Super User

Valmet to supply the world’s fastest coated board making line for APP’s Guangxi Jingui Pulp and Paper in China

Valmet will supply a coated board making line (PM 2) with extensive packages of automation and Industrial Internet solutions for APP’s Guangxi Jingui Pulp and Paper’s (GJPP) Qinzhou mill in China. The start-up is scheduled for 2021.

The order is included in Valmet's orders received of the first quarter 2020. The value of the order will not be disclosed. The total value of an order of this type and scope is typically around EUR 150-200 million.

When started-up, PM 2 will be the world’s fastest and very modern coated board making machine with the highest capacity. It will follow the footsteps of APP’s Ningbo PM 4 machine that was started-up in 2014 and is currently the fastest folding box board (FBB) machine in the world.

“The most important target for GJPP was that PM 2 will be a high-capacity board machine line with state-of-the-art technology. The customer also emphasized the importance of low operating cost. Valmet’s coated board line and its very low energy and water consumption values were proven to be the lowest ones when comparing to competitors,” says Timo Saresvuo, Senior Sales Manager, Valmet.

“The most important target for GJPP was that PM 2 will be a high-capacity board machine line with state-of-the-art technology. The customer also emphasized the importance of low operating cost. Valmet’s coated board line and its very low energy and water consumption values were proven to be the lowest ones when comparing to competitors,” says Timo Saresvuo, Senior Sales Manager, Valmet.

Technical information about Valmet’s delivery

Valmet's delivery for PM 2 will include a high-speed coated board making line from broke collection to reel and winders. Three OptiFlo Foudrinier headboxes, OptiFormer Multi forming section and OptiPress Linear press section produce high-quality base board. Four OptiCoat Jet blade coating stations ensure the high coating quality. OptiCoat Dry air dryers are very energy efficient in addition to maintaining the high coating quality. The delivery will also include complete process ventilation system for board machine with OptiAir high humidity hood and heat recovery. Center-driven OptiReel Linear reel combined with two OptiWin Drum two-drum winders with Dual Unwind deliver substantially high capacity level without any compromises on safety.

The wide automation package includes Valmet DNA Automation System for process and drive controls as well as runnability and condition monitoring. The Valmet IQ Quality Management Solution features scanning measurements, related machine and cross direction controls and profilers.

The delivery will also include a comprehensive Paper Machine Clothing, spare parts and consumables packages. The start-up and the further optimization of the new board machine will be supported remotely from Valmet Performance Center utilizing the latest Industrial Internet solutions. Data-based and proactive remote support is fast and efficient way to ensure that the machine is meeting the planned start-up curve.

The 8,850-mm-wide (wire) board machine will produce ivory board grades (folding boxboard, FBB) with the basis weight range of 190-300 g/m2. The design speed of the machine will be 1,450 m/min and the daily capacity approx. 3,800 tonnes.

Information about the customer Guangxi Jingui Pulp and Paper

Guangxi Jingui Pulp and Paper was formally established in 2003 and is a part of APP-China. Total annual production volume of APP’s mills reached 11 million tons. Today, APP-China is delivering quality products to meet the growing global demand for tissue, packaging and paper from customers all over the world. Guangxi Jingui Pulp & Paper employs more than 1,500 employees.

Stora Enso to make Annual General Meeting available via webcast

Stora Enso is offering a possibility to follow its Annual General Meeting (AGM) via webcast as a precautionary measure to decrease any risk of infection of the new COVID-19 coronavirus.

The company strongly encourages any shareholders who

- have recently visited a risk area for coronavirus infection,

- have symptoms of illness,

- or who are part of the risk group,

to consider following the AGM by webcast or authorizing another person to represent them at the meeting.

Shareholders, who have registered for the event, but who decide not to attend the meeting, are asked to cancel their registration by e-mail This email address is being protected from spambots. You need JavaScript enabled to view it. or by phone +358 204 621 245. The AGM will be held on Thursday 19 March 2020 from 16:00 EET. Doors will open at 15:30 EET and shareholders will be asked to go directly to meeting hall after registration.

