Displaying items by tag: korber

Körber Business Area Tissue’s Tissue Innovation Days to start again on September 27 and October 4

Over the course of these two days customers and partners will be able to discover the innovations that Körber Business Area Tissue is developing in the automation and digital fields

In order to meet the needs of all customers and partners there are two sessions scheduled by Körber Business Area Tissue for each of the themed days of September 27 and October 4.

Mauro Luna, Chief Sales & Marketing Officer Körber Business Area TissueSeptember 27 will focus on Auto Web Starter, an innovative solution in the field of automation in the tissue industry. During the two sessions scheduled for this day it will be possible to discover and discuss how the use of fully automated systems can help in the management and processing of tissue.

Mauro Luna, Chief Sales & Marketing Officer Körber Business Area TissueSeptember 27 will focus on Auto Web Starter, an innovative solution in the field of automation in the tissue industry. During the two sessions scheduled for this day it will be possible to discover and discuss how the use of fully automated systems can help in the management and processing of tissue.

On October 4 the two sessions will be dedicated to presenting Körber’s digital offers, a selection of intelligent services and solutions that combine artificial intelligence and big data with the technological experience that distinguishes the machines developed and presented on the market by Körber Business Area Tissue. An example of these solutions is FactoryPal's Boost designed to constantly optimize machine settings for maximum OEE.

“We are happy restart the Tissue Innovation Days after the summer break. These days are of great value for us, not only to create new bonds and consolidate existing relationships with our customers, but also because these are important occasions to let companies know the different fields in which we at Körber Business Area Tissue can support their business as a strategic partner offering 360 ° solutions” comments Mauro Luna, Chief Sales & Marketing Officer Körber Business Area Tissue.

To subscribe to the webinar just register at the following link: Tissue Innovation Days_ 27thSeptember-4thOctober_2022

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 12,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Technologies and Tissue, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

South Florida Tissue Paper chooses Körber Business Area Tissue technologies to expand its business in the retail sector

The rising costs of raw materials and product transport due to reduced imports from the Chinese market are the main variables that are creating price increases with the risk of penalizing sales in the US tissue market, even though, paradoxically, demand in some regions is greater than available local production capacity.

An example of this is Florida, a territory that in recent years has experienced exponential growth in population thanks to an increase in births and greater employment of immigrants.

It’s in this context that South Florida Tissue Paper, a third-generation company founded in Miami in 1997, aims to become the main player not only in the AFH (Away From Home) sector by consolidating its positioning but by expanding its own work in new business areas such as retail tissue.

In order to better approach the market, the company needed to have a technology capable of increasing capacity, versatility, and automation at every stage of the conversion process while ensuring a high quality of the finished product. “We were looking for a strategic partner able to understand the logic of the American market, able to offer not only advanced and competitive technologies but 360 ° consultancy that anticipates the needs of the tissue sector. We found all these characteristics in Körber” comments Juan Corzo III, VP of Operations at South Florida Tissue Paper.

In order to better approach the market, the company needed to have a technology capable of increasing capacity, versatility, and automation at every stage of the conversion process while ensuring a high quality of the finished product. “We were looking for a strategic partner able to understand the logic of the American market, able to offer not only advanced and competitive technologies but 360 ° consultancy that anticipates the needs of the tissue sector. We found all these characteristics in Körber” comments Juan Corzo III, VP of Operations at South Florida Tissue Paper.

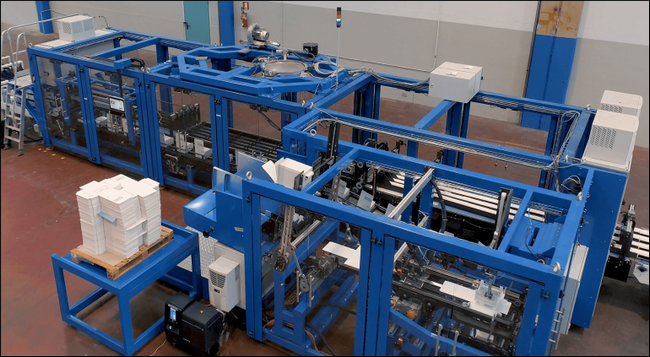

The perfect solution for the company is the Perini Myline from Körber. This line has been designed for the production of toilet and kitchen paper rolls up to 200 mm, or 8 inches, in diameter, and is capable of handling parent rolls up to 2500 mm, or 98 inches, in diameter at a speed maximum of 600m / min and a production of 40 logs/min.

