Displaying items by tag: Toscotec

Liuzhou Liangmianzhen Paper Product starts up also the second Toscotec-supplied MODULO-PLUS TM.

On September 29th Liuzhou Liangmianzhen Paper Product Co., Ltd. has started up the second of two MODULO-PLUS ES tissue lines supplied by Toscotec at its mill in Liuzhou, Guangxi. In the next couple of weeks will follow the start-up of the TT WIND-M high-speed slitter rewinder.

Following the start-up of the first Toscotec’s tissue machine on September 11th at Liangmianzhen Paper Product mill, the start-up of this second tissue line was also successfully achieved according to schedule. These two new lines will increase the company’s tissue production by 42,000 t/y.

Toscotec’s scope of supply includes a MODULO-PLUS ES machine, designed for a speed of 1500 m/min, featuring TT SYD-15FT (4572mm) and double press configuration, Milltech’s steam-heated hood, stock preparation equipment, electrical and control systems, spare parts for the entire plant and a full service package.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. Since 2013 Toscotec has been the market leader in tissue machines sales.

Toscotec-supplied MODULO-PLUS tissue machine starts up at Liuzhou Liangmianzhen Paper Product mill in China

Liuzhou Liangmianzhen Paper Product Co., Ltd. has started up the first of two MODULO-PLUS ES tissue lines supplied by Toscotec at its mill in Liuzhou, Guangxi.

In the next couple of weeksthe start-up of the second tissue line and of the TT WIND-M high-speed slitter rewinder will follow suit.

This is the first imported tissue machine to come on stream at Liangmianzhen Paper Product mill, one of Liangmenzhen Group’s subsidiaries, and thanks to the strong partnership between Toscotec and the Chinese producer, start-up was successfully achieved according to schedule.

This first new line alone will increase the company’s tissue production by 21k t/y.

Toscotec’s scope of supply included a MODULO-PLUS ES machine, designed for aspeed of 1500 m/min, featuring TT SYD-15FT (4572mm) and double press configuration, Milltech’s steam-heated hood, stock preparation equipment, electrical and control systems, spare parts for the entire plant and a full service package.

The significant advantage of Toscotec’s technology has been proved to be its cutting-edge Energy Saving drying package: Toscotec’s TT DOES (Drying Optimization for Energy Saving) ensures the lowest energy consumption,

with the highest machine performances. Its reliance on steam, as the sole drying energy source, perfectly meets the twofold objective of Chinese producers to profit from the most accessible and cost-effective energy source and achieve maximum production of high-quality tissue.

About Toscotec S.p.A.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. Since 2013 Toscotec has been the market leader in tissue machines sales.

Paper Prime S.A. enters into tissue production with a new Toscotec Tissue Line

![]() Paper Prime S.A., company belonging to Trevipapel Group which produces Joker Gold brand hygiene professional products (AFH) in Portugal, has signed a contract with the Italian manufacturer Toscotec for the supply of a tissue line in Vila Velha de Rodão.

Paper Prime S.A., company belonging to Trevipapel Group which produces Joker Gold brand hygiene professional products (AFH) in Portugal, has signed a contract with the Italian manufacturer Toscotec for the supply of a tissue line in Vila Velha de Rodão.

The new tissue line is scheduled to come on stream in the last quarter of 2016.

Trevipapel S.A. has stepped up its expansion plan and in line with the strong partnership established with Toscotec, decided to place this order with the Italian manufacturer, based on Toscotec’s technological advantages, which delivers top product quality and considerably reduces the mill's energy costs. The investment is estimated in 35 million euros and its aim is to supply paper reels to Trevipapel converter units and export. The new paper mill will be also in line with a pulp mill which will add increased value to the investment providing eucalyptus based slush pulp.

Toscotec’s turn-key project for TM#1 includes stock preparation plant for dry virgin pulp, AHEAD-2.0S tissue machine with Steel Yankee Dryer TT SYD-16FT, machine auxiliaries including Milltech Gas fired Hood, steam & condensate and dust removal system, electrification starting from medium voltage cabinets & control system, additional plants and complete engineering and erection activity. A three unwind stand rewinder TT WIND-Hcompletes the supply.

Machine operating speed will be 2,000 mpm with a net trim width of 2750 mm and an average annual production of 38,000 tpy .

- About Trevipapel Group

Established in 1991 and headquartered in Lousã, district of Coimbra, Trevipapel Group has grown from a small private company into one of the leading manufacturer providers of hygiene professional products (AFH) in the Portugal due to its Joker Gold brand. With 2 manufacturing plants strategically located in the center of the country, where are actually converted 20,000 tpy, it serves Portugal, Spain, central Europe and started export to Africa and South America.

