Displaying items by tag: IPEX

IPEX 2010 Continues Positive Trend in Print Media Industry

"IPEX 2010 was well attended and our customers showed great interest in our new products and services," says a satisfied Bernhard Schreier, CEO of Heidelberger Druckmaschinen AG (Heidelberg), in summing up the trade show. More than 50,000 international visitors came to Birmingham between May 18 and 25, 2010 to find out about the numerous innovations being showcased by Heidelberg under the "HEI Performance and HEI Value" banner. "We received numerous orders for equipment and services from all over the world and in all market segments, including around 900 printing units in all formats and over 90 postpress machines. The positive mood in the industry is continuing thanks to the tangible upward trend," adds Schreier. Customers from the UK, Chinese, and Indian markets were particularly keen to invest.

"IPEX 2010 was well attended and our customers showed great interest in our new products and services," says a satisfied Bernhard Schreier, CEO of Heidelberger Druckmaschinen AG (Heidelberg), in summing up the trade show. More than 50,000 international visitors came to Birmingham between May 18 and 25, 2010 to find out about the numerous innovations being showcased by Heidelberg under the "HEI Performance and HEI Value" banner. "We received numerous orders for equipment and services from all over the world and in all market segments, including around 900 printing units in all formats and over 90 postpress machines. The positive mood in the industry is continuing thanks to the tangible upward trend," adds Schreier. Customers from the UK, Chinese, and Indian markets were particularly keen to invest.

The solutions offered by Heidelberg were geared to customer needs and covered market trends such as lean manufacturing, short-run color printing, green printing, and web-to-print. There were tailor-made solutions to suit each and every customer - from small family businesses to large companies and from industrialized nations to emerging markets. The presentations in the center of the Heidelberg stand put the focus on the company's Services and the Prinect workflow, which make customers even more competitive.

The Speedmaster CX 102, which was making its global debut at IPEX 2010, caught big attention. By the end of the event, 15 of these presses with a total of more than 90 printing units had been sold worldwide, thereby opening up a new market segment. The CX 102 is printing with a production speed of 16,500 sheets per hour and lies between the Speedmaster SM 102 / CD 102 and the Speedmaster XL 105. Its high productivity and great flexibility make the CX 102 suitable for both commercial and packaging printers. The Speedmaster SM 52 Anicolor with new coating unit and short delivery also sold well. This compact press enables customers to apply a wide variety of surface finishes with extremely short make-ready times.

A Belgian customer invested for example in a Speedmaster XL 75 with Prinect Inpress Control, Autoplate XL and the new CleanStar. This combination ensures environmental friendly print production through a dramatic reduction in waste and dust levels in the pressroom. One UK customer ordered not one but three Speedmaster XL 105 presses with a total of 32 printing units - all with Prinect Inpress Control, Autoplate XL, and CutStar - for a highly industrialized production facility. The final item in this order was a KH 82 folding machine. A Chinese print shop ordered three Speedmaster CD 102 presses and one Speedmaster SM 74, representing a total of 19 printing units. And the production operations of a Russian customer will soon be boosted by a Eurobind 1300 adhesive binder. All the prepress, press, and postpress machines displayed at the show were sold to customers, too. The service and workflow presentations proved to be a big draw. Small and medium-sized print shops in particular were impressed by the new Prinect S workflow, which provides a fast and reliable entry level solution to lean print production. Heidelberg also announced new partnerships with local MIS and Web-to-Print suppliers. Last but not least, there was great interest in the company's Saphira consumables, which produce optimum results on Heidelberg equipment. "We were able to provide our customers with a credible and touchable demonstration of our state-of-the-art technologies and comprehensive range of services to boost competitiveness," confirms Schreier. "We will also introduce a digital printing solution and will then be able to offer the technology with the best price-performance ratio for the particular business model. This is a logical step for our customers because it is understood that offset and digital printing complement each other," he adds.

The service and workflow presentations proved to be a big draw. Small and medium-sized print shops in particular were impressed by the new Prinect S workflow, which provides a fast and reliable entry level solution to lean print production. Heidelberg also announced new partnerships with local MIS and Web-to-Print suppliers. Last but not least, there was great interest in the company's Saphira consumables, which produce optimum results on Heidelberg equipment. "We were able to provide our customers with a credible and touchable demonstration of our state-of-the-art technologies and comprehensive range of services to boost competitiveness," confirms Schreier. "We will also introduce a digital printing solution and will then be able to offer the technology with the best price-performance ratio for the particular business model. This is a logical step for our customers because it is understood that offset and digital printing complement each other," he adds.