The Perini Myline is a well-established technology, with more than 60 lines sold around the world since 2016. The Perini Myline rewinder is based on the well-established Sincro exchange phase system. The technology offers the perfect balance between cost and OEE to maximize ROI and guarantees simplicity of operation and easy maintenance. The line is also equipped with a laminator-embosser with 409mm diameter steel rollers, and it is water lamination capable utilizing Körber's Aquabond technology which eliminates the use of glue, making it greener, more efficient, and less expensive.

“With the view of developing our business, we had two different requirements: to select a line that would increase our production capacity and identify a trustworthy partner capable of providing careful and timely technical support. With Körber's Perini Myline we are convinced that we have found a reliable, efficient solution to help us consolidate not only our role in the AFH sector but also to be able to compete in the retail sector. In addition, with Körber Business Area Tissue’s local assistance we can be sure of relying on an experienced partner who is available at any time to provide personal assistance for every need," comments Juan Corzo III.

“Tradition and innovation have always been part of Körber's core business. We believe in the value of relationships and in the constant exchange of information with our customers in order to offer them innovative solutions that can support and diversify their business. We are honoured that South Florida Tissue Paper has chosen Körber Business Area Tissue as a strategic partner to consolidate their presence in the American market and develop their retail business" comments Claudio Muñoz, Marketing Director at Körber Business Area Tissue.

South Florida Tissue Paper

South Florida Tissue Paper Company is a family-owned and operated company that has been providing services and the finest products since its start in 1997 in Miami, FL. Production began with the Jumbo Roll Tissue and the Center Pull Towels which quickly expanded to a diverse variety of paper products for the away-from-home market throughout the years. South Florida Tissue Paper Company provides state-of-the-art paper product fabrication and we are able to control every step of the process from our modern facilities. Our Miami manufacturing facility produces a wide range of paper products and distributes them nationwide as well as internationally to South America, Central America and the Caribbean. With the expansion of South Florida Tissue Paper Company Dominican Republic (Inpaca), we have been able to expand into other markets internationally.

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customer's operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 12,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape technological change. In the Business Areas of Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations, we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

Körber opens its doors to its suppliers on 15 June 2022 for Körber Italian Supplier Day

Collaboration, sustainability, and innovation: these are the topics around which the Körber Italian Supplier Day is centered

The pandemic has changed the dynamics of all markets, highlighting the criticalities issue of the economies but at the same time opening up new opportunities. Supply Chain is one of the business sectors that have been affected significantly and companies and suppliers alike are facing new challenges.

Paolo Sodero, Head of Purchasing of Körber Business Area TissueKörber thanks to its experience in the sector and its cutting-edge research and development centre, is evolving from a simple machinery supplier to a strategic partner of technologically advanced solutions through the Körber ecosystem. With an ear to the market, the company shares all critical issues with customers and suppliers and understands the demands imposed by the tissue sector by comparing individual expertise to offer innovative, advanced, and sustainable solutions.

Paolo Sodero, Head of Purchasing of Körber Business Area TissueKörber thanks to its experience in the sector and its cutting-edge research and development centre, is evolving from a simple machinery supplier to a strategic partner of technologically advanced solutions through the Körber ecosystem. With an ear to the market, the company shares all critical issues with customers and suppliers and understands the demands imposed by the tissue sector by comparing individual expertise to offer innovative, advanced, and sustainable solutions.

"In order to strengthen ties and further refine the collaboration for the future, we have created this day dedicated to Körber suppliers to continue to create value together and dive into dialogue about current and future challenges of the sector" comments Paolo Sodero, Head of Purchasing of Körber Business Area Tissue.

During this day, selected partners will have the opportunity to participate in thematic workshops and learn about the ecosystem with the Körber Business Area Tissue representatives. A revolutionary market approach that allows all the technologies involved in the tissue converting process to be integrated into a single solution: from raw material to finished product, all the way up to distribution logistics.