- About Toscotec S.p.A.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. Since 2013 Toscotec has been the market leader in tissue machines sales.

Toscotec absorbs Milltech into tissue technology business

Toscotec has absorbed tissue machine hood and ventilation specialist Milltech into its own tissue technology operations.

Toscotec purchased Milltech in 2012 and has since operated it as a separate company, but now believes Milltech’s solutions are best offered as a brand within Toscotec’s portfolio.

All of Milltech’s employees have transferred to Toscotec, including managing director Luca Linari, who takes on the role of Sales & Product Manager for Energy and Environmental Systems for Toscotec.

This development makes Toscotec one of the few tissue machinery suppliers which can offer the entire suite of technology for tissue production from one source.

“This is a natural evolution for us,” said Toscotec managing director Alessandro Mennucci. “When we acquired Milltech it created an ideal synergy because minimizing energy consumption is central to our technological vision. Milltech has proved its worth in this respect, but there is no longer any benefit from it remaining a separate company. Its manufacturing facilities are already on site here at Toscotec, and it is strategically rational to operate as one entity.”

About Toscotec S.p.A.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. From 2013-2015 Toscotec was the market leader in tissue machines sales.

Visy Paper started up VP#5 in Melbourne, Australia after Toscotec's Press Section upgrade

Visy Paper PM5 has successfully started up in end of March 2015 at Colaroo, Melbourne – Australia, after a press section upgrade carried out by the Italian company Toscotec. VP5 paper machine produces coating base sheet and test liner for export, from recycled paper.

Visy is one of the world’s largest privately owned paper, packaging and recycling companies; it was established in Melbourne, Australia in 1948 as a manufacturer of corrugated cardboard boxes, and today’s operational footprint extends in over 120 sites across Australia, New Zealand, Thailand and Vietnam and trading offices across Asia, Europe and the USA.

The project aim was to increase test liner paper quality and the overall efficiency of the press section, thus increasing the energy savings. The goal was achieved by the installation of a new framing for the press section and the introduction of a state of the art shoe press - TT XPress as third nip, working with a maximum nip load of 1300kN/m at an operating speed of 1000 m/min. The addition of a new TT SteelDryer-SD1500 at the beginning of the dryer section, completed the upgrade.

The short shut down period and the success of the installation was a result of the strong and constant partnership and cooperation between Toscotec, Build Run Repair, Visy’s dedicated Project Management Group, and the Mill that led to the quick achievement of the expected performances.

About Toscotec S.p.A.

Since 1948 TOSCOTEC, based in Lucca, Italy, has specialized in machinery for the Tissue and Paper industries. The company provides top of the range machinery and system solutions for complete turn-key plants ranging from 40 to 260 TPD and designs and manufactures TADVISION for the premium tissue and towel markets that require Through Air Dried technology.

Actually Toscotec is the market Leader in Steel Yankee Dryers with sales of over 160 Steel Yankees up to 22’ in diameter and widths up to 6000 (236”mm).

Toscotec replies to Voith’s patent infringement allegations

![]() With regard to Voith Paper’s press release of 8th July 2015, Toscotec S.p.A. wishes to advise that on 5th December 2014 it filed an application before the Court of Turin in order to have Voith’s patent no. EP 0926296 declared invalid due to the lack of requirements of novelty and inventive step.

With regard to Voith Paper’s press release of 8th July 2015, Toscotec S.p.A. wishes to advise that on 5th December 2014 it filed an application before the Court of Turin in order to have Voith’s patent no. EP 0926296 declared invalid due to the lack of requirements of novelty and inventive step.

Furthermore, Toscotec has filed an application for an urgent precautionary measure before the Court of Rome, which is dealing with the suit initiated by Voith. By means of its application, Toscotec has requested the court to declare that (i) its tissue machine “AHEAD-2.0S, shoe press version” does not infringe Voith’s patent no. EP 0926296, (ii) said patent is invalid, and (iii) Toscotec’s above-mentioned machine does not interfere with Voith’s above patent.

Toscotec has always respected, respects and will continue to respect intellectual property rights of third parties.

Toscotec has made a name for itself worldwide as one of the leading companies in the tissue machine manufacturing market, in particular for the quality and innovation of its products.

In the face of action aimed at discrediting Toscotec within the market, Toscotec reserves its position to take all appropriate action to protect its rights before the competent courts.

Toscotec to rebuild PM1 at ISMA 2000 S.L in La Torre de Claramunt-Spain

Toscotec with its associate Milltech have been awarded a contract to deliver a major dry-end rebuild of the ISMA 2000 S.L. PM 1 in La Torre de Claramunt, Barcelona- Spain. The start-up of the rebuilt machine is scheduled for the beginning of 2016.

