Displaying items by tag: voith

Voith successfully starts up the rebuilt XcelLine PM 11 at heinzelpaper Laakirchen

The leading full-line supplier Voith has successfully completed the rebuild of the PM 11 at the heinzelpaper plant in Laakirchen, enabling the XcelLine paper machine to produce up to 470,000 tons of corrugated base paper per year. The conversion from graphic papers to corrugated base papers marks a significant milestone for the Austrian company, which looks back on a longstanding partnership with Voith.

- PM 11 produces up to 470,000 tons of corrugated base paper per year.

- Voith solutions enable the production of low basis weights at high speeds.

- As the leading full-line supplier, Voith delivered a tailor-made, end-to-end package for efficient and sustainable corrugated base paper production.

“This large and technologically demanding rebuild is proof of our vision and the strength of our partnership with Voith,” said Dr. Thomas Welt, CEO of heinzelpaper. “The fast and high-quality XcelLine PM 11 will set a new benchmark for efficient and sustainable paper production. With this rebuild, we have clearly demonstrated how sustainable solutions contribute to more efficient paper production. We are very satisfied with the project progress and the successful start-up. My thanks go to the entire Laakirchen and Voith team!”

Voith supplied a complete tailor-made package of highly efficient components, including proven stabilization and drying concepts and a comprehensive engineering package. These solutions enable efficient and sustainable production of low basis weights at high speeds, thereby contributing significantly to increasing production capacity from 330,000 tons to 470,000 tons per year.

The entire paper machine fabrics, including installation, is also part of the scope of supply. Ideal conditioning of the forming wires is ensured by the Voith CleanLine Excell, which is supplied with the fabrics. With the help of the Forming OnQ-Sense, which was also supplied and installed, heinzelpaper Laakirchen can ensure a reduction in vacuum while maintaining the same dry content, thus saving energy in the long term. The installed ProTect crossbars enable press felt measurements to be carried out while the machine is running without personnel having to enter the press interior.

“The successful start-up of PM 11 at heinzelpaper Laakirchen demonstrates our high level of expertise in delivering customized solutions that meet the specific requirements of our customers,” said Martin Jauch, Senior Vice President Rebuilds at Voith Paper. “Our goal was to enable more resource-efficient operation after the rebuild while maximizing the machine's potential with solutions that will last for decades. We are proud to be working with heinzelpaper Laakirchen again and to be making a significant contribution to their sustainable growth.”

During the rebuild, the paper machine and two VariTop reel stands were retrofitted, numerous components were relocated, and the web guide was adapted to the new requirements. Special attention was given to optimizing the Tandem NipcoFlex press to enable stable web running without breaks. In addition, the Voith experts installed a new SpeedSizer for applying surface strength and an energy-efficient post-dryer section. The necessary control and regulation changes were implemented by installing efficient automation systems from Voith.

With this successful start-up, Voith strengthens its position as a reliable partner to the paper industry and a leading full-line supplier for efficient and sustainable paper production.

About heinzelpaper

The heinzelpaper site combines the Laakirchen and Steyrermühl mills in Upper Austria, which are located just a few kilometers apart. As part of the Heinzel Group, heinzelpaper stands for a strong combination of tradition, innovation and sustainability in paper production.

The Laakirchen mill specializes in the production of environmentally friendly, lightweight corrugated base papers made from recycled paper for the European market. Production runs on the PM10 paper machine and, since April 2025, on the new PM11.

At the Steyrermühl mill, the PM6 paper machine, which belongs to the Group's sister company heinzelpöls, produces high-quality kraft papers that cover a wide range of packaging and specialty papers for a variety of customer requirements.

The long-established Laakirchen and Steyrermühl mills were founded in 1867 and 1868, respectively, and today employ around 700 people at the heinzelpaper site.

About Heinzel Group

Heinzel Group produces market pulp and packaging paper at three locations in Europe and trades in pulp, paper, waste paper and packaging solutions worldwide. With the production companies heinzelpöls, heinzelpaper and Estonian Cell, Heinzel Group is one of the most important pulp and paper producers in Central and Eastern Europe. The three trading companies of Heinzel Group – heinzelsales, Europapier and Bunzl & Biach – respond flexibly to the most diverse customer needs internationally. The growth success of the Heinzel Group is based on entrepreneurial spirit and a focus on long-term partnerships. Sustainability is the focus of all its activities.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport. Founded in 1867, Voith today has around 22,000 employees, sales of € 5.2 billion and locations in over 60 countries worldwide and thus is one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and supports customers in significantly reducing their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve the availability and efficiency of their systems in all sections of the production process.

