Displaying items by tag: voith

Dryness improvement with Voith product combinations

International Paper Luiz Antonio, Brazil, have increased their dryness on PM LAN2 by 2.7%, operating the right combination of Voith products. As a result, PM LAN2 has reached record reel speeds of 1,180 m/min, exceeding previous speed by 10.4%. Consolidating those results, through process adjustments and machine crew development, will generate a potential production increase of 52 t/day.

In 2011, IP Luiz Antonio began the implementation of a project for optimizing press efficiency of PM LAN2. Voith had offered a complete press analysis with specialist measurement tools and knowledge to collect the necessary data. From the analysis results, a Voith press water balance was performed followed by engineering recommendations for fabric designs, roll cover material and surface geometry. The high water storage capacity of the Voith polyurethane covers along with the press felts resulted in a 2.7% increase in dryness from 41.12% to 43.85%.

IP Luiz Antonio produces uncoated woodfree copy paper on the 5.10 m wide PM LAN2, at an average speed of 1,110 m/min, helped by a combination of Voith products such as SolarFlow suction roll cover, PrintFlex V4L felts and G2000 press rolls together with PrintFlex S3 in the third press.

Product Manager Eurípedes L. Valadão Junior, IP Luiz Antonio, states: "This development was a clear demonstration that combined efforts between supplier and customer through motivated people are capable of breaking many paradigms, generating significant impact on efficiency and quality in the production process."

Dryness increase with Voith polyurethane covers

By operating with Voith polyurethane covers, Radece papir, Slowenia, was able to increase the dryness after the first press of the PM 4 by 0.8%.

This result was possible due to the special surface designs of Voith’s polyurethane covers. A press analysis with unique Voith measurement equipment provided the necessary data. Based on the results, a water balance analysis was carried out and the optimum surface design for this application was calculated. The surface configurations of the Voith polyurethane covers are very flexible and allow an individual adjustment to the customer needs.

"The deployment of the polyurethane cover was a complete success. The dryness after the first press of our PM 4 increased by 0.8%. We are totally happy. The Voith covers are a worthwhile investment", confirmed Ales Knavs, Production Technologist Radece papir.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers.

Weig Karton Mayen saves 190 man-hours a year for roll cleaning thanks to Voith

Due to severe fouling inside the DuoStabilizer rolls of the first dryer group of its KM 6 board machine, Weig Karton has until now had to clean the stabilizer rolls once a year. This cleaning process is extremely laborious, as the approx. 130 mm thick tender side covers have to be dismantled every time. As production time increased the dirt on the rolls caused considerable difficulties.

To make cleaning easier, manholes were drilled into the tender side covers of five rolls as part of an on-site service by FRS OnSite. In addition, openings and covers were provided in the disks separating threading zone and rolls. These measures allow Weig Karton to save about 38 hours of cleaning work a year for each of the five rolls – around 190 hours in total.

The difficult part of this process was to drill through the particularly thick cover. However, Voith’s specialists were able to master this challenge thanks to their extensive experience. FRS OnSite carries out maintenance and inspection on rolls and cylinders directly on customer machines. This saves a lot of time and money. After just 80 man-hours, FRS OnSite successfully completed its work on KM 6 – considerably earlier than envisaged in the ambitious 96-hour scheduled program. It was also possible to dynamically balance the DuoStabilizer rolls during this mechanical service at the customer’s premises. This helps the machine run at optimum performance.

At its plant in Mayen, Germany, Weig produces board on two machines, KM 3 and KM 6. The 5.30 m wide KM 6 machine produces around 340,000 metric tonnes of plasterboard for the corrugated and plasterboard industry.