Shareholders, who have registered for the event, but who decide not to attend the meeting, are asked to cancel their registration by e-mail This email address is being protected from spambots. You need JavaScript enabled to view it. or by phone +358 204 621 245. The AGM will be held on Thursday 19 March 2020 from 16:00 EET. Doors will open at 15:30 EET and shareholders will be asked to go directly to meeting hall after registration.

Stora Enso’s private shareholders can follow the AGM by webcast. Please note that this means the shareholder’s shares are not considered to have attended the meeting. It is not possible to speak or vote over the webcast. To follow the webcast, shareholders need to sign in with a Finnish bank ID or Finnish mobile certificate. The meeting language is Finnish, and some of the speeches are held in English. Simultaneous interpretation or subtitles are not available over the webcast.

More information on following the AGM via webcast and authorizing another person is available on the company website.

Stora Enso aims to keep the meeting as short as possible, fulfilling all legal requirements. That is why no refreshments will be served after the meeting and there will be no product displays prior to the meeting. Stora Enso follows the development relating to coronavirus and will take additional measures if needed. With these precautionary measures, Stora Enso aims at contributing to a safe environment. In normal circumstances about 300 shareholders attend Stora Enso’s Annual General Meetings.

Important information for the 113th Annual General Meeting of ANDRITZ AG - Precautions due to coronavirus

The Austrian government has adopted further measures to stop the coronavirus from spreading. These measures also affect the Annual General Meeting of ANDRITZ AG on March 25, 2020.

From today’s perspective, it will not be possible, according to the new regulations, to hold an Annual General Meeting if more than 100 people attend.

The Executive Board will make every effort to hold the Annual General Meeting on March 25, 2020, subject to any further measures and restrictions imposed by the authorities, also because a dividend can only be paid to the shareholders if the Annual General Meeting adopts a resolution to this effect.

However, the shareholders’ health must be our highest priority. That is why we recommend the shareholders of ANDRITZ AG to designate Dr. Michael Knap as voting proxy, bound by instructions, instead of personally attending the Annual General Meeting. A special proxy form can be downloaded below.

In addition, shareholders can contact Dr. Michael Knap directly c/o IVA – Interessensverband der Anleger, Feldmühlgasse 22, 1130 Wien, or by e-mail to: This email address is being protected from spambots. You need JavaScript enabled to view it..

Unfortunately, we cannot allow any guests to attend either. The traditional buffet after the Annual General Meeting has been canceled. If necessary, we will also make arrangements to keep the number of persons in any one room to the limit permitted.

We kindly ask for your understanding concerning these precautions in the interests of our shareholders’ safety and of holding the Annual General Meeting on March 25, 2020 in accordance with the restrictions applied by the Austrian government.

Depending on how the situation develops, ANDRITZ AG also reserves the right to implement further security measures in coordination with the authorities and to cancel the Annual General Meeting at short notice.

The ANDRITZ AG Executive Board kindly asks for your understanding concerning these measures and repeats its request not to attend the Annual General Meeting personally and to make use of a voting proxy instead.

Below you can download important information:

- ENCLOSURES OF ITEM 1 OF THE AGENDA:

- Annual financial report 2019

- Financial statement of ANDRITZ AG 2019 (German only)

- Corporate Governance report 2019

- Proposal for the use of the net earnings

- Report of the Supervisory Board - ENCLOSURES OF ITEM 7 OF THE AGENDA:

- Wolfgang BERNHARD: Declaration pursuant to § 87 (2) AktG & Curriculum vitae

- Overview Supervisory Board meetings and Committee meetings 2019

- ENCLOSURE OF ITEM 8 OF THE AGENDA:

- Remuneration policy of ANDRITZ AG

- Supplement to the ANDRITZ remuneration policy

- ENCLOSURES OF ITEM 9 OF THE AGENDA:

- ANDRITZ Stock Option Program 2020

- Explanations and comments on the ANDRITZ 2020 Stock Option Program

Södra wins two awards at PPI Awards 2020

We are absolutely delighted to announce that we won awards for both Environmental Leadership and Marketing Campaign of the Year at the 2020 PPI Awards in Portugal earlier this week.