Enhancing suction roll performance with TrackLight AR

Suction zones and seal strips are typically inaccessible within the suction roll. With TrackLight AR, Voith offers a virtual window into the roll, enabling real-time monitoring of both the suction box and the edge deckle position. This technology ensures consistent settings and minimizes downtime for suction roll maintenance.

Suction rolls play a crucial role in the papermaking process. Their primary function is to remove moisture from the paper web. “With the perfect setting, we maximize dewatering for a high dry content. When the suction rolls perform at optimal levels, tension is maintained, and the paper web is guided accurately through the machine. This ensures smooth and controlled runability and operation,” explains Halim Takhedmit, Digital Product Manager at Voith Paper.

Suction rolls play a crucial role in the papermaking process. Their primary function is to remove moisture from the paper web. “With the perfect setting, we maximize dewatering for a high dry content. When the suction rolls perform at optimal levels, tension is maintained, and the paper web is guided accurately through the machine. This ensures smooth and controlled runability and operation,” explains Halim Takhedmit, Digital Product Manager at Voith Paper.

The ability to having the roll perpetually correctly adjusted increases dewatering and resource savings. With positioning of the suction box of the forming roll, it is possible to influence the dry content of the paper web by 1 to 2 %.

Optimum adjustment is the biggest challenge and requires a high level of expertise, because the operator cannot look inside the suction roll. Suction zones are restricted through sealing strips and edge deckles. Neither are visible and can only be identified through markings on tender side. The suction roll shell covers the suction box, so sealing strips are also not visible.

“With TrackLight AR, we enable the operator to virtually look into the roll and adjust the settings more quickly and precisely. Therefore, we can reduce downtimes and increase stable operation. This tool allows very easy handling and a high level of user friendliness,” says Stephan Sicking, Vice President Sales EMEA at Voith Paper.

When setting up TrackLight AR, experts at Voith workshops conduct precise measurements of the roll and proceed to build and test the digital twin of the suction zone. Finally, the product is seamlessly set up at the site, ensuring a smooth integration into the papermaking process.

Voith and Sun Paper achieve early start-up of Nanning PM 2 and PM 3 state-of-the-art packaging paper machine

Recently, Sun Paper's two state-of-the-art packaging paper machines PM 2 and PM 3 were successfully commissioned at the Nanning, China site within one month. PM 3 successfully passed the tests in only three weeks and achieved a record-breaking start-up time of only one hour from stock on wire to the first saleable paper roll. With the start-up of the two state-of-the-art XcelLine machines from Voith, Sun Paper consolidates its leading position in the global paper industry and sets another milestone in the long-standing cooperation between the two companies. The exceptional performance is the result of many years of trust and close cooperation between the Sun Paper and Voith teams. The daily exchange of knowledge and thorough project preparation led to significantly reduced downtimes during project implementation.

- Within a month, Sun Paper has started up two packaging paper machines ahead of schedule – this is the fourth follow-up order of this kind between Voith and Sun Paper

- PM 3 sets a new start-up world record: Only one hour from stock on wire to the first saleable paper roll

- Voith's XcelLine machines are characterized by the highest performance: PM 2 reached the designed production within three weeks after start-up, PM 3 within two weeks. The paper produced is of stable quality and already meets customer requirements from the first reel

“PM 2 and PM 3 in Nanning are the 13th and 14th paper machines in the partnership between Sun Paper and Voith. Our long-standing cooperation with Voith has taught us that a good business relationship is not only based on one-time success but also on mutual support and long-term growth,” says Li Lu, Chairman of Sun Holdings Group. “We continue to work closely together in the packaging paper business. From PMs 31/32 and PMs 36/37 in Zoucheng to PM 1/2s in Laos and PMs 2/3 in Nanning, we and Voith have demonstrated through concrete actions that a true partnership is based on deep mutual trust and shared values.”

“The highly efficient implementation and rapid commissioning of the Nanning project is just one example of this successful long-term strategic alliance,” confirms Ying Guangdong, Vice General Manager and Chief Engineer of Sun Paper. “It not only strengthens the cooperation between Sun Paper and Voith in the field of packaging paper but also shows our determination to jointly seek sustainable and innovative solutions.”

