Displaying items by tag: alfa laval

New streamlined Alfa Laval Unique Mixproof CIP and Process valves meet market demand

Alfa Laval is unveiling two new hygienic valves, the Alfa Laval Unique Mixproof CIP and Unique Mixproof Process, extending its hygienic double-seat valve range to meet market demands. With the introduction of these two innovative mixproof valves, manufacturers concerned about product integrity now have a cost-effective way to enhance product safety while boosting process efficiency and sustainability.

Proven performance, refined for purpose

These two newcomers are built on proven performance, yet refined for purpose. The Unique Mixproof CIP is a double-seat valve that safely and efficiently manages the flow of cleaning media during cleaning-in-place (CIP). The Unique Mixproof Process, a compact version of proven Alfa Laval double-seat valves, is configurable and available in various sizes to meet manufacturers’ fundamental hygienic processing requirements. Both are capable of simultaneously routing two different fluids without the risk of cross-contamination, thereby contributing to more uptime and reduced total cost of ownership.

“These new Unique Mixproof valves deliver product safety, process flexibility, straightforward maintenance, and opportunities for water and CIP media savings,” says Anders M. Lyhne, Product Portfolio Manager, Alfa Laval.

“These new Unique Mixproof valves deliver product safety, process flexibility, straightforward maintenance, and opportunities for water and CIP media savings,” says Anders M. Lyhne, Product Portfolio Manager, Alfa Laval.

Reliable, cost-effective product protection

Manufacturers can rely on the Unique Mixproof CIP and Unique Mixproof Process for cost-effective product safety. Alfa Laval double seat technology with seat lift keeps the fluids separated, ensuring efficient cleaning and complete protection against the intrusion of harmful microorganisms. With a fully balanced design, the valves can easily handle high pressure without the risk of pressure shocks. Moreover, they are certified according to FDA, 3A and other recognized standards.

Greater process flexibility

Enhance the reliability and flexibility of manufacturing process setups with proven valve technology that matches specific production requirements. Like the entire Alfa Laval Unique Mixproof range, the Unique Mixproof CIP and Unique Mixproof Process valves are compact and modular, offering greater process flexibility. Modular in design and available in types and sizes that suit different applications, the Unique Mixproof CIP and Unique Mixproof Process valves help manufacturers adapt to changing process requirements. Using these valves in combination with the Alfa Laval ThinkTop control units offers even greater process flexibility and control.

Simplified service

Built on the Alfa Laval Unique SSV and Mixproof platforms, these hygienic top-loaded double-seat valves minimize the risk of unplanned downtime while spending as little time and resources as possible on routine maintenance. Proven seal technology with defined compression extends the intervals between service, while a maintenance-free actuator with no adjustable components maximizes uptime and minimizes the total cost of ownership.

Enhanced sustainability

Combined with Alfa Laval ThinkTop, these new Unique Mixproof valves eliminate unnecessary product loss while delivering up to 90% savings in water and CIP media . The reduced use of CIP fluids contributes to a lower total cost of ownership while minimizing the environmental impact in the process industries. Good for people, good for business, and good for the planet.

To learn more, visit www.alfalaval.com/UniqueMixproof/news

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day. It’s all about Advancing betterTM.

Alfa Laval has 16,700 employees. Annual sales in 2020 were SEK 41.5 billion (approx. EUR 4 billion). The company is listed on Nasdaq OMX.

New Alfa Laval ThinkTop pulse seat clean for drain valves saves up to 95% in CIP liquid

Drain valves comprise up to 20% of all valves in a typical processing plant. But cleaning them is costly, difficult and time-consuming due to long cleaning cycles and the risk of pressure shocks. The new Alfa Laval ThinkTop pulse seat clean addresses all these issues, quickly and effectively making drain valves spotless while delivering savings of up to 95% in Cleaning-in-Place (CIP) liquid.

ThinkTop is raising the bar on water savings yet again. The new pulse seat clean feature does for drain valves what the burst seat clean did in 2019 for mixproof valves. While burst seat clean reduces CIP liquid for mixproof valves by up to 90%, the pulse seat clean cuts drain valve CIP liquid consumption by up to 95%.

More savings, more uptime

Imagine the savings made possible by using this standard automated valve-position feature, triggered by a rising programmable logic controller (PLC) signal and controlled by the Alfa Laval ThinkTop V50 and V70 sensing and control units.