The PPI Awards are dedicated to recognising the achievements of companies, mills and individuals in the pulp and paper sector. The awards also serve as a platform that celebrates leadership, vision, innovation and strategic accomplishments within the industry. Our marketing campaign focusing on sustainability, The Journey, won the Bringing Paper to Life - Marketing Campaign of the Year Award, while our groundbreaking OnceMore™ technology to recycle textiles won the category for Environmental Leadership - From Sustainable Forestry to Waste Management.

Linda Ottosson, Head of Marketing Communication: “A sustainable future requires everyday heroes and new ways of thinking. It can be as easy as actively choosing products from responsible-managed forests, but we also need to maximize our part as an industry and communicate our sustainability credentials to a wider audience beyond our immediate target market. This is what we did with The Journey campaign and we are delighted to see its value recognised.”

According to the judges, “The winner of this category really went the extra mile when it comes to the global promotion of paper products as it told the world about the sustainability of the industry. It deliberately targeted customers' customers and beyond to redress misconceptions around, and raise awareness of, the sustainability of the modern industry.”

Win number 2: OnceMore™

The forest is an important part in the transition to a sustainable bioeconomy. Today, more smart products can be made from the forest than ever before and now Södra wins the prize for its sustainable and ground-breaking innovation OnceMore™

Johannes Bogren, Vice President of Södra Cell Bioproducts, was equally delighted: “A new, exciting journey has started for Södra. We can now offer circular flows of textile fibres so that a sweater can become a sweater again - this is a unique global solution for post-consumer waste!”

The jury’s verdict: “The pulp and paper industries can be very proud of all the work that has been done over recent decades on the environmental front, and now, at last, all that hard work is being rewarded by a general public that really ‘gets’ the fact that the products this industry makes are simply the best renewable, reusable and recyclable products on the market. But it’s not just paper products, there are other industries that are now open for the pulp and paper industries to enter into with its deep environmental know-how and process experience. The winner of this category clearly demonstrates this.”

Angeline Elfström, Customer Relations Manager, highlighted the team effort involved: “These achievements are the result of a lot of people working very hard – colleagues on The Journey project, the communication department, those behind and in front of the cameras and our external agencies such as Studio Dittmer. The OnceMore™ project team included a cross-functional team from our mills, Innovation, product development, sales and marketing. This really is a team award.”

Read more:

www.sodra.com/thejourney

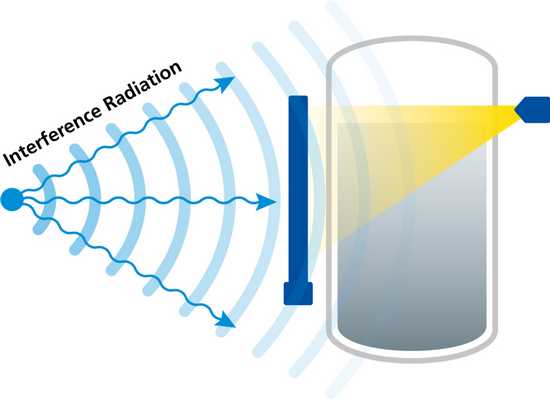

Dealing with radiation interference in radiometric level measurements

The effects of interference radiation on radiometric measurements can be considerable and must therefore be controlled. As it is neither predictable when interference radiation will be present, nor how much the impact of a distant NDT testing on a nucleonic measurement is, customers need a reliable system that is automatically dealing with such events. Over time, the technology and philosophy for dealing with interference radiation has evolved and become more sophisticated.

Berthold offers sophisticated products that manage interference radiation and provide the customer with a stable and reliable measurement that ensures a continuous process, avoids unscheduled shutdowns and therefore generate a real benefit for the customer. The features XIP (X-Ray Interference Protection) or RID (Radiation Interference Discrimination) are used for this. We help plant operators to get “RID” of problems caused by interference radiation and in doing so, we make sure they are always in control.