Operating efficiency is an important parameter to judge the success of a project, according to Fu Guoling, Project Director of Nanning PM 2/3 and Zoucheng PM 36/37 production line, and continues, “Voith's machines have superior performance: PM 2 reaches designed production within three weeks after start-up, PM 3 within two weeks”, Guoling explains. “The paper is of excellent and stable quality and has been very well received by the market. At the same time, excellent management on both sides has significantly shortened the project duration, resulting in an even faster economic profitability. In addition, the installation of two machines for the left and right sides optimizes the investment by reducing operating and maintenance costs, maximizing the utilization of raw materials, and thus further improving economic return.”

The PM 2 and PM 3 machines in Nanning have a wire width of 7.3 m and has achieved a design speed of 1,200 m/min. PM 2 produces high-quality packaging paper with a basis weight of 140-250 gsm and an annual capacity of around 520,000 tons. PM 3 specializes in high-quality packaging paper with a basis weight between 100-160 gsm and has an annual capacity of around 480,000 tons. As the leading full-line supplier, Voith supplied all components from headbox to reel, including industry-leading automatic control systems and digitalization solutions from the Papermaking 4.0 portfolio, such as MCS, QCS and OnCare.Health.

Kurt Yu, President of Voith Paper Asia, says, “We are very honored to be the key partner in Sun Paper's ambitious plans for the packaging paper sector. Each follow-up order is not only a recognition of the product, but also an expression of appreciation for our many years of trustful cooperation.”

With the successful commissioning of the two machines in Nanning, Sun Paper achieves a significant milestone in the coordinated development of the Guangxi Beihai-Nanning region and its sites in Shandong, Laos and Guangxi. This step strengthens the company's position and promotes the creation of a self-sufficient forest pulp-paper system. Through a low-carbon, circulating production chain, Sun Paper ensures efficient raw material control and strengthens its competitiveness in the market.

About Sun Paper

Founded in 1982, Shandong Sun Paper is a leader in the papermaking industry in China. It ranks among China's Fortune 500 companies and is one of the world's 30 largest paper manufacturers. It has been awarded the National Green Factory recognition. The company possesses strong technological innovation capabilities, being responsible for one project in the National 863 Program and over 30 technology research projects at national and provincial levels, as well as being the proud recipient of significant technology innovation awards such as first place in the National Prize for Progress in Science and Technology, the Commendation Award in the China Grand Awards for Industry, and second place in the National Award for Technological Invention. By inventing the world’s first process of continuous cooking of dissolved wood pulp, extracting xylose from hydrolyzed liquid, and making the world’s first sheet of chemical-free paper in its “Additive Free” household paper range, the company has achieved “Three World Firsts” with its technological innovations.

Sun Papers strives to implement its ESG policies to create a sustainable and respected world-class enterprise. Based on its leading implementation and outstanding achievements in years of environmental, social and corporate governance management, Sun Paper (002078.SZ) has been incorporated by Hang Seng Indexes as one of the constituents in the Hang Seng (China A) Corporate Sustainability Benchmark Index. The company is proud to be amongst China's Top 100 ESG Listed Companies, and has been incorporated into the China Securities Index’s Securities Times ESG 100 Index.

About Sun Holdings

Shandong Sun Holdings Group Co. Ltd. is the controlling shareholder of Sun Paper and a leading cross-national papermaking group integrating forestry, pulp and papermaking. For a long time, Sun Holdings has been unwavering in its implementation of new development strategies, deepening its promotion of replacing old energies with new, expanding foreign business, implementing the “double carbon” strategy and actively participating in the “One Belt One Road” initiative. It has strived to create a green circulatory production chain that integrates forestry, pulp and papermaking, pushing ahead with a highly efficient and coordinated development of the three important bases of Shandong, Guangxi and Laos. In 2022, Sun Holdings achieved a 70.6 billion Yuan turnover, becoming one of China's 500 largest companies and one of the top 500 Chinese private enterprises. It ranked first in an Overall Review of the Top 10 Papermaking Enterprises in China's Light Industry.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, Voith today has around 21,000 employees and earns 4.9 billion euros in sales. It has locations in more than 60 countries and is one of Europe’s major family-owned companies.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

