Displaying items by tag: Heidelberger Druckmaschinen AG

Heidelberg Concludes Negotiations on Planned Package of Cost-Cutting Measures

The management and works council of Heidelberger Druckmaschinen AG (Heidelberg) have agreed on a package of measures in a reconciliation of interests.

The package comprises an agreement to forgo collectively agreed payments and company contributions, the company's option of drawing on additional working hours and an innovative working-time concept. One element of the agreement is that staff can voluntarily reduce their contractual working hours to 57 percent of the original level on a permanent basis, with a corresponding cut in pay. The company will provide compensation for part of the lost salary for a period of maximum four years. The working hours of staff adopting this employment model will be based on company needs.

This concept is intended to reduce the number of compulsory redundancies still required. Taken as a whole, the package of measures is expected to cut around 500 jobs worldwide at Heidelberg until October 2010, around one third of these in the sales organizations. As part of this package voluntary and socially acceptable measures have already resulted in some staff leaving the company or concluding agreements to terminate their contract of employment.

As planned, the company is thus implementing its package of cost-cutting measures, including saving of non-personnel cost. A key element of this package is to cut costs by an initial EUR 60 million in financial year 2010/2011 and a total of EUR 80 million in financial year 2011/2012. Together with the EUR 400 million of savings already achieved in financial year 2009/2010, this will result in total annual savings of EUR 480 million by financial year 2011/2012.

"Following constructive talks, management and employee representatives have agreed on a Heidelberger Weg (Heidelberg Way) - a strategy for adapting existing capacities to the order situation while still keeping as many staff and thus as much valuable know-how as possible at the company. We have also achieved our savings targets," said Heidelberg CEO Bernhard Schreier. "The package of measures now agreed marks a new departure for everyone involved in the negotiations and demonstrates a great sense of responsibility on all sides," he added.

As of June 30, 2010, the Heidelberg Group had a workforce of 16,218 worldwide, thereof 10,942 in Germany.

Preliminary Incoming Orders and Free Cash Flow in First Quarter of Financial Year 2010/11 Above Expectations

According to preliminary figures, Heidelberger Druckmaschinen AG (Heidelberg) continued the positive trend in incoming orders in the first quarter of financial year 2010/11. This was due to the continued rise in demand in a number of regions (particularly China), positive exchange rate movements, and, above all, the trade shows IPEX in the United Kingdom and ExpoPrint in Brazil during the reporting period (April 1 - June 30, 2010).

At EUR 786 million - thereof approx. EUR 45 million account for exchange rate movements - preliminary incoming orders in the first quarter were up significantly on the same quarter of the previous year (EUR 550 million), and also above the previous quarter (EUR 678 million). However, the order situation worldwide remains unsettled. It is shaped by the continuing weakness of the markets in the U.S. and Japan. In contrast, some European markets and regions in Asia, especially China, and South America are showing considerable improvement.

In the first quarter, the preliminary free cash flow will be in the region between EUR 50 million and EUR 60 million and thus far in excess of the same period of the previous year (EUR -29 million). The positive development in free cash flow is largely due to an improved working capital management, including higher customer prepayments and optimized payment flow for capital expenditure. Though, the previously stated information does not point to any continuation or substantial improvements of this development in the remainder of the financial year compared to earlier forecasts of the free cash flow for financial year 2010/11.

Thanks also to exchange rate movements, preliminary sales in the first quarter are slightly above the figure for the same period of the previous year at approximately EUR 560 million (compared to EUR 514 million the previous year). Thereof about EUR 35 million account for exchange rate movements. The preliminary operating result (excluding special items) in the first quarter will improve as planned compared to the same quarter of the previous year (EUR -63 million).

The company will publish further details and an explanation of the figures for the first quarter of the financial year on August 10, 2010.

For further information, please contact:

Heidelberger Druckmaschinen AG

Corporate Public Relations

Thomas Fichtl

Phone: +49 (0)6221 92 5900

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Heidelberg News Strikes Gold

Heidelberg customer magazine scoops top award at the Best Of Corporate Publishing Awards 2010

For the first time, the customer magazine of Heidelberger Druckmaschinen AG (Heidelberg) - "Heidelberg News" (HN) - has been awarded gold in the "BCP - Best of Corporate Publishing Awards", Europe's largest competition for corporate publications, making the magazine by far the most successful publication in the entire print media industry.