"Synergy: this is the key word for a day which aims to be a moment of discussion on the present but at the same time a moment to discuss new ideas, express needs and challenges to develop joint new strategies for the future. The value and voice of suppliers are essential stimuli to further innovate and offer the market solutions that are even more performing, efficient, and sustainable than the current ones ". concludes Paolo Sodero.

The day will end with the Safety Contractor Awards, an acknowledgement to those suppliers who were the most outstanding in terms of compliance with safety and control procedures. The goal of the event is to focus on the issue of sustainability, a key element in the supply chain. To gain a better understanding of social, environmental as well as governance practices and activities and elaborate joint initiatives for a better future, Körber, is currently introducing a digital platform for collecting sustainability data from suppliers. as part of the next steps to achieve the sustainability target of the Group.

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers' operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape technological change. In the Business Areas of Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations, we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

An electromagnetic induction system for hot embossing: a cutting-edge technology, well ahead of other roll heating systems.

At iT’s Tissue 2022, Körber Business Area Tissue unveils a further evolution: Warm-up Contactless Double.

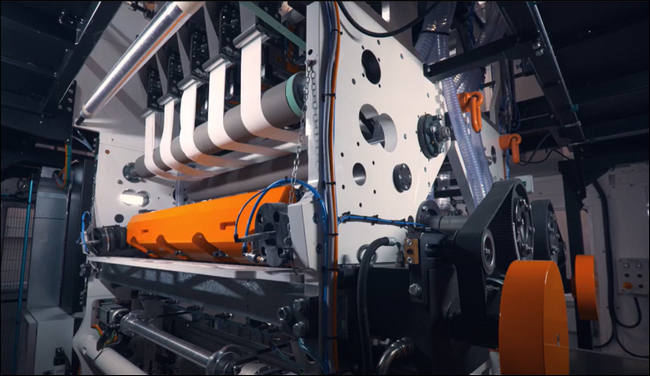

The traditional systems for heating embossing rolls using piping with hot oil or pressurized water, or with heating elements, use up large amounts of energy, have high heat dissipation and are underperforming.

Andrea Gambini, Global Research & Development Director of Körber Business Area Tissue"The heating systems used so far in production," comments Eng. Andrea Gambini, Global Research & Development Director of Körber Business Area Tissue, "are now too underperforming: heating the embossing roll by means of a hot liquid flowing inside it requires a high use of energy, as does trying to heat it with a heating system with resistors. Oil systems require dedicated facilities to heat and recirculate large masses of oil, greatly impacting the environment and creating unsustainable conditions. In addition, these factors contribute to lower overall equipment efficiency (OEE)."

Andrea Gambini, Global Research & Development Director of Körber Business Area Tissue"The heating systems used so far in production," comments Eng. Andrea Gambini, Global Research & Development Director of Körber Business Area Tissue, "are now too underperforming: heating the embossing roll by means of a hot liquid flowing inside it requires a high use of energy, as does trying to heat it with a heating system with resistors. Oil systems require dedicated facilities to heat and recirculate large masses of oil, greatly impacting the environment and creating unsustainable conditions. In addition, these factors contribute to lower overall equipment efficiency (OEE)."

The tissue market is constantly evolving," says Eng. Gambini, "and with it comes the need to offer more effective, efficient, sustainable and user-friendly solutions. Safety, simplicity, flexibility and efficiency: are the cornerstones on which the Warm-up Contactless Double system is likewise based. It will be presented at iT's Tissue 2022 on the in-phase DESL (Double Embosser Synchronizer Lamination) product and it will be possible to have a tangible example of how it works and how easy it is to integrate into the new 456AX embosser to achieve maximum production efficiency. And now that induction heating is finally doubled, all the benefits are also doubled.

"Our patented Warm-up Contactless system," says Eng. Gambini, "heats the embossing rolls from the outside without any physical contact with the rolls themselves and reduces heating times by 1/3, resulting in energy savings of more than 60%. This system can be used with any existing engraved rolls and is designed not to interfere with the operator's work." These features combine to show how state-of-the-art is the Warm-up Contactless system and demonstrate how Körber Business Area Tissue cares about sustainability.