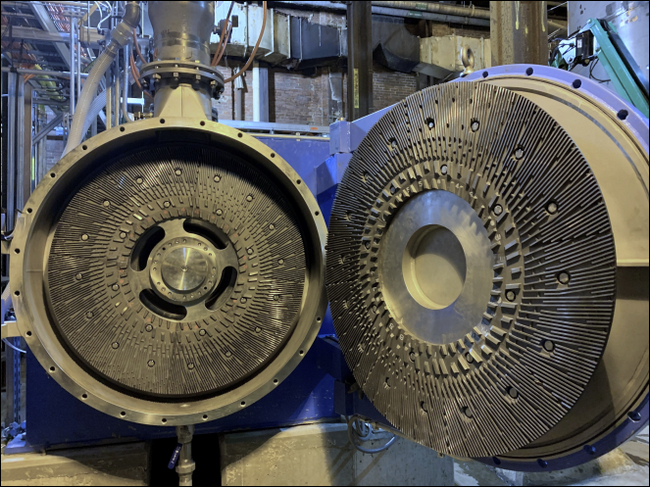

Voith introduces new Pluralis Hot Stock (HS) refiner fillings

Voith is supplementing its proven Pluralis family with new Pluralis Hot Stock (HS) refiner fillings. Representing a significant advancement in refining technology, they are specifically designed to meet the demanding requirements of pulp mills and to minimize resource consumption. In addition, Pluralis HS refiner fillings can significantly improve paper quality, energy efficiency and overall pulp mill performance.

- The latest solution in refining offers significant energy and raw material savings for pulp mills and hence promotes sustainability

- Designed for high shive reduction and improved throughput

- The use of an STT alloy provides increased abrasion resistance and longer service life

“The new Pluralis Hot Stock refiner fillings combine the high efficiency of the leading Pluralis technology with ideal shive reduction,” says Elias Fleschhut, Global Product Manager at Voith Paper. “Offering impressive shive reduction of 75 to 90 percent, HS fillings significantly increase fiber yield and reduce energy consumption.”

Designed for long service life and highest production throughput

The use of STT alloy provides increased abrasion resistance and longer service life, even under the harsh conditions of a pulp mill with operating temperatures above 90 °C and high throughput requirements. The arrangement of the bars in a non-parallel orientation ensures that the edges intersect at an optimal angle and treat the largest possible percentage of fibers. The design was developed specifically for high kappa pulps and offers the highest production throughput and high shive reduction with extended service life.

Pluralis HS refiner fillings can be used in Voith refiners as well as refiners from other common manufacturers with diameters from 20 to 54 inches.

To learn more about fiber preparation and Voith's proven Pluralis product line, please visit: https://voith.com/corp-en/papermaking/fiber-treatment-with-pluralis-and-thewall.html.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith continues its growth path in a difficult market environment: Sales and earnings targets met

The Voith Group performed satisfactorily in a challenging environment over the 2022/23 fiscal year (October 1, 2022 to September 30, 2023). Both in terms of operating business and financially, Voith remains in a robust position. The Company increased all key performance indicators in the reporting year and reached the defined growth and earnings objectives. Group net income improved compared to the previous year. The broad sectoral and geographical diversification, the established market position in the three Group Divisions and regional supply chains contributed to the encouraging development.

- Orders received see a favorable development, orders on hand once again at all-time high

- Group sales (+13 percent) and EBIT increased

- Increase in cash flow and Group net income

- All three Group Divisions make contribution to positive development

“In the past fiscal year, Voith has once again proven its resilience. Despite a challenging economic environment, we continued to generate profitable growth and increased cash flow. The clear focus on sustainable technologies is paying off,” comments Dr. Toralf Haag, CEO of Voith.

2022/23 fiscal year at a glance: All key performance indicators improved

The Voith Group increased all of its key performance indicators over the 2022/23 fiscal year. All three Group Divisions contributed to this development.

At € 6.14 billion, orders received exceeded expectations once again and increased 19 percent on the high level seen in the previous year. The orders on hand reached a new all-time high at € 7.22 billion. Over the same period, Group sales rose by 13 percent to € 5.51 billion. The operating result (EBIT) was € 245 million. The return on sales improved to 4.4 percent (previous year: 4.1 percent), while the return on capital employed (ROCE) increased to 12.1 percent (previous year: 10.5 percent). The Group net income rose to € 73 million as a result of the favorable development of the operating business over the reporting period and despite the higher interest rate level and the associated increase in financing costs.

The increase in earnings was achieved and further investments in the future were made. Expenditure on research & development increased by 9 percent to € 232 million. Financially, the Voith Group remains in a sound position. The equity ratio stood at 23.9 percent in the reporting year (previous year: 24.1 percent). The operating net cash flow saw a positive development in comparison to the previous year and returned a figure of € 306 million (previous year: € 93 million). Likewise, the net debt also improved.