“The ThinkTop pulse seat clean brings unheard-of savings in CIP liquid to process plant owners and operators compared to conventional PLC timer-controlled seat cleaning,” says René Stietz, Product Portfolio Manager, Valves and Automation, Alfa Laval. “Alfa Laval is the first and only valve automation solutions provider to deliver significant savings in CIP liquid for drain valves.”

Faster, more effective pulse cleaning

Short bursts, or pulses, drive the valve cleaning process, activating the valve when shear forces peak. Each position-based pulse takes less than a second, preventing pressure shocks in the system. The pulse creates high turbulent flow as the liquid passes through the narrow gap between the valve house and valve seat, effectively removing all residuals for spotless drain valves.

100% cleaning validation of drain valves

The pulse seat clean makes control and validation of valve cleaning cycles easy. The valve position is not controlled by the PLC timer but by the Alfa Laval ThinkTop. Besides reducing the volume of CIP liquid used, programming the sensor to open and close the seat quickly ensures faster, more rigorous cleaning and hygiene than timer-controlled cleaning. The ThinkTop also verifies that valve cleaning has been completed.

Intended for use with single-seat valves or butterfly valves used as drain valves, pulse seat clean is a standard feature of ThinkTop V50 and V70 sensing and control units with one solenoid valve. Regardless of actuator mode, the drain valve may be configured as a normally open or normally closed shutoff or changeover valve. The pulse seat clean simplifies valve commissioning, prevents pressure shocks, and reduces CIP liquid and time.

To learn more, visit www.alfalaval.com/ThinkTop

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day. It’s all about Advancing betterTM.

Alfa Laval has 16,700 employees. Annual sales in 2020 were SEK 41.5 billion (approx. EUR 4 billion). The company is listed on Nasdaq OMX.

New Alfa Laval PlusClean cleaning nozzle revolutionizes tank cleaning with 100% coverage

With the introduction of the new Alfa Laval PlusClean® cleaning nozzle, Alfa Laval’s broad tank cleaning portfolio is set to take a giant leap forward. The PlusClean delivers unprecedented 100% tank cleaning coverage, up to 80% savings in water and cleaning media costs, and no product contamination. Paired with a top-mounted tank cleaning device and installed flush with the tank wall or bottom, the PlusClean raises productivity and lowers total cost of ownership.

No shadows areas, no risk of contamination

“Integrating Alfa Laval PlusClean cleaning nozzles into any tank and tank cleaning process means there’s nowhere for contaminants to hide,” says Janne Pedersen, Global Portfolio Manager, Tank Cleaning, Alfa Laval. “Now the promise of optimal tank cleaning is truly a promise that we can keep. No shadow areas and no risk of product contamination. Period.”

Easy to install, simple to use

With its optimized, high-impact spray pattern, the PlusClean delivers 100% cleaning coverage in shadow areas that other tank cleaning spray nozzles miss. Installed flush with the tank wall or bottom, the cleaning nozzle has a revolutionary, built-in adjustment function that makes installation easy and operation effective, providing cleaning coverage in shadow areas, such as beneath agitator blades. This ensures thorough tank cleaning, unmatched by other tank cleaning devices.

Competitive advantage

Perfect for the pharmaceutical, dairy, food, beverage, and home-personal care industries, this innovative cleaning nozzle provides even more efficient cleaning and improves process efficiency and safety as well as product quality. This translates into higher productivity and increases competitive advantage for those who choose to add the PlusClean to their tank cleaning processes.

Sustainability at the core

At Alfa Laval sustainability is at the core of our business, and the PlusClean is no exception. This revolutionary cleaning nozzle delivers significant water and cleaning media cost savings, minimizing the impact on the environment.

For demanding hygienic applications

The standard Alfa Laval PlusClean is supplied as a media spring-activated cleaning nozzle for hygienic process tank cleaning. A special pneumatic-driven version is also available. For sterile and aseptic process tank cleaning, there’s the Alfa Laval PlusClean UltraPure, which is backed by Alfa Laval Q-doc documentation package to ensure full traceability across the entire supply chain.

Discover how 100% cleaning coverage from the Alfa Laval PlusClean boosts yield and cuts costs. To learn more, visit www.alfalaval.com/plusclean.

For further information, please contact:

Janne Pedersen

Global Portfolio Manager, Tank Cleaning Equipment, Alfa Laval

Phone: +45 22 77 84 52

E-mail: janne.pedersen(at)alfalaval.com

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day. It’s all about Advancing betterTM.