According to George Clarke, Managing Director of Heidelberg UK and this year's IPEX President, IPEX 2010 was a "recovery show"  and by far the most important IPEX ever for the industry. "Visitor numbers were just as high as at the last IPEX four years ago and many decision-makers from around the globe attended the event. We have taken orders for 140 printing units in all formats for the UK alone," says a confident Clarke.

and by far the most important IPEX ever for the industry. "Visitor numbers were just as high as at the last IPEX four years ago and many decision-makers from around the globe attended the event. We have taken orders for 140 printing units in all formats for the UK alone," says a confident Clarke.

The HEI Productivity and HEI Eco tours also proved extremely popular. Consultancy services and measures to ensure green production are exactly what print shops are looking for. Heidelberg demonstrated its consistent approach to environmental protection by carbon neutralizing its entire trade show presentation.

Follow this link to find a comprehensive overview of the IPEX 2010 news from Heidelberg:

www.heidelberg.com

Picture 1:

Heidelberger Druckmaschinen AG at IPEX 2010: Heidelberg CEO Bernhard Schreier was delighted at selling more than 15 Speedmaster CX 102 presses, a model making its global debut at the trade show.

Picture 2:

Heidelberger Druckmaschinen AG at IPEX 2010: Demonstrations of short-run printing on the Speedmaster SM 52 Anicolor proved a magnet for visitors. Thanks to extremely short make-ready times and 90 percent less waste, Anicolor technology boosts productivity and benefits the environment.

Picture 3:

Heidelberger Druckmaschinen AG at IPEX 2010: The comprehensive Heidelberg software and service portfolio was at the heart of the company's stand.

Picture 4:

Heidelberger Druckmaschinen AG at IPEX 2010: The focus was on customers, with Heidelberg experts providing advice on made-to-measure solutions.

First Heidelberg Speedmaster CX 102 for German Customer

The first press of the Speedmaster CX 102 series, introduced by Heidelberger Druckmaschinen AG (Heidelberg) as a world premiere on the occasion of IPEX in Birmingham, has been sold to German commercial printshop Kern GmbH, located in Bexbach, Saarland. The new machine is designed for industrial offset printing and joins the ranks between the Speedmaster SM 102 / CD 102 and the Speedmaster XL 105. André Kern, Managing Director of Kern GmbH, outlines the company's philosophy: "We have always been fascinated by innovations. With the Speedmaster CX 102 we have been provided with the XL 105 peak performance technologies plus a considerably increased productivity, which however allows us to stick to the familiar and proven format."

The first press of the Speedmaster CX 102 series, introduced by Heidelberger Druckmaschinen AG (Heidelberg) as a world premiere on the occasion of IPEX in Birmingham, has been sold to German commercial printshop Kern GmbH, located in Bexbach, Saarland. The new machine is designed for industrial offset printing and joins the ranks between the Speedmaster SM 102 / CD 102 and the Speedmaster XL 105. André Kern, Managing Director of Kern GmbH, outlines the company's philosophy: "We have always been fascinated by innovations. With the Speedmaster CX 102 we have been provided with the XL 105 peak performance technologies plus a considerably increased productivity, which however allows us to stick to the familiar and proven format."

Convincing versatility

In the forefront of the investment, André Kern and his team also had evaluated medium-format presses of different manufacturers. "Asian suppliers in particular are currently offering rock-bottom prices that are very tempting at first glance," says Kern. "However, our job portfolio and three-shift operation require a press, which delivers excellent productivity, consistent print quality and high availability from start to finish. In addition, we print on an extremely wide range of substrates, running the gamut from 50 gsm flimsy paper to board weighing over 300 gsm. We are certain that the Speedmaster CX 102 is the best solution for our diversity of requirements. The smooth running of the press and its ergonomic operation are convincing. Ever since we made the decision to invest in the Speedmaster CX 102, everyone is excitedly anticipating the world's first in its kind. As a long-term customer, we know that we can always rely on the well-proven quality and performance in regard to Heidelberg innovations."

Lean processes and highly productive equipment as key to success

This state-of-the-art print shop runs a highly automated operation, and its central production processes are fully integrated via the Prinect Workflow. The new Speedmaster CX 102 five-color press with coating unit continues the tradition of the 70 × 100 cm format. To date, two Speedmaster SM 102 units were in operation - one six-color and one eight-color press. The six-color press has now been replaced by the new Speedmaster CX 102.

coating unit continues the tradition of the 70 × 100 cm format. To date, two Speedmaster SM 102 units were in operation - one six-color and one eight-color press. The six-color press has now been replaced by the new Speedmaster CX 102.