Dr. Toralf Haag: “Our net assets and financial position are sound. The reliable long-term access to capital gives us the necessary entrepreneurial scope to invest in further profitable growth and into the future viability of Voith.”

Strategic focus: Industrial sustainability

Voith continues its commitment to the megatrends of decarbonization and digitalization. The ongoing transformation from a traditional mechanical engineering company to a sustainable technology group with a high level of digital expertise offers promising new business opportunities. To this end, Voith is continually investing in the strategic and technological refinement of its product portfolio, in new growth areas as well as in efficient structures and processes.

Voith has identified hydrogen technology, electrical drive systems, cargo rail and energy storage as growth areas – with the objective to use Voith’s existing broad expertise in the areas of hydropower, paper production, mobility and industrial applications beyond the current product portfolio.

Along with organic growth, Voith benefited from two acquisitions in the Group Division Turbo in the reporting period. IGW Rail (acquired in October 2022) and Argo-Hytos (acquired in August 2022) were included for the first time and for the full fiscal year for the first time, respectively, in the reporting year. This resulted in an acquisition-related increase of around € 210 million in orders received and around € 230 million in sales.

In the 2022/23 fiscal year, all three Group Divisions contributed to positive development

The Group Division Hydro sustained its position in the 2022/23 fiscal year in an ongoing challenging market environment. Orders received grew to € 1.92 billion (previous year: € 1.18 billion). One of the main reasons for the growth is the increase in volume in a current major project. Sales improved to € 1.19 billion (previous year: € 1.05 billion). EBIT increased minimally to € 6 million (previous year: € 2 million). Increasing profitability remains an important objective for the Group Division Hydro.

The Group Division Paper once again made the largest contribution to the sales and earnings of the Voith Group. The operating result (EBIT) reached € 145 million (previous year: € 131 million). Sales grew to € 2.24 billion (previous year: € 2.20 billion). Orders received decreased slightly on the high previous-year figure to € 2.10 billion (previous year: € 2.26 billion).

The Group Division Turbo recorded the clearest sales and EBIT growth of all three Group Divisions, also benefiting from the two acquisitions. Sales and EBIT increased to € 1.99 billion (previous year: € 1.56 billion) and € 80 million (previous year: € 48 million), respectively. Orders received grew from € 1.64 billion to € 2.05 billion.

Outlook 2023/24 fiscal year: Slight decline on high level of orders received and sales, further increase in earnings anticipated

The current 2023/24 fiscal year is accompanied by great economic and geopolitical uncertainties. Alongside the war in Ukraine, these include the new conflict in the Middle East. Economic factors are also placing a burden on the development of the global economy. The extraordinarily high inflation rates in most countries and the associated restrictive monetary policy by central banks are dampening global economic growth. The growth prospects worldwide are continuing to deteriorate as a result.

Voith sees itself well prepared to meet these challenges. The broad sectoral and geographical diversification; the established market position in all three Group Divisions; and, a sound balance sheet makes the Company resilient. A conscious decision has been made to continue investing, even in times of crisis, in research and development, partnerships and innovations, vocational training and in the ongoing strategic and organizational development of the Company. By doing so, Voith is in a good position to continue generating sustainable and profitable growth.

For the 2023/24 fiscal year, Voith expects a stable development in its key performance indicators. In particular, profitability shall further improve. With regard to the operating result (EBIT), the Company assumes a slight increase. Likewise, growth in the return on capital employed (ROCE) is planned. The level of orders received and Group sales below the high figures seen in the reporting year is anticipated.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, Voith today has around 21,000 employees and earns 4.9 billion euros in sales. It has locations in more than 60 countries and is one of Europe’s major family-owned companies.

Successful start-up of Asia Symbol's Rugao board machine 13

At the end of October, Voith successfully started up Asia Symbol's BM 13 at Rugao, 180 km north of Shanghai, China. The state-of-the-art machine is 8.16 m wide with a design speed of 1,400 m/min and an annual capacity of around one million tons. It mainly produces high-quality white folding boxboard in the basis weight range of 170 to 400 gsm.

