Thanks to renewable energy regulations, the demand for tall oil is increasing. The by-product of the kraft pulping process industry can improve the efficiency of a pulp mill and be sold as a commercial product to processing industries.

The EU’s ‘Renewable Energy Directive’ requires all EU countries to ensure that at least 10% of their transport fuels come from renewable sources by 2020. The EU is also planning even more ambitious targets for greenhouse gas emission reductions to fulfill its pledges towards the Paris Agreement of which decarbonisation of the transport sector is a cornerstone.

This regulatory nudge has increased interest in tall oil as a biofuel feedstock.However,this emerging demand for the raw material competes with the use for more traditional tall oil derivatives, such as resin and fatty acids produced in distilleries. Whilst the price for crude tall oil has been slowly increasing to around 400-500 EUR/t, due to biodiesel competition and increase of the distillates product prices, the regulatory pull increases the competitiveness of tall oil as a biofuel feedstock from a biofuel manufacturer’s perspective.

What is tall oil?

Tall oil is a commercially important by-product of softwood (i.e. pine or spruce) from pulp production. It is produced by first separating ‘tall oil soap’ from the ‘black liquor’ that is formed in the pulping process. The tall oil soap can then be reacted with acid to product ‘crude tall oil’.

Pulp mills burn the black liquor to generate heat and electricity. As soap removes some capacity of burning the black liquor and hinders the operation of the evaporation plant , it makes sense for the mills to separate the soap from black liquor.

Besides producing tall oil of the separated soap, soap can alternatively be sold or burned for additional electric power but this is often not so profitable.

So in addition to bringing income to the mill as a commercial product (even more than selling the soap as such), separating tall oil from soap improves the overall efficiency and operations of the mill as primary processes are not compromised.

Capacity expansion potential

As the price of crude tall oil increases, coupled with more modern techniques for extracting this raw material at existing softwood pulp mills, it is becoming more and more lucrative for pulp producers.

As the price of crude tall oil increases, coupled with more modern techniques for extracting this raw material at existing softwood pulp mills, it is becoming more and more lucrative for pulp producers.

The key factors impacting the profitability of tall oil production are:

- the local market environment and demand

- the scale of pulp production

When the softwood pulp production capacity is roughly 100,000 tons per year or more, tall oil separation for commercial purposes is usually more profitable than the alternative use of soap.

Currently, there are an estimated 40 softwood pulp mills globally that could utilise tall oil separation based on their annual pulp production capacity but are yet to capitalise on the opportunity. In Northern and Central Europe, tall oil separation is already quite common but the biggest untapped potential with current pulp production assets lies in the US.

Tall oil business case

Investment in a new tall oil plant is a feasible option both for mills with too small or outdated tall oil plants as well as for mills without an existing plant. For mills that sell tall oil soap and do not have a tall oil acidulation plant, the investment payback time is usually between 1-3 years.

In case the mill burns the soap in the recovery boiler, commercial benefits are further improved by the fact that the mill can increase pulp production when recovery boiler capacity can be utilised for black liquor combustion instead of soap burning. If a too small or outdated tall oil plant is renewed with the aim of increasing tall oil production by 25%, the investment payback time varies between 2-5 years.

Based on pulp production growth forecasts up to 2030, an additional 300,000 tons p/a of crude tall oil could enter the market. These capacity expansions would help supply the growing demand for crude tall oil and would mark significant growth opportunities for tall oil applications.

Did you know?

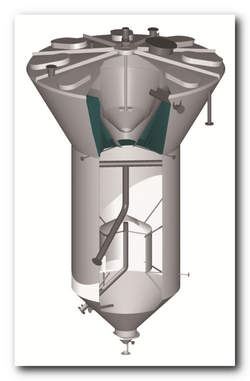

Pöyry provides complete, value adding service offering to pulp mills, from developing raw material sourcing strategies and conducting market research and business case analysis to delivering HDS® (Hydro Dynamic Separator) tall oil plants and providing operational support and performance improvement. Over the past 30 years, we have delivered more than a third of the world’s tall oil plants and helped several mills to design or improve their soap and tall oil separation processes in order to increase profitability and efficiency to drive growth.

Jarno Peltonen Director, Pulp Technology, Industry Business Group, Pöyry