For further information please visit this link: www.berthold.com/rid

Toscotec-supplied tissue line comes online at Picknik Marketing, South Africa

South African tissue manufacturer Picknik Marketing Pty Ltd started up a MODULO-PLUS tissue machine supplied by Toscotec at its Johannesburg mill. The new line produced high quality tissue from day one.

The MODULO-PLUS machine has a sheet width of 2,750 mm, an operating speed of 1,500 m/min, and a production capacity of 75 t/d. It features a second-generation TT SYD Steel Yankee Dryer and energy-efficient, gas-fired TT Hood. The supply also includes the stock preparation and approach flow equipment and an off-line shaft puller. The service package includes erection supervision, commissioning, start-up assistance and training.

Itzik Nikfard and Rafi Nikfard, Directors of Picknik Marketing Pty Ltd, say, “This project marks a key expansion phase for our company. Due to the success of our SnowSoft brand, we are expanding our presence in the regional market, and are determined to continue on this trend by investing in advanced technology. Toscotec’s machinery will sustain our future growth by delivering the tissue quality and production efficiency we need to succeed in South Africa.”

“We are very happy to have partnered on this new project with Picknik Marketing, who is one of the most important local producers in South Africa”, says Toscotec Area Sales Manager Matteo Giorgio Marrano, “The successful start-up of this line is the result of the close cooperation between our technical teams. Toscotec thus strengthens its position in the South African market, where we successfully installed three complete tissue lines and one major rebuilding project since 2017.”

About Picknik Marketing Pty Ltd

Established in 1999, Picknik Marketing Pty Ltd manufactures high quality tissue products including toilet paper, serviettes, paper towels, facial tissue under the brand SnowSoft and wadding-jumbo rolls.

Lenzing solid in a historically difficult market environment

Lenzing – Despite a generally difficult demand environment for textile fibers and a drastic drop in prices for standard viscose, the Lenzing Group recorded a solid business development in 2019. The disciplined implementation of the sCore TEN corporate strategy and the accompanying focus on specialty fibers once again helped to mitigate the effect of unprecedentedly low standard viscose prices.

As a result, revenue dropped by 3.3 percent from EUR 2.18 bn to EUR 2.11 bn in 2019, driven by lower selling prices as well as standard fiber volumes. Due to positive mix effects and more resilient specialty fiber prices, the share of specialty fibers increased from 45.5 percent to 51.6 percent of revenue. The earnings development was largely influenced by the decline in revenue, but also by negative currency effects on material and personnel costs. EBITDA (earnings before interest, tax, depreciation and amortization) fell by 14.4 percent from EUR 382 mn to EUR 326.9 mn. The EBITDA margin declined from 17.6 percent to 15.5 percent. Net profit, at EUR 114.9 mn, was 22.4 percent lower than in the previous year at EUR 148.2 mn. Earnings per share amounted to EUR 4.63 (2018: EUR 5.61).

The Management Board will propose at the 76th Annual General Meeting a dividend of EUR 1.00 per share for the 2019 financial year (2018: dividend of EUR 3.00 plus a special dividend of EUR 2.00 per share), which is equivalent to a total dividend payout of EUR 26.6 mn. The Supervisory Board accepted this proposal at its meeting held on March 11, 2020.

“Lenzing and the entire textile value chain operated in a historically difficult market environment in 2019, which had a negative impact on our revenue and earnings development. The focus on specialty fibers has been contributing to the company’s resilience in the reporting period and we feel very well positioned with our corporate strategy. Our goals for 2024 underpin this confidence in our future”, says Stefan Doboczky, Chief Executive Officer of the Lenzing Group. “The implementation of the key projects in Thailand and Brazil plays a central role in further strengthening our market position and in accomplishing our ambitious climate targets. We are very satisfied with the progress of both projects,” Doboczky adds.

CAPEX (acquisition of property plant and equipment) amounted to EUR 244 mn in 2019, reflecting the Lenzing Group’s investment activities on increasing internal pulp production and raising the share of specialty fibers in line with the sCore TEN strategy. The major projects in Brazil and Thailand will have an increased impact on the CAPEX volume as of 2020.

