Displaying items by tag: POM Technology Oy AB

AFT ANNOUNCES START-UP OF NEW POM APPROACH FLOW SYSTEM AT STORA ENSO OULU

AFT is pleased to announce the successful start-up of a new POM® approach flow system at Stora Enso Oulu on the recently converted and commissioned board machine 7. The machine is now producing a high quality kraftliner called AvantForte™ by Stora Enso in both brown and white top. The kraftliner product has three layers of fiber to feature the strongest in the Stora Enso kraftliner portfolio, an essential element for e-commerce and food packaging.

The new wet end from AFT includes a complete POM approach flow system for all 3 layers including headbox screening, POMix stock processors to feed the paper machine, POMp degassers for air removal, a POMlock drop leg and a cleaning system. Basic engineering and mill site services were included as part of AFT’s offerings.

Compared to traditional systems with silos and tanks, the compact POM system runs efficiently with less water, energy and few web breaks. This is helping to enhance the environmental performance of board machine 7, while providing fast grade changes, process stability and sheet cleanliness.

Despite challenges from the pandemic, installation and start-up of the POM system were completed on time, helping the overall machine conversion and environmental projects to proceed ahead of plan.

“AFT is proud to have been selected for this project following similar successful installations at other Stora Enso mills”, says Timo Koivisto, Vice President - Process and Equipment Solutions. “We strive to deliver innovative technologies that help our customers produce high quality products in a sustainable way.”

ABOUT AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

Global teamwork: AFT’s growing advantage

The Pulp and Paper Industry just gained an advocate for teamwork, naming Jacques Beauchemin as President and CEO of AFT. In his previous position as CFO, Jacques was instrumental in helping to acquire two of AFT’s largest innovations with Finebar and POM. He has built a reputation for fostering teamwork within the organization, travelling regularly to AFT’s five manufacturing sites and promoting global collaboration.

Jacques BeaucheminSays Jacques: “My focus is to strengthen our teams, built around core capabilities. Each person in our company has the support to grow and continuously improve; together we have a strong work force. We are doing more to understand our customer’s needs and bring opportunities for personal growth to our employees. We want big picture thinkers who understand customer processes, good collaborators, and individuals who can multi-task. That’s the essence of a great team.

Jacques BeaucheminSays Jacques: “My focus is to strengthen our teams, built around core capabilities. Each person in our company has the support to grow and continuously improve; together we have a strong work force. We are doing more to understand our customer’s needs and bring opportunities for personal growth to our employees. We want big picture thinkers who understand customer processes, good collaborators, and individuals who can multi-task. That’s the essence of a great team.

One recent example for key change has been to unify our global project management and service teams. This change presents a single face to our customers and strengthens our internal collaboration. It is at times a challenge to stay locally focused while being globally collaborative within the organization; my past leadership with our global information technology team will help. Our support needs to be at the same high level for customers located around the world."

Follow this link for more of Jacques interview as he steps in to lead AFT: http://ow.ly/JEa030kVnr1

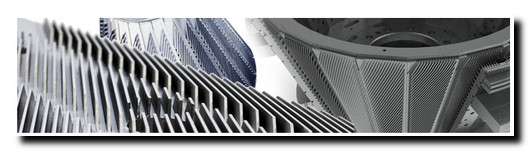

Refiner plate MiniSegment™ extends value, saves money for LC refining

AFT Finebar®, part of the global Aikawa Group, has developed the MiniSegment™ refiner plate – the latest advancement in diffusion bonded refiner plate technology. The MiniSegment allows mills to replace only the working surface of the refiner plate, reducing the overall cost of ownership.

AFT Finebar®, part of the global Aikawa Group, has developed the MiniSegment™ refiner plate – the latest advancement in diffusion bonded refiner plate technology. The MiniSegment allows mills to replace only the working surface of the refiner plate, reducing the overall cost of ownership.

The MiniSegment is installed on an Adapter Plate, which is bolted to the mounting surface using the existing refiner bolt holes. In addition to saving money by replacing only the fiber-contacting portion of the refiner plate, the MiniSegments weigh considerably less than a traditional plate, making them easy to position when bolting and safer to handle.

AFT Finebar MiniSegments can be applied to nearly any single disk, double disk, or Tridisk low consistency refiner.

Stora Enso orders a compact approach flow system from POM Technology Oy Ab for its Ostroleka Mill

POM Technology Oy Ab has received an order for the supply of a compact approach flow system for Stora Enso’s new testliner machine in Ostroleka Mill in Poland. The start-up is scheduled for the first quarter of 2013.