"Building on our experience in the tissue industry, with the desire to innovate by offering our customers more innovative technological solutions, our R&D centre has further advanced Warm-up Contactless by expanding our product portfolio with the double embossing system, which retains all the advantages of the solution already on the market, and allows it to be used in the production of kitchen towels as well," concludes Eng. Gambini.

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customer's operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape technological change. In the Business Areas of Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations, we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

Körber Business Area Tissue’s R&D presents a new folding head capable of changing the product’s cut off

MTC ITF Change is the new machine for the production of interfolded products that is able to change the cut-off format of the product simply by replacing the cassette

Körber Business Area Tissue is introducing to the market MTC ITF Change, the first solution capable of modifying the cut off of the product. By replacing a single cassette it is possible to change the cut format in a simple, fast, and automated way without compromising the quality of the finished product.

MTC ITF Change is the ideal solution for companies that need to develop interfolded sheets of different lengths without losing OEE.

Patented by Körber Business Area Tissue, the MTC ITF Change has only two folding rolls, which the cutting function is incorporated into.

The cassette can be replaced automatically with a few manual operations without the intervention of a specialized operator.

The preparation of the cassette with a different format takes place in advance in the warehouse, outside the machine, and the replacement occurs with a few simple manual operations that do not require the intervention of a skilled worker. The adjustment of the new product with the help of Körber’s Sam systems is completely automated. The MTC Sam reel system reads the characteristics of the parent reel and sends the data to the production line which automatically adapts the operating parameters through dedicated software.

The preparation of the cassette with a different format takes place in advance in the warehouse, outside the machine, and the replacement occurs with a few simple manual operations that do not require the intervention of a skilled worker. The adjustment of the new product with the help of Körber’s Sam systems is completely automated. The MTC Sam reel system reads the characteristics of the parent reel and sends the data to the production line which automatically adapts the operating parameters through dedicated software.

The right vacuum level is self-adjusted with MTC Sam vacuum, and thanks to MTC Sam cut system the operator is no longer responsible for verifying that the cutting blade is in optimal conditions. If the system detects a quality problem it will send a warning directly via HMI, thereby preventing any product defects, interruptions, or line stoppages.

Another advantage is that the maintenance of MTC ITF Change is performed offline, offering greater convenience for the operator who does not have to intervene inside the machine, allowing a significant reduction in production downtime

“The fold market is constantly evolving according to market trends. Over the years, customers have increasingly expressed the need to be able to customize their offer. To meet this need, and thanks to the experience gained in the interleaved sector, we decided to develop a flexible solution capable of automatically changing the cutting length based on the desired characteristics. The innovative technology created for the fold market will allow our customers to further expand their business “comments Giovacchino Giurlani, Managing Director of Körber Business Area Tissue’s fold division.

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

Körber’s solutions are able to respond to the changing needs of the packaging market

Modular, flexible, intuitive: Körber Business Area Tissue offers its customers a wide range of packaging solutions to meet every need, we well as an innovative product specifically for the North American market

Understanding the demands of the market, anticipating the requirements of its customers, and promptly responding to the changing needs of the tissue sector: this is what makes Körber Business Area Tissue a strategic partner that offers companies targeted solutions aimed at increasing and developing new business segments.

Research and innovation have always been central tenets of the company, which, thanks to its wide range of packaging solutions, offers modular, flexible and easy-to-install machines. Körber Business Area Tissue supports customers in choosing the best technology to produce quality tissue products in a market that is in constant evolution.

The efficient, safe, and sustainable packaging solutions created by Körber Business Area Tissue demonstrates the power of what can happen when the history of performance and the future of innovation come together. See the most recent packaging innovation by the company:

Casmatic Zephyrus A completely new and patented innovation in the tissue sector that uses delta robot technology to pick the tissue products in carton boxes, offering high flexibility in production thanks to the possibility of increasing capacity by adding specific modules. It can be integrated into an existing packaging line between the log saw and the packaging machine with the possibility of producing in three different modes: Full production, Mixed production, and Bypass. In the first it packs all the product made by the converting line, in the second it lets through all the product that is packaged by a traditional wrapper, and the third is a mix of both. The customer can thus produce additional and sustainable pack formats made out of cardboard and microwaved carton, with the possibility to expand its business, with minimum impact on the existing layout. The delta robots ensure maximum flexibility and precision in product handling, providing the ability to package different products at the same time. With this new solution the boxes can be made with recyclable cardboard and furthermore, once opened, the box can be closed again, keeping the product uncontaminated and easy to store. The use of this technology allows you to develop and increase the business related to e-commerce in a simple, fast, and personalized way.