Alfa Laval has 16,700 employees. Annual sales in 2020 were SEK 41.5 billion (approx. EUR 4 billion). The company is listed on Nasdaq OMX.

Easy as this: Reduce cleaning time by 70% and operating cost by up to 80%!

Efficient and cost-effective cleaning

Effective cleaning is critical to product integrity, productivity and profitability in all hygienic industries. By choosing the right cleaning equipment, you can reduce water, chemicals and energy costs as well as decrease cleaning time between production cycles.

Now also retrofitting through small tank openings

Now also retrofitting through small tank openings

As part of the market’s most consistent portfolio of rotary jet head tank cleaning machines, we recently added three Alfa Laval rotary jet heads, GJ A2, GJ A6 and GJ PF FT.

This gives you the opportunity of easy installation of rotary jet head technology in small size tank openings like 3" or 4", where static spray ball and rotary spray heads are normally mounted in today. By retrofitting with one of the three small GJ jet heads, you avoid reworking the tank to accommodate upgrading tank cleaning equipment, meaning low installation cost.

Easy to upgrade from static spray balls

When higher cleaning efficiency is required, it is easy to upgrade your static spray balls to the Alfa Laval GJ Rotary Jet Head technology. Simply unclip the static spray ball and replace it with a new clip-on GJ rotary jet head, that uses a cleaning pattern ensuring dynamic and effective distribution of water to the inner tank surfaces. The high mechanical force generated by the strong jet impingement, efficiently removes remaining products and residues to provide the best conditions required for hygienic production.

Rotary jet heads clean tanks 70% faster than the static spray ball technology. Because of faster cleaning, it uses less water and chemicals - and thereby reducing operating costs by up to 80%. Rotary jet heads provide exceptional cleanability, better and safer end-product quality and greater overall output for all hygienic applications.

By using Alfa Laval tank cleaning machines, you get...

- Faster cleaning = More production uptime

- More efficient cleaning = Minimizing risk of product lost due to contamination

- Impact cleaning = Reducing the use of water and chemicals

- Automated cleaning = Validated process ensuring high product quality

- Fast payback = Often less than 1 year, due to low operating cost

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2016, posted annual sales of about SEK 35.6 billion approx. 3.72 billion Euros. The company has about 17 300 employees.

Save up to 60% time and 70% water with this new powerful tank cleaning machine

Fast and cost effective cleaning

Saving time and water are some of the KPIs which have the most attention in the hygienic industries. The new Alfa Laval TJ40G rotary tank cleaning machine uses a high-impact jet stream to effectively clean tough tank residues and minimize the risk of product contamination. This four-nozzle rotary jet head also cleans tanks 60% faster than static spray ball technology, which increases production uptime. And because it cleans faster, this new device uses less water and less cleaning agents thereby reducing operating costs by up to 70%.

The Alfa Laval TJ40G is capable of handling tough tank residues as well as solids up to 1mm in the cleaning fluid in tank sizes 50-1000 m³. This is particularly important for demanding process lines, such as applications within the brewhouse, where both the size and the amount of particles may be re-circulated in cleaning media before completing the cleaning cycle.

The Alfa Laval TJ40G is capable of handling tough tank residues as well as solids up to 1mm in the cleaning fluid in tank sizes 50-1000 m³. This is particularly important for demanding process lines, such as applications within the brewhouse, where both the size and the amount of particles may be re-circulated in cleaning media before completing the cleaning cycle.

Complete self-cleaning system

Not only does the Alfa Laval TJ40G rotary tank cleaning machine provide spotless cleaning of the tank interior, it also cleans itself – inside and out.

Its hygienic self-cleaning construction ensures that the flow of the cleaning fluid reaches the exterior surfaces of the rotary jet head, as well as the critical interior components such as all bushings, bearings and inner surfaces. This minimizes the risk of product contamination and ensures a high product quality.

Alfa Laval's rotary tank cleaning machines are designed with numerous of features to ensure self-cleaning of the machine, such as directional flow from small jets in the hub that cleans the exterior of the machine. A low pressure loss over the machine provides increased cleaning efficiency compared with other tank cleaning machine running at same inlet pressure. This result in lower cleaning cost as the unit can run at lower pressure/flow compared to other tank cleaning machines.

All Alfa Laval rotary tank cleaning devices comply with Good Manufacturing Practice (GMP).

