Displaying items by tag: abb

ABB and Cartiera Fornaci partner to transform paper testing

Leading Italian manufacturer of recycled cardboard, Cartiera Fornaci, has placed an order for ABB’s L&W Autoline paper testing equipment to be installed at its board mill in Fagnano Olona, Italy. The compact version of the technology unit will automate Cartiera Fornaci’s entire paper testing process, enhancing efficiency, accuracy and sustainability.

- Italian recycled cardboard manufacturer chooses ABB’s L&W Autoline for automated paper testing

- L&W Autoline streamlines operations, boosts quality and offers significant waste reduction

- Win highlights the growing trend of smaller mills embracing digital transformation for efficiency and sustainability

Cartiera Fornaci has been a staple of the Italian pulp and paper industry for over 60 years. Cartiera Fornaci’s mill, which delivers 55,000 tons of recycled cardboard between 360 to 1000g/m2 to its customers yearly, will leverage the L&W Autoline solution to replace its current manual testing processes. Some of the mill’s testing is currently carried out manually and in writing, a time-consuming process prone to human error. With the implementation of L&W Autoline, the Fornaci mill team will benefit from automated paper testing, which is typically 10 times faster than manual testing, with complete results available in under 10 minutes.

Armed with these insights, Cartiera Fornaci will be empowered to make more informed decisions and take quicker corrective action and adjust their processes and parameters in real time. These optimizations will deliver increased efficiencies with significant waste reduction, saving energy and raw materials usage.

“We are excited to partner with ABB as they support us on our journey of digital transformation,” said Benedetta Cattaneo, Managing Director at Cartiera Fornaci. “We were captivated by L&W Autoline from the first demonstration and can clearly see the value it will deliver to our mill as we move away from manual, time intensive processes into a new age of automated insights.”

“While large mills have historically led the way in adopting technologies enabling digital transformation, smaller mills are increasingly recognizing the significant benefits digitalization and automation offers and its importance in keeping pace with larger players,” said Erik Teunissen, Area Sales Manager, ABB Italy. “We hope that Cartiera Fornaci’s adoption of the L&W Autoline sets a positive example for other smaller mills looking to enhance their competitiveness and sustainability in the evolving pulp and paper industry.”

ABB’s L&W Autoline is the fastest and most reliable automated paper testing solution. It meets current industry standards (ISO/TAPPI) and delivers accurate and repeatable quality reports in minutes, allowing production to react faster to process disturbances.

The scope of the testing modules includes: Bendtsen Roughness, Thickness, Moisture, Burst P, Bending 50 mm, Grammage.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

ABB control room, power distribution and robotics technologies help Metsä Fibre mill excel in productivity and efficiency

ABB’s control room environment, power distribution and robotics have been a part of Metsä Fibre’s technologically advanced sawmill’s pioneering levels of productivity and efficiency. The customer’s Rauma mill is Finland’s largest ever sawmill investment at €260 million and uses machine vision, artificial intelligence (AI) and integrated information systems for consistent quality and cost efficiency.

- Rauma sawmill in Finland has been designed to reach productivity levels that are three times higher than typical outputs in Europe

- Metsä Fibre’s €260 million project represents the country’s largest ever sawmill investment

- The sawmill turns out a maximum of 40 logs per minute on a 130-meter sawline, reaching speeds up to 250 meters per minute

Building on a long-term relationship with parent company Metsä Group, ABB provided Extended Operator Workplace (EOW) tables for maximum ergonomics, visualization and communication, as well as electrical power distribution, transformers and robots. Since the technologies were commissioned a year ago the sawmill has turned out 40 logs per minute on a 130-meter sawline with a maximum sawing speed of 250 meters per minute, all managed from an ABB-designed central control room. The sawn pine timber is exported worldwide and can be used in construction – including windows, doors and general joinery, woodworking, furniture and packaging.

“With the support of partners, including ABB, we are achieving productivity that is at least three times higher than what is possible across the rest of Europe,” said Jaakko Vierola, Technical Director of the Rauma sawmill project, Metsä Fibre. “The durability of components and the service ABB provides exactly when we need it are crucial.”