- Asia Symbol's Rugao BM 13 starts up successfully and will produce one million tons of high-quality white folding boxboard per year

- The full line was supplied by Voith and is characterized by excellent performance in terms of product quality, production efficiency, and operating and maintenance costs

- Project reflects important partnership between Voith and Asia Symbol and reinforces the strategic alliance of both companies in the paper industry

“Voith has always been a reliable partner for us. Thanks to Voith's full-line package, the Rugao BM 13 achieves excellent results in terms of product quality, production efficiency, and operating and maintenance costs, which further strengthens our competitive advantage in the market,” says Eric Xu, General Manager Rugao BM 13 of Asia Symbol.

“I thank both teams for the successful start-up! Asia Symbol is a partner that always sets new goals to achieve excellence. We look forward to deepening our business relationship in the future,” says Carlos Lin, Senior Vice President Order Execution and Operations, Voith Paper Asia.

The full-line solution supplied by Voith for the Rugao BM 13 includes a wide portfolio of state-of-the-art solutions, from BlueLine stock preparation and intelligent XcelLine paper machine to two VariFlex Performance winders with a fully automated Flying Splice reel change. For the plant, Voith and Asia Symbol placed a special focus on sustainable and efficient solutions. In addition to the resource-saving Triple NipcoFlex press, an energy-efficient EcoHood dryer hood, ropeless transfer in the dryer section and contactless qDry Pro drying with the HelioX infrared emitters are installed. Voith also supplied a comprehensive wear parts package and a wide range of automation solutions, including the OnControl MCS, DCS, Drive Control, OnQuality MD/CD Control and the OnCare Health condition monitoring system.

Successful project despite challenges

Despite a tight timeframe, complex tasks and challenging conditions due to the global pandemic, the project was successfully implemented. The project team benefited from mutual trust based on many years of successful cooperation. The Voith and Asia Symbol team worked cross-nationally with the local teams and enabled a smooth execution of the project through very close and committed cooperation from planning to implementation.

The commissioning of Rugao BM 13 now strengthens Asia Symbol's market position and reinforces its supply chain. The line supports Asia Symbol's goal of reducing CO2 emissions from paper production and promoting the joint development of local upstream and downstream industries. The start-up has laid a solid foundation for future cooperation and development between the two parties, which aim to further deepen their collaboration in the fields of technological innovation and sustainable development.

About Asia Symbol

Asia Symbol is a world leading producer of pulp and paper under the RGE Group. Its main products are BHKP, NBKP, DP, liquid packaging board, high grade ivory board and uncoated wood-free printing and office paper. The products are sold at home and abroad. Asia Symbol is committed to sustainable development and the exploration of long-term renewable resources for paper production to facilitate regional economic development and the welfare of the local community. The company's principle is to operate in a manner that creates value for the community, the country, the climate, the customer and the company.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, Voith today has around 21,000 employees and earns 4.9 billion euros in sales. It has locations in more than 60 countries and is one of Europe’s major family-owned companies.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith to supply a complete pulping and wastewater pre-treatment system to Graphic Packaging International

Graphic Packaging International (GPI), a leading global provider of sustainable consumer packaging, has recently commissioned Voith to supply multiple stock preparation lines, integrated reject handling and the wastewater pre-treatment system for its newest, most advanced coated recycled board (CRB) mill being built in Waco, Texas. With Voith’s tailored process solutions, GPI is expected to improve the efficiency and sustainability of its facility and will ultimately save energy, water and fibers. The installation of the new system and components is targeted for completion in 2025.

“Voith’s proven and innovative pulping technology and wastewater pre-treatment solutions are key to reaching our high product quality targets and improving efficiency and sustainability. Our close partnership is based on trust and the very reliable cooperation we have enjoyed in the past,” says Rusty Miller, Senior Vice President Engineering and Technology at Graphic Packaging.

“We are happy to be partnering with GPI again and are eager to support them with our leading technology in stock preparation for efficient recycling of fibers and separation of contaminants. Our state-of-the-art wastewater pre-treatment system enables GPI to minimize freshwater consumption which is one main focus of the project,” adds Michael Hmielewski, Director of Project Sales at Voith.