At a wire width of 8,600 mm and a design speed of 1,800 m/min, the new Narew PM5 project will produce 455,000 metric tons of testliner per year. The new paper machine is designed for the production of lightweight testliner and recycled fluting in a basis weight range of 65-140 g/m².

The POM compact approach system delivery includes: two POMix Stock Processors for efficient stock mixing, three POMp Degassers for white water dearation, two POMlock suction leg sealing units as well as compact process solutions and engineering for whole approach flow system. Stora Enso’s focus of this investment was on operational savings from improved drainage, cleanliness and quality as well as on space and especially energy cost savings, which all are met by POM System applications and principles.

The new Stora Enso Ostroleka PM5 order continues Stora Enso’s orders to POM Technology Oy Ab. POM Tehnology has successfully delivered several POM Degassing solutions to Stora Enso Varkaus and Imatra Mills in Finland. POM Technology Oy Ab will become part of Aikawa Fiber Technologies (AFT) at beginning of year 2012.

Aikawa gathers forces to give papermakers a choice in stock preparation solutions

New organization under a single brand is driven by customer requests for alternatives to avoid being “boxed in” for key technologies

For many years, Aikawa Iron Works worked quietly to build its foundation as a premier supplier of stock preparation technologies in Japan. Its acquisitions of specialist companies such as AFT Screen Plates of Canada, Finebar of the USA, and POM Technology of Finland were conducted with little fanfare.

“Perhaps we have operated under-the-radar,” admits Masaki Aikawa, Chairman of the Aikawa Group. “But that has been our style. We put performance ahead of self-promotion.”

In pursuit of higher performance and recognition, the Aikawa Group is announcing a name change and a new, consolidated global organization. “This is in response to our customers’ requests,” Aikawa admits. “They want alternatives to the packaged offerings of the ‘Big Box’ major suppliers. They prefer the freedom to select the best single equipment, with the expertise to put systems together when required.”

The new organization is being consolidated outside of Japan under the umbrella of Aikawa Fiber Technologies (AFT), which is guided by Michael Stephens, President and a 35-year veteran of the pulp and paper industry.

Stephens says that AFT is being structured into teams to serve the three major customer groups for Aikawa outside Japan: screen manufacturers (original equipment manufacturers) who contract with AFT for manufacturing of screen cylinders, plates, and rotors; mills who order these engineered wear parts directly from the company; and mills looking for technical solutions for fiber processing, stock preparation, and machine approach applications.

“Each of these customer groups has unique needs that often times are addressed separately,” Stephens says. “But there are also occasions where customers need solutions that cross over from capital equipment to engineered wear parts to process/systems knowledge. When this happens, we don’t want to confuse our customers with separate interfaces or separate companies with different ways of working.”

According to Stephens, in the contract manufacturing segment, AFT produces more screen cylinders than any manufacturer in the world. Stephens explains, “Most of the OEMs are customers of ours and we give them preferred pricing based on volume. The focus here is on high-precision, low-cost manufacturing that is private-labeled for OEMs.”

The fiber processing and stock preparation solutions are a combination of Aikawa technologies and the technologies of the former POM Technology Oy of Finland, which Aikawa acquired. POM has a patented compact wet end technology for paper machines. Timo Koivisto, formerly the head of POM Technology, is responsible for AFT’s Process/Equipment Solutions team.

The transition from separate companies to a unified AFT organization is currently underway and will be completed by year’s end, according to Stephens. Key management decisions will be announced in the near future.

POM GasMaster portable air meter

POM Technology Oy AB is a leading supplier of paper machine's compact wetend. POMS purger, which is the key component of the patented POM System, is a simple and compact component to remove the air which is in the process. The inventor, Paul Olof Meinander received the Wallenberg price for this concept in 2004, in Sweden. Today, the POM Technology Oy Ab company belongs to the Aikawa Group and has so far delivered nearly 70 systems worldwide.

GasMaster portable air meter

Based on experience, POM Technology Oy Ab has now developed a simple and robust portable air meter, suitable for all paper and paperboard factories.

It is important for all manufacturers of paper, tissue and paperboard to know and comply with air levels of wetwnd, not only when they have problems. Many problems arise because of air, for example papertears, impurities, MD variations, poor retention and drainage.

By eliminating the air in papermanufacturingprocess you improve the papermachines efficiency and paperquality.At the same time wetend becomes more stable, dewatering and papertrail strength increases.

POM GasMaster can be easily moved to different positions. It has a high accuracy and can measure both the amount of gaseous and dissolved air.

POM Technology is represented by Nipman Papertechnology in Scandinavia.