The electrical distribution system with medium voltage and distribution transformers was designed and delivered by ABB. ABB’s robots, motors and drives were connected to other equipment, with 1,000 variable speed drives considered to be crucial to automation optimization. The overall speed of the process is also due to a group of six robots equipped with machine vision.

Metsä Fibre and ABB specialists have worked together to maximize automated data collection through a third-party automation system. The strategy has been to use high levels of monitoring for quality and performance, minimize wood waste through sawing and sizing optimization and eliminate manual handling through robots and automatic loading at the 24/7 mill. The sawmill’s by-products such as wood chips, sawdust and bark are used to produce pulp and bioenergy.

“The Rauma sawmill operates much like a process industry plant, where equipment cannot be maintained at night or on weekends, but electrical devices must always be reliable,” said Esa Kivioja, Industry Segment Manager for ABB in Finland. “Here, we implemented the sawmill's power distribution with the same quality standards as we did in Metsä Fibre's bioproduct mills in Äänekoski and Kemi. This is a whole new concept in mechanical forest industry facilities.”

“The energy efficiency of motors and other electrical equipment also plays a role. The impact of ABB's deliveries is even more evident in the fact that production can continue without disruptions, and there is no idle time for the equipment.”

To support the Metsä Fibre team and the installed technologies on site, ABB also offers its spare parts and spare equipment services, as well as technical support.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Expect more from your energy management system with ABB

Lower energy consumption, cheaper energy, decarbonization, higher product quality, better asset utilization, improved safety,. . . The pulp & paper industry’s wish list is long. Yet it is also realistic. ABB provides digital solutions so that criteria like these can be managed efficiently, in real time. And they can be implemented step by step, as ambition and insight grow.

Lower energy consumption, cheaper energy, decarbonization, higher product quality, better asset utilization, improved safety,. . . The pulp & paper industry’s wish list is long. Yet it is also realistic. ABB provides digital solutions so that criteria like these can be managed efficiently, in real time. And they can be implemented step by step, as ambition and insight grow.

Let’s assume that you have just left the boardroom and are wondering how you will deliver the annual reduction in energy use and spend that you have just promised, let alone systematically track and report actual consumption and costs. And do it all without diverting your scarce human resources from their main job of getting the product out on time and exactly according to the specification. If you are like most companies, you probably lack good systems for accessing energy data quickly or in a form that will steer the path to achieving your goals. The deployed databases, systems, and applications tend to be multiple and scattered around the mill, with users focusing on only part of the picture.

For managers, sustainability, and energy efficiency experts at UPM, ABB makes the situation visible at a glance, in real time, across 14 mills in Europe. They can search for improvement potential; visualize how they are progressing towards their energy performance goals and compare their plant with world-class performers. Not just for electricity, but also water, steam, environmental KPIs. The true savings come from how the management drives accountability - by assigning targets and actual results according to people roles and responsibilities. Energy and sustainability data is automatically and consistently aggregated in the appropriate line of command. Alarms and events are assigned to alert personnel should energy consumption be off target and draw the user’s attention to ‘hot spots’. ABB’s industrial-grade energy management system is certified according to ISO 50’001 Energy Management Standard - establishing necessary structures to sustain results over time.

The truth about your energy bill

While the value of energy reductions should not be trivialized it is only part of the strategy. One key component is the management of energy contracts. The contracts with most providers are several hundred pages in length and contain numerous schedules that outline pricing based on consumption rates and time of day. Effectively reconciling the usage invoiced from the supplier with the contract terms, even at a macro level, is a time consuming and manually intensive exercise that is often maintained by a single individual within the organization. If estimation of the energy usage after the fact is based on average values, money is left on the table.

Energy procurement planning and forecasting

Article by - Anis Korchi - Global Portfolio Manager for Sustainability in the Digital Business Line, Process Industries, ABB.ABB’s software helps UPM, SAPPI and other mills accurately model the energy consumption inside the mill, to understand how it relates to changes in the production plan, what additional energy sources are available, and what subsystems can have power shed if needed. With the forecasts based on actual production plan it can ensure that the contractual obligations for energy purchases are satisfied in the most cost-effective way, avoiding excess usage or peak time tariffs and penalties. All our clients using load planning and forecasting solution report that they easily save 2-4% of the overall purchase energy price, with a return on investment of just months.