ISMA 2000 SL, is a familiar Company, with operating centers in Catalonia and the Balearic Islands The main business in Barcelona, is the production and processing of tissue products, while in Mallorca the activity is focused on the collection and recovery of waste paper. The main recognized company products are from 100% recycled paper and include: AFH towel, Kitchen rolls, sheets stretcher rolls, napkins, toilet paper.

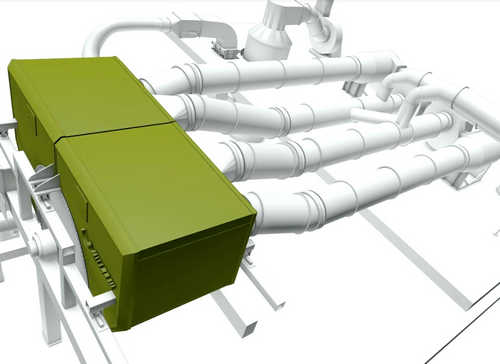

Toscotec's delivery includes a major rebuild of the PM1 dry end section, which will be replaced with a TT DOES (Drying Optimization for Energy Saving) package. This will features a new TT SYD-3600MM provided with Toscotec patented solution for head insulation, a new Yankee steam & condensate system and a Duo-system Yankee hood, SMART type, from Milltech.

Engineering, training start up and commissioning services are also included in the package.

The aim of the rebuild is to increase the production and the performances of the crescent former machine up to 90 tpd. This is the decision that has driven ISMA 2000 to apply for the TT DOES package from Toscotec.

“Our broad conclusion after a deep technical evaluation - says Fernando Luz, Company General Manager, - is that we are forced either to increase output for the same or less specific energy consumption input. Toscotec large experience and reliable approach with its proven TT DOES package, already applied in several mills working conditions worldwide, has matched our requirement in this direction. This rebuild completes the one already initiated in the phase of pulp treatment allowing us to use complex raw material with high quality fibers and increasing efficiency and reducing energy consumption”

Toscotec-supplied AHEAD-2.0 tissue machine started up at Fortissue S.A., Portugal.

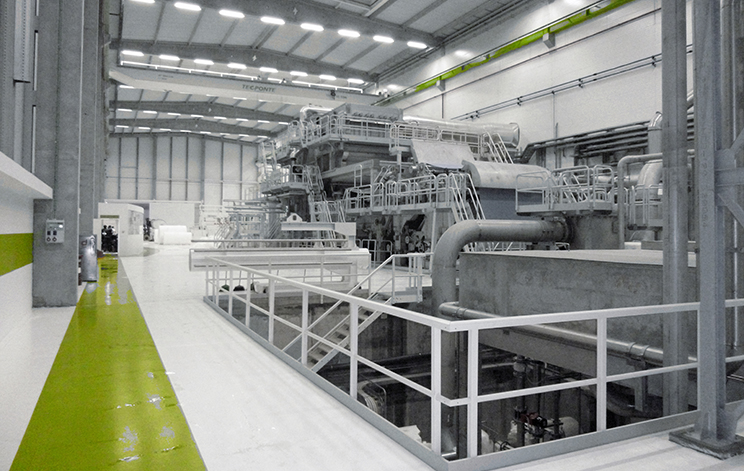

The Toscotec-supplied AHEAD-2.0 tissue machine at Fortissue S.A., the new productive division of Suavecel S.A based in Viana do Castelo, in the coastal and delta region of Rio Lima about 75 km north of Porto, was successfully started up in early April 2015. The machine came easily on stream after the commissioning period and is now producing high quality tissue products according to the guaranteed technological parameters.

Due to the excellent cooperation between Fortissue and Toscotec the line started up smoothly on schedule, 18 months after the order signature of the turn key contract.

The new Toscotec's line, based on the best available technology, includes an AHEAD-2.0 crescent former tissue machine with TT Headbox-MLT double-layer, a Steel Yankee Dryer (TT SYD-16FT), Milltech hood, steam&condensate and dust removal system.

The supply also comprises stock preparation plant for virgin pulp, vacuum plant, boiler plant, air compressors and electrification & control system. A three unwind stands tissue slitter rewinder TT WIND-H and an automatic roll handling system complete the delivery.

The project has been fully managed by Toscotec on an EPC (Engineering Procurement and Construction) basis.

With a net web width of 2820 mm and a maximum drying capacity of 120 tpd, the new tissue line has a capacity of 35,000 tpa making Suavecel active on the entire tissue production process.

The combination of technical expertise with the right equipment and tools required to a superior productive performance, is the key to success of the company’s project, and it largely accounts for the increasing growth that Suavecel is experiencing since 1996, year of its foundation. Before the start-up of the new machine, the Portuguese company was engaged in the transformation of paper, namely producing toilet paper, paper towel, pocket tissues and paper napkins, but also offering some products for the AFH sector.