HN had already been awarded silver six times in Europe alone in the previous years, and various gold and platinum medals have come its way on the North American continent. In awarding the magazine its latest accolade, the panel of judges explained their decision with the following words: "Nominated last year and on the winners' podium this year, Heidelberg News offers a deep insight into the world of print technology. Complex interrelationships are explained in simple terms, and the whole is combined with clear and logical images and illustrations."

"Heidelberg News is a key element of our integrated concept for addressing customers - a concept in which print products play a central role and the focus is on a partnership-based approach. We therefore see this success in the BCP Awards as an incentive to continue pursuing this strategy," says Adriana Nuneva, Head of Global Marketing and Communications at Heidelberger Druckmaschinen AG.

In all, over 600 publications participated in the competition. The award ceremony took place as part of the Corporate Publishing Congress in Hamburg. As usual, the event was organized by Forum Corporate Publishing e.V., which this time played host to around 650 guests. This industry association presents the BCP Award annually in collaboration with trade magazines acquisa, Horizont, w&v, and Schweizer Werbewoche.

Heidelberg Speedmaster CX 102 Celebrates German Premiere at the Dusseldorf Site's Open House

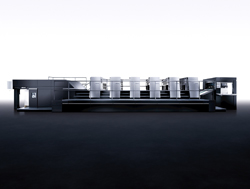

Around 2,000 visitors came to the Open House held by Heidelberger Druckmaschinen Vertrieb Deutschland GmbH (HDD) under the slogan "HEI Lights 2010". The event took place at the Dusseldorf site between June 10 and 12, 2010. The Open House showcased the company's key trade show innovations from IPEX 2010 in the U.K., including the German debut of the new Speedmaster CX 102. Designed for industrial offset printing with a production speed of 16,500 sheets per hour, this press celebrated its world premiere at IPEX 2010. Lying between the Speedmaster SM 102/CD 102 and the Speedmaster XL 105, the Speedmaster CX 102 is aimed at both commercial and packaging printers. The sales launch coincided with the trade show and was a resounding success, with Heidelberg quickly selling 15 presses featuring some 100 printing units to customers from around the world. The Open House event brought further orders for the Speedmaster CX 102.

The Dusseldorf site also showcased other innovations from IPEX, such as the Speedmaster SM 52 Anicolor with space-saving short delivery for the new coating unit, and a version of the indexed cold foil system FoilStar that makes surface finishing even more cost-effective. The Prinect print shop workflow also had a strong presence at the event, and included the very latest functions unveiled at IPEX. Another highlight was the new Prinect Image Control that delivers far higher resolution for spectral image measure-ment, offers enhanced ease of operation, and has been technologically completely redesigned. "We want these new technical solutions to capture the imagination of our customers, and for our extended service portfolio to help them overcome these rather difficult times," explained Karl Saueressig, Head of the West sales region. There are positive developments on the market - also in the German economy - and the volume of incoming orders at Heidelberg is increasing. At IPEX 2010, Heidelberg received numerous orders for equipment and services from all over the world and in all market segments, including more than 900 printing units in all formats and over 90 postpress machines. The sales concluded at the Open House event in Dusseldorf confirmed this positive trend.

In addition to machine demonstrations, visitors to the Open House in Dusseldorf also attended presentations on inline finishing, investment financing, and successful corporate governance. The event program was rounded off by a range of offerings, such as a Speedmaster SM 52 or Speedmaster SM 74 complete with Prinect Axis Control at an attractive special price. Combined with the standard system for color measurement and control, the Speedmaster SM 52 and SM 74 make a good team for effective quality assurance. With Prinect Axis Control, the press inks up faster, and less waste is produced during makeready. That in turn brings benefits for the environment.