Article by - Anis Korchi - Global Portfolio Manager for Sustainability in the Digital Business Line, Process Industries, ABB.ABB’s software helps UPM, SAPPI and other mills accurately model the energy consumption inside the mill, to understand how it relates to changes in the production plan, what additional energy sources are available, and what subsystems can have power shed if needed. With the forecasts based on actual production plan it can ensure that the contractual obligations for energy purchases are satisfied in the most cost-effective way, avoiding excess usage or peak time tariffs and penalties. All our clients using load planning and forecasting solution report that they easily save 2-4% of the overall purchase energy price, with a return on investment of just months.

Demand side management to optimize energy costs

Possibly one of the most critical uses of energy information is to optimally shift the energy usage at times of lower energy prices, when production constraints allow. ABB has successfully implemented a project at MKK mechanical pulp mill in Austria when operations schedules get automatically adjusted according to electricity spot price driving up to 15% of energy cost reduction. The software leverages existing process flexibilities to improve profitability, making sure energy is balanced without jeopardizing production.

The energy management can be further connected to the various operations management systems such as the manufacturing execution system (MES), asset performance management (APM), advanced process control (APC) and AI/ML analytics – including the steam/power and water treatment optimizations. Considering digital solutions in additional areas as well as systems integration and industrial cyber security aspects, can have a major impact on your financial improvements, sustainable development, and reputation.

learn more: https://new.abb.com/industrial-software/sustainability/energy-management-system-enms

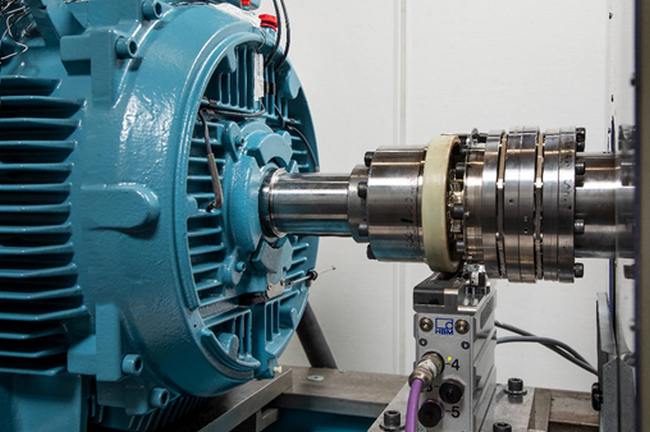

ABB is first in world to deliver IE5 ultra-premium motor efficiency in explosive environments

ABB has extended its award-winning IE5 SynRM (synchronous reluctance motor) series with a brand-new addition: the IE5 SynRM Increased Safety motor. In a world-first, customers operating in hazardous area industries can now ensure safety and boost their energy efficiency by deploying motors that offer up to 40 percent lower energy losses compared to commonly used IE3 motors.

- 40 percent lower energy losses in the most challenging of spaces: hazardous areas

- Cooler-running motor ensures a cost-efficient and competitive solution for increased reliability, lower maintenance needs and a longer life

The new version of the IE5 SynRM motor has been developed for use in potentially explosive atmospheres across a wide range of demanding variable speed industrial applications. It offers accurate control and high efficiency throughout the whole speed range, even at partial loads. This makes it the ideal upgrade choice for standard induction motors in pumps, fans and compressors for industries where explosive gas, vapor or dust might be present, such as oil and gas, chemicals, wood processing and flour milling.

In addition to energy savings, the new SynRM Increased Safety motors can help customers specify a more cost-effective installation. For example, in Zone 1, the cooler running design could allow the use of an increased safety motor where a flameproof motor with a special enclosure would be the traditional choice. While in Zone 2, the improved loadability of SynRM motors, that enables more power to be delivered from the same size as an induction motor, is important. This could enable a smaller, and therefore lower-cost, motor to fulfill the same duty.

Stefan Floeck, Division President IEC Low Voltage Motors, ABB, says: “We have achieved a significant world-first by bringing the benefits of IE5 ultra-premium efficiency to the hazardous area sector. Adopting best-in-class technology has made our IE5 SynRM motors a game-changer for operators in a wide range of industries. They see the capability to improve energy-efficiency as key to achieving their net zero ambitions while optimizing their business costs.”