Casmatic CMB 270 A high-speed bundling machine that has proven to be among the most reliable and performing on the market. Designed to produce up to 27 bundles per minute in a wide range of formats, it is equipped with intelligent systems to easily, quickly, and automatically change format. Furthermore, thanks to the TOSS longitudinal welding system, the solution allows a 60% reduction in air and energy consumption compared to existing models on the market. Casmatic CMB 270 is also available in the NA version. The Casmatic CMB 270 NA version has been modified to accept all US and Canadian bundle formats on one machine using an innovative triple infeed system: stacker, bypass and revolver upender. The stacker allows for production of bundles with cores horizontal, while the revolver upender allows the handling of products requiring bundles with cores vertical. This patented infeed replaces the stacker for the revolver upender in a matter of minutes thanks to a simple, fully automated changeover that operators activate from the HMI panel.

Casmatic A6T XL A solution designed for certain geographic market areas, such as North America, which require taller packages up to 410 mm in height. The core of this innovation lies in the insertion of a series of four pneumatic cylinders that allow the entire towing unit to be lifted when there is a need to create formats higher than 305 mm.

The machine allows you to process different types of products according to individual needs: single rolls with a diameter of up to 240 mm, rolls with a diameter of up to 205 mm for two-ply formats, and finally, rolls with a diameter of up to 135 mm for three-ply formats. The customer can thus adapt the existing formats with large diameter rolls, enabling him to keep up with emerging market trends.

To improve the quality of the sealing, A6T XL has a system of split sealing belts, which decouples the output speed of the packs from the tow and that of the belts, lowering the temperature and reducing energy consumption during side sealing.

Carbon T wrapper machine designed to achieve maximum performance in terms of production yield. This machine reaches a speed of over 200 packs per minute, ensuring a very high level of quality of the finished product. Extremely versatile and easy to use thanks to the automatic format change, which also includes the automatic management of the trolleys through the patented Trolley One Touch system. Even less experienced operators can easily and safely manage the machine.

The quality of the primary packaging is automatically monitored by Casmatic Sam pack, a solution that is able to manage any defective packages through a series of HD cameras and light bars that scan each side of the package. Through a neural network instructed by a deep learning algorithm, the solution is able to detect most visible defects for any format, so any non-compliant packages can be managed as needed. Casmatic Sam Pack then manages all the production data in a database, so that all the desired quality control analyzes can be performed.

“The global pandemic has revolutionized the world, and has highlighted the need to address the ever-growing requirements that the tissue market has manifested and is still highlighting. Two trends have emerged from these evolutions between supply and demand in recent years: e-commerce and sustainability. Thanks to a wide range of packaging solutions, Körber Business Area Tissue is able to support customers in developing their business by offering the desired degree of customization in line with emerging market needs." Commented Nicolò Squarzoni, Körber Business Area Tissue’s Product Manager.

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

Körber Business Area Tissue will be present at Tissue World in Miami with solutions specifically for the packaging sector

With its longstanding experience in the tissue packaging sector and its ecosystem approach, Körber Business Area Tissue, at the Tissue World in Miami, will present new and innovative technological solutions for the North American market to support customers in their continued business growth.

The tissue industry is facing significant pressures in terms of commodity price volatility, competition in global markets and increased demand for product differentiation. This is a highly challenging scenario, especially considering that the environmental impact of the tissue industry must also be increasingly taken into account.

Pete Augustine, President of Körber Business Area Tissue North AmericaTo address the changing needs of both market and customers, Körber is positioning itself as a strategic partner capable of providing comprehensive solutions such as the “Körber ecosystem.” The ecosystem includes all the know-how and expertise of the Group’s various Business Areas, from Supply Chain all the way to the most advanced artificial intelligence software. Thanks to this approach Körber is the only truly integrated and global supplier with an exclusive product portfolio on the market and a global presence.