Heidelberg has combined all its services in a dedicated division in order to boost the competitiveness of print shops. This illustrates its commitment to becoming a service company for the entire print media industry. "Among other things, the portfolio aims to deliver higher productivity and round-the-clock press availability in print shops, in addition to ensuring eco-friendly production," explained Temur Karbassioun, Senior Vice President Systemservice at HDD. The portfolio serves the entire value-added chain of Heidelberg customers and covers the full lifecycle of the equipment. The service offering is divided into two categories. Technology services keep machinery operating smoothly. This category includes service agreements such as Heidelberg Systemservice36Plus and the Partner Program, on-site repairs and troubleshooting, Original Heidelberg Service Parts, and Remote Services. Productivity services help customers unlock additional potential using consultancy services, Print Color Management, and production monitoring and certification.

Heidelberg boasts the most efficient service and logistics network in the industry worldwide, with around 4,000 service staff at 250 branch offices in 170 countries. In Germany, a total of 600 service specialists are on hand to deal with customers' needs.

Panel discussion on "Challenges and Success Criteria for the Print Media Industry in Germany"

On the evening of the first day of the Open House, a panel discussion was held on the subject of "Challenges and Success Criteria for the Print Media Industry in Germany". The discussion was chaired by Prof. Heinz-Reiner Treichel from the University of Wuppertal. The participants were Oliver Curdt, Manager Director of the Print and Media Association in North Rhine-Westphalia; Peter Dieckmann, Deputy Chairman of the Management Board of VR-Leasing AG; Frank Eigler, Managing Director of Eigler & Hermann Design and agency Scheufele, Hesse, Eigler; Rüdiger Maass, Managing Director of the Fachverband Medienproduktioner (association of media production specialists); and Bernhard Schreier, CEO of Heidelberg. The experts agreed that the print media industry must position itself strategically on the market and invest more heavily in marketing and employee training. The important thing is to ensure that the quality and added value of print is marketed properly using cross-media applications and eye-catching finishes, for example. "Everything that can go online will go online. And if it makes sense to print something, then it will continue to be printed in future," said Bernhard Schreier. The key factors are quality, deadline, price and orientation to the specific target group. It is specialized print shops that will prove successful in the future. "There is a future for print and we want to make sure that our customers can make money doing what they do," concluded Schreier.

Heidelberg at ExpoPrint Latin America 2010: Great interest in customized solutions for the Latin American print media industry

The portfolio of Heidelberger Druckmaschinen AG (Heidelberg) was received with great interest at ExpoPrint Latin America 2010, which took place from June 23 to 29 in Sao Paulo, Brazil. The company exhibited a comprehensive range of state-of-the-art technologies and services under the slogan HEI Performance - HEI Value. The spotlight was trained on the cost-effective and environmentally friendly production of print products. On an area of 1,500 m², Heidelberg covered the entire value-added chain for advertising and packaging printing - from prepress to press and postpress, including workflow integration, Saphira consumables, Original Heidelberg service parts, service agreements, and other services. Visitors also had the opportunity during the trade show to tour the Print Media Academy of Heidelberg in Sao Paulo and find out about the biggest range of training courses for the print media industry in South America.

New Speedmaster CX 102 makes its debut in South America

The new Speedmaster CX 102 sheetfed offset press - which Heidelberg unveiled at IPEX in Birmingham in May 2010, quickly leading to more than 20 sales worldwide - has now celebrated its premiere in South America. Customers from Brazil also placed orders for the new Speedmaster CX 102 at ExpoPrint.

Designed for industrial offset printing, this press is capable of reaching production speeds of 16,500 sheets per hour and lies between the Speedmaster SM 102 / CD 102 and the Speedmaster XL 105. This press puts the finishing touch to the Heidelberg 70 x 100 cm format and provides up- coming print shops in emerging markets in particular with attractive cutting-edge technology.

"Alongside China, Brazil is an important up- coming market for Heidelberg and offers great potential for further growth in the print media industry. This is also underlined by the numerous sales that were made at ExpoPrint with a large number of small and medium-sized businesses and industrial companies from all over the region. We expect the emerging markets to play an increasingly important role in our business development in the years ahead," says Bernhard Schreier, Heidelberg Chief Executive Officer.