A key benefit of IE5 SynRM Increased Safety motors is that they run cooler than standard designs. Bearing temperatures are reduced by up to 15°C and winding temperatures by up to 30°C. This provides increased reliability, prolongs the motor’s lifetime and reduces maintenance needs.

The SynRM design combines the performance advantages of permanent magnet technology, with the simplicity and service-friendliness of an induction platform. To ensure an environmentally friendly design, the motors don’t contain magnets or rare earth metals.

IE5 SynRM Increased Safety motors are available with output power of 5.5 to 315 kilowatt (kW) in frame sizes IEC 132-315.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

ABB’s spare parts analytics to optimize operations for Vietnam’s leading paper manufacturer

ABB has successfully devised a spare parts and maintenance program for Saigon Paper, Vietnam’s leading paper manufacturer, enabling the company to drive productivity in their mills.

- ABB leverages its proprietary spare parts analysis tool to help enhance Saigon Paper Corporation’s mill parts inventory

- Accurate spare parts inventory reduces breakdown incidents, improves machine availability and optimizes productivity

- A solid inventory of spare parts offers a competitive advantage, allowing mills to avoid production losses

The ABB team created a recommended spares and gap analysis using mySpareParts Manager, an ABB-facing tool that built a custom report with required distributed control system (DCS) spare parts for Saigon Paper’s operations. Not only did it show how to optimize the cost of inventory and the exact lifecycle of the DCS equipment for advance planning of upgrading and replacing, but it also helped identify the minimum necessary spare parts, expanding initial scope from seven items to fifteen.

With proactive spare parts becoming more important to avoid production losses, having a solid inventory of spare parts is a clear competitive advantage. Saigon Paper will now be able to benefit from reduced breakdown incidents, improved machine availability and optimized productivity with low maintenance costs, while focusing on energy efficiency, further boosting profit margins.

“Our investment in ABB’s service is paying off already by giving us a better overview of the DCS spare parts needed in order to optimize the cost of inventory and improve productivity in our mills,” said Mr Quy Luu Tu, Maintenance Manager of Saigon Paper. “We expect to have the same service from ABB for all other equipment and software as well.”

“Strong collaboration has always been key to our long-standing relationship with Saigon Paper, and this really helped us to better understand their existing spare parts inventory for the entire ABB installed base, while driving towards a sustainable production process,” said Duong TranDai, Business Director, ABB Vietnam.

“Strong collaboration has always been key to our long-standing relationship with Saigon Paper, and this really helped us to better understand their existing spare parts inventory for the entire ABB installed base, while driving towards a sustainable production process,” said Duong TranDai, Business Director, ABB Vietnam.

Saigon Paper Corporation is the leading supplier of quality tissue and industrial paper and owns one of the country’s largest paper mills. Their paper mills collectively have an annual production capacity of 43,680 tons of tissue paper and 224,640 tons of industrial paper.

Both of their mills rely on ABB Ability™ System 800xA DCS to keep production running, and ABB is their long-term partner and preferred supplier for QCS, automation, drives, motors and electrification.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation

Asia Symbol Group in China expands use of ABB’s MES to increase productivity

ABB has been awarded a software and service contract by Asia Symbol Group in China to provide the ABB Ability™ Manufacturing Execution System (MES) for a new production line, with delivery and commissioning ongoing throughout 2022.

- ABB and pulp and paper producer Asia Symbol reinforce long-standing relationship with expansion of ABB Ability™ Manufacturing Execution System (MES) to cover new production line

- Upgrade to extend productivity and profitability at the company’s mill in Guangdong, China

- MES is specifically designed to enable pulp and paper producers to optimize storage, energy and raw material usage

The expansion will help Asia Symbol to optimize its overall production process across all lines at its Guangdong mill, providing better oversight for planning, scheduling and continuously improving efficiency and reducing waste. A rich application experience will give operators greater real-time visibility across the entire manufacturing process, creating a visual factory to ensure the delivery of products of the right quality at the right time.

Specifically designed to enable pulp and paper producers achieve operational excellence and maximum performance, ABB’s MES helps optimize storage, energy and raw material usage, in turn improving product output and quality.