On a production area of some 2,200 square meters, a team of 35 works for manufacturers of branded goods, cosmetic suppliers, insurance companies, and consumer goods producers. The company produces items such as brochures, catalogs, and other marketing materials using offset and digital printing. Kern GmbH also uses its in-house mailing center to provide a wide variety of logistics services for direct marketing customers. The Kern GmbH is a family-run company in the fourth generation, managed by Juergen, Joachim, and André Kern. The Bexbach-based printshophas a subsidiary in Sarreguimines, France.

Picture 1:

Heidelberg introduced the Speedmaster CX 102 on the occasion of IPEX 2010. This marked the world premiere of a new printing press for industrial offset printing with a production speed of 16,500 sheets per hour. The new press, which manages flimsy papers, stiff board and a wide range of plastic materials as well, convinces by its high productivity and its versatility.

Picture 2:

The Speedmaster CX 102 provides André Kern with the XL 105 peak performance technologies the and considerably increased productivity- and allows the company to stick to the familiar and proven format.

For further information, please contact:

Heidelberger Druckmaschinen AG

Corporate Public Relations

Dirk Henrich

Phone: +49 (0)6221 92 5910

Fax: +49 (0)6221 92 5096

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mondi sponsors OEMs at this year’s IPEX: “the global event for print, publishing and media.”

Taking place in Birmingham, UK from May 18th- 25th, recognized Original Equipment Manufacturers will demonstrate the high quality print results achieved together with Mondi’s premium papers.

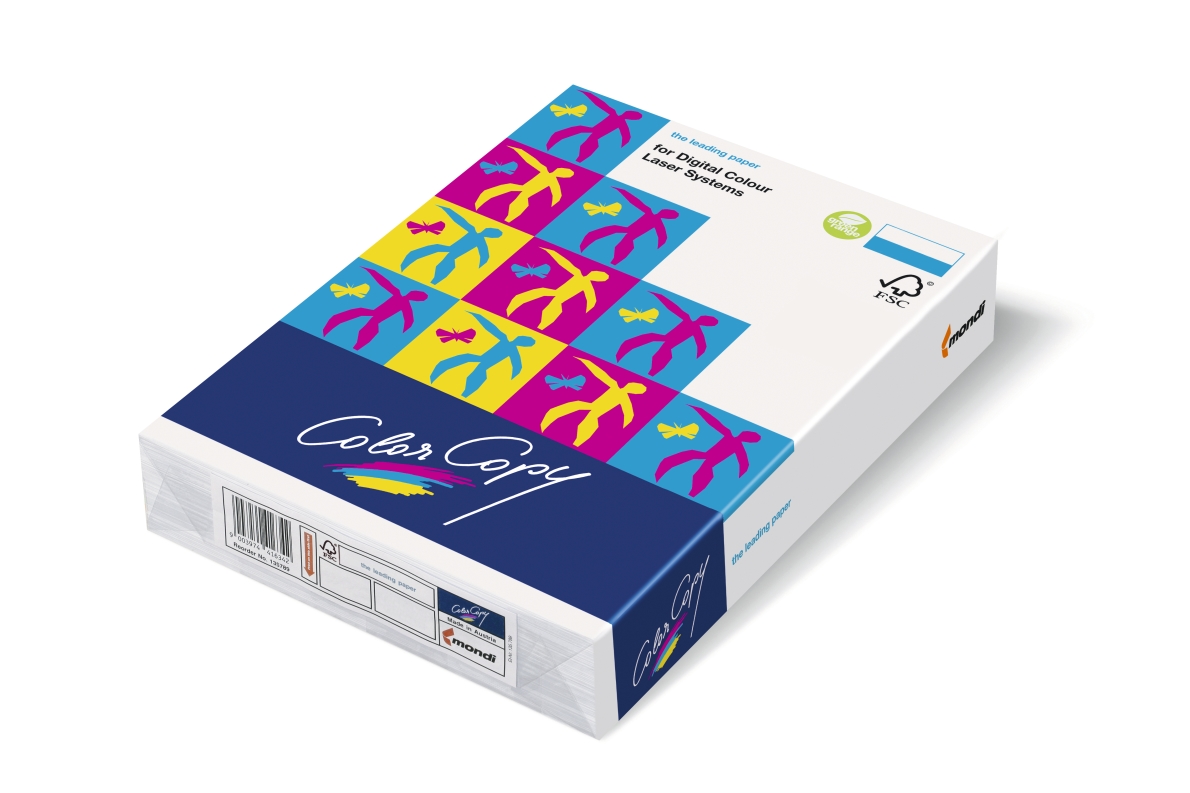

Vienna, 11th May, 2010 – Mondi will be present at this year’s IPEX fair as a paper sponsor for some of the printing industry’s most recommended OEMs. This year, Mondi has sponsored Xeikon, Konica Minolta, Xerox, and Canon with supplies of Color Copy — the first colour laser paper in the world to be specifically designed for colour laser systems. In addition to Color Copy, Xeikon will also receive IQ premium in 80 gsm — an ideal paper for text and graphics due to its high whiteness. Mondi’s new HP Indigo certified products will also be available for viewing in the paper sample swatch book at the HP stand.