“Throughout the years - Nuno Ribeiro, CEO of Fortissue and Suavecel, said – our company has successfully met the challenges, based on its ability for a sustainable growth along with suitable development policies, as the notion of growth does not necessarily mean improvement. The company has made a considerable investment effort in capital and human resources in order to achieve the winning combination of these two concepts”.

Toscotec delivers a Second Tissue Line to AMS BR Star Paper S.A, in Portugal

Italian leading paper machinery manufacturer Toscotec will supply a second tissue line to the Portuguese producer AMS BR Star Paper in its plant in Vila Velha de Ródão, in the east of the country. At the present, the mill already houses an AHEAD-2.0S line from Toscotec, with an overall capacity of 110 tpd, started up in 2009. The new machine will come on stream on third quarter of 2015.

Toscotec’s “turn-key” project for TM#2 includes stock preparation plant for virgin pulp, AHEAD-2.0S tissue machine with Steel Yankee Dryer TT SYD-15FT, machine auxiliaries including hood and air systems by Milltech, electrification & control system, additional plants and complete engineering and erection activities. Machine speed will be 2000 mpm with a net trim width of 2820 mm and a daily production of 110 tons for the Customer Consumer and Away from Home markets.

The successful cooperation between the two companies, demonstrated in the TM#1 project, as well as the Toscotec technology and its excellence and experience in complex “turn-key” projects worldwide, has been the decisional factor for AMS to choose once again the Italian company for this challenging project.

AHEAD-2.0 line of tissue machines, the company’s best-of-breed range, represents the state-of-the-art for Toscotec technology and it’s designed to satisfy all production needs in terms of both the type of raw materials used and the quality of the end product. The best available technology and a flexible design with tailor made solutions, has been awarding Toscotec for more than 40 orders for AHEAD lines in the last four years, becoming so far the reference tissue machinery supplier in this segment.

The ultimate concept affecting the AHEAD line, that the Company is expected to launch in the next IT’S Tissue edition, is PRODERGY.The new PRODERGY is the first tissue machine that unites top performance in terms of production and end product quality with maximum energy efficiency, as a result of the special configuration of the drying section. With a net trim width of 5600 mm and an operating speed of 2000 mpm and is fitted with steam heated hood by Milltech and the biggest steel Yankee ever built for tissue paper production. So far PRODERGY extends the AHEAD-2.0 line to the new horizon of production of tissue in a sustainable way.

About Toscotec S.p.A.

Since 1948 TOSCOTEC, based in Lucca, Italy, has specialized in machinery for the Tissue and Paper industries. The company provides top of the range machinery and system solutions for complete turn-key plants ranging from 40 to 260 TPD and designs and manufactures TADVISION for the premium tissue and towel markets that require Through Air Dried technology.

Actually Toscotec is the market Leader in Steel Yankee Dryers with sales of over 160 Steel Yankees up to 22’ in diameter and widths up to 6000 (236”mm).

GRIGISKES AB starts up the new TOSCOTEC Tissue Line at Vilnius mill.

Lithuania’s GRIGISKES has successfully started up the new Toscotec-supplied 110 tons/day tissue PM 6 at Vilnius mill. The site already houses the 17,000 tpy tissue PM5 modernized with the installation of a Toscotec Steel Yankee Dryer TT SYD-4200MM in early 2011.

The new Toscotec’s line includes AHEAD-1.5S crescent former tissue machine with single-layer headbox, single press configuration and a Steel Yankee Dryer (TT SYD-15FT), machine auxiliaries (gas heated hood with three stages heat recovery system, machine dust and mist removal system, hall ventilation system were Milltech’s), stock preparation plant for virgin pulp and electrification & control system.

A two unwind stands tissue slitter rewinder TT WIND-M and an automatic roll handling system completed the supply. The machine design speed is 1900 mpm with a net web width of 2750 mm. The project has been managed by Toscotec on an EPC (Engneering, Procurement & Construction) basis.

"As announced earlier, erection of new production line was terminated in the beginning of March. All components of new machine were tested during first half of month and this week we produced the first batch of paper. We are very happy to announce that production start was smooth, and quality of first paper batch supports our optimistic belief in rightness of the investment. Having started production with new paper machine, we expect fast growth of our turnover and profit." - Gintautas Pangonis, president of GRIGISKES AB says.

New paper production line will match the needs of Company's processing lines of paper products and will allow further development of paper production and sales. ([..]RISI)

Toscotec S.p.A.

T. +39 0583 40871 – F. + 39 0583 4087 800