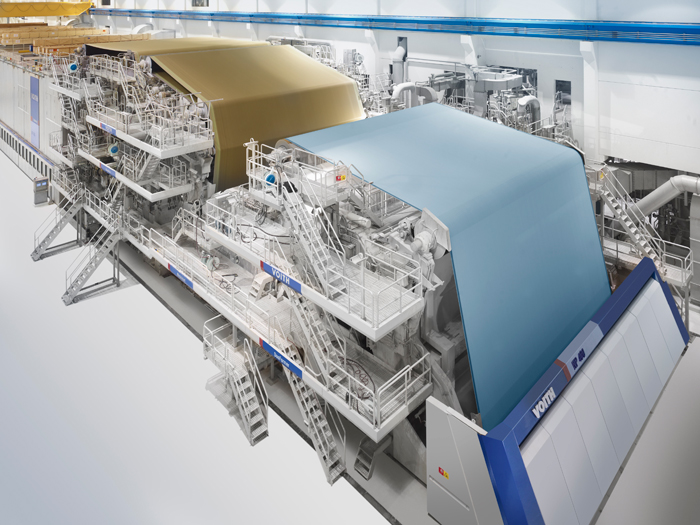

Varel successfully puts PM 4 into operation following a major rebuild

For the fourth time in a row, Voith Paper has been entrusted with a very complex project by paper and cardboard mill Papier- und Kartonfabrik Varel, Germany. Along with increasing the production capacity and expanding the range of products on the PM 4, the core goals were efficient energy use and environmentally friendly paper production.

The PM 4 was successfully restarted in mid of July after its extensive rebuild. Corrugated media and test liners with a basis weight range of 120 to 220 g/m2 are produced. In the future, up to 50% of its capacity should consist of white test liner. The PM 4 is designed for a net cut working width of 5,100 mm and an annual capacity of 300,000 metric tons.

The PM 4 was successfully restarted in mid of July after its extensive rebuild. Corrugated media and test liners with a basis weight range of 120 to 220 g/m2 are produced. In the future, up to 50% of its capacity should consist of white test liner. The PM 4 is designed for a net cut working width of 5,100 mm and an annual capacity of 300,000 metric tons.

Due to the raw materials that will now be required, the rebuild included a significant expansion of the stock preparation on three lines for which Voith provided the essential machines. Worth mentioning here is a patented system for the white stock preparation line.

The paper mill received new approach flow systems, the headboxes were renewed, and both fourdriniers were extended. A DuoFormer D hybrid former was installed on the back ply, while the top ply received a DuoShake shaker unit. The dryer was completely renewed and a SpeedSizer film press with contact-free web drying was integrated. In addition, the PM 4 received a soft calender and MasterReel rewinder. A new unwinder for larger full reel spools was installed on the winder.

Furthermore, Voith was responsible for the modernization of the paper machine controls and the OnQ ModuleJet profile control system. The complete contact-free drying as well as roll covers, clothing, and doctor blades were included in the scope.

The complete contact-free drying as well as roll covers, clothing, and doctor blades were included in the scope.

Varel hopes to achieve significant energy savings after the rebuild. Environmental aspects are of critical importance. Varel wants to manufacture environmentally friendly products as resource-saving as possible. A significant reduction in the CO2 emissions of the entire paper production is the goal.

Together with the PM 5, which was provided by Voith Paper as well and also has a capacity of 300,000 metric tons, Varel can offer the entire range of products processed by the corrugating media industry on a 100% recovered paper basis.

Perlen Papier counts on Voith as its service partner

Swiss-based papermaker Perlen Papier AG signed a service agreement with Voith Paper Automation for the automation components of its PM 4 and PM 7 in Perlen. Voith has already had a service agreement with Perlen Papier AG for the PM 4 quality control system since 2004. The new PM 7 went on line in September 2010. The machine, which is working at full capacity, is expected to produce 300,000 metric tons of newsprint this year. Following the final acceptance inspection of the PM 7, the two companies are now going one step further in signing the service agreement effective since September 2011.

The PM 7 will benefit from a complete Voith automation package which covers the recovered paper preparation, the paper machine and winder as well as the packing and transport. With the new service agreement Voith ensures high availability in the long term and provides clearly defined performance guarantees for the specified system components.

