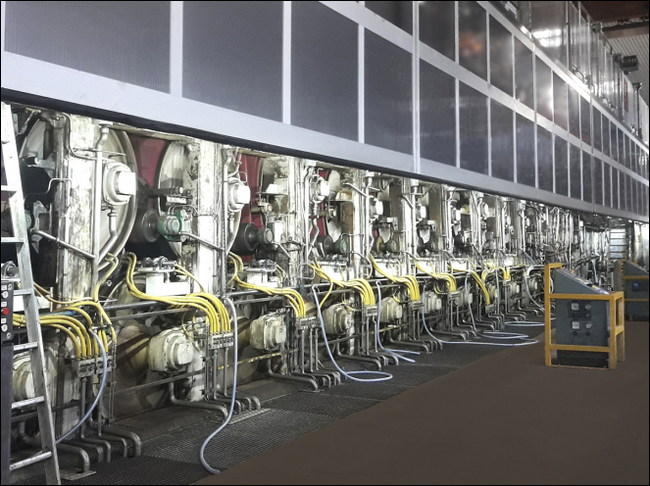

Toscotec will supply a technological upgrade to Cartiera del Vignaletto at their Zevio production site near Verona in Northern Italy. The project includes the complete upgrade of the cogeneration plant and air systems of the mill’s PM4 and PM5.

With this investment, Cartiera del Vignaletto aims to substantially increase the energy efficiency of its operations by installing cutting edge energy generation equipment designed for energy saving.

Cartiera del Vignaletto comments, “Toscotec delivered a tailor-made technical proposal based on our specific requirements by developing interesting ideas step by step with our team. They also demonstrated a high degree of flexibility in putting forward a customised implementation plan that would allow us to efficiently integrate the installation phase with our production shutdown program.”

Cartiera del Vignaletto’s tissue mill in Zevio (Verona), Italy.

Cartiera del Vignaletto’s tissue mill in Zevio (Verona), Italy.

Domenico Ventura, Application Engineer at Toscotec, says, “We are very happy to begin a cooperation with an important Italian producer such as Cartiera del Vignaletto. The new cogeneration plant is state-of-the-art for energy efficiency and the installation of Toscotec’s TT Hydrogen Burner with a customized design for cogeneration provides the mill with a wide range of operation options in the future.”

About Cartiera del Vignaletto

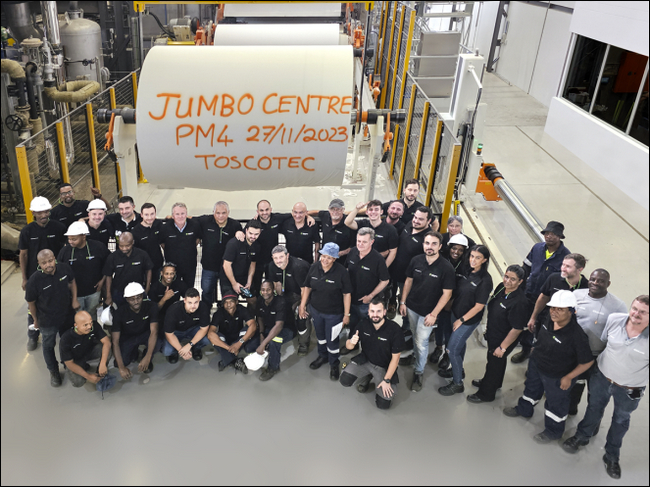

Founded in 1966, Cartiera del Vignaletto has a daily production capacity of approximately 140 tons at its tissue mill in Zevio, near Verona, in Northern Italy. They produce jumbo and rewound rolls of different grades ranging from 15 to 45 gsm, covering the complete range of tissue products, including facial, bath, handkerchief, napkins, kitchen roll, etc.

Contact

Riccardo Gennai

Sales Manager, Tissue division Toscotec

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.