Expansion of pulp capacities

The expansion and modernization of the dissolving wood pulp plants in Lenzing and Paskov, which started in 2017, will increase pulp production capacities by roughly 35,000 tons annually. The expansion in Lenzing was successfully implemented in the second half of 2019. At roughly the same time, the new capacities at the Paskov plant were gradually started up. This process will be completed in the first quarter of 2020.

Based on the decision to build a dissolving wood pulp plant in Brazil with its partner Duratex, Lenzing will increase its self-supply by 500,000 tons annually, thus strongly enhancing backwards integration. The plant is expected to start operations in the first half of 2022. Lenzing and Duratex hold 51 percent and 49 percent, respectively, in the joint venture. Industrial CAPEX are expected to total roughly USD 1.3 bn (based on current exchange rates and customary tax refunds).

Expansion of specialty fiber capacities

In 2019, Lenzing also started the construction of a state-of-the-art lyocell production facility in Thailand. The investment for the new plant with a capacity of 100,000 tons amounts to roughly EUR 400 mn. Construction work started in the second half of 2019. The completion is scheduled for the end of 2021.

Lenzing aims to achieve stable and profitable growth and to improve the ecological footprint of the textile and nonwovens industry by expanding the production of specialty fibers. In addition, the conversion of production capacities from standard viscose to LENZING™ ECOVERO™ branded specialty viscose fibers progressed well during the reporting period. LENZING™ ECOVERO™ fibers are very well received on the market thanks to their very favorable ecological footprint and their unique identification technology.

Lenzing shines at the Oscars

The TENCEL™ brand’s visibility was further increased through co-branding during the reporting period. Compared with the previous year, the number of end products labeled with the TENCEL™ brand nearly doubled to 173 mn. The digital marketing concept “Where to buy” was introduced on the website www.tencel.com in the first quarter of 2019. Based on this concept, products made from TENCEL™ fibers can be presented and linked in the online shops of more than 135 partners, including brands like H&M, Levi’s, Allbirds, Victoria’s Secret, Esprit, Pottery Barn and Asos.

Lenzings fibers were also a great success at this year’s Oscar ceremony in Los Angeles. Three dresses worn by nominees and winners were handmade from fabrics with our TENCEL™ Luxe filaments. The strong response on social media accelerated awareness for this sustainable and innovative product of the Lenzing Group.

Science Based Targets initiative approves climate targets

During the reporting year Lenzing announced its goal of a substantial reduction in CO2 emissions, for which investments of more than EUR 100 mn in sustainable technologies and production facilities are earmarked in the coming years. As a first milestone set for the year 2030, Lenzing aims to cut its own CO2 emissions per ton of product by 50 percent. For 2050, Lenzing has announced a vision towards net-zero CO2 emissions. The Science Based Targets initiative, the most recognized organization in the field of climate-relevant target setting, scientifically validated Lenzing’s climate targets in the second half of 2019. Lenzing is consequently the first producer of wood-based fibers with set science-based targets.

Lenzing sets ambitious goals for 2024

The Lenzing Group worked on adapting its goals as part of the sCore TEN strategy in the reporting period. The primary focus in the coming years is on the implementation and execution of set climate targets and investment projects in Thailand and Brazil. Lenzing aims to increase the share of high-quality specialty fibers in fiber revenue to 75 percent by 2024 and the share of internally produced pulp to more than 75 percent. In line with its strategic commitment for 2024, Lenzing strives to reduce CO2 emissions per ton of product by more than 40 percent compared with 2017. The EBITDA target for 2024 is EUR 800 mn.

The solid development in recent years despite very difficult market environment at times, reassures Lenzing in its strategic direction. Today, the company is substantially more resilient than it was a few years ago due to its specialty strategy and its strong brands based on innovation and acting sustainably. Lenzing continues to see strong structural growth in the global fiber market over the coming years, with demand for wood-based cellulosic fibers expected to grow 4 to 6 percent per year until 2024, thus nearly twice as fast as the global fiber market.

