Increased production, product quality, and lower energy consumption: Smurfit Kappa starts up rebuilt machine at Hoya

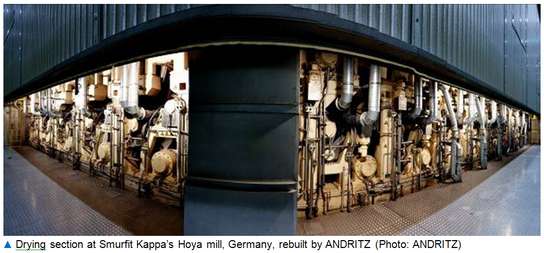

International technology Group ANDRITZ has successfully completed a rebuild of PM2’s dryer section at Smurfit Kappa’s Hoya mill, Germany. As a result, Smurfit Kappa – one of the leading producers of paper-based packaging in the world with more than 41,000 employees in 32 countries – is able to achieve its goals for capacity, product quality, and energy consumption.

ANDRITZ’s scope for rebuilding the testliner and fluting machine at Hoya included:

- Complete dismantling of the old dryer section and rebuilding it with new frame and rolls; installation of a PrimeRun web stabilization system; installation of ropeless tail-threading (PrimeFeeder); replacement of the old size press with a PrimeCoat Film film press; and installation of a new energy-recovery hood. Even with the reduction in basis weight for the lighter weight packaging paper, capacity was increased by 17%. In addition formation was improved and energy consumption was significantly reduced.

- For the project’s second phase, PM2’s output was increased by another 17%. ANDRITZ PULP & PAPER moved the reel and enlarged the after-drying section by adding PrimeDry ST and PrimeDry DT dryers along with a PrimeRun web stabilization system. The new components have a design speed of 1,200 m/min, at a width at reel of 7,600 mm.