Dirk Breuer, Technical Director at Perlen Papier AG, explains why Perlen is relying on external service support when it has a very experienced and well-trained maintenance team on site: "The automation in a paper machine is becoming increasingly complex. This is why we need experts to provide us with professional support. And in Voith we have found the perfect partner to rely on".

The agreement includes a remote diagnostic service of the automation system. A Voith service technician logs into the Perlen system via an online connection to check the current status and if necessary eliminate malfunctions or carry out optimizations.

In addition, the Emergency on Call service module provides a 24-hour/7-day standby service by Voith's service team with a contractually guaranteed response time. This ensures that Perlen Papier's maintenance team gets fast, direct support.

The service agreement also stipulates preventive maintenance schedules. Thus, the automation components MCS and DCS including system technology, and the quality control system with scanners, actuators and controls are checked. The downstream processes at the winder or packaging system are also monitored and constantly improved by the Voith service technicians.

Perlen Papier AG was founded in 1873 and is one of the key manufacturers of magazine paper and newsprint in Switzerland. In 2010 the family-owned company had a workforce of 381 and posted a net turnover of 182 million euros.

Technical concept convinces Stora Enso Sachsen

Stora Enso Sachsen, Germany, placed the order for the rebuild of Eilenburg PM 1 with Voith Paper. In this case, Voith's technical concept for the rebuild was convincing. The rebuild comprises former, press, dryer section as well as calender and air system. The installation of a NipcoFlex press and the rebuild of the existing calender to a Janus calender by reusing some of the existing components must be mentioned in particular.

Stora Enso Sachsen would like to improve paper quality as well as runability by the rebuild of PM 1. Furthermore, the operating speed of the production line is to be increased to 2,000 m/min. The rebuild is scheduled for May 2012.

PM 1 produces newsprint and telephone directory paper in a basis-weight range of 34-48.8 g/m2 from 100% recovered paper.

New condition monitoring system at Gold East Paper

For their mill in Dagang, China, Gold East Paper decided in favor of the advanced OnV ConditionMonitoring system from Voith which monitors bearings. It is installed at the mechanical pulping line of the stock preparation and helps to prevent unplanned machine downtimes.

The system consists of 166 new vibration sensors. The vibration measurements are processed enabling analyses and diagnoses for early detection of bearing damages. An extension of the sensor assembly by 25 vibration detectors is planned to monitor further bearings. The new monitoring system will provide optimal availability of the machine and thus save costs.

After years of good cooperation and experiences, Gold East Paper is again putting its trust in Voith. The reliability of the already installed condition monitoring systems in the PM 3 and the offline coating machine 2 also contributed to their decision.

Gold East Paper was established in 1997 as a greenfield mill and currently became one of the largest manufacturers of art paper worldwide. The mill compound is approximately six square kilometers, has three paper machines and two offline coating machines. It is located at Dagang, Zhenjiang City in the Jiangsu Province which is aside of the Yangtze River, China's largest river.

Voith Paper supports Norske Skog in achieving goals

Voith Paper has enabled the long-time customer Norske Skog Bruck, Austria, to achieve success through the application of SkyTop doctor blades on their PM 4 as well as during the shift internal kart race. In the early summer "Team E" of line 4 organized a kart race in the Austrian city of Graz, where the tires squeaked and the focus laid firmly on having fun. The well-established cooperation between Norske Skog and Voith was evident on the racetrack, where even on the roughest of asphalt surfaces both high performance and speed were achieved.

Voith Paper has enabled the long-time customer Norske Skog Bruck, Austria, to achieve success through the application of SkyTop doctor blades on their PM 4 as well as during the shift internal kart race. In the early summer "Team E" of line 4 organized a kart race in the Austrian city of Graz, where the tires squeaked and the focus laid firmly on having fun. The well-established cooperation between Norske Skog and Voith was evident on the racetrack, where even on the roughest of asphalt surfaces both high performance and speed were achieved.