To learn more about Voith’s innovative solutions for an effective use of water, please visit: https://voith.com/corp-en/industry-solutions/papermaking/papermaking-for-life/water.html

About Graphic Packaging International

Graphic Packaging International, headquartered in Atlanta, Georgia, is committed to providing consumer packaging that makes a world of difference. The company, a leading fiber-based consumer packaging provider, serves the world’s most widely recognized food, beverage, foodservice, and other consumer products companies and brands. The Company operates on a global basis, is one of the largest producers of folding cartons and fiber-based foodservice products in the United States and Europe, and holds leading market positions in coated recycled paperboard, coated unbleached kraft paperboard and solid bleached sulfate paperboard. Additional information about Graphic Packaging, its business and its products is available at https://www.graphicpkg.com.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

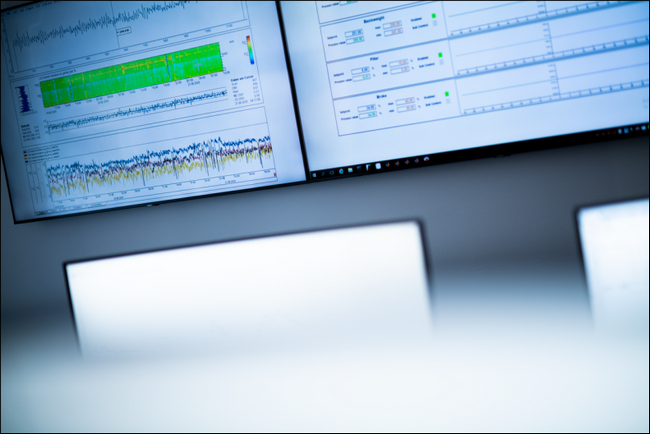

Voith opens new OnPerformance.Lab (OPL) in São Paulo

Voith announces the opening of a new OnPerformance.Lab (OPL) site in São Paulo, Brazil, South America. With this expansion, Voith strengthens its regional footprint and expands its service, optimization and consulting activities. The new OPL site is specifically designed to support paper manufacturers in automation, digitalization and achieving their sustainability goals.

Remote support represents an important part of Voith's service portfolio and complements existing on-site services offered by the leading full-line supplier. Customers can quickly and easily access the expertise of the experts and jointly find solutions to individual challenges. In this way, short-term problems can be solved efficiently, and long-term optimization projects can be carried out successfully. With the OPL, Voith takes a holistic and integrated approach that enables sustainable improvements.

"With the new location in São Paulo, we want to offer our customers even greater proximity and support," says Ivan Medeiros, Head of Digital and Automation at Voith Paper South America. "We want to help them use digitalization profitably and increase their resource efficiency to reliably achieve their goals."

The OPL in São Paulo is part of a global initiative by Voith to offer comprehensive know-how and expertise to its customers worldwide. Existing OPL locations can be found in Heidenheim, Germany; Kunshan, China; and Tokyo, Japan. The opening of additional regional offices is planned to further strengthen the regional footprint.

Interested customers can get in touch at any time to benefit from the wide range of digital solutions and service offerings. For more information on the Voith OnPerformance.Lab, visit https://voith.com/corp-en/onperformancelab/paper.html.

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Record commissioning: Voith and Sichuan Huaqiao Fenghuang Paper successfully start up highly efficient PM 6 packaging paper machine in only six months

On August 13, Sichuan Huaqiao Fenghuang Paper successfully started up its highly efficient XcelLine packaging paper machine at the Guanghan site. The leading full-line supplier Voith delivered the entire line. The project set a new record for the fastest start-up of such a paper machine. Only six months passed from installation to successful start-up – two months ahead of schedule. The commissioning of the BlueLine OCC stock preparation system and the XcelLine paper machine took just four and five weeks, respectively.

“Many thanks for the hard work and technical innovation of both teams! The very good performance of PM 6 is the excellent result of the continuous efforts and close cooperation of both teams,” says Yang Lichang, Project Manager Huaqiao Fenghuang in Sichuan. At the same time, the high performance reflects the outstanding efficiency of the Voith paper machines. The successful startup will further increase Huaqiao Fenghuang's production capacity and create a solid foundation for our future development.”

PM 6 has a width of 7.92 meters and a design speed of 1,400 meters per minute. It mainly produces high-quality packaging paper in the range of 90 to 170 gsm and has an annual production capacity of about 400,000 tons. The associated BlueLine OCC stock preparation line has an impressive capacity of 2,200 tons per day and is currently the largest OCC line in the Asian market.

Voith not only supplied the intelligent XcelLine paper machine and BlueLine OCC stock preparation line, but also leading control systems such as MCS, QCS, DCS, QMS and OnCare.Health. These advanced solutions enable full automation of the production process, ensuring stable product quality, a reliable process, and lower operating and maintenance costs. In addition, PM 6 uses Voith's latest industrial design, which combines the outstanding performance of the XcelLine paper machine with a high level of industrial aesthetics.