Dieter Brandt, Head of South America/Lead Market Sao Paulo at Heidelberg, adds: "Heidelberg has been a reliable partner for customers in South America for decades. Numerous trade show visitors from across Latin America came to our booth to find out how Heidelberg can help them increase their competitive edge through cutting-edge technology, state-of-the-art services, and complete solutions from a single source. We are therefore very pleased with the outcome of the trade show."

ExpoPrint Latin America was being held for the second time after its debut in 2006. The event had been fully booked since the end of 2009, with over 400 exhibitors on an area of 30,000 m2. More than 35,000 visitors from across the region passed through the doors during the event.

Figure: The portfolio of Heidelberger Druckmaschinen AG was received with great interest at ExpoPrint Latin America, enabling the company to make numerous sales.

For further information, please contact:

Heidelberger Druckmaschinen AG

Corporate Public Relations

Matthias Hartung

Phone: +49 (0)6221 92 5077

Fax: +49 (0)6221 92 99 5077

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Leading French Packaging Group Invests in Three Speedmaster XL 105 Presses with Prinect Inpress Control

French packaging print shop LGR Emballages S.A. is investing in three Speedmaster XL 105 presses from Heidelberger Druckmaschinen AG (Heidelberg). All three presses are equipped with the Prinect Inpress Control color measuring system, which controls color and register on the fly.

French packaging print shop LGR Emballages S.A. is investing in three Speedmaster XL 105 presses from Heidelberger Druckmaschinen AG (Heidelberg). All three presses are equipped with the Prinect Inpress Control color measuring system, which controls color and register on the fly.

Headquartered in Oyonnax, LGR is one of France's largest packaging printers specializing in the manufacturing of pharmaceutical packaging (N°1 in France, N°3 in Europe) and litho printed corrugated boxes (N°2 in France). 650 employees work at 9 sites in France, Spain, and Belgium. "Our motto is to maintain technology leadership by using state-of-the-art presses that represent the ultimate in innovation. Prinect Inpress Control was one of the factors that led us to opt for Heidelberg. Pharmaceutical packaging in particular involves short runs, and the pressure on prices forces us to keep rationalizing our operations," explains LGR managing director Torben Reine.

A Speedmaster XL 105 press has been operating at the Montelimar Le Teil plant, which specializes in pharmaceutical packaging, for four years. One of the two new machines is already in operation, while the other is being installed in the summer. "It's impressive how quickly we achieve OK sheets with Prinect Inpress Control, resulting in extremely short makeready times, less waste, and very high quality," says a satisfied Philippe Ratte, member of the LGR Management Board responsible for technology. "This kind of highly industrialized and highly productive operation is particularly important for pharmaceutical packaging, with runs starting at just 2,000 sheets," he adds.

The third new Speedmaster XL 105 will work alongside two existing Heidelberg presses at the LGR-CFL St. Eusèbe plant, which focuses mainly on packaging for the pharmaceuticals and healthcare industry.

"Our strategy of using presses from a single manufacturer at each of our plants has proved very successful. That's why we see Heidelberg as one of our strategic partners", explains Reine.

LGR is a member of the PharmaPact Group, a European strategic alliance for the pharmaceutical industry comprising three leading folding carton manufacturers. The two other companies are Edelmann in Germany and Nampak in the U.K and Italy. This alliance offers large pharmaceutical companies efficient suppliers who operate globally and also serve the local needs of individual production sites. In the area of corrugated board, LGR recently entered into a cooperation agreement with A & R Carton, a Swedish company based in Malmo.

www.lgr-emballages.com/

www.pharmapact.com/

Figure: Peak Performance Class: Speedmaster XL 105.

For further information, please contact:

Heidelberger Druckmaschinen AG

Corporate Public Relations

Hilde Weisser

Phone: +49 (0)6221 92 5066

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

IPEX 2010 Continues Positive Trend in Print Media Industry

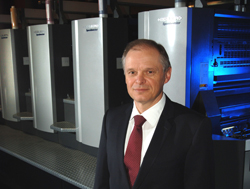

"IPEX 2010 was well attended and our customers showed great interest in our new products and services," says a satisfied Bernhard Schreier, CEO of Heidelberger Druckmaschinen AG (Heidelberg), in summing up the trade show. More than 50,000 international visitors came to Birmingham between May 18 and 25, 2010 to find out about the numerous innovations being showcased by Heidelberg under the "HEI Performance and HEI Value" banner. "We received numerous orders for equipment and services from all over the world and in all market segments, including around 900 printing units in all formats and over 90 postpress machines. The positive mood in the industry is continuing thanks to the tangible upward trend," adds Schreier. Customers from the UK, Chinese, and Indian markets were particularly keen to invest.