This also applies to the success on PM 4. For more than three years Voith SkyTop doctor blades have been used on the center press roll of the paper machine in Bruck an der Mur where wood-containing graphic paper is produced. The application of SkyTop on the center roll significantly helps in achieving improved paper machine performance. Doctor contamination was greatly reduced and the running time was considerably extended.

Moreover SkyTop achieves a constant roughness of the roll surface affecting the paper quality in a positive way. "With SkyTop blades we succeed in maintaining the roughness of the center ceramic roll for the entire roll cover width on the designated high level over several years", explains Gernot Christöfl, Assistant Line Manager PM 4. The performances on the racetrack and the increase in doctor blade efficiency together demonstrate the close and trustful cooperation between Norske Skog and Voith Paper.

Norske Skog Bruck PM 4 manufactures 57 to 90 g/m2 wood-containing graphic paper at machine speeds of up to 1500 m/min.

Grupak Hidalgo in Mexico selects Voith for complete OCC recovered fiber system

In order to assure high quality pulp from recovered fiber while minimizing fiber loss and consuming low energy, Grupak Hidalgo S.A. de C.V. has selected Voith Fiber & Environmental Solutions to supply a complete OCC recovered fiber system, designed for 600 BDMTPD, for their new mill site in the municipality of Emiliano Zapata in Mexico. The startup of the OCC system is scheduled for the first quarter of 2013.

Voith's scope of supply includes the new IntensaPulper R, which provides superior defibering capabilities while consuming less power than competitive pulpers. Also included is Voith's TwinPulp III detrashing system, complete coarse cleaning and screening systems, fine cleaning with EcoMizer Technology and fine slotted screening with C-bar slotted baskets and MF power-saving rotors. Voith-Meri will supply the pulper feed system including the Auto Wire Cutting machine plus the Compax reject press and other reject handling equipment.

Key to Grupak's supplier selection was the fact Voith's system is guaranteed to achieve high quality pulp with less fiber loss and lower energy consumption. Grupak verified the technology through mill visits in Spain where Voith has successful installations.

Grupo Unipak, S.A. de C.V. PT. is a large Mexican company producing a variety of food packaging products. The company currently produces liner and fluting grades for its own integrated use on two machines located in Cuernavaca,Mexico.

New quality control system increases process stability at Rondo Ganahl

Rondo Ganahl, the Austrian manufacturer of premium corrugated cardboard, recently invested in a new quality control system for the PM 2 in Frastanz. Among other adaptations, the existing measuring system was replaced by a new Voith LSC scanner with moisture, ash and basis weight measurement and a color sensor. As the Voith LSC measurement system is rugged and easy to service, future maintenance and service costs will be lower.

Rondo Ganahl, the Austrian manufacturer of premium corrugated cardboard, recently invested in a new quality control system for the PM 2 in Frastanz. Among other adaptations, the existing measuring system was replaced by a new Voith LSC scanner with moisture, ash and basis weight measurement and a color sensor. As the Voith LSC measurement system is rugged and easy to service, future maintenance and service costs will be lower.

Due to the inability to measure ash before the rebuild, moisture content was being measured as too low and unnecessary drying energy was expended. Using the ash sensor combined with the basis weight sensor, it is now possible to accurately determine the final moisture content. This reduces fiber consumption by around 1%, while drying energy is reduced by about 2.5%.

Installing a color sensor reduced the amount of broke when switching paper grades from brown to white test liner. The display of the chromaticity coordinate on the monitor also allows a faster response time. In addition, the measurement system reduces the response time when there are process fluctuations, thus ensuring consistent quality.

Another component of the automation solution is the OnQ GradeManager. This automatic grade changer substantially reduces grade change time and the broke resulting from startup loss. Altogether, this amounts to an additional production volume in A-grade quality of 5.6 metric tons per grade change.

Due to the teamwork between Voith Paper and Rondo Ganahl, the rebuild was successfully carried out in only three days of downtime.