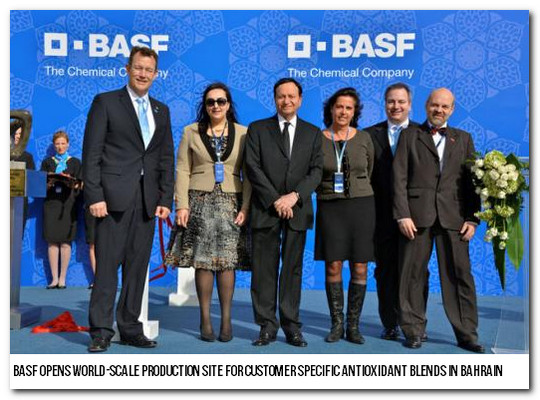

BASF opens world-scale production site for customer specific antioxidant blends in Bahrain

BASF is opening a state-of-the-art production site for customer specific antioxidant blends (CSB) in the Kingdom of Bahrain. This is the largest facility of this kind worldwide and will become fully operational in December.

With this investment BASF Plastic Additives continues to strengthen its position as the leading partner in plastic additives for the plastic processing industry worldwide and shows its strong commitment to supportthe growth of the polymer industry in the Gulf Corporation Council (GCC). CSB are additives-blends individually tailored to meet individual customer needs and are an integral part of the portfolio BASF offers to the plastics industry.

“BASF’s investment in this new site demonstrates our steadfast commitment to support growing industries in the Middle East, while at the same time setting standards with regard to quality, safety and employee training,” said Michael Heinz, Member of the Board of Executive Directors of BASF, during the opening ceremony.

Kamal bin Ahmed, Minister of Transportation and Acting Chief Executive of the Bahrain Economic Development Board, said: “We are delighted to welcome BASF, a leading international company, to Bahrain. Large manufacturing firms like BASF are playing an increasingly important role in our economy and will be a significant part of our plan to create sustainable long term economic growth and high quality jobs.”

The new facility, which is based on proprietary CSB technology, will provide local production and services tothe fast growing polymer market in the Middle East with special focus on key customers in the countries of the GCC. It comes in addition to the existing manufacturing agreement for CSB with Astra Polymer in the Kingdom of Saudi Arabia, which has been extended earlier this year.

John Frijns, Head of Plastic Additives Europe/ EAWA, stresses the necessity of local structures: “As BASF, we are committed to accompany the growth in the region with technical and flexible supply solutions through local production. ”

The new facility is part of a strong antioxidants production network comprising Asia, Europe and the Americas, which will be further optimized once the new capacity comes on stream.

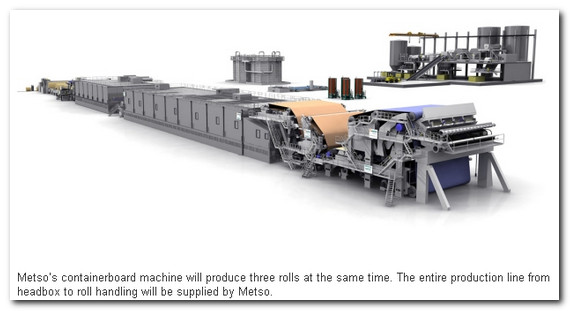

Metso-supplied boardmaking line starts up at Liansheng Paper Industry in China

On October 28, 2012, Liansheng Paper Industry (Longhai) Co., Ltd started up their new Metso-supplied containerboard production line, PM 5, at their Longhai site in Fujian province in China.

On October 28, 2012, Liansheng Paper Industry (Longhai) Co., Ltd started up their new Metso-supplied containerboard production line, PM 5, at their Longhai site in Fujian province in China.

"The PM 5 start-up was successful with a stable operating process. The desired targets were achieved. I hope that we can continue a very good cooperation with Metso also in the future,” says Rongjun Xue, Project Manager of Liansheng Paper.

The new 7.25-m-wide PM 5 has an annual production capacity of approximately 350,000 tonnes of recycled testliner in the basis weight range of 100 to 140 g/m2. The design speed is 1,200 m/min.

Metso’s delivery included a complete boardmaking line from headbox to reel with air systems, a size supply system, a quality control system and a winder.

The PM 5 testliner production line features a novel two-layer forming process with only one hybrid forming unit equipped with the new OptiFlo layering headbox. With this innovative technology a two-layer web can be produced with only one headbox providing excellent profiles due to a unique dilution system and good formation due to new type of hydraulics.

Liansheng Paper Industry (Longhai) Co., Ltd. is a subsidiary of Fujian Liansheng Paper Co., Ltd. The company was founded in 1999 and is based in Zhangzhou, China. A third Metso-supplied production line for Fujian Liansheng, PM 6, is to start up at the Longhai site in December this year. The PM 6 boardmaking line will produce recycled fluting grades and it has the same width and design speed as the PM 5.

Metso to provide multi-year mill maintenance to Greenpac Mill in the USA

Metso and Norampac have reached an agreement in principle for Metso to supply the mill maintenance services for Greenpac Mill in Niagara Falls, NY, in the United States. With this mill maintenance agreement Metso will establish and manage all maintenance systems and procedures at the mill. The value of the agreement will not be disclosed.

The new linerboard machine at the Greenpac Mill will be supplied by Metso; the order was announced in 2011. The machine is scheduled to start up in the third quarter of 2013. The agreement includes recruitment of all maintenance personnel prior to start-up. Upon start-up, Metso will assume full responsibility of the mill maintenance operations for the entire production facilities at the Greenpac Mill.

“We are pleased to collaborate with Metso in creating a unique world-class operation at our Greenpac site. The outsourcing of maintenance is a first of its kind for Norampac and its partners in North America – after visiting a similar world-class site in Europe we were convinced of the benefits, performance and customer satisfaction of Metso maintenance operations, which will further contribute to the project’s success,” commented Marc-André Dépin, President and Chief Executive Officer of Norampac.

The Metso mill maintenance model optimizes the use of Total Productive Maintenance (TPM), Metso's streamlined reliability centered maintenance (Applied RCM) and condition-based maintenance. The model ensures the highest possible equipment efficiency and cost optimization.

Greenpac Mill LLC is a partnership controlled by Cascades and managed by Norampac. Created in 1997, Norampac, a Division of Cascades Canada ULC, is the largest containerboard producer in Canada and the 6th largest in North America, with 4,239 employees. Today, Norampac operates several containerboard and boxboard mills, corrugated product plants, folding carton plants and a graphic center in Canada and the United States.

Modified Production Line Opens New Doors for Walki in the Construction Industry

Insulation properties and the energy efficiency of many thermal insulation materials, such as polyurethane or mineral wool, can be considerably enhanced with the use of Walki facings. Helped by a significant investment in new production technology, Walki Group can offer an even wider palette of premium-quality insulation and construction facing materials to building material and insulation manufacturers – while at the same time produce less waste during production.

Walki Group, a leading supplier of technical barrier laminates and protective materials, has its eye set on the fast-growing insulation and construction facing materials market. With the Group’s latest investment in new manufacturing technology, the company can offer its facing materials to an even wider market, while at the same time further enhance the quality of its products.

Walki Group, a leading supplier of technical barrier laminates and protective materials, has its eye set on the fast-growing insulation and construction facing materials market. With the Group’s latest investment in new manufacturing technology, the company can offer its facing materials to an even wider market, while at the same time further enhance the quality of its products.

-With rising energy prices and more focus on sustainable use of resources, better insulation plays a key role in moving towards increased sustainability. This also creates higher demand for facing materials, which can improve the insulation properties of our customers’ products significantly, notes Business Line Manager Kari Salminen.

Quality improvement through new technology

High-quality facings are an integral component of building materials and insulation products. In addition to enhancing thermal performance, highly engineered facing material can also act as a vapour barrier, and help to reduce the risk of corrosion and mould growth in the materials.

In mid-August 2012, Walki’s production line in Valkeakoski, Finland, has been re-engineered to run more efficiently. It also has the capability to utilise a much wider range of raw materials now, in order to meet the challenges of new and emerging demands of customers and markets.

- Walki has always strived to be a leading facing materials supplier on the market and this we seek to achieve by listening closely to our customers. What Walki has learned from this exchange of views is that there is a growing need on the market for even more stable and better performing facings, says Salminen.

- Helped by the investment Walki is prepared to meet the needs of its customers even quicker than before. The latest in-line facility improvements will allow us to produce facings which are modern and stable and avoiding holes or pitting of lacquers, or uneven surfaces that can lead to corrosion.

Helping businesses to create a better brand image

Building material and insulation manufacturers can support and expand their brand by having facings with their brand logos and product names printed directly on the facing material of their final products.

Walki is an environmentally responsible company therefore it uses only water-based inks for printing.

- Our new in-line printing technology is a clear asset for many of our customers, who want to increase their brand image in a cost-efficient and environmentally sustainable way, says Walki’s Plant Director Timo Saahko.

Walki’s production line also features a web tension control system, which delivers higher production efficiencies in addition to improved and more stable quality.

- It also means the company generates a lot less waste during the manufacturing process.

Future growth especially in radiant barrier products

Pierrick Girard from Walki’s sales office in France has been actively working with French providers to identify new end uses for Walki’s products. This he believes will open doors for Walki to the fast-growing radiant barrier foil insulation industry as well as other sectors.

-After the investment, we have received very good feedback on the first trials with our customers on the quality of our materials. Customers have noted, for instance, that the tension of the reels and thickness control is excellent.

The high-level stable profile of the rolls is appreciated and welcomed and will contribute substantially to improved runnability on our customers’ machines, adds Girard. /ins

Mondi Syktyvkar awarded EU Ecolabel for all uncoated fine papers produced at the mill

Produced at Mondi Syktyvkar mill, the company’s well-known office and offset brands Snegurochka, IQ economy, IQ allround, MAESTRO® standard, MAESTRO® special, and MAESTRO® PRINT (offset) are now EU Ecolabel certified

Mondi Syktyvkar in Komi, Russia was recently awarded the EU Ecolabel for all papers produced at the mill. The EU Ecolabel is a certificate issued by the European Union, which verifies the environmental profile of a product or service. Products and services bearing the EU Ecolabel are certified as having a lower impact on the environment than other products in the same product group. The EU Ecolabel is a purely voluntary scheme enacted to encourage the purchasing of green products and services. It is a means by which customers choose products deemed environmentally conscious based on core environmental parameters.

Mondi Syktyvkar in Komi, Russia was recently awarded the EU Ecolabel for all papers produced at the mill. The EU Ecolabel is a certificate issued by the European Union, which verifies the environmental profile of a product or service. Products and services bearing the EU Ecolabel are certified as having a lower impact on the environment than other products in the same product group. The EU Ecolabel is a purely voluntary scheme enacted to encourage the purchasing of green products and services. It is a means by which customers choose products deemed environmentally conscious based on core environmental parameters.

The main criteria examined by the EU Ecolabel are emissions to air and water, energy use, sustainable forest management, the presence of hazardous chemical substances, waste management, information on packaging, fitness-for use/performance, and information provided about the EU Ecolabel. Specific for paper products, the EU Ecolabel stipulates the use of recycled fibres or virgin fibres from sustainably managed forests.

“Our office and offset papers produced at Mondi Syktyvkar fulfil the demands of the domestic market, where the environmental paper profile is increasingly important and adds value to the product. Snegurochka is recognised as Russia’s number one selling office paper. It now bears the EU Ecolabel in addition to being FSC® certified and part of Mondi’s eco-conscious Green Range,” said Klaus Peller, CEO Mondi Syktyvkar mill.

This year, Mondi succeeded in including all Mondi branded uncoated fine papers in its Green Range. Green Range papers must be FSC or PEFC™ certified, 100% recycled, or totally chlorine free bleached (TCF). Mondi maintains a strong position on sustainable forestry having attained FSC certification for all Mondi owned or leased forests. Moreover, 61% of the company’s total wood supply is FSC (46%) or PEFC (15%) certified; the remainder meets the FSC Controlled Wood Standard, which ensures legal compliance and no deforestation.

Earlier this year, Mondi Syktyvkar won three awards at the 2012 All Russian Awards for Environmental Safety and Ecological Management: nature preservation, technology (BAT), and ecological management. Most recently, Mondi received two WWF Environmental Paper Awards for “Transparency”, having listed 92% of its branded uncoated fine papers on WWF's Check Your Paper database, and “Best Environmental Performance Paper Brands” for 100% recycled NAUTILUS® SuperWhite. Mondi Group was also the recipient of the 2012 PPI Award (Pulp and Paper International) for Environmental Strategy of the Year in the company category.

To communicate Mondi’s achievements in a fun and entertaining manner, the company has launched a Green Range trivia game. For every participant, Mondi donates one euro to the NGO OroVerde’s reforestation project “Guatemala – Tree for Tree”. Participants also have a chance to win eco-friendly prizes. Visit www.mondigroup.com/gogreentrivia

Resolute Announces Sale of Mersey Assets

Resolute Forest Products Inc. has announced that the province of Nova Scotia, represented by the minister of the Department of Economic and Rural Development and Tourism, has completed the purchase of all the shares of Bowater Mersey Paper Company Limited for nominal consideration.

Resolute Forest Products Inc. has announced that the province of Nova Scotia, represented by the minister of the Department of Economic and Rural Development and Tourism, has completed the purchase of all the shares of Bowater Mersey Paper Company Limited for nominal consideration.

Bowater Mersey is the former joint venture between Resolute (51%) and The Washington Post Company (49%), formed to hold the Mersey newsprint mill, located in Brooklyn, Nova Scotia, and other associated assets, including private timberlands, the Oakhill sawmill and Brooklyn Power Corporation. Resolute operated the Mersey newsprint mill until it was indefinitely idled in June of 2012.

Before closing the transaction, Resolute purchased from Bowater Mersey the assets associated with the Oakhill sawmill and, in connection with the closing, certain components of the paper mill, which can no longer be used to make paper. At closing, Resolute received a cash payment of approximately $18 million, representing a reimbursement of working capital advances by Resolute to Bowater Mersey to fund its operations, net of transaction-related items.

SOURCE: RESOLUTE FOREST PRODUCTS INC.

NewPage Releases 2011-12 Sustainable Development Report

NewPage Corporation, the leading producer of printing and specialty papers in North America, announced that the release of its 2011-12 Sustainable Development Report, Making a Difference.

NewPage Corporation, the leading producer of printing and specialty papers in North America, announced that the release of its 2011-12 Sustainable Development Report, Making a Difference.

"Because our products come from the forest, NewPage has a unique opportunity to make a difference to the world around us by managing and using resources sustainably," said George Martin, president and chief executive officer for NewPage. "At NewPage sustainability means operating in a way that meets our company's need to thrive and grow without compromising the ability of future generations to do the same. We know that we need to continuously improve to meet our sustainability goals, and we have a long history of doing this in all aspects of our business."

NewPage produces an annual sustainable development report to provide its stakeholders a look at the company's performance and activities designed to improve the way we manage human, natural and financial resources. The company focuses on five key areas of sustainability:

- Healthy, Safe and Engaged Employees

- Responsible Sourcing of Raw Materials

- Efficient and Sustainable Manufacturing

- Responsible and Safe Products

- Strong, Viable Communities

Making a Difference provides an overview of the company's performance and latest actions in these five key areas. Highlights from the report include:

- Improved safety performance with a Total Case Incident Rate (TCIR) of 2.14 in 2011 compared to 2.65 in 2010.

- Increased chain-of-custody certified product sales to 28 percent of total sales (up two percent from 2010).

- Procured 48 percent of its fiber from certified and recycled sources (down one percent from 2010), and all fiber was procured from North America and in compliance with the requirements of the U.S. Lacey Act and European Union Timber Regulation for legal fiber sources. All NewPage mills also have maintained chain-of-custody systems that are third-party certified to FSC®, PEFC and SFI standards.

- Met 95% of the pulp needs for our paper products from internal pulp production.

- Fifty-four percent of the total energy used in NewPage operations was produced from biomass fuels, a renewable energy source primarily derived from the company's manufacturing byproducts (up one percent from 2010).

- Achieved a 12 percent reduction in total greenhouse gas emissions from 2005 levels, bringing NewPage closer to the company's goal to cut total greenhouse gas emissions by 15 percent from 2005 levels by 2020.

- Researched, developed and launched four new products: TrueJet®, Sterling® Premium, PointTrac™ TT and OmniPoint™ over the past two years.

- Continued to contribute time and financial resources to charitable organizations and strategic partners. Partnerships with nonprofit organizations like World Resources Institute and customers such as L.L.Bean and McGraw-Hill have been formed to help preserve and increased the amount of certified forestland and improve the recycling practices of paper products at the end of their useful life.

"Despite the challenges our company has faced, we made real progress on all fronts in 2011 and 2012. While we had to make many tough decisions, we kept our eyes on our business strategy and focus on our employees and customers. We drove productivity using Lean Six Sigma and launched a number of important new products to position NewPage for sustainable success," said Martin.

To download a printable PDF of the report, or to learn more about NewPage Corporation, please visit www.NewPageCorp.com/sustainability.

SOURCE NewPage Corporation

Sipat stratred up PM2 in Meknes, Morocco, after a major rebuilding

The Moroccan tissue producer Sipat has been successfully started up PM2 machine in Meknes after a major rebuilding. The Italian company Toscotec has been the supplier of the rebuilding of the existing PM2 in crescent former. The dry end of the same PM2 was rebuilt in 2009 by Toscotec too.

The Moroccan tissue producer Sipat has been successfully started up PM2 machine in Meknes after a major rebuilding. The Italian company Toscotec has been the supplier of the rebuilding of the existing PM2 in crescent former. The dry end of the same PM2 was rebuilt in 2009 by Toscotec too.

The Sipat TM 2 started up smoothly according to the time schedule and produced a good-quality saleable product from the very beginning.

Sipat S.A. - Societé Industrielle Des Papiers Tissues, established in 1978, is owned by the El Kendouci family. With a production capacity of 16.000 tpy, the company can satisfy the request of the Moroccan market, capable of absorbing 70% of SIPAT’s capacity, and exports the rest to other African markets. The production range includes mainly facial tissue, then toilet rolls, napkins, and kitchen towels.

Toscotec's delivery included a major rebuild of the original Toschi sloped wire forming section, which has been replaced with a ![]() Plustype crescent former with TT HEADBOX SL-T, a rebuild of the existing approach system and of the felt run as well as YD doctoring system. Furthermore electrification and a new machine control system completed the package. The project has been handled on a turnkey basis, including dismantling of the existing equipment, installation of the new machinery, start-up assistance and training services.

Plustype crescent former with TT HEADBOX SL-T, a rebuild of the existing approach system and of the felt run as well as YD doctoring system. Furthermore electrification and a new machine control system completed the package. The project has been handled on a turnkey basis, including dismantling of the existing equipment, installation of the new machinery, start-up assistance and training services.

The new machine parts have been designed for an operative speed up to 1300 mpm with a reel width of 2750 mm.

The purpose of the PM2 rebuilding was to meet the regional growing market demand in terms of products quality and production capacity with an increased output, as well as to reduce energy consumption.

The fast delivery and installation timing combined with very good performances of the machine few days after the start up underline once more Toscotec leadership not only in providing capital projects to the tissue industry with innovative energy-savings concept, but also in managing complex and integrated rebuilds with fast pay-back time for the final customers.

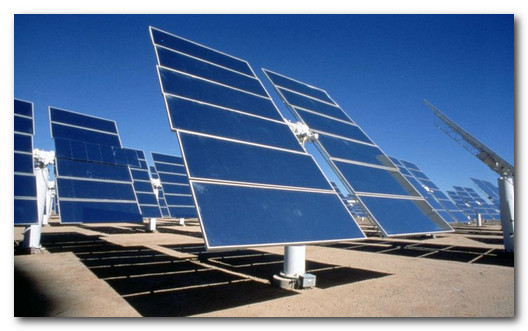

Alfa Laval wins another large solar power order, this time in South Africa

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has received an order from Abengoa to supply Alfa Laval Packinox heat exchangers to a concentrated solar power plant in South Africa. Delivery is scheduled to be finalized in 2014. Due to a confidentiality agreement Alfa Laval is unable to disclose the exact value of the order.

The Alfa Laval Packinox heat exchangers, specifically developed for this application, will be the heart of the thermal storage system where heat from solar power is stored in molten salt, thereby enabling electricity production even on rainy days or at night. The solution will allow the plant to operate for additional hours on stored energy, in this case an additional 3 hours (from 12 to 15 hours) which is a 25 percent efficiency increase compared to normal daytime solar power production.

“Last year we announced an order to the world’s largest solar power plant in the US for the same unique solution”, says Lars Renström, President and CEO of the Alfa Laval Group. “This order confirms the unmatched energy efficiency of our Alfa Laval Packinox heat exchangers for this innovative application.”

Did you know that … all of Europe’s energy needs could be met by capturing less than 1% of the light falling on the Sahara and Middle Eastern deserts alone?

(Source, the Guardian)