"IPEX 2010 was well attended and our customers showed great interest in our new products and services," says a satisfied Bernhard Schreier, CEO of Heidelberger Druckmaschinen AG (Heidelberg), in summing up the trade show. More than 50,000 international visitors came to Birmingham between May 18 and 25, 2010 to find out about the numerous innovations being showcased by Heidelberg under the "HEI Performance and HEI Value" banner. "We received numerous orders for equipment and services from all over the world and in all market segments, including around 900 printing units in all formats and over 90 postpress machines. The positive mood in the industry is continuing thanks to the tangible upward trend," adds Schreier. Customers from the UK, Chinese, and Indian markets were particularly keen to invest.

The solutions offered by Heidelberg were geared to customer needs and covered market trends such as lean manufacturing, short-run color printing, green printing, and web-to-print. There were tailor-made solutions to suit each and every customer - from small family businesses to large companies and from industrialized nations to emerging markets. The presentations in the center of the Heidelberg stand put the focus on the company's Services and the Prinect workflow, which make customers even more competitive.

The Speedmaster CX 102, which was making its global debut at IPEX 2010, caught big attention. By the end of the event, 15 of these presses with a total of more than 90 printing units had been sold worldwide, thereby opening up a new market segment. The CX 102 is printing with a production speed of 16,500 sheets per hour and lies between the Speedmaster SM 102 / CD 102 and the Speedmaster XL 105. Its high productivity and great flexibility make the CX 102 suitable for both commercial and packaging printers. The Speedmaster SM 52 Anicolor with new coating unit and short delivery also sold well. This compact press enables customers to apply a wide variety of surface finishes with extremely short make-ready times.

A Belgian customer invested for example in a Speedmaster XL 75 with Prinect Inpress Control, Autoplate XL and the new CleanStar. This combination ensures environmental friendly print production through a dramatic reduction in waste and dust levels in the pressroom. One UK customer ordered not one but three Speedmaster XL 105 presses with a total of 32 printing units - all with Prinect Inpress Control, Autoplate XL, and CutStar - for a highly industrialized production facility. The final item in this order was a KH 82 folding machine. A Chinese print shop ordered three Speedmaster CD 102 presses and one Speedmaster SM 74, representing a total of 19 printing units. And the production operations of a Russian customer will soon be boosted by a Eurobind 1300 adhesive binder. All the prepress, press, and postpress machines displayed at the show were sold to customers, too. The service and workflow presentations proved to be a big draw. Small and medium-sized print shops in particular were impressed by the new Prinect S workflow, which provides a fast and reliable entry level solution to lean print production. Heidelberg also announced new partnerships with local MIS and Web-to-Print suppliers. Last but not least, there was great interest in the company's Saphira consumables, which produce optimum results on Heidelberg equipment. "We were able to provide our customers with a credible and touchable demonstration of our state-of-the-art technologies and comprehensive range of services to boost competitiveness," confirms Schreier. "We will also introduce a digital printing solution and will then be able to offer the technology with the best price-performance ratio for the particular business model. This is a logical step for our customers because it is understood that offset and digital printing complement each other," he adds.

The service and workflow presentations proved to be a big draw. Small and medium-sized print shops in particular were impressed by the new Prinect S workflow, which provides a fast and reliable entry level solution to lean print production. Heidelberg also announced new partnerships with local MIS and Web-to-Print suppliers. Last but not least, there was great interest in the company's Saphira consumables, which produce optimum results on Heidelberg equipment. "We were able to provide our customers with a credible and touchable demonstration of our state-of-the-art technologies and comprehensive range of services to boost competitiveness," confirms Schreier. "We will also introduce a digital printing solution and will then be able to offer the technology with the best price-performance ratio for the particular business model. This is a logical step for our customers because it is understood that offset and digital printing complement each other," he adds.