“IPEX is a major international event and as a global manufacturer of Uncoated Fine Paper, Mondi is pleased to participate alongside Xeikon, Konica Minolta, Xerox, Canon, and HP,” says Johannes Klumpp Marketing and Sales Director of Mondi Uncoated Fine Paper. “With this year’s focus on digital printing technologies, it is important to demonstrate how Mondi’s paper technologies have developed in conjunction with OEMs to produce exceptional print results.”

Both part of Mondi’s digital print portfolio, IQ premium and Color Copy are available in a wide range of grammages and formats. According to the Graphic Technology Research Association FOGRA, Color Copy has once again set the benchmark as Europe’s leading paper for overall print quality. More recently, it was qualified for Xeikon digital duplex presses — a confirmation of manufacturer confidence in Color Copy’s excellent runnability and machine protection.

The last IPEX, which occurred 4 years ago, attracted visitors from over 159 countries, 40% of which came from outside of the UK. More information about Mondi’s digital product portfolio and its environmental accreditations can be found at: www.mondigroup.com/digitalprinting.

Contact

Jolene Pozniak, Communications Manager, Uncoated Fine Paper

Tel: +43 (1) 79013 – 5663, e-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

IPEX Innovations from Heidelberg Boost Efficiency and Competitiveness

At this year's IPEX trade show in the U.K. city of Birmingham from May 18 to 25, 2010, Heidelberger Druckmaschinen AG (Heidelberg) will be showcasing the latest developments in its product and service portfolio. The company's stand in Hall 8 will focus on current market trends such as lean, environmentally friendly production for print shops. "Our aim is to ensure that our customers are well positioned to face future challenges, and we will work with them to develop and successfully implement new business options in a changing environment," stated Heidelberg CEO Bernhard Schreier.

* New products and services put print shops in an excellent position for when the economy picks up again

* Focus on solutions for new business options

* Heidelberg views IPEX as a trend barometer for the printing industry in 2010

* Initial signs of macroeconomic recovery in parts of the world

Heidelberg still offers the best price-performance ratio in the industry thanks to numerous prepress, press, and postpress innovations combined with the integration of all process steps. The successful entry of Heidelberg into the large-format sector in 2008 underlines the fact that innovations and, above all, greater customer benefits are the driving forces behind investments in the industry. "For Heidelberg, IPEX is a trend barometer and also an opportunity for the printing industry in 2010," said Schreier.

Despite initial positive signs in some parts of the world, it is still too soon to anticipate a significant turnaround in the economy in the near future. "Companies who invest in new technologies and new areas of business now, though, will be well positioned for the future," stated Schreier. Heidelberg would be using the trade show to continue redefining parts of the market with further innovations, he said. "Our customers expect us to boost their competitiveness with the latest technologies and a comprehensive service portfolio. We will definitely meet their expectations at IPEX," he stressed.

Heidelberg provides local support for its customers with a wide range of services that pave the way for sustainable business success. "We will also optimize and expand our range of products and services," stated Schreier. The digital printing was a market segment with excellent prospects that customers would increasingly add to their portfolios and for which Heidelberg was looking for a suitable partner, he explained. "We have the ideal service and logistics network for this, which gives us a clear competitive edge," Heidelberg's CEO stated. He added that the two technologies were predicted to successfully continue side by side on the future market.

Schreier also underlined that it was vital not to ignore the structural changes in the industry, but to adapt to them. He added that the global print volume of just under EUR 400 billion was an encouraging sign for the development of the market and that, when the economy picked up again, commercial printing would recover too and lead to new investments in this offset market segment. Packaging printing has enjoyed greater stability during the crisis and offers growth potential for Heidelberg. "We have systematically geared our range of products and solutions to the requirements of our customers in both market segments and ensured that they represent the state of the art. This makes us confident that both our customers and our companies are extremely well positioned for the recovery to come," concluded Schreier.

For further information:

Heidelberger Druckmaschinen AG

Corporate Public Relations

Thomas Fichtl

Phone: +49 (6221) 92 5900

Fax: +49 (6221) 92 5069

E-Mail:

!- var prefix = 'mailto:'; var suffix = ''; var attribs = ''; var path = 'hr' + 'ef' + '='; var addy79141 = 'thomas.fichtl' + '@'; addy79141 = addy79141 + 'heidelberg' + '.' + 'com'; document.write( '' ); document.write( addy79141 ); document.write( '' ); // -->This email address is being protected from spambots. You need JavaScript enabled to view it.