“ABB has been our trusted MES partner due to high competency and clear focus on the entire pulp and paper operation, from mill floor to enterprise level planning. We have benefited from their approach to convert digital data into world-class business results and are looking forward to the expanded use of ABB’s MES over our entire mill,” said Mr. Liang LiFu, IT Manager at Asia Symbol's Guangdong production base.

“Our operations team is commissioning the MES implementation while the other two production lines are still running,” said Shankar Singh, Digital Product Line Manager, Pulp and Paper, ABB. “We are pleased to be supporting Asia Symbol in reaching their operational goals through our MES which will provide transparency across the value chain and optimize material flow within their paper mill.”

This latest contract affirms the strong, long-standing relationship between ABB and Asia Symbol, a world leading producer of pulp and paper under the RGE Group. In recent years this has seen the provision of paper machine drives and QCS products, and the successful extension of ABB’s MES service to Asia Symbol’s three production lines at the Guangdong production base.

Last year, ABB secured another MES upgrade project from APRIL Group for its Kerinci mill in Indonesia, which is also part of RGE Group. The order covers three paper machine lines with 1.5 million tons of annual production and was delivered in Q1 2022.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation

German packaging producer integrates ABB’s automatic paper testing for faster quality insights

Containerboard manufacturer Papierfabrik Adolf Jass Schwarza GmbH has successfully integrated ABB’s latest L&W Autoline automatic testing solution into its production process, largely replacing manual laboratory measurements.

- Papierfabrik Adolf Jass Schwarza GmbH (Jass) has annual capacity of one million tons of corrugated base papers

- Installation of ABB’s next generation L&W Autoline automatic paper testing solution paves way for digitally centralized laboratory

- Jass moves from manual to automated testing for quicker, more frequent results and improved quality optimization opportunities

The move is part of wider digitalization project at the mill, which produces one million tons of corrugated base papers annually, and brings quality inspection closer to the production floor. Jass operators will gain reliable quality insights faster, enabling them to adjust the process and parameters to ensure increased efficiencies through fewer rejects, saving energy and raw materials usage.

Quality data from the L&W Autoline is collected in the mill's quality management system via integration with the ABB Ability™ System 800xA distributed control system and OPC communication, thus adding automated laboratory data to the mill's universal view of product quality.

“The integration of L&W Autoline automatic paper testing means we have completed the move from time-consuming manual paper testing so that our personnel can focus on quality adjustments and optimization for our end products,” said Dr. Uwe Weiss, Technical and Production Manager, Jass. “We are highly satisfied with its performance and already see the benefits of having more quality data in less time.”

“Reducing measurement uncertainty or test variability is at the heart of what automating paper testing systems can provide paper mills, enabling papermakers to make more informed decisions and take quicker corrective action,” said Felix Schäufler, Sales Specialist, ABB. “The addition of the new L&W Autoline, with the latest software standards, provides closer production control, therefore reducing the number of rejects and saving Jass both energy and raw materials.”

ABB’s next-generation L&W Autoline is the fastest and most reliable automated paper testing solution. It meets current industry standards (ISO/TAPPI) and delivers accurate and repeatable quality reports in minutes, allowing production to react faster to process disturbances.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation

ABB supports Sun Paper’s new Beihai mill with automation, electrification and motors order

Sun Paper, in close collaboration with ABB, has successfully launched another pulp mill, at the new Beihai location in Guangxi, China. ABB has installed three sets of its flagship distributed control system (DCS) ABB Ability™ System 800xA®, two sets of mechanical pulp drive systems, four refiner motors and auxiliary high-voltage cabinets, and over 30 high and low-voltage motors.

- Implementation of ABB Ability™ System 800xA® distributed control system (DCS) at Sun Paper’s new pulp mill to drive operational accessibility

- Combined pulp production lines at the new Beihai mill represent the largest pulp production capacity among comparable lines in the global market

- The latest contract marks ABB’s 15th DCS implementation over a 20-year relationship with Sun Paper

The Beihai mill currently produces 600,000 tons of bleached mechanical pulp (APMP line and BCTMP line) and 800,000 tons of bleached pulp (BKP). The combined daily production capacity across the three lines reaches up to 4,200 air-dried tons and currently represents the largest pulp production capacity among comparable lines in the global market.