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2015, posted annual sales of about SEK 39.7 billion (approx. 4.25 billion Euros). The company has about 17 500 employees.

This is it! Don’t let poor tank cleaning performance waste your time, water and energy

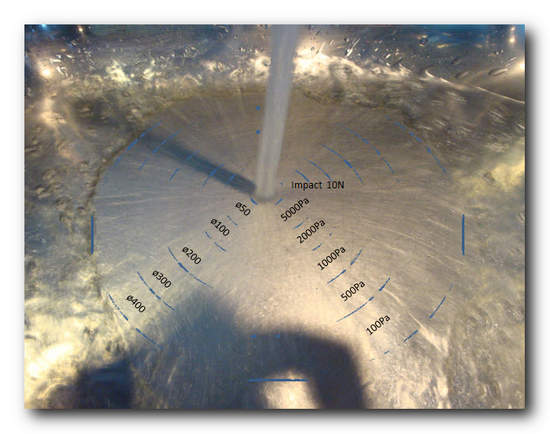

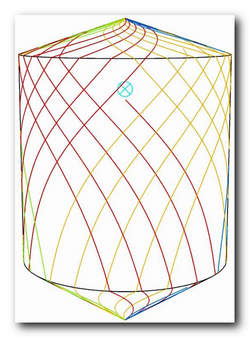

When the water jet, coming from a rotary jet head cleaning device, hits the tank wall, it generates a force of impact (N). After impact, the jet spreads out and creates a cleaning footprint with high wall sheer stress force (Pa). As the cleaning machine is rotating in a 3D motion, the footprint is "moving" around inside the tank in a predefined pattern and cleans the entire tank surface with high wall shear stress. The further away from the impact point the less wall shear stress (mechanical action) is achieved.

Traditional spray balls are static. This means the majority of the tank cleaning energy comes from water cascading down over the tank wall at low wall shear stress. This way of cleaning requires large amounts of time, water and energy in order to compensate for the poor cleaning performance.

One cleaning cycle might be sufficient

Because of the unique design of Alfa Laval Rotary Jet Head, the first - out of eight - cleaning cycles is hitting the tank wall at an evenly dense cleaning pattern throughout the entire tank surface. The distance between the footprint tracks is relatively wide, but if the product is easy to clean off (e.g. milk or syrup) it only requires little wall shear stress to be removed. This means the pre-rinse cleaning of the tank is done using only one cleaning cycle and you are saving time, water and energy.

Because of the unique design of Alfa Laval Rotary Jet Head, the first - out of eight - cleaning cycles is hitting the tank wall at an evenly dense cleaning pattern throughout the entire tank surface. The distance between the footprint tracks is relatively wide, but if the product is easy to clean off (e.g. milk or syrup) it only requires little wall shear stress to be removed. This means the pre-rinse cleaning of the tank is done using only one cleaning cycle and you are saving time, water and energy.

One cleaning cycle typically takes 1-3 min. and now that the product is effectively removed from the tank wall, the jet will offset the second cleaning cycle and thereby minimizing the distances between the jets. More cleaning cycles are needed for products that are harder to clean.

Payback time

Compared to a static spray ball, the Alfa Laval Rotary Jet Head is a higher initial investment, but its low operating cost gives a short payback time - often less than one year.

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2015, posted annual sales of about SEK 39.7 billion (approx. 4.25 billion Euros). The company has about 17,500 employees.

Energy efficient pumping and gentle handling of sensitive process fluids

Cutting energy use while safeguarding product quality

Proven performance and reliability

Alfa Laval SRU rotary lobe pumps are carefully engineered to provide reliable performance, trouble-free operation and superior energy efficiency for demanding applications in the dairy, food, beverage, personal care and pharmaceutical industries.

It is an excellent choice for duties that require contamination-free pumps to meet high standards of hygiene, low-shear and low-pulsation operation. This pump handles both Cleaning-in-Place and Sterilization-in-place, and can be supplied with thorough documentation to support rigorous validation requirements.

Consistency with minimal risk of contamination

Alfa Laval SRU rotary lobe pumps are designed with features that maximize performance and minimize the risk of contamination. These include a defined compression front cover sealing, rotor nut retention design, drainable pump head and ultra-clean surface finishes.

Understanding of flow patterns is vital to ensure high efficiency fluid transfer with low pulsation, low shear and low noise characteristics. Alfa Laval employs Computational Fluid Dynamics (CFD) to establish exact geometry for the rotors and rotor case.