Outlook

The International Monetary Fund expects a slight recovery of global economic growth to 3.3 percent in 2020, while at the same time warning of several risks. The increased frequency of extreme weather events and currently also the coronavirus crisis could have a strong impact on the global economy in 2020. The currency environment in the regions relevant to Lenzing is also expected to remain volatile.

Demand on the global fiber markets is currently difficult to predict due to the spreading of the coronavirus, which is paralyzing large parts of the textile value chain, especially in China. According to preliminary calculations, cotton stock levels will remain high in the 2019/2020 season. The price levels for cotton and polyester are expected to remain subdued.

Capacity expansions for standard viscose are expected to be lower than in 2019, but will nevertheless lead to an increase in surplus capacity. The pressure on prices, which have been at a historic low for a considerable period of time, should therefore persist in 2020. Despite additional lyocell capacities in China and low visibility, the Lenzing Group expects the comparatively positive development of its specialty fiber business to continue.

Driven by the challenging situation in standard viscose and low paper pulp prices, prices for dissolving wood pulp are expected to remain at low levels. Caustic soda prices in Asia have already declined significantly over the past months; this development is now also noticeable in Europe.

The above effects significantly impact earnings visibility for 2020. The Lenzing Group currently expects the result for 2020 to be below the level of 2019.

The market developments reassure the Lenzing Group in its chosen corporate strategy sCore TEN. Lenzing will continue to put a particular focus on the strategic investment projects which will yield a significant contribution to earnings starting from 2022.

Verso Corporation Announces Change in Senior Leadership

Verso Corporation (NYSE: VRS) has just announced that Michael A. Weinhold has resigned as President of Verso, effective March 10, 2020.

Verso Corporation (NYSE: VRS) has just announced that Michael A. Weinhold has resigned as President of Verso, effective March 10, 2020.

"On behalf of the entire Board and senior leadership team, I want to thank Mike for his leadership and contributions to Verso's success over the years and wish him the very best in his future endeavors," said Verso's Chief Executive Officer Adam St. John.

"I am honored to have been part of Verso's senior leadership team since the company's inception in 2006," Weinhold said. "It has been a pleasure working with the many passionate, talented and dedicated people at Verso, and I wish them continued success."

Circularity is a “no regret option” for the European industrial transition

Circularity is a “no regret option” for the European industrial transition: it is now time to recognise circular low carbon forest-based industries as a strategic value chain!

The Green Deal has to be translated into a business case, strengthening sustainable and circular industrial value chains in Europe, and ensuring that they are considered of strategic importance.

For that reason, Cepi, on behalf of the European Paper Industry, applauds the increased support to low carbon value chains in the “New approach to industrial policy” released by the European Commission on 10 March.

“With the proper regulatory framework, the European paper industry together with the forest-based industrial value-chain can become one of the main forces driving the transition to a competitive, low-carbon and circular economy” said Jori Ringman, Cepi Director General.

“With the proper regulatory framework, the European paper industry together with the forest-based industrial value-chain can become one of the main forces driving the transition to a competitive, low-carbon and circular economy” said Jori Ringman, Cepi Director General.

The European paper industry is already working together with the Forest-based value-chain, to deliver products made from sustainable, circular and regenerative raw materials to European consumers and export markets.

We also recognize the importance of the new governance method of building inclusive partnerships, making sure that national authorities and industry work closely together. Member States and the EU have to accompany the industrial transition to climate neutrality by securing clean and affordable energy for all industrial sectors with the adequate infrastructure – it is a prerequisite for deep emission reductions.

As an industry deeply committed to recycling, Cepi also recognizes that the Circular Economy Action Plan published today 11 March goes in the right direction by identifying key areas to enhance recognition of sustainable products and by incentivising waste policies that will close existing gaps in the recycling loops.

We support a reinforced waste policy in support of circularity and agree with the identification of packaging as a priority sector for the Circular Economy Action Plan.