According to George Clarke, Managing Director of Heidelberg UK and this year's IPEX President, IPEX 2010 was a "recovery show"  and by far the most important IPEX ever for the industry. "Visitor numbers were just as high as at the last IPEX four years ago and many decision-makers from around the globe attended the event. We have taken orders for 140 printing units in all formats for the UK alone," says a confident Clarke.

and by far the most important IPEX ever for the industry. "Visitor numbers were just as high as at the last IPEX four years ago and many decision-makers from around the globe attended the event. We have taken orders for 140 printing units in all formats for the UK alone," says a confident Clarke.

The HEI Productivity and HEI Eco tours also proved extremely popular. Consultancy services and measures to ensure green production are exactly what print shops are looking for. Heidelberg demonstrated its consistent approach to environmental protection by carbon neutralizing its entire trade show presentation.

Follow this link to find a comprehensive overview of the IPEX 2010 news from Heidelberg:

www.heidelberg.com

Picture 1:

Heidelberger Druckmaschinen AG at IPEX 2010: Heidelberg CEO Bernhard Schreier was delighted at selling more than 15 Speedmaster CX 102 presses, a model making its global debut at the trade show.

Picture 2:

Heidelberger Druckmaschinen AG at IPEX 2010: Demonstrations of short-run printing on the Speedmaster SM 52 Anicolor proved a magnet for visitors. Thanks to extremely short make-ready times and 90 percent less waste, Anicolor technology boosts productivity and benefits the environment.

Picture 3:

Heidelberger Druckmaschinen AG at IPEX 2010: The comprehensive Heidelberg software and service portfolio was at the heart of the company's stand.

Picture 4:

Heidelberger Druckmaschinen AG at IPEX 2010: The focus was on customers, with Heidelberg experts providing advice on made-to-measure solutions.

Heidelberg Sells Another Large-Format Press to China

Yiwu Feile Color Printing Co. Ltd. from Zhejiang province recently signed the agreement for a Speedmaster XL 145 five-color press - the first in eastern China. This increases the number of large-format presses from Heidelberger Druckmaschinen AG (Heidelberg) on the growth market of China to three. Color-Bridge Printing & Packaging Co. Ltd. has already been using a Speedmaster XL 162 six-color press plus coating for its commercial and packaging jobs for a year. Last fall, Feng Yiu Packaging Co. Ltd. invested in a Speedmaster XL 145 six-color press for packaging printing.

Yiwu Feile Color Printing had been founded ten years ago and now has over 40 employees. The pressroom already houses three Speedmaster CD 102 presses - one five-color and two four-color units. The average job run is 5,000 to 10,000 sheets and the company operates two shifts around the clock. Managing Director Ye Wei is convinced the investment in the Speedmaster XL 145 will significantly boost print quality and also increase sales. The largest local specialist market for consumer goods is located in Yiwu, where the print shop is based. Demand for brochures and flyers is continuing to grow. Yiwu Feile Color Printing follows Heidelberg standards to the letter and is well-known for its excellent print quality. The company continues to place its faith in consumables and services from Heidelberg. "As well as our own corporate culture, we have innovative technology from Heidelberg to thank for our position as number one on the local market," says Ye Wei.

Large format enjoys worldwide success

The large-format presses from Heidelberg are of interest to industrial-scale commercial and packaging print shops. Speedmaster XL 145 and XL 162 presses are based on the technological platform of the XL 105 and deliver impressive benefits such as faster makeready times, less paper waste, consistently high print quality, good flexibility with a range of substrates, and high press availability. These features are enhanced by simultaneous washing of the inking unit, blanket, and impression cylinder, and synchronized plate changes in all printing units in just a few minutes. Last but not least, the Prinect print shop workflow enables this format class to be fully integrated in an end-to-end solution.

Figure:

Delighted with their continued joint success: Ye Wei (left), Managing Director of Yiwu Feile Color Printing Co. Ltd. and Benny Huang, General Manager of Heidelberg China Co., Ltd Shanghai at the signing of the agreement for a Speedmaster XL 145.