In addition to DCS implementation, the mill will integrate ABB’s Relion® 615 protection and control series of relays with the 800xA for both the APMP and BCTMP mechanical pulp production lines, together with Load Commuted Inverter (LCI) drives solution. This will enable soft starting for multi-motor connections, significantly reducing the start and stopping impact of the refiner motors on the power grid to ensure production safety and stability.

ABB was able to meet Sun Paper’s objective to strengthen the interconnection between the DCS and laboratory data and gain access to the status monitoring of the refiner motor system. This achieved system-wide centralized information management, helping managers understand on-site conditions in real-time to support their pulp production decisions. They can also manage remote operations and configurations using mobile devices such as tablets and phones, which improves the collaboration and convenience of the system. This advanced setup of the DCS safeguards production stability and lays a solid foundation for future expansion and other digital solutions.

“We have chosen ABB’s solutions over others for years because we greatly value their outstanding product quality and engineering services,” said Mr Ying Guangdong, deputy general manager and chief engineer of Shandong Sun Paper Industry Joint Stock Co. Ltd. “As for the pulp project at the Beihai Mill, the ABB team has consistently demonstrated their excellent project execution and collaborative strengths, ensuring the smooth start-up of our new production line.”

“ABB has been working closely with Sun Paper for over two decades now and this latest strategic cooperation at their new Beihai mill further strengthens our collaboration,” said Mr YueMing Liu, ABB Pulp and Paper Industry lead, North Asia and China. “Our advanced automation, electrification and digital solutions are supporting Sun Paper in their digital transformation and sustainable development journey.”

During their 20+ year collaboration, ABB has provided 15 DCSs to Sun Paper, safeguarding unparalleled system connectivity, as well as a collaborative, real-time decision-making environment for its paper production lines and pulp mills. This latest project follows the recent completion of four pulp production line projects at Sun Paper’s Shandong production base.

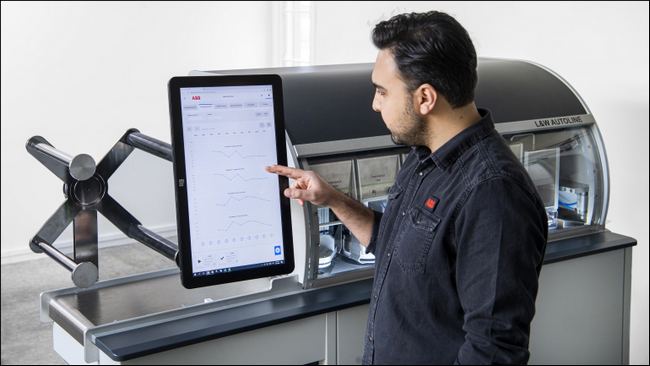

ABB increases Asian automated paper testing footprint with newest solution now in Vietnam

ABB has built on its established relationship with Cheng Loong Corporation by securing a contract to bring its L&W Autoline automated paper testing solution to a mill in Vietnam.

- Moving from manual testing to ABB’s L&W Autoline solution will help Cheng Loong Corporation improve quality and save time

- Contract with paper mill follows previous order in customer’s Taiwan HQ

Cheng Loong Binh Duong Paper Company’s mill in the southeast of Vietnam will now have the market’s fastest and most reliable automated paper testing solution to deliver accurate and repeatable quality reports in minutes. The L&W Autoline will be fitted with modules for thickness, tensile stiffness orientation (TSO), moisture, bursting strength and grammage measurements – improving quality and saving time when compared to stand-alone laboratory testing.

Automated paper testing has traditionally been less common in the Asian market compared to other parts of the world. However, usage is increasing with double the installations in Southeast Asia over recent years, underscoring the need for expedited quality feedback that today’s operations require. Automated paper testing generates frequent, reliable quality information and allows faster process corrections due to quicker tests and more data points.

Technician working with the L&W Autoline user interface

Technician working with the L&W Autoline user interface

The upgrade will replace the mill’s manual laboratory testing, which, despite confirming final product quality does not capture all irregularities nor is produced in real time.