Pete Augustine, President of Körber Business Area Tissue North AmericaTo address the changing needs of both market and customers, Körber is positioning itself as a strategic partner capable of providing comprehensive solutions such as the “Körber ecosystem.” The ecosystem includes all the know-how and expertise of the Group’s various Business Areas, from Supply Chain all the way to the most advanced artificial intelligence software. Thanks to this approach Körber is the only truly integrated and global supplier with an exclusive product portfolio on the market and a global presence.

Körber Business Area Tissue will be present at Tissue World in Miami from 16th to 18th March 2022 at stand D20 to present new packaging solutions with technologies that provide the perfect balance between sustainability, efficiency, and profitability.

The American market is characterized by its constant search for automation, efficiency, and new technologies that are capable of creating large format packs, especially as e-commerce is still booming.

Körber's R&D also plays a key role in designing solutions for the packaging of high-performance, automated, easy-to-use tissue products that also allow the development and growth of business related to e-commerce.

A speech by Pete Augustine, President of Körber Business Area Tissue North America, is planned for March 17th at 3.30 pm ET (USA). Among other things he will provide an overview of the latest technological solutions developed by the company in the field of packaging and how they can help tissue manufacturers and converters to develop their business.

These are some of the innovations that will be presented at the event:

- Casmatic A6T XL, a new version of the best-selling wrapper Casmatic A6T, that meets requirements for large tissue packs up to 16”/ 410mm.

- Casmatic Zephyrus, a new modular, flexible and easy to install model that introduces a new concept of sustainable packaging that is suitable for e-commerce sales

- Casmatic CMB270 NA – a bundler designed specifically for the North America market, able to offer greater versatility and speed for the formats that are most in demand in the American market.

- Sam Pack - The exclusive system for automatic monitoring and quality management of primary packaging which, thanks to the use of artificial intelligence, stands out for its precision, reliability and ease of use.

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

Körber Business Area Tissue presents an interfolded napkin that’s perfect for wrapping tacos

Thanks to MTC ITF omni taquera it’s possible to create facial products, towels, folded toilet paper, and taco napkins with a dispenser using one single machine

Körber Business Area Tissue’s latest innovation enables to create the complete line of interfolded products (facial, towels, folded toilet paper, napkins), including napkins for wrapping tacos, with a single machine.

Stefano Anelli, Körber Business Area Tissue Fold Sales Manager, comments: “The South American market needed to have a napkin specifically designed for wrapping tacos. From this need and from the collaboration between the sales office, research & development, and specialized technicians, the MTC ITF omni taquera was born, an extremely versatile solution that can be installed on the MTC IFT omni lines that allows to produce all the interfolded products, including the napkins for tacos, with a single bending head.”

Ideal for companies that work with diversified clientele, the taquera option can be integrated on all MTC ITF omni lines and offers a competitive advantage for all those companies looking for a flexible and versatile solution that’s capable of responding to changing market needs.

MTC ITF omni taquera combined with automatic packaging of napkins in a portable dispenser with serial extraction is a very contemporary solution because it allows to preserve the hygiene and safety of the finished product while avoiding contamination of the wipes.

Anelli concludes: "Thanks to MTC ITF omni taquera Körber Business Area Tissue confirms its role as a company that is attentive to offering its customers cutting-edge and innovative solutions. The know-how acquired over the years in the fold sector and the continuous desire to create highly performing products has allowed the company to develop a competitive product with high growth margins. The solution created for the South American market, in fact, can be used in different sectors with similar product needs. "

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

Engraving Solutions: Focus on sustainability with Buy-Back and Rised, the solutions that give new life to embossing rolls

Engraving Solutions, the Körber Group company that specializes in designing and engraving embossing rolls, presents two innovative services that meet tissue manufacturers’ demand for products with a low environmental impact.

Giacomo Tambellini, Sales Account and Product Engineer comments: "For some time we have observed that our customers have two major needs: on the one hand they need solutions that limit the waste of energy and raw materials, and on the other hand they are concerned with cost saving. With the two new Buy-Back and Rised services, we believe we have responded to both requirements”.