“The successful start-up of PM 6 exemplifies the strong technical competence and professional qualifications of both teams, and it also demonstrates the benefits of full-line delivery from Voith,” says Carlos Lin, Senior Vice President Order Processing and Operations at Voith Paper Asia-Pacific. “The full-line delivery reduces integration and coordination efforts for the customer, lowers operational risk and ensures product quality, all of which increase product competitiveness."

“Voith is committed to sustainable and environmentally friendly papermaking through innovative technologies that significantly reduce the consumption of fibers, energy and water,” confirms Kurt Yu, President at Voith Paper Asia-Pacific. "PM 6 symbolizes the shared passion and commitment of both teams to the paper industry. Voith's goal is to work with its customers to drive environmentally friendly development of the paper industry with reduced carbon emissions."

The excellent start-up performance is the result of the joint efforts of both teams. Voith's teams in China and Germany worked closely together to respond quickly to customer requirements. Early partial deliveries, shortening of installation and run-in phases, and other measures ensured that customer expectations were met in the best possible way. At the same time, the Sichuan Huaqiao Fenghuang Paper team demonstrated outstanding implementation strength and professional competence.

About Sichuan Huaqiao Fenghuang

Huaqiao Fenghuang Group is a diversified multinational enterprise with various industries. It is a large cross-border enterprise mainly engaged in six economic sectors: modern agriculture, industrial manufacturing, real estate, trade, finance, and international investment and trade activities. Sichuan Huaqiao Fenghuang Paper Co, Ltd. is a wholly-owned subsidiary of the Group and the largest coated paper manufacturer in Sichuan. Its main products are coated papers, high quality, light weight and environmentally friendly paperboard, corrugated base papers and other products. The production capacity is one million tons per year. Through continuous technical research and development, quality and service improvement, the company has become a supplier of high-quality, efficient and environmentally friendly packaging materials.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of €4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Energy savings and decarbonization are key topics of Voith's research and development work

At the end of April, Voith unveiled a completely new disruptive concept for paper manufacturing in collaboration with hygiene and healthcare company Essity. This concept enables CO2-neutral paper production as well as fresh water savings of up to 95 percent and energy savings of up to 40 percent. Currently, Voith and Essity are working on a pilot plant in Heidenheim, Germany. In addition to the disruptive concept, Voith is also focusing its research and development on other promising solutions. The leading full-line supplier invests around 100 million euros annually in the development of more efficient and sustainable solutions to drive decarbonization in paper production.

- Voith and Essity work on an innovative concept for CO2-neutral paper production

- For the electrification of paper drying, Voith is developing various concepts to avoid fossil fuels and reduce CO2 emissions

- Voith is involved in various industry initiatives, such as the ‘Modellfabrik Papier’, to promote the decarbonization of paper production using completely closed systems

An important field of action for decarbonization is the drying of paper, as this is where the greatest energy consumption occurs. Drying cylinders are typically heated with steam, which is often generated by burning fossil fuels. In order to dispense with the use of fossil fuels, Voith is working intensively on concepts for the electrification of paper drying. In the process, various technologies are evaluated to determine their potential and identify suitable solutions depending on the energy source at the site. This leads to significant reductions in CO2 emissions at the paper mills.

In addition to electrification, heat pumps for heat recovery are included in the development approaches to further improve the sustainability balance. Digital solutions, intelligent control systems and innovations in the area of fabrics and roll covers offer additional efficiency benefits.

Voith is a member of various industry initiatives to drive forward the decarbonization of paper production. One such initiative is the ‘Modellfabrik Papier’, in which companies along the value chain work with research institutes and higher education institutions on pre-competitive basic research.

Dr. Lada Bemert, Vice President New Business and Research at Voith Paper and Deputy Chairwoman of the shareholders’ committee of the Modellfabrik Papier, confirms the positive impact of the initiative. "With the help of completely closed systems, no more unused energy should escape from the process in the future,” explains Bemert. “Building on our research results, our aim is to make the technologies available to industry as quickly as possible. In doing so, we are setting an important course for the future."

Sustainability program Papermaking for Life

As part of the "Papermaking for Life" innovation and development offensive, Voith Paper is presenting versatile technologies and initiatives that lead to more efficient and sustainable processes in papermaking. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. Learn more about Voith Paper's innovations in the area of sustainability: www.voith.com/papermaking-for-life/innovation. For more information on the Modellfabrik Papier, click here: https://modellfabrikpapier.de/en/home-en/.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of €4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.