Robust construction – low maintenance

To deliver reliable operation and low maintenance the SRU features a robust gearbox construction with heavy-duty shafts, torque locking assemblies and taper roller bearings throughout.

Certification, specification and standards

Alfa Laval SRU rotary lobe pumps comply with EHEDG, 3-A, 3.1 and FDA hygienic standards and have ATEX approval for use in explosive environments.

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2014, posted annual sales of about SEK 35.1 billion (approx. 3.85 billion Euros). The company has about 18 000 employees.

The economic and sustainable choice for tank cleaning

When higher cleaning efficiency is required, it is easy to upgrade from static spray balls to the Alfa Laval Toftejorg SaniMidget SB Rotary Spray Head technology. Simply unclip the static spray ball and replace it with a new clip-on rotary spray head, which uses a spray pattern ensuring dynamic and effective distribution of rinse water to the inner tank surfaces in delivering the best cleaning results.

As the spray head rotates, its fans produce an impact on the tank wall and a well distributed falling film without the cascading flow that can be experienced with static spray balls. The result is better cleaning performance than a static spray ball.

Its perfectly flushed bearings and crevice-free design optimize cleaning procedures. Self-draining and self-cleaning, both inside and out, its spray head complies with current Good Manufacturing Practices and delivers up to 70% savings on water, chemicals and energy.

Performance reliability and long service life

Designed with minimal pressure loss, the Alfa Laval Toftejorg SaniMidget SB Rotary Spray Head starts to rotate at pressures of less than 0.1 bar. It is made of safe, non-reactive and hygienic materials to ensuring product quality and they hold the 3A and EHEDG certifications. Rotary spray head technology has proven successful in providing reliable and repeatable cleaning performance and a long service life.

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2014, posted annual sales of about SEK 35.1 billion (approx. 3.85 billion Euros). The company has about 18 000 employees.

Unmatched mixing performance

Alfa Laval Rotary Jet Mixer effectively handles liquid and powder mixing, gas dispersion and Cleaning-in-Place (CIP) while reducing time, energy and costs.

Alfa Laval Rotary Jet Mixer effectively handles liquid and powder mixing, gas dispersion and Cleaning-in-Place (CIP) while reducing time, energy and costs.

In many applications the Alfa Laval Rotary Jet Mixer provides a faster and more efficient mixing than conventional methods. It combines high blending precision with minimized mixing times and up to 50% reduction in energy requirements. Based on rotary jet head technology, it can be used in tanks between 100 and 800,000 liters in size.

Equipped with two or four nozzles, the Rotary Jet Mixer is positioned below liquid level in the tank. Liquid is withdrawn from the tank outlet by a pump and circulated via an external loop to the mixer. It helps reduce operating expenses while achieving fast and efficient mixing. A single Rotary Jet Mixer can handle liquid mixing, gas dispersion and powder dispersion applications – plus tank cleaning – without requiring separate equipment for each process, thereby delivering significant savings.

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2014, posted annual sales of about SEK 35.1 billion (approx. 3.85 billion Euros). The company has about 18 000 employees.

Alfa Laval expands aftermarket business, acquires niche company with sales of SEK 50 million

Alfa Laval Group – a world leader in heat transfer, centrifugal separation and fluid handling – has acquired an aftermarket company, specialized in separation technology. The company will remain a separate organization and offer its own parts and services under its own brand name. Revenues are estimated to reach about SEK 50 million this year and the company is consolidated as from July 3, 2015.

Alfa Laval Group – a world leader in heat transfer, centrifugal separation and fluid handling – has acquired an aftermarket company, specialized in separation technology. The company will remain a separate organization and offer its own parts and services under its own brand name. Revenues are estimated to reach about SEK 50 million this year and the company is consolidated as from July 3, 2015.

The acquisition is in line with the strategy of the Alfa Laval Group of acquiring companies that complement the existing business in terms of products, geography or in the form of new sales channels. In this case the Alfa Laval Group adds a complementary aftermarket channel.

“With the acquisitions we are adding presence in an important niche of the aftermarket,” says Lars Renström, President and CEO of the Alfa Laval Group. “

Did you know that… the value of the aftermarket for separation is estimated to be four times the value of new sales?

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2014, posted annual sales of about SEK 35.1 billion (approx. 3.85 billion Euros). The company has about 18 000 employees.