Design for recycling is a pre-requisite for the circularity of fibre-based products. We are fully engaged in improving the future recyclability of paper products with recommendations such as the European “Paper-based Packaging Recyclability Guidelines”. Applying these guidelines will allow the entire value chain to innovate on packaging functionality while keeping the recyclability of paper packaging in mind, as a core preoccupation.

It the same spirit, we launched the new fibre-based value chain alliance 4evergreen, a forum to engage and connect industry members from across the fibre-based packaging and food service value chain, from paper and board producers to packaging converters, brand-owners and retailers, technology and material suppliers, waste sorters and collectors, and more. The common objective of 4evergreen members is to deliver a holistic approach to optimise the sustainability and circularity of the fibre-based packaging’s life cycle.

In the context of recent waste import restrictions by China, the European paper industry is set to recycle even more in Europe, as it makes additional investments in paper recycling capacities. The paper industry is already recycling 49 million tonnes of paper in Europe (2018 data) and the amount has been growing since 2000. For the investments to happen, the European paper industry material must be separately collected (Cepi has already provided guidance on separate collection for paper and board) and reach the mills with the right level of quality.

Therefore, the Circular Economy Action Plan correctly identifies the facilitation of EU internal shipments of waste and secondary raw materials as well as the convergence of waste collection systems as priorities.

We look forward to taking full advantage of the new industrial strategy and circular economy action plan. Concretely, this means manufacturing sustainable forest-based solutions made from renewable raw materials, making our production processes even more efficient and our value chains perfectly fit for a climate-neutral Europe.

International Paper Named One Of The 2020 World's Most Ethical Companies® By Ethisphere For The Fourteenth Consecutive Year

Recognition honors those companies that take the long view with a purpose-based strategy and strive to create positive change throughout their global communities.

International Paper (NYSE: IP) a world leader in renewable fiber-based packaging, pulp, and paper products, has been recognized by Ethisphere, a global leader in defining and advancing the standards of ethical business practices, as one of the 2020 World's Most Ethical Companies.

International Paper has been recognized for a fourteenth consecutive year and is one of only two honorees in the forestry, paper and packaging industry. In 2020, 130 honorees were recognized spanning 21 countries and 51 industries.

![]() "Receiving this prestigious award fourteen years in a row highlights International Paper's ongoing commitment to be among the most successful, sustainable and responsible companies in the world. Ethics is one of our core values, which is why we strive to do the right things, in the right ways, for the right reasons – all of the time. We call it the IP Way," said Sharon Ryan, General Counsel, and Corporate Secretary. "Our more than 50,000 team members and 25,000 customers in 150 countries rely on IP to be an ethical partner wherever we do business."

"Receiving this prestigious award fourteen years in a row highlights International Paper's ongoing commitment to be among the most successful, sustainable and responsible companies in the world. Ethics is one of our core values, which is why we strive to do the right things, in the right ways, for the right reasons – all of the time. We call it the IP Way," said Sharon Ryan, General Counsel, and Corporate Secretary. "Our more than 50,000 team members and 25,000 customers in 150 countries rely on IP to be an ethical partner wherever we do business."

"Congratulations to everyone at International Paper for earning this recognition," said Ethisphere's Chief Executive Officer, Timothy Erblich. "This is a moment to acknowledge the leaders working to advance corporate cultures defined by integrity and affirm those companies contributing to broader societal imperatives and the greater good."

Methodology & Scoring

Grounded in Ethisphere's proprietary Ethics Quotient®, the World's Most Ethical Companies assessment process includes more than 200 questions on culture, environmental and social practices, ethics and compliance activities, governance, diversity, and initiatives to support a strong value chain. The process serves as an operating framework to capture and codify the leading practices of organizations across industries and around the globe. Best practices and insights from the 2020 honorees will be released in a report and webcast in March and April of this year.

All companies that participate in the assessment process receive an Analytical Scorecard providing them a holistic assessment of where their programs stand against the demanding standards of leading companies.

Honorees

The full list of the 2020 World's Most Ethical Companies can be found at https://worldsmostethicalcompanies.com/honorees

SOURCE International Paper