Further information for journalists:

Heidelberger Druckmaschinen AG

Corporate Communications

Hilde Weisser

Phone: +49 (0)6221 92 5066

Fax: +49 (0)6221 92 5069

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

IPEX Innovations from Heidelberg Boost Efficiency and Competitiveness

At this year's IPEX trade show in Birmingham, United Kingdom, from May 18 to 25, 2010, Heidelberger Druckmaschinen AG (Heidelberg) will be showcasing the latest developments in its product and solution portfolio. The leading international solution provider for sheetfed offset printing is focusing its trade show presence on its extensive portfolio of state-of-the-art technologies and services under the slogans HEI Performance and HEI Value.

"We are confident that the IPEX trade show will further reinforce the noticeable upwards trend in the industry," said Bernhard Schreier, Heidelberg Chief Executive Officer. "The show could mark a positive turning point for the industry in 2010."

Providing customers with the best support for different market requirements

As part of its trade show presence, Heidelberg will draw on the economic developments of the recent past and explore the structural changes in the industry in order to show customers specific alternative methods to boost their competitiveness. "The fact is that the global annual print volume totaling nearly EUR 400 billion has seen stable development over the past ten years with some slight fluctuations. However, the picture has differed from region to region," explained Bernhard Schreier. "In the industrial nations, advertising printing will not return to pre-crisis levels, while packaging printing, on the other hand, will grow slightly. In the emerging countries, however, strong growth is evident in both advertising and packaging printing."

Taking this market development into consideration, Heidelberg will be showcasing solutions at IPEX that demonstrate to companies in the developed economies how to adjust to the changes in the industry by improving productivity and optimizing processes overall, e.g. through high-productivity machines or process integration using software, in order to secure market success. For prepress, press, and postpress companies in emerging countries, on the other hand, the focus is on productive standard equipment to satisfy the growing demand for print products on their home markets.

"We have systematically geared our range of products and solutions to the requirements of our customers in the advertising printing and packaging printing segments and ensured that they represent the state-of-the-art. We therefore confidently believe that both we and our customers are well placed for the recovery," said Schreier.

New products help to master the challenges of the future

With numerous prepress, press, and postpress innovations, including integration of all process steps, Heidelberg can offer users the leading solution portfolio in the industry, and is committed to doing so in the future, too. IPEX 2010 will mark the world premiere of the Speedmaster CX 102, a new press for industrial offset printing capable of reaching production speeds of 16,500 sheets per hour. As well as high productivity, the Speedmaster CX 102 is impressively versatile and is aimed at both commercial and packaging printers.

The new press is positioned between the Speedmaster SM 102 / CD 102 and the Speedmaster XL 105. This press puts the finishing touch to the Heidelberg 70 x 100 cm (27.56 x 39.37") format and offers the perfect solution for every press speed and level of productivity.

A further IPEX innovation from Heidelberg is Prinect S - a workflow solution for small and medium-sized print shops that provides a fast and reliable gateway to lean print production. Users benefit from all the basic print shop workflow functions required to combine prepress and pressroom management in a single system.

Trade show presence focuses on current market trends

At the trade show, the company will run practical demonstrations to highlight how media service providers, print shops, and postpress specialists can act on current market trends such as Lean Manufacturing, Ecological Printing or Web-to-Print and successfully adapt their portfolios accordingly. Heidelberg will demonstrate at IPEX how to optimize business and production processes across the entire value added chain of sheetfed offset printing, while also minimizing their environmental impact.

The numerous practical demonstrations will enable visitors to find out how they can achieve economic success with short-run high-end print applications, stand out from the crowd with creative print applications, and make the Internet an integral part of their business strategy. Heidelberg is proving that environmentally friendly production has long ceased to be just an empty buzzword, not only with special training measures at its own production sites, but also by making its whole trade show presence in Birmingham climate-neutral. This measure covers the whole carbon footprint, including the assembly and dismantling phases, the trade show personnel's trip to the site, and the paper used in the practical demonstrations.