“We were already aware of ABB’s capabilities, and professional consultancy, from other Cheng Loong sites, said Ming-Chun yu, Quality Control Section Supervisor, Cheng Loong Binh Duong Paper Company. “We knew that we needed to make the move to automated paper testing and the L&W Autoline to help us reach our mill’s objectives. We look forward to reaping the benefits of the time savings, increased quality control checks and flexibility in our production.”

“With increased production a key focus for their future, we were convinced that Cheng Loong Binh Duong Paper Company’s mill would benefit the most from automating paper testing to keep up with the new demands,” said Karin Hermansson, Global Product Line Manager, Laboratory Testing and Industry Instrumentation, ABB. “The Binh Duong mill will now have a competitive advantage in its ability to consistently produce a high-quality product while optimizing operational costs. We’re proud to be part of their journey with ABB’s L&W Autoline solution.”

While Cheng Loong’s new containerboard machines (BM2) will make use of the S model, which has space for six automated testing modules; ABB also offers the L&W Autoline L with space for 13 modules. Both models can handle everything from sample preparation to the final reel report with minimal operator involvement, all conforming to industry standards and improving mill efficiency.

ABB extends to offer new insertion design and larger flow-through options

ABB has updated its KPM KC7 Microwave Consistency Transmitter portfolio with a larger flow-through sensor to fit process pipes with a diameter of up to 16”, giving more customers the choice to measure the total consistency of mixed pulps with a flow-through sensor. The technology leader has also launched a redesigned insertion type with a new dual-plate sensor.

- ABB adds redesigned dual-plate insertion model to its KPM KC7 Microwave Consistency Transmitter offering

- New larger flow-through microwave sensor options cater to mill installations that previously could only use insertion types

- Update to portfolio provides most representative process pipe consistency measurement on the market

Both of the device options will be used in the stock preparation area of mills, which feeds the wet end of the paper machine. The enlarged flow-through model, extending from a previous maximum of 12”, expands ABB’s market reach to those with wider diameter pipes that previously could only use insertion types, but that can now consider both. The larger size, capturing the whole pipe diameter, means the most representative measurement on the market and provides precise, reliable measurements of total consistency regardless of flow rate for superior process control.

Both of the device options will be used in the stock preparation area of mills, which feeds the wet end of the paper machine. The enlarged flow-through model, extending from a previous maximum of 12”, expands ABB’s market reach to those with wider diameter pipes that previously could only use insertion types, but that can now consider both. The larger size, capturing the whole pipe diameter, means the most representative measurement on the market and provides precise, reliable measurements of total consistency regardless of flow rate for superior process control.

For mills opting for the insertion style, the dual-plate design is the only one on the market with an optional temperature sensor that can be retracted for abrasive and unscreened processes, a feature also available with the flow-through model. The parallel antennas avoid microwave reflections in the pipe and generate a self-cleaning effect, removing the risk of obstructions and therefore increasing uptime and reducing maintenance costs compared to other devices.

Microwave measurement is becoming more popular due to its low calibration requirements, high accuracy, and ability to measure total consistency independent of process variables and fiber properties. Unlike optical and sheer force technologies, KPM KC7 is unaffected by both process changes, such as flow speed, pressure and turbulence, and variations in pulp species, fiber length and freeness.

“ABB individually verifies each sensor before implementation to ensure high accuracy, said Karin Hermansson, Product Line Manager at ABB. “With this update to fit larger pipes, reduce obstructions and ensure smooth temperature readings for even the most difficult processes, we can now meet the most diverse requirements in the complex world of papermaking.”

The expansion means that ABB’s KPM KC7 sensor portfolio is now equipped with an added pressure sensor – available as a spare part – to further improve diagnostics. With no moving parts or preventive maintenance requirements, the updated sensors - compatible with third-party couplings for simple upgrades and replacements - make for easy operation and maintenance to ensure a low total cost of ownership.

The application usage extends across paper, tissue, board and pulp producers, from recycled pulping to end of machine stock preparation, and can even be used for municipal and industrial wastewater. KPM KC7 is particularly good for users of recycled raw material and pulp and paper mill teams that prefer to measure and control total consistency with microwave technology.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation