Ianadmin

Siemens expands its portfolio of current monitoring relays with IO-Link

The Sirius 3RR24 current monitoring relay for IO-Link enhances the switching technology portfolio of the Siemens Industry Automation Division. The new Sirius 3RR24 monitors motors over the complete torque curve and is also dimensioned for current monitoring of the overall plant. The device detects load shedding, for example when a belt snaps, or motor overloads due to overloading of the driven conveyor belt or crane. Sirius 3RR24 also detects current imbalances, phase sequences, ground faults, as well as any cable breaks. The current data can be read off the device locally on a display. The current monitoring relay can be integrated into the load feeder without incurring wiring costs by mounting it on a Sirius 3RT2 contactor.

The Sirius 3RR24 current monitoring relay for IO-Link enhances the switching technology portfolio of the Siemens Industry Automation Division. The new Sirius 3RR24 monitors motors over the complete torque curve and is also dimensioned for current monitoring of the overall plant. The device detects load shedding, for example when a belt snaps, or motor overloads due to overloading of the driven conveyor belt or crane. Sirius 3RR24 also detects current imbalances, phase sequences, ground faults, as well as any cable breaks. The current data can be read off the device locally on a display. The current monitoring relay can be integrated into the load feeder without incurring wiring costs by mounting it on a Sirius 3RT2 contactor.

In addition to the autonomous monitoring function, measured values and data are transferred from the relay to the higher-level control over the IO-Link interface. This simplifies detailed troubleshooting and diagnostics. Communication over IO-Link also makes commissioning much easier. The Sirius relay can either be parameterized directly on the device, or from the PLC, which shortens commissioning especially in the case of repeated parameterization. If a device has to be replaced, the new relay will be parameterized automatically through data comparison with the parameter server. Work can then continue immediately after replacement, and no special knowledge of controllers or monitoring relays is required for replacement. This reduces the overhead involved in maintaining the plant.

Sirius 3RR24 expands the current portfolio of monitoring relays for IO-Link that monitor variables such as temperature, speed, power factors and even voltages.

More information is available on the Internet at: www.siemens.de/relais

Negotiation Partners Settle for Reconciliation of Interests

In conclusion of their discussions about the restructuring measures at Voith Paper, the chief negotiators of Voith Paper and the relevant Workers' Council Committees have settled for a reconciliation of interests on September 11, 2012.

In May 2012, Voith Paper had announced restructuring measures due to a structurally induced ongoing decline in sales in the field of graphic paper machines.

According to the reconciliation of interests both sides have agreed upon that about 50 jobs less than the initially intended figure will be cut at Voith Paper in Germany and Austria. This is a total of 670 rather than the initial 710. This means that 317 job cuts will affect the location Heidenheim. At the location Ravensburg, 218 jobs will be cut, while Krefeld cuts down on 66 jobs and St. Poelten in Austria on 69 jobs.

Regarding the implementation of these adaptive measures, the negotiation partners have agreed on the following key points:

- It is still the declared goal to introduce all measures in the most socially acceptable way and, wherever possible, avoid forced redundancies. If forced redundancies really are inevitable, they will, at the earliest, come into effect at the end of 2013. This does not affect the existing operational rules in Heidenheim and Krefeld.

- The existing Centers of Competency including Automation at all German Voith Paper locations and in St. Poelten/Austria will remain there until the end of 2015.

- Voith will establish a training corporation at the location Ravensburg. Employees will be offered severance payments, combined with the option of changing into this training corporation.

- The location Ravensburg will continue to operate maintenance and manufacturing services on a small scale.

- The R & D facilities in Ravensburg and Krefeld will remain at their locations.

This concluding settlement paves the way for the reorganization of Voith Paper as of October 1, 2012. The company will provide further information on the results of the reorganization in the next few weeks.

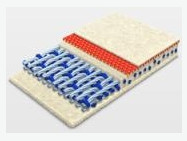

New Revolution press felt developed by Voith

Voith’s newly developed Revolution press felt has now been launched into the market for production of board and packaging paper. With the aid of this innovation, paper production is even more efficient.

Voith’s newly developed Revolution press felt has now been launched into the market for production of board and packaging paper. With the aid of this innovation, paper production is even more efficient.

Along with increased drying performance, Revolution ensures shorter start-up phases, energy savings and consistent quality characteristics over its entire service life. The key innovation of Revolution is its structure, which has a special polymer layer. Revolution can thus control the flow of water before, during and after passage through the nip. For this reason, it dewaters better and contaminates less. The dry content is higher by up to 2% than with a conventional felt. The self-cleaning effect also helps to ensure the performance of the press felt remains the same over its entire service life.

Paper produced with the aid of Revolution has especially good surface characteristics due to the larger contact surface with the paper or board web. It was confirmed in practical testing that this new press felt allows substantially shorter start-up times. From the beginning, the level of nip dewatering is very high. Revolution thus has a positive effect on the energy balance.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers.

Cascades Invest $22 Million in its Folding Carton and Microlithography Operations

Cascades Inc. a leader in the recovery and manufacturing of green packaging and tissue products, announces major investments in several of the folding carton and microlithography plants of its Norampac Division. Thanks to a total investment of $22 Million, the Viau (Montréal, Québec), Mississauga (Ontario), Winnipeg (Manitoba) and Cobourg (Ontario) plants will benefit from the installation of new modern equipement that will optimize their production and efficiency.

With this investment program, the Lachute (Québec) folding carton plant will be closed at the latest by the end of the first quarter of 2013, and its customers will be progressively transferred to other Norampac facilities. Nearly 155 employees will be affected by the closure of the Lachute plant, however approximately 40% of them will have the opportunity to be relocated in other Norampac and Cascades units in Québec. Norampac has taken necessary measures to offer the appropriate support to the employees that will not be relocated.

Investments

The installation of modern and versatile equipement in these plants will lead to an enhanced synergy between the microlithography and folding cartons sectors, which will allow Norampac to increase its productivity and efficiency. The modernization of equipement will be achieved through the installation of two new state of the art printing presses in the Viau and Mississauga plants. These presses, one of which has a printing capability of up to 7 colours and an ultraviolet drying process, were designed to offer the latest technology and are among the best in the industry. The optimization project also includes the installation of new equipement in the Group's other folding carton plants, namely a new gluer in Winnipeg and forming equipment in Cobourg. Thanks to its unique characteristics, this new equipment will allow the plants to better respond to the growing demand for more varied and better quality packaging and printing.

“These investments are in line with Cascades' strategy that aims to modernize and improve the profitability of our packaging assets”, explained Marc-André Dépin, President and Chief Executive Officer of Norampac. “This is our Group's most important investment in the folding cartons sector in several years”, added Mr. Dépin.

In closing Mr. Dépin stated "The folding carton marketin Canada continues to be key to our strategy in the packaging sector. This market benefits from stable growth that closely matches that of the consumer market for food products sheltering it from the negative cycles that affect industrial products. Cascades occupies an enviable position in the folding carton market in Canada and these investments will allow us to consolidate and improve upon this position in the coming years."

Verso Introduces Aspect™ SCK Release Papers

Verso Paper Corp. introduces Aspect™ SCK Release Papers, an exciting addition to its Aspect™ line of label and release papers. Now comprised of cut and stack labels, pressure sensitive face sheets and SCK release liners, Verso's Aspect™ Label and Release Papers deliver the aesthetics, strength and performance required for quality and efficient label production.

"Our premium SCK Release Liner is a high performing, extremely efficient and cost effective liner, allowing lower silicone coat weight and reduced adhesive usage due to better, more consistent profiles," says Mike Weinhold, Verso's Senior Vice President of Sales, Marketing and Product Development. "With a perfect balance between desired optical properties, performance requirements and cost effectiveness, our Aspect™ SCK Release Liner is sure to become the industry standard."

Aspect™ SCK Release Liner has high strength, superb apparent density, low dirt count and opacity, exceptional die-cutting performance, excellent cure and holdout and smooth surface characteristics.

Verso's Aspect™ Label and Release Papers product line will be produced on the No. 4 paper machine at Verso's mill in Androscoggin, Maine. "Androscoggin's No. 4 paper machine is a well-positioned asset, with relative machine scale and an integrated pulp supply," Weinhold explains. "Androscoggin, like all of our mills, has a strong manufacturing focus on producing consistent, quality products, and our Aspect™ line of label and release papers is no exception. We understand our customers want a product and a supplier they can rely on, and Verso delivers on both of those needs," he says.

Source: Verso Paper Corp.

UPM taking frontrunner steps with global EMAS registration

All of UPM’s European pulp and paper mills are now certified in accordance with the EU Eco-Management and Audit Scheme (EMAS), a voluntary environmental management system. In addition, the Fray Bentos pulp mill in Uruguay is the first non-European mill to be included in the EMAS. Altogether UPM’s corporate registration and the respective environmental statement cover total 21 pulp and paper mills.

This year the environmental reporting is more comprehensive than ever before. “The widening of the EMAS scope to include the first non-European site was a logical step for UPM’s environmental management and reporting. UPM’s focus is on producing more with less energy, water and waste, and with lower carbon footprint,” says Päivi Salpakivi-Salomaa, Vice President, UPM Environment.

In 2011, UPM carried out numerous projects aimed at improving material efficiency in pulp and paper mills. Especially the amount of landfill waste was significantly reduced thanks to new options found to re-use of ash at the Finnish mills.

This first non-European EMAS registration is a continuation of a pilot project between UPM, EU, Finnish Environmental Institute SYKE, the Finnish Ministry of the Environment and Inspecta Certification.

“We’re delighted to see that EMAS is moving from European to global use and hope that the efforts of UPM to continually improve their environmental performance show the way for other international companies. Third party verification of the environmental data increases transparency, and gives credibility to companies using EMAS around the world,” states Soledad Blanco, Director Sustainable Resources Management, Industry & Air from the Environment Directorate General of the European Commission.

“We are glad that the Finnish company has decided to make this ground breaking expansion of EMAS scheme. We believe that openness in environmental reporting is beneficial and should be promoted globally,” says Tuula Varis, Director General, from the Finnish Ministry of the Environment.

UPM’s pulp and paper mills environmental statement is available at www.upm.com > About UPM > Downloads > Responsibility

Cham Paper Group Holding AG: Further progress in the restructuring

The Cham Paper Group's transformation process is progressing more rapidly than expected. As the Group announced today, by April 2013 it will be ready to  commence production of speciality papers for the tobacco industry, which are currently produced in Cham, at the Italian site in Carmignano and distribute the papers from there. The extensive tests on coating machines in Cham using externally produced raw papers are also proceeding with success and will be concluded by early 2013. These are needed to produce 'digital imaging' and 'BARnamic' speciality papers, which will also see future production in Switzerland. The second paper machine in Cham will therefore be decommissioned by March/April 2013.

commence production of speciality papers for the tobacco industry, which are currently produced in Cham, at the Italian site in Carmignano and distribute the papers from there. The extensive tests on coating machines in Cham using externally produced raw papers are also proceeding with success and will be concluded by early 2013. These are needed to produce 'digital imaging' and 'BARnamic' speciality papers, which will also see future production in Switzerland. The second paper machine in Cham will therefore be decommissioned by March/April 2013.

The development and sales teams are systematically preparing themselves for the completion of the transformation and the new direction that the Group will be taking in spring 2013. The market has thus far responded well to the changes announced. In August 2012, the Board of Directors assigned management the task of planning a new innovation and coating centre, located away from the current company site, in or around Cham.

On 1 September 2012, Marcello di Giacomo took up his role as the new site manager at Carmignano, also becoming a member of the Management Board at the same time. From April 2013, the Carmignano site will become the most important production facility in the Cham Paper Group and the backbone of an efficiency-oriented production and logistics platform in the eurozone.

Leaving the Cham Paper Group, however, is CFO Patrick Schmid. Patrick Schmid has been with the Cham Paper Group for 17 years, working in various positions. In 2005, he became Head of Finance at the Swiss site and since 2010 he has been the Group's CFO. The Board of Directors and the management team would like to thank him for his huge commitment, particularly in the planning and implementation of the transformation process over the last two years, and wish him the very best both personally and professionally for the future. The Group will release more information regarding the vacant position of CFO at a later point.

Metsä Board organizes a Capital Market's Day on 19 September 2012 in London

Metsä Board Corporation, part of Metsä Group, organizes a Capital Market’s Day on September 19, 2012 in London, UK. The event is organized on invitational basis for analysts. The focus of the day will be on Metsä Board’s growth potential in the traditional European and North American markets as well as in the fast growing Asian markets.

analysts. The focus of the day will be on Metsä Board’s growth potential in the traditional European and North American markets as well as in the fast growing Asian markets.

The event will be organized in the premises of Metsä Board’s highly valued cartonboard customer Unilever, a leading global consumer goods company. As part of the Capital Market’s Day, participants will get an insight on the role of sustainable and high quality packaging as well as the importance of a close partnership with a paperboard supplier and a customer in the global consumer goods business.

Presentation materials will be available on Metsä Board's website www.metsaboard.com on 19 September 2012 by 13 p.m. EET.

METSÄ BOARD CORPORATION

Change in Metsä Board’s Corporate Management Team

Mika Paljakka (43), who has held the Corporate Management Team position of SVP, Human Resources of Metsä Board Corporation, part of Metsä Group, has been appointed Sales Director, Cartonboards, USA. Paljakka will be located in the Metsä Board’s US sales office and he will report to Jorma Sahlstedt, SVP, Paperboard sales, USA.

Mika Paljakka (43), who has held the Corporate Management Team position of SVP, Human Resources of Metsä Board Corporation, part of Metsä Group, has been appointed Sales Director, Cartonboards, USA. Paljakka will be located in the Metsä Board’s US sales office and he will report to Jorma Sahlstedt, SVP, Paperboard sales, USA.

Susanna Tainio, VP, Human Resources, (37) is responsible for Metsä Board’s human resources related matters as of today.

From now on Metsä Board’s Corporate Management Team is the following:

- Mikko Helander, CEO

- Matti Mörsky, CFO

- Pasi Piiparinen, SVP, Head of Paperboard business area

- Seppo Puotinen, SVP, Head of Paper and Pulp business area

- Sari Pajari, SVP, Supply Chain and Business Development

- Jani Suomalainen, SVP, Purchasing

METSÄ BOARD CORPORATION

RockTenn Announces Closing of Senior Notes Offering

RockTenn (NYSE: RKT) has announced the closing of its previously announced offering of senior notes. RockTenn completed the issuance of $350 million aggregate principal amount of 3.500% senior notes due 2020 and $350 million aggregate principal amount of 4.000% senior notes due 2023. The notes were offered only to persons in the United States and to, or for the account or benefit of, U.S. persons, in each case that are qualified institutional buyers in accordance with the Securities Act of 1933, as amended (the “Securities Act”), and to non-U.S. persons outside the United States in accordance with Regulation S under the Securities Act. The notes are guaranteed on an unsecured, unsubordinated basis by certain of RockTenn’s existing and future domestic subsidiaries.

RockTenn will use the net proceeds from the offering to prepay a portion of the outstanding loans under its credit facility and to pay costs and expenses relating to such prepayment, including accrued and unpaid interest thereon. RockTenn currently expects to repay approximately$288.0 million outstanding under its revolving credit facility, approximately $345.5 million outstanding under its term loan A facility and approximately $54.5 million outstanding under its term loan A2 facility, although the exact amounts allocated to the individual facilities may change.

The notes have not been registered under the Securities Act or the securities laws of any jurisdiction and may not be offered or sold in the United States or to, or for the account or benefit of, U.S. persons absent registration or an applicable exemption from the registration requirements of the Securities Act and any applicable state securities laws.

This press release does not constitute an offer to sell or the solicitation of an offer to buy the notes or any other securities, nor shall it constitute an offer, solicitation or sale in any jurisdiction in which such offer, solicitation or sale is unlawful.

Source: RockTenn