Buy-Back and Rised are complementary: the first is in fact a buy-back service, conceived after a careful evaluation of the unused embossing rollers by the Körber purchasing department; the engraved pattern on the roller is immediately destroyed and the surface regenerated to be used again.

The second service is Rised, thanks to which a new roller is made starting from the one regenerated. The result is a product with the same performance as the new one, but at a lower cost.

Tambellini concludes: "This is a truly circular economy: thanks to the buy-back service, unused rollers are recycled, while with Rised products are created as new, safeguarding the environment by reducing the emissions necessary to build new ones".

Körber Business Area Tissue: double-digit growth, continued market leadership in Europe and North America and development of its core business in China, Latin America, and Africa

These are landmark results in a sector that has developed in different ways during the pandemic: on the one hand costs of raw materials and energy increased; on the other hand, new opportunities arose within the fields of e-commerce and of eco-sustainable products.

Oswaldo Cruz Jr., Chief Executive Officer of the Körber Business Area Tissue, comments: “Our customers are under tremendous pressure. There is certainly a great demand for tissue products, but due to the increase in costs, their margins decreased. It is therefore important to actively support them in terms of speed and technologically advanced solutions and services, but more importantly through an integrated approach to help them to reduce costs ".

Oswaldo Cruz Jr., Chief Executive OfficerTherefore, to respond to developments and stay at the forefront of shaping our customers’ success, the Körber Business Area Tissue is evolving more and more from a machinery supplier to a strategic partner that provides broader solutions. This includes for example combining skills in converting and packaging with those of other Business Areas within the Körber ecosystem, such as the Business Area Supply Chain’s cutting-edge logistics, or the Business Area Digital’s cloud-based technology and advanced AI-driven software.

Oswaldo Cruz Jr., Chief Executive OfficerTherefore, to respond to developments and stay at the forefront of shaping our customers’ success, the Körber Business Area Tissue is evolving more and more from a machinery supplier to a strategic partner that provides broader solutions. This includes for example combining skills in converting and packaging with those of other Business Areas within the Körber ecosystem, such as the Business Area Supply Chain’s cutting-edge logistics, or the Business Area Digital’s cloud-based technology and advanced AI-driven software.

This approach is complemented by the characteristics that have made Körber the only truly integrated and global supplier in recent years with an exclusive product portfolio on the market and a global presence. Mauro Luna, Chief Sales & Marketing Officer of the Körber Business Area Tissue continues: “Think globally, act locally- is our great strength in addition to our large portfolio that allows us to serve different requirements. In China for example, practical and solid products without a core are preferred, so we offer technologies such as Solid + that enable our customers to manufacture such products. In the United States soft and voluminous products are preferred, so we offer Perini Constellation, which makes uniform and soft rolls at very high speeds.

Our broad range of product is supplemented by an on-the-ground presence throughout the world: in addition to the Tuscan headquarters with the plants in Lucca, Bologna and Porcari, there are production facilities in the United States, Brazil, China, and offices in Japan with a total of over 1.200 people employed. This enables us to operate a considerable sales force and number of technicians worldwide who can respond to customer inquiries quickly and promptly”.

This global setup is also vital for product development. In China for example, alternative fibers to cellulose such as bamboo or wheat have already been used for some time. We adapt and offer the expertise gained from working with these alternative fibers easily for other markets.

Another key element that in 2021 enabled Körber Business Area Tissue to support clients in overcoming their challenges and achieving their Overall Equipment Effectiveness objectives was certainly innovation, which is never an end in itself, but always aims to increase production efficiency or support customers in the development of new business, such as e-commerce.

Luca Frasnetti Chief Technology Officer of the Körber Business Area Tissue concludes: "This year there are three key innovations that we have presented and that will mark our development for the next few years. Warm-up Contactless, a breakthrough innovation that uses induction for embossing; Casmatic Zephyrus that allows our customers to develop and increase business related to e-commerce in a simple, fast and personalized way; and SAMs, real-time production supervisors which identify any possible deviation from what has been established and take appropriate decisions within the previously established limits, regardless of an operator's skill level".

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.