Boosting performance with Heidelberg's service portfolio

In order to be successful nowadays, print shops need to do more than just use state-of-the-art technology. Services from suppliers are playing an ever greater role in ensuring that equipment is available round the clock and in helping users unlock the full potential of a machine or integrated solution.

To give customers faster access to these benefits as and when they require them, Heidelberg has combined its entire service portfolio in a dedicated division. The portfolio covers a print shop's entire value added chain and the full life cycle of machinery - from the initial investment to resale.

This includes comprehensive analysis and consulting services, e.g. for process enhancement and system integration, along with training measures for employees and concrete support for certification to ISO or the latest environmental standards. In Hall 8 at IPEX, visitors can obtain practical information about the full range of remote diagnosis and inspection functions, supply of Original Heidelberg spare parts, the range of Saphira consumables, and the service agreements offered as part of Heidelberg Systemservice.

IPEX reinforces upwards trend in the industry

The first upward trends are clearly apparent in various regions. "Companies that invest now in new technologies, new areas of business or processes within their business, will be well placed for the future," says Bernhard Schreier. "Customers are accustomed to us boosting their competitiveness through the latest technologies and a comprehensive service portfolio," he states, adding: "And at this year's IPEX, they won't be disappointed."

For further information, please contact:

Heidelberger Druckmaschinen AG

Corporate Public Relations

Dirk Henrich

Tel: +49 (0)6221 92 5910

Fax: +49 (0)6221 92 5069

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Executive Forum in Heidelberg for print managers from July 13 to 16, 2010

The Print Media Academy (PMA) of Heidelberger Druckmaschinen AG (Heidelberg) is hosting the next Executive Forum which will be taking place in Heidelberg, Germany from July 13 to 16. The four-day intensive seminar at the Print Media Academy is first and foremost geared to participants from all over the world, offering them the opportunity to broaden their knowledge of the sector and share experience and strategies for success.

"The pressure to compete and changing market dynamics are continuing to increase. Managers in the print media industry therefore always need to be up to date on current trends in the industry and comprehensive, sustainable methods of strategic management," says Martina Brand, Head of International Business Training at the Print Media Academy. That's why the seminar will be focusing on the different aspects of business management in particular. Further presentations and discussions will spark new ideas within the areas of finance, controlling, leadership and marketing & management. Participants will also have the chance to discuss their own experience with experts and colleagues and get valuable feedback.

The course will be led by Stan Solomidis and Martina Brand. Solomidis is the owner and director of Synthesis Australia Pty Ltd. Stan sits on the board of some very competitive and marketing oriented printing businesses and this experience coupled with his corporate experience makes him well equiped to assist printing managers who are looking to improve their firm's performance. Martina Brand is in charge of International Business Training at the Print Media Academy in Heidelberg.

The Executive Forum has established itself within the print media industry as an important international forum. Executives from all over the world use the opportunity to share country-specific experience and network in an informal atmosphere. Previous venues have included Shanghai, Hongkong, Moscow, Sao Paulo, and Dubai.

The location for the event is the Print Media Academy in Heidelberg. The seminar fee is EUR 1,990 plus VAT, which includes lunch and drinks on each day and all seminar handouts. As the number of participants is limited, early registration is recommended. The seminar language is English.

Up-to-date seminar information and profiles of the speakers are available on the internet at www.print-media-academy.com

About the event organizers

The Print Media Academy (PMA) of Heidelberger Druckmaschinen AG, Germany, is a center for training and communication in the print media industry, with 18 sites worldwide. This year the Print Media Academy in Germany celebrates its 10th anniversary. Last year alone over 9,000 participants from all over the world attended training programs at the PMA.

Figure:

The next Executive Forum will be taking place at the Print Media Academy in Heidelberg from July 13 to 16, 2010, offering international print managers the opportunity to expand their knowledge, share experience, and learn about success strategies.

For further information on the seminar, please contact:

Heidelberger Druckmaschinen AG

Print Media Academy

Silvia Becker (registration office)

Phone: +49 6221 92 5011

Fax: +49 6221 92 4929

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

For further information for journalists, please contact:

Heidelberger Druckmaschinen AG

Corporate Public Relations

Hilde Weisser

Phone: +49 6221 92 5066

Fax: +